Biesse 'Rover B7.40FT-K" CNC Machine  Ended

Ended

MIllwork Adamo 5925 Tomken Rd # 11 Mississauga, ON Canada L4W 4L8

Mississauga, ON Canada

- Winning Bid : $6,700.00 USD Sold

- 75 Bid(s)

- High Bidder: m****z

Biesse Rover Altendorf & SCM Sliding Saws - Millwork Adamo Complete Shop Closure ( Closed #61209649 )

Dock Level Loading

-

Pick Up Location

Mississauga, ON Canada

-

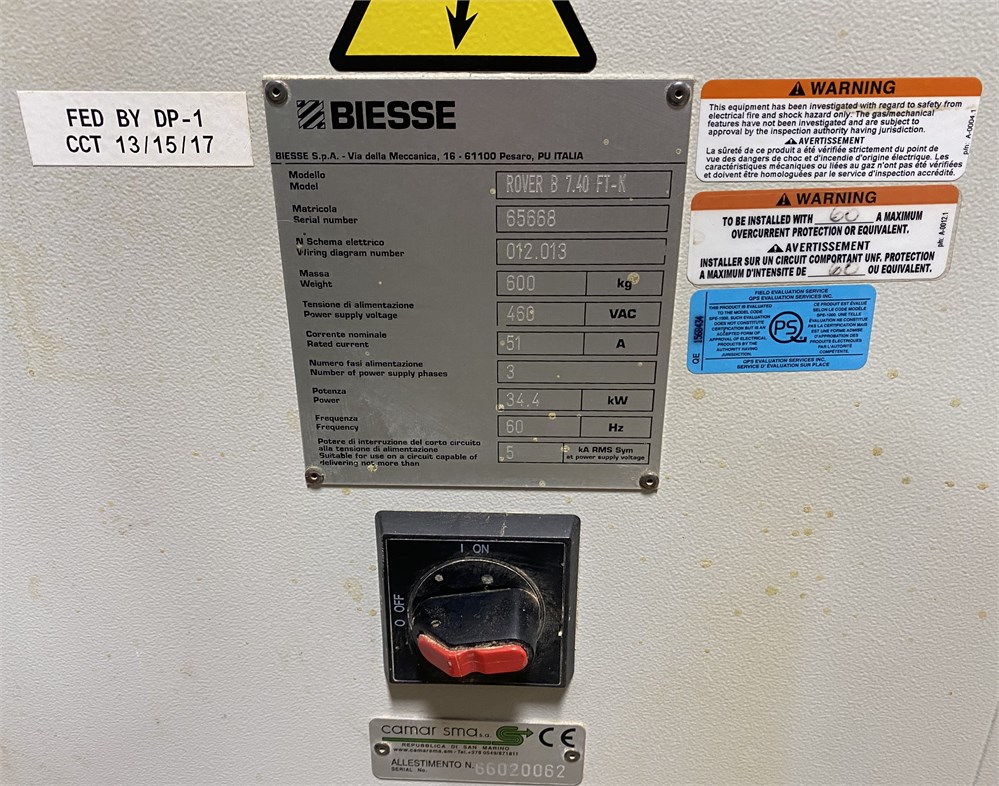

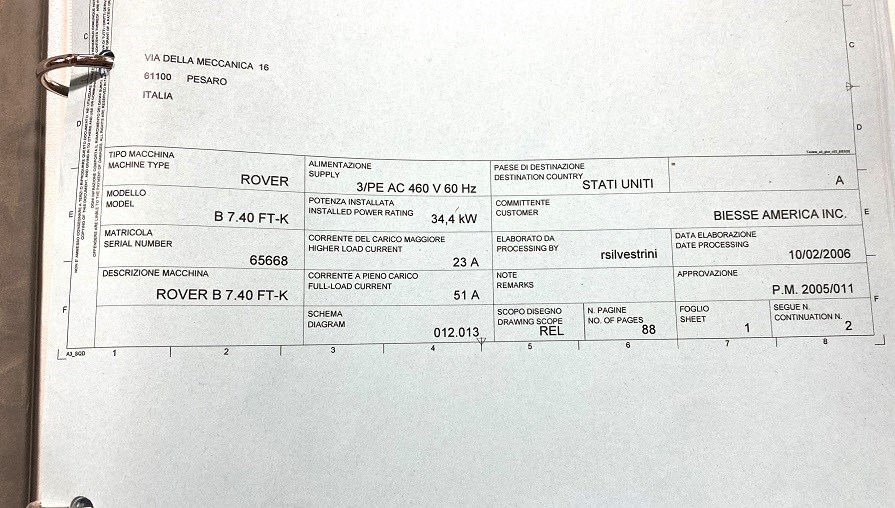

Make

Biesse

-

Model

Rover 7.40FT-K

-

Serial Number

65668

-

Year

2006

-

Phase

3 PHASE

-

Voltage

575 VOLT

-

Load Out Period

Jan 25 2024

-

Estimated Dimensions

Coming Soon

-

Estimated Weight

8,000 lbs

-

Seller Comment

-

Load Fee

2200

-

Lot Notes

-

page views

397

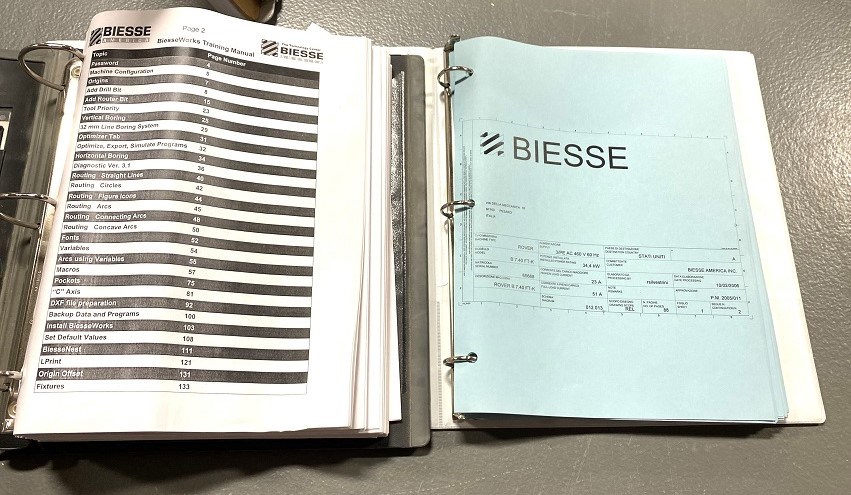

Biesse Rover B7.40FT-K CNC

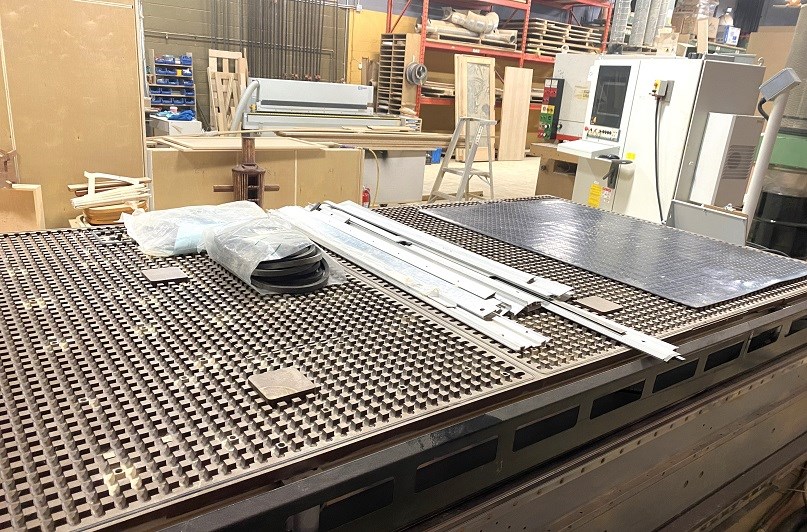

Moving Gantry machine with X Axis travel = 145?, Y axis travel = 61?. X Axis working field with all tools is 145? ? Main spindle is 157?, Y Axis working field with all vertical spindles is 60-1/2? ? Main spindle is 72-3/4?. Z axis clearance is 7?. Programmable feed rates: X and Y axis up to 3937 inches per minute, Z axis up to 1181 inches per minute

12.2 HP Vertically mounted fully programmable HSD Electrospindle,? HSK-F63 type ATC; variable speed from 1000 ? 24,000 RPM with maximum torque 12,000 ? 20,000 RPM

