Venjakob "Venflow" Staining Line and Flow Coating Machine  Ended

Ended

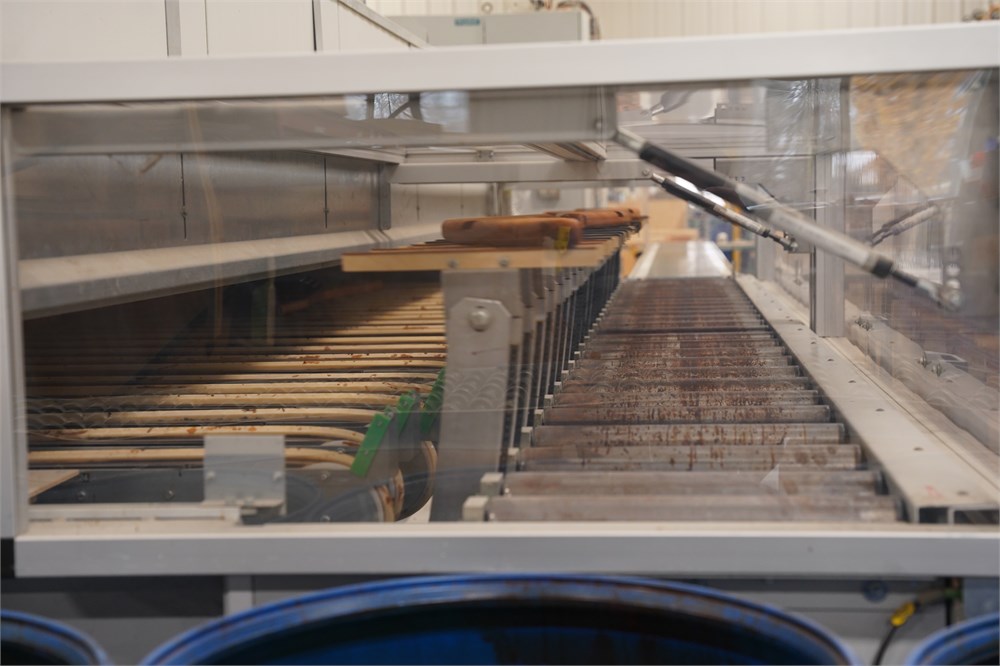

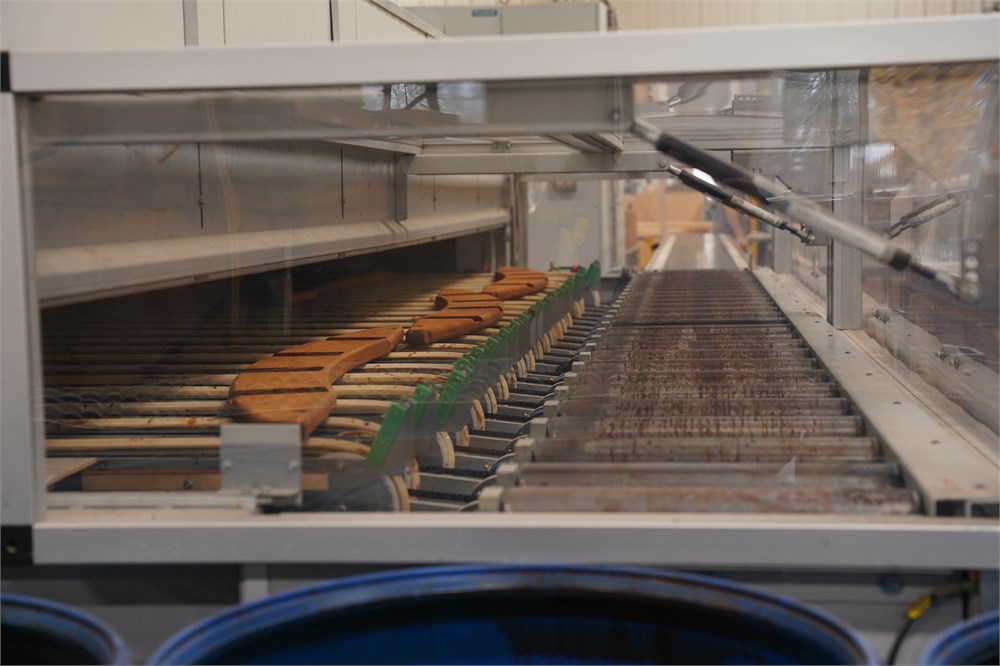

Venjakob "VenFlow" Staining Line and Flow Coating Machine - Walden, NY

Walden, NY USA

- Starting Bid : $2,500.00 USD Reserve Price Not Met

- 0 Bid(s)

Venjakob "Venflow" Staining Line with Flow Coater - Walden, NY ( Closed #61241502 )

Well-known manufacturer of educational furniture in the greater New York City area is auctioning a Venjakob "Venflow" Staining Line with Flow Coater no longer required for continuing operations.

-

Pick Up Location

151 Bowne Dr, Walden , NY 12586

-

Make

Venjakob

-

Model

VenFlow

-

Serial Number

-

Year

-

Phase

3 PHASE

-

Voltage

208-230/460

-

Load Out Period

January 18th - January 25th, 2024 By appointment only

-

Estimated Dimensions

See photos and description

-

Estimated Weight

See photos and description

-

Seller Comment

This lot requires a rigger, see home page for details.

