Salvador/Stiles "Superangle 600" Optimizing Cut-off Saw - Miter (2021)  Ended

Ended

M&M Recreation - Day 1 - Corsicana, TX

Corsicana, TX

- Winning Bid : $51,250.00 USD Sold

- 51 Bid(s)

- High Bidder: r****m

M & M Recreation Retirement Day 1 - Complete Woodworking & Finishing Facility ( Closed #62271967 )

Open House Feb 28th & Feb 29 8:30AM-4:00PM Contact Eric Beach 704-608-9830 or [email protected] - 3500 US-287, Corsicana, TX 75109

-

Pick Up Location

Corsicana, TX

-

Make

Salvador/Stiles

-

Model

"Superangle 600"

-

Serial Number

B 541

-

Year

2021

-

Phase

3 PHASE

-

Voltage

460 VOLT

-

Load Out Period

See Homepage

-

Estimated Dimensions

52'L x 6'D x 6-1/2'H

-

Estimated Weight

7,000 Lbs

-

Seller Comment

A rigger is required. Buyer's Responsibility for Break-down, loading and removal.

-

Load Fee

Rigger: Tom Preston - Preston Machinery 269-685-7591 [email protected]

-

Lot Notes

-

page views

1564

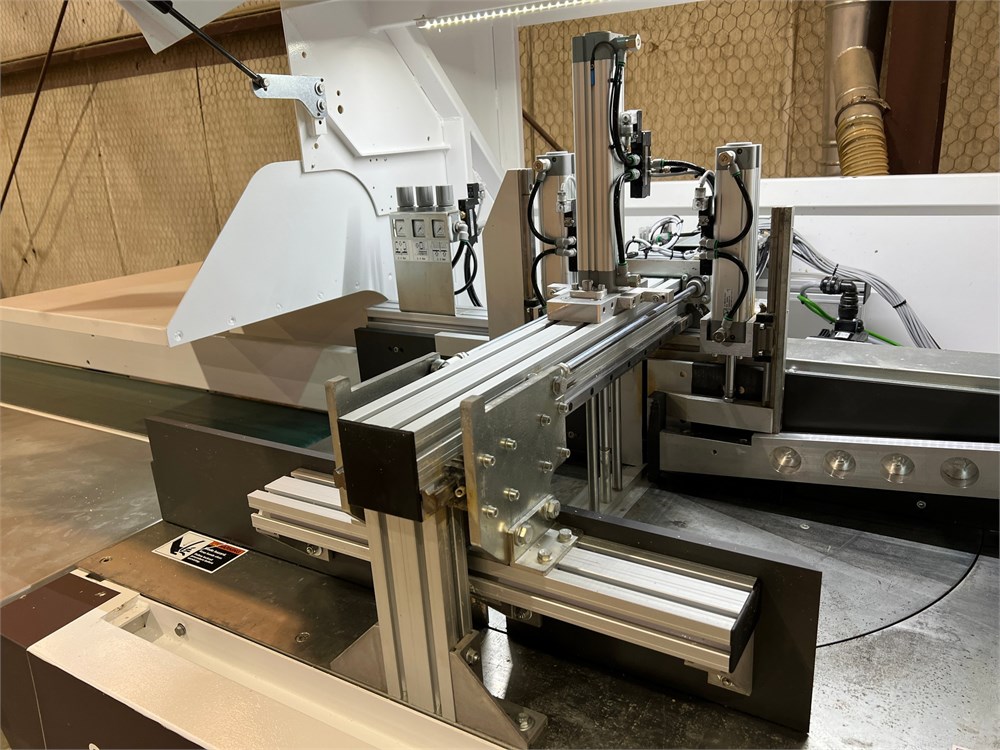

Salvador/Stiles "Superangle 600" Optimizing Cut-off Saw - Miter (2021)

The SALVADOR SUPERANGLE 600 is a pusher optimizing cut-off/defect saw that provides complete chop to length and optimization of wood strips including the elimination of defects.

The infeed is made of heavy-duty steel frame with working height of 1000mm (39") from floor level. Safety is provided by a light curtain. The pusher slides on double hardened rails. The reading operation uses two sensors, one for the overall length and the other to read the crayon marks.