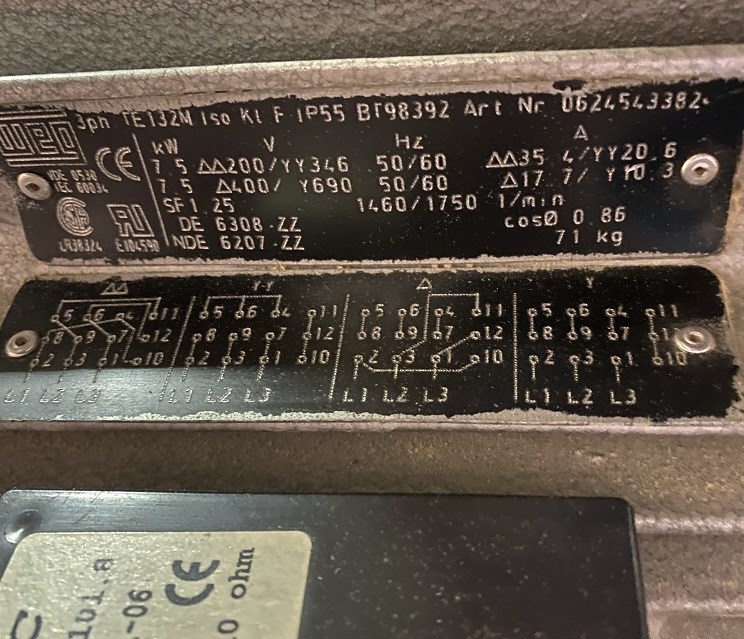

(12) Independent vertical spindles at 32 mm center distance, (6) of which are placed along X axis and (6) along Y axis; (4) units for horizontal opposed boring, (2) of which are placed along X axis and (2) along Y axis to perform horizontal drilling on the 4-panel sides. 2.3 hp inverter driven motor, spindle rotation speed 4000 RPM

The spindle is served by a Automatic Ride Along 10-position Tool Changer for On The Fly tool changes

Flat Table Design for Nested Based Manufacturing with (2) independent working zones; (4) external pop-up reference pins

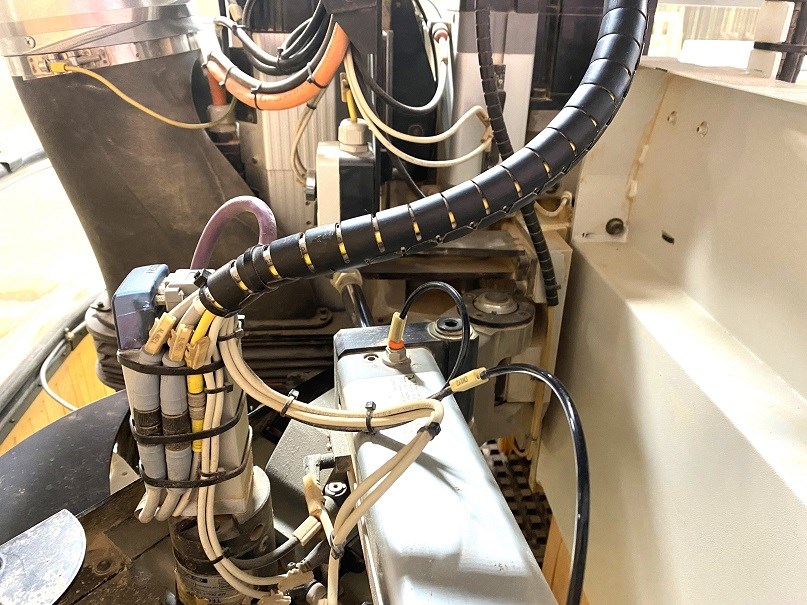

Top quality linear guides provide the high precision linear tracking systems for the X, Y and Z-axes. The X-axis drive system utilizes a hardened, helical rack. Hardened, precision ground, recirculating ball screw drives the Y and the Z-axis. Forced lubrication system for linear guides and ball screw

Emergency stop rope and pressure sensitive safety mats that will instantly place machine in pause cycle when stepped on; surrounding safety cage. Sound absorbing protective head enclosure with debris curtain around the bottom edge

The NC1000 Numerical Control is a PC, MS-Windows based technology. Pentium 1.8 Ghz CPU with 128 MB RAM and 20 GB hard drive, CR-ROM reader, mouse, USB ports, parallel port, serial port and network card. BiesseWorks software and (2) BiesseWorks keys for remote and machine programming capability. Operating system for real-time multitask processing, programs can be transferred via diskette or downloading by cable

(1) 10 HP Becker Vacuum Pump

Includes Assortment of tooling and manuals

Listed specifications were taken from manufacturer's published information and is assumed to be correct but not guaranteed. Bidder is encouraged to inspect the machine, call with questions or contact the manufacturer for more information.

The listed specifications & information were taken from the manufacturer’s published information, internet research, or seller’s description.

The specifications & information are assumed to be correct; however, in no way, guaranteed. Bidders are encouraged to inspect the machine, call with questions, or contact the manufacturer for more information.

Please log in to view the bid history

LoginUS & CDN CUSTOMS BROKER

Cole International (905) 672-6255

US BUYERS SHIPPING QUOTES:

Always Trucking (Aaron) 541-608-6532

SHIPPING WITHIN CANADA QUOTES;

Logistics Decisions (Adam) (905 -331-8900

No information available

CDN FUNDS: This Auction is Being held in CDN Funds.

PAYMENT: Is Required Within 48 hrs of Auction Ending.

PAYABLE METHOD: To Equipment Authority

REMOVAL: At Buyers Expense

REMOVAL DEADLINE: Jan 25, 2024

INSPECTION DATE: By Appointment Call 416-904-2475

AUCTION END DATE: Tue, Jan 16 2024 at 11:00 am PDT

BUYER PREMIUM: 15% Buyer Premium Sur Charge Will Be Added to All Lots