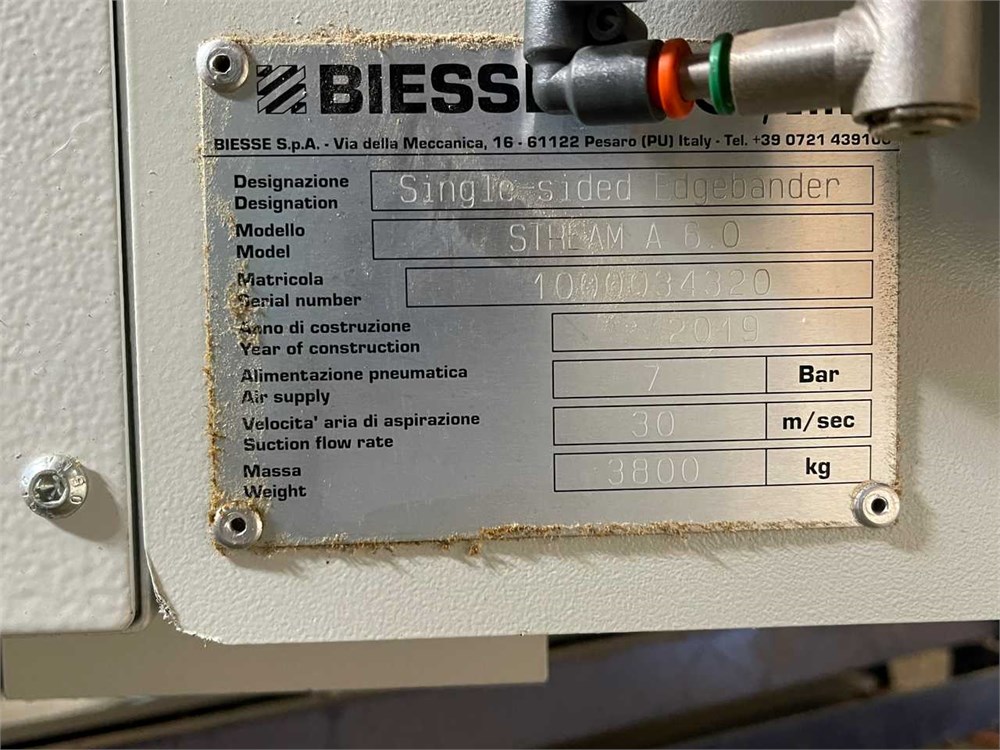

Biesse "Stream A 6.0" Edgebander (2019)  Ended

Ended

Complete Woodworking Plant Auction - East Palo Alto, CA

United States, CA

- Winning Bid : $52,950.00 USD Sold

- 107 Bid(s)

- High Bidder: j****o

Complete Woodworking Plant Auction - East Palo Alto, CA ( Closed #59521250 )

After 46 years, the owner of Knotty Hole Woodworks is retiring and closing it's 33,000 square foot plant. Located in the heart of the San Francisco Bay area, Knotty Hole is renowned for high end solid wood and panel projects. This auction includes late model Biesse edgebander with Doucet return conveyor, Dantherm 25,000 CFM dust collection system, late model Biesse/Omal CNC bore and dowel machine, Raimann gang rip saw, Weinig moulders, Holzma beam saw, Weeke CNC, classical machines, forklift, late model delivery truck, supplies, raw materials and much more!

-

Pick Up Location

351 Demeter St. East Palo Alto, CA 94303

-

Make

Biesse

-

Model

Stream A 6.0

-

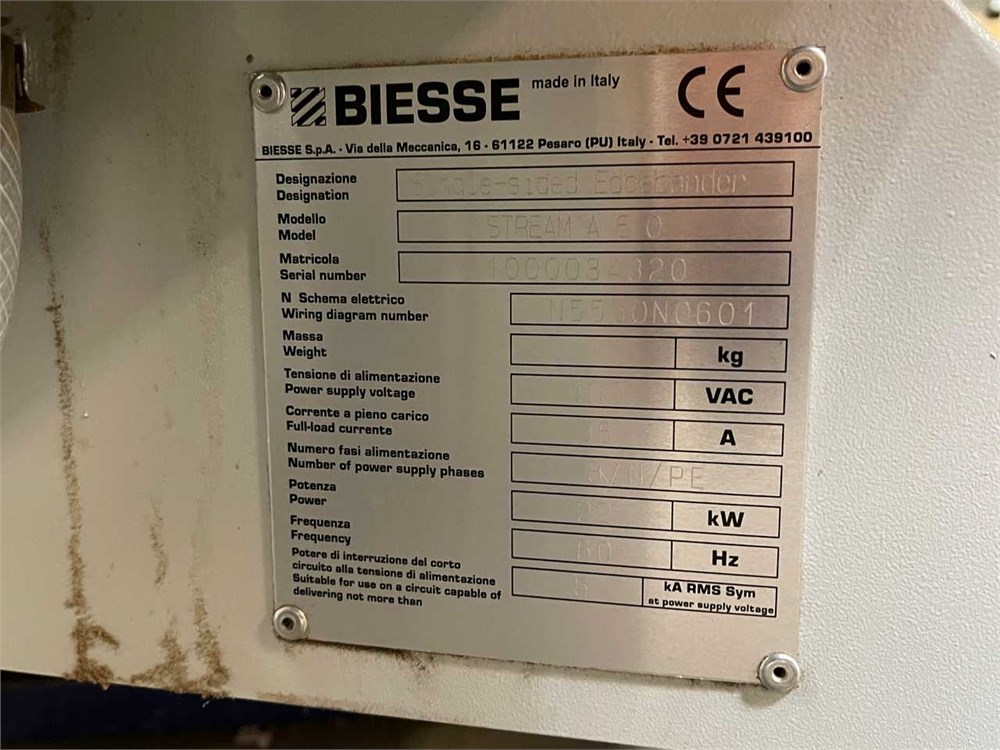

Serial Number

1000034320

-

Year

2019

-

Phase

3 PHASE

-

Voltage

208-230/460

-

Load Out Period

See home page for details

-

Estimated Dimensions

300" L x 55" W x 76" H

-

Estimated Weight

9,000 Pounds

-

Seller Comment

This lot requires a rigger, see home page for details.

-

Load Fee

-

Lot Notes

-

page views

699

Biesse "Stream A 6.0" Edgebander

See video of machine in operation

See original proposal for full details

10 - 60 mm panel height

140 mm (5.5") minimum panel length

85 mm (3.3") minimum panel width (150 mm length)

50 mm (1.9") minimum panel width (250 mm length)

25 mm panel protrusion from track

14 - 64 mm edgebanding height

0.4 - 3 mm coiled banding thickness

0.4 - 22 mm strip banding thickness

Bottom feed track

Variable feed speed, 12/18/20/25 MPM

Top pressure belt

Motorized positioning of top beam

Infeed fence with panel spacer, NC controlled

Manual infeed system for narrow panels

Automatic edge feeding systems for coils or strips

3 mm maximum coiled banding thickness

Guillotine for cutting coiled banding

NC control for z axis for edge guide device

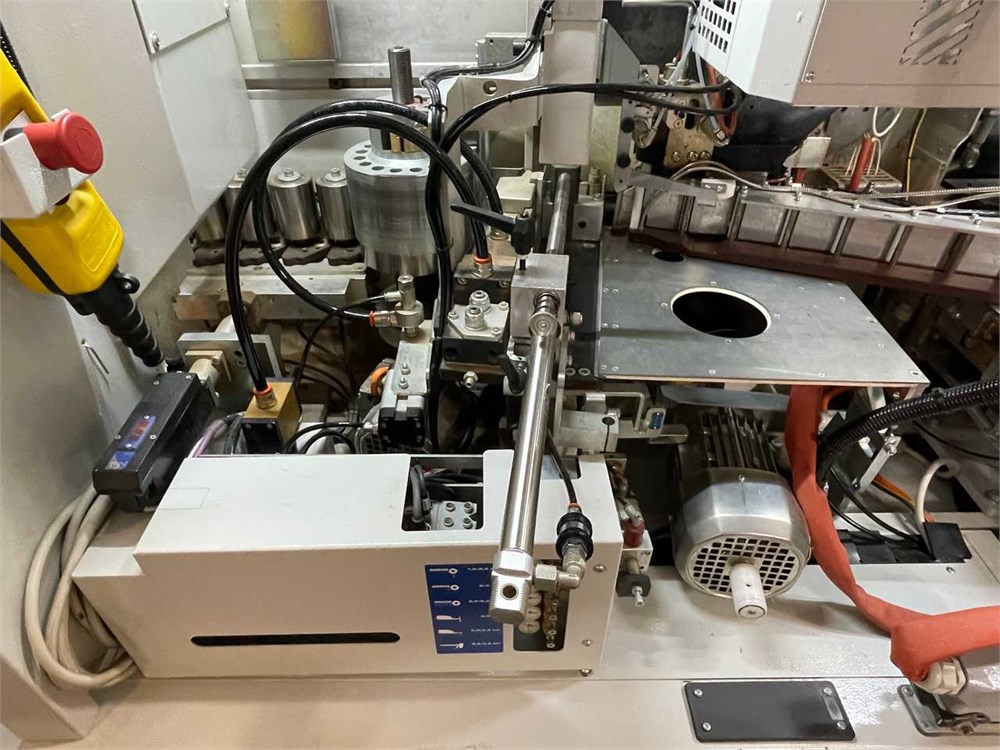

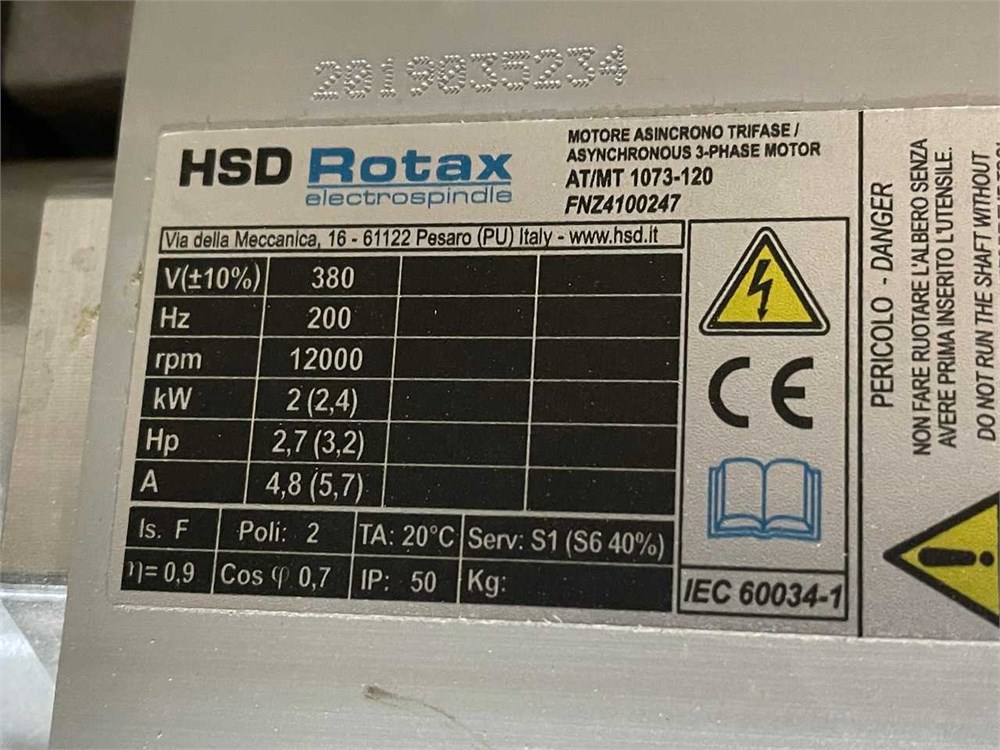

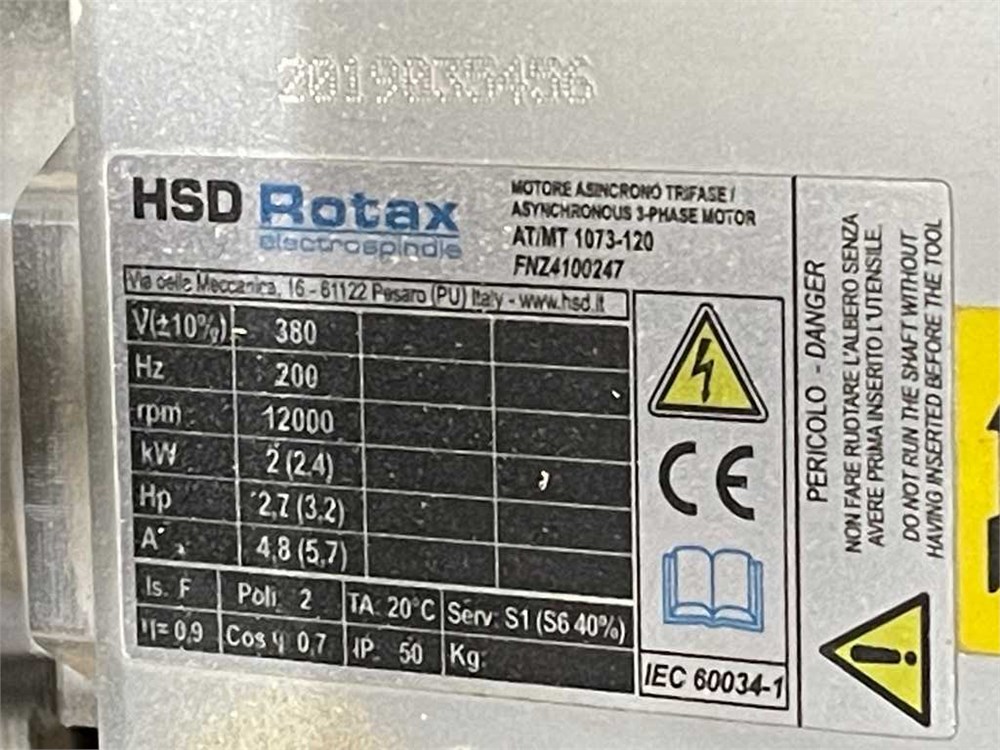

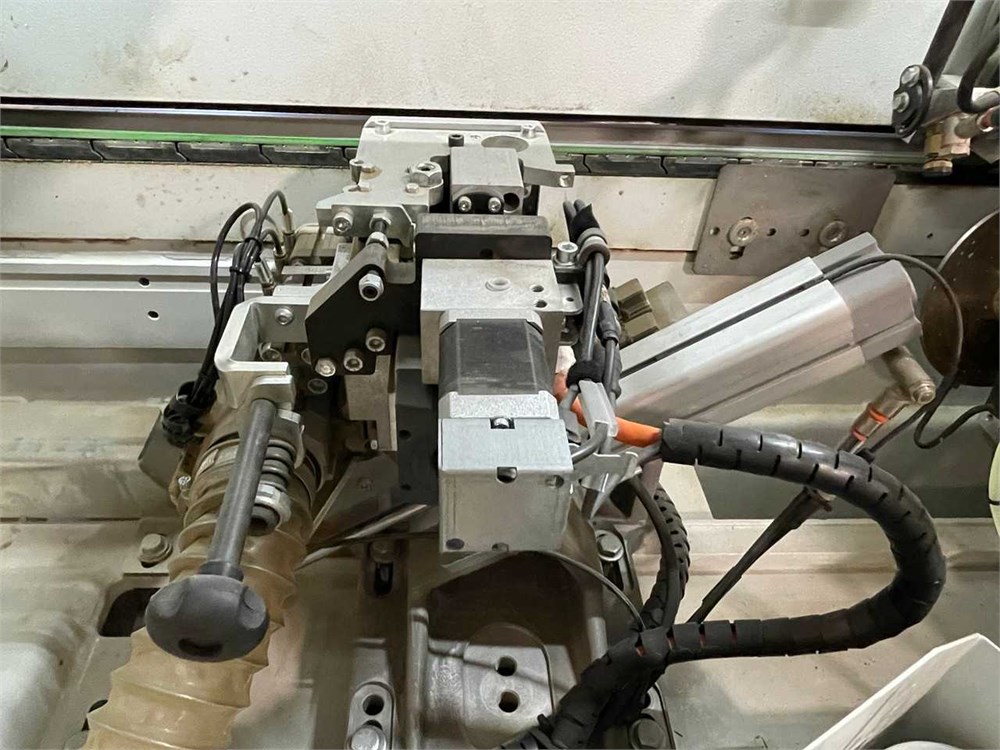

Premill unit with two (2) motors)

4.7 HP, 12000 RPM

NC adjustment on first copy shoe

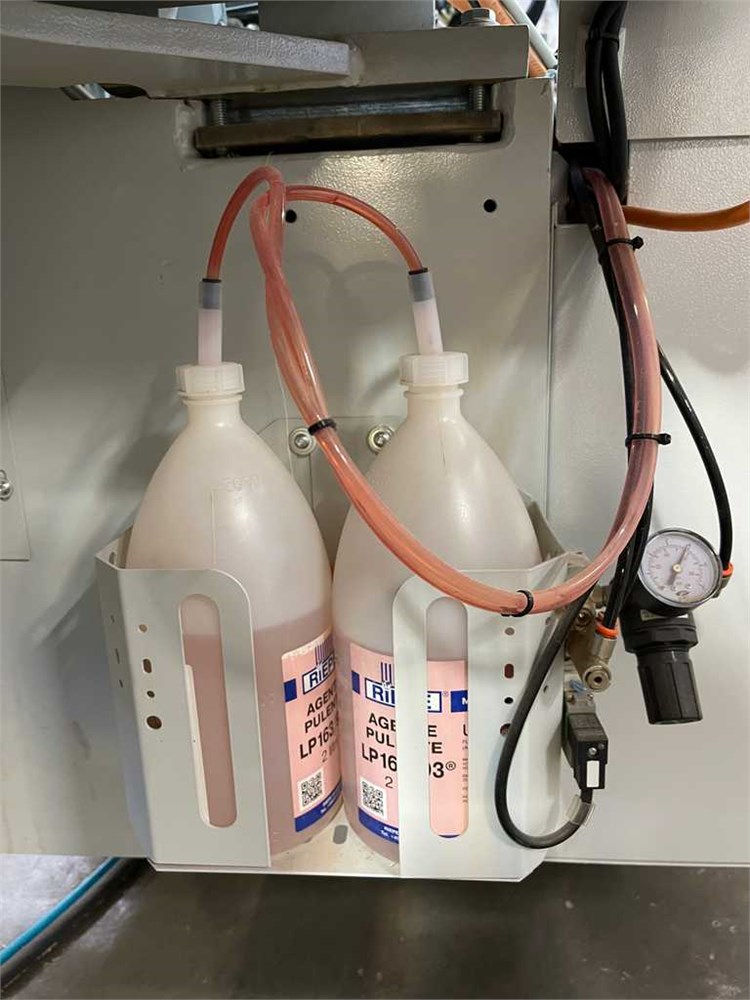

Anti-adhesive unit

Infrared heating lamp

Glue pre-melting device

Hybrid gluing unit for EVA or PUR

Pressure unit, NC controlled

One (1) driven roller

Five (5) idle rollers, 60 mm/2.4" diameter