-

Load Fee

-

Lot Notes

-

page views

625

Venjakob "Venflow" Staining Line and Flow Coating Machine

SEE VIDEO

FEEDING BELT CONVEYOR

For feeding the batches into the flow coater

Belt with marked area to build a gap for the angle transfer.

Technical Data:

length: 2300 mm

|

Pric |

IMPREGNATION MACHINE VEN FLOW

for flow coating of window profiles in continuous production with a water-based impregnation (viscosity similar to water)

The material is sprinkled on the surface and remains for approx 10 seconds. After this time a high-pressure air knife nozzle will blow the access material from the surface.

The whole cabin is built with fall to the side to collect the rest of the material. It is reused after passing a filter system. The cabin is built of stainless steel.

The blowing off of the access material by air knife is effected by a high pressure fan.

The machine comprises:

-

- conveyor system

with spray protected roller system.

length 3000 mm

-

- sprinkling zone

with two nozzle systems adjusted to reach the whole surface of the workpiece.

length: 200 mm

-

- penetration area

length ca. 1000 mm

time of residence ca. 10 sec

-

- blowing zone

with adjustable knife nozzles

air supply with high pressure fan

air flow adjustable by frequency converter

length ca. 1000 mm

air speed ca. 40 m/sec

-

- supply

to supply the two sprinklers with fluid and collector for recovered material.

workpiece tolerances:

twist: max. 1° on the whole length

straightness max. 0,5mm deviation/m in

horizontal and vertical

weight distribution: evenly on whole length

coating material: waterbased impregnation

Unstable components can not be repositioned when tilted.

-

- operating width

for components up to max. 305mm

|

Pr |

MOULDING ANGLE TRANSFER VEN TRANS 90°

conveying from a lengthwise direction to a crosswise,

comprising:

1 excenter-transfer arms integrated into the driven infeed roller conveyor.

The tacted transfer system allows a minimum distance between the single mouldings on the following cross transfer system.

Technical Data:

length of roller conveyor: 4500 mm

roller pitch: 185 mm

number of transfer arms: 22

spacing 185 mm

tacting cycle: max. 30/min.

MOULDING CROSSWISE V-BELT CONVEYOR

for the handling of mouldings following an angle transfer.

Mouldings are conveyed by means of various v-belts along the system. The unit is fitted with an insulation cover between the conveyor. A drying tunnel can be fitted on top of the unit.

Technical data:

length: 4000 mm

operating width: 4200 mm

number of belts: 22

distance of belts: 185 mm

outfeed prepared for an additional angle transfer position of driving shaft in the middle gaps for passing of the carriers of the angle transfer

|

Price |

JET DRYING TUNNEL 70 °C

made of sandwich elements with fire-preventing insulation material.

The even distribution of air over the full operating width is reached by using slot nozzles on the full width of the tunnel.

One combined heating-, fan- and filter unit in compact design produces the air required for the process. A high capacity fan circulates the air through the F5 filter and heat exchanger. The tunnel can be operated with two different air speeds in the first and second tunnel section. All areas of the dryer are easily accessible through inspection panels for maintenance and cleaning. At the tunnel sides every 2000 mm insulated openings are fitted for observing the operating level.

Circulating air and exhaust air speed and volumes are controlled by manually adjustable air flaps. The air flow is secured by air flow switches in the tunnel, to keep the set volumes of air.

Included in the delivery is one temperature control system.

technical data:

length: 3000 mm

operating width: 4200 mm

opening height: 80 mm

air temperature: 50 °C

air speed: 25 m/sec

heating medium: hot water,

heat capacity (max)+15/70°C 50 kW

exhaust air volume 500 m3/h

electric consumption: 5,0 kW

|

Price |

5 MOULDING ANGLE TRANSFER VEN TRANS 90°

conveying from a lengthwise direction to a crosswise,

comprising:

1 excenter-transfer arms integrated into the driven infeed roller conveyor.

The tacted transfer system allows a minimum distance between the single mouldings on the following cross-transfer system.

Technical Data:

length of roller conveyor: 4500 mm

roller pitch: 185 mm

number of transfer arms: 22

spacing 185 mm

tacting cycle: max. 30/min.

BELT CONVEYOR

As a return conveyor

Technical Data:

length: 5300 mm

CONTROL CABINET

for all quoted items, with all necessary control and protection elements, motor relay indicators, displays and main switch. All elements are internally pre-wired on marked series clamps.

The cabinet includes all free contacts for interlocking our and also machines of other suppliers.

OUTFEED COVEYER NOT INCLUDED WITH MACHINE

Listed specifications were taken from manufacturer's published information and is assumed to be correct but not guaranteed. Bidder is encouraged to inspect the machine, call with questions or contact the manufacturer for more information.

The listed specifications & information were taken from the manufacturer’s published information, internet research, or seller’s description.

The specifications & information are assumed to be correct; however, in no way, guaranteed. Bidders are encouraged to inspect the machine, call with questions, or contact the manufacturer for more information.

Please log in to view the bid history

LoginIf a load fee is established for an individual lot, that fee will include loading onto a flatbed truck (only) by the seller. Any individual lot without a load fee will be the buyer's responsibility to remove and load (at buyer’s expense).

Payment is due within 24 hours of auction close. Payments must be made via bank wire transfer for any amount above $1,500. Credit cards may be used up to $1,500 (3% processing fee). Please Contact Sabrina Burns with payment questions at 209-839-7707 Any sales tax exemption documents are to be emailed to [email protected] at time of purchase/invoice for tax exemption consideration.