The transmission of power from the motor to the carriage is accomplished by a steel reinforced toothed belt 50mm wide. The part is held in place by two aligners before and after the blade insuring a square cut.

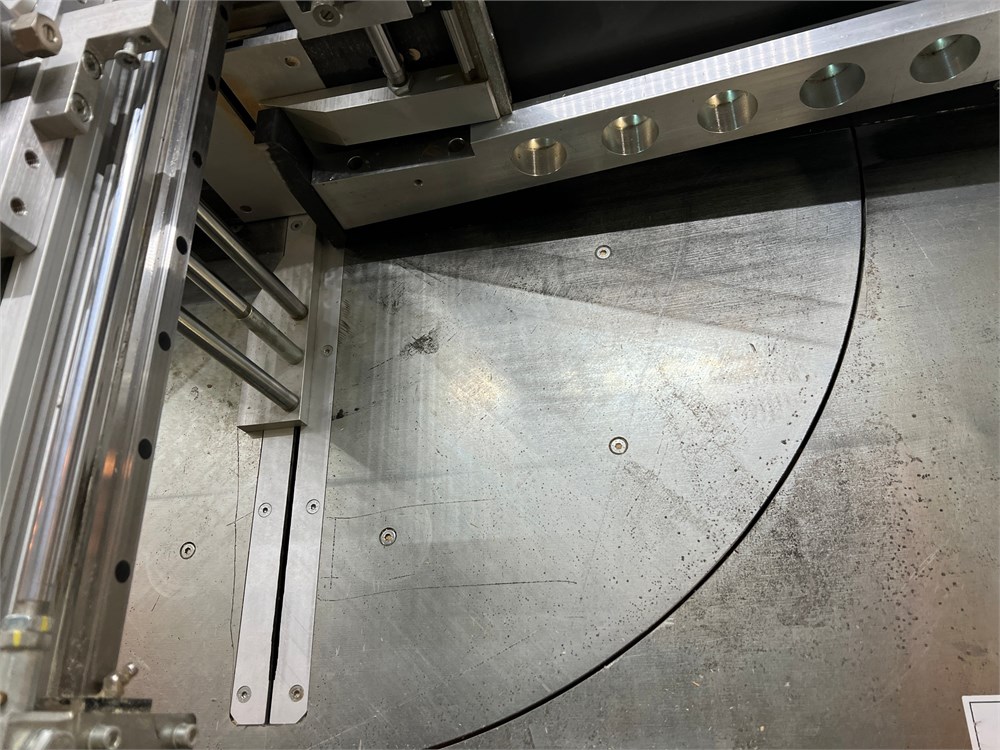

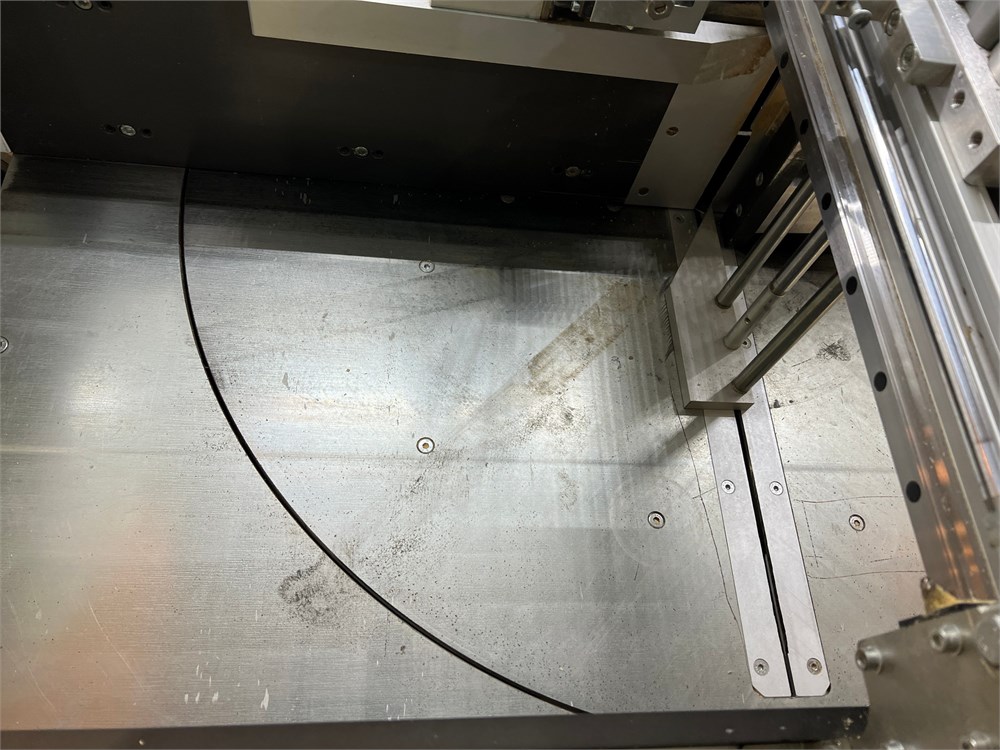

The saw box area is enclosed by interlocking steel cover with a large widow for clear view. The saw travels through an aluminum table insert that can be easily changed as needed. High efficiency motor IE3 rating helps to keep power consumption to the minimum.

The operating software is a customized Windows based program designed to be intuitive and specially designed for optimization of the wood. There is a large 19" monitor at operator eye level. The PC is set up with SSD double hard drive with the second being a clone to have an ready to go back up already in the machine. Cut lists can be uploaded remotely by network connection or flash drive. Chop length optimization can be set for minimum waste priorities. The optimizer supports defecting crayons as well as up to (5) grade qualities.

Electronics, the multi tap transformer steps down higher voltages , 460 - 600 to the voltage requited by the machine.

SP 15 Magnetic Strip Measurement, technology improves positioning from basic encoder standards to absolute measurement's of +/- 0.1mm.

Outfeed with 0 degree belt and 1 pc double ejector. For applications of many work pieces cut at angles its best to eject the work pieces together with one large rack and pinion ejector. Work pieces are pulled from the saw on an out feed belt. Once the parts are clear of the saw the large ejector manages all cuts in one push onto the steel table for collection.

WORKING CAPACITY:

Maximum board length before cutting 5100mm (16')

Minimum board length before cutting 500mm (19.6")

TECHNICAL SPECIFICATIONS

Main saw power 15 HP

Saw blade specifications SA600 Max 600mm dia. bore 35mm

Maximum pusher reading speed 60M/min (200'/min)

Maximum pusher pushing speed 60M/min (200'/min)

CUTTING CROSS SECTION

0°: 100mm x 360mm / 160mm x 310mm

+/- 45°: 100mm x 260mm / 160mm / 220mm

+/- 70°: 100mm x 120mm / 160mm x 100mm

Minimum 15mm x 30mm

Number of cuts within last 40mm of board One (1)

Maximum workpiece weight 110 kgs (242 lbs)

Pneumatic requirements

Compressed air supply 600 - 800 kPa (6-8 bar)

Maximum air consumption 300 Nl/min

Dust extraction:

intake diameter 160mm upper / 120mm lower

Extraction system collection speed 28M/s

Dust extraction capacity 1800 - 2000 m³/h

The information provided in this lot was gathered from literature, internet & physical inspection. It is thought to be accurate; but not guaranteed. Bidders are urged to use the open house or private inspection periods to inspect and verify.

The listed specifications & information were taken from the manufacturer’s published information, internet research, or seller’s description.

The specifications & information are assumed to be correct; however, in no way, guaranteed. Bidders are encouraged to inspect the machine, call with questions, or contact the manufacturer for more information.

Please log in to view the bid history

LoginIf a load fee is established for an individual lot, that fee will include loading onto a flatbed truck (only) by the seller. Any individual lot without a load fee will be the buyer's responsibility to remove and load (at buyer’s expense). MachineryMax does not ship- All buyers responsible for their own freight - For freight quotes please contact your preferred broker, or contact Aaron, at Always Trucking 541-608-6532

Payment is due within 24 hours of auction close. Payments must be made via bank wire transfer for any amount above $1,500. Credit cards may be used up to $1,500 (3% processing fee). Please Contact Sabrina Burns with payment questions at 209-839-7707 Any sales tax exemption documents are to be emailed to [email protected] at time of purchase/invoice for tax exemption consideration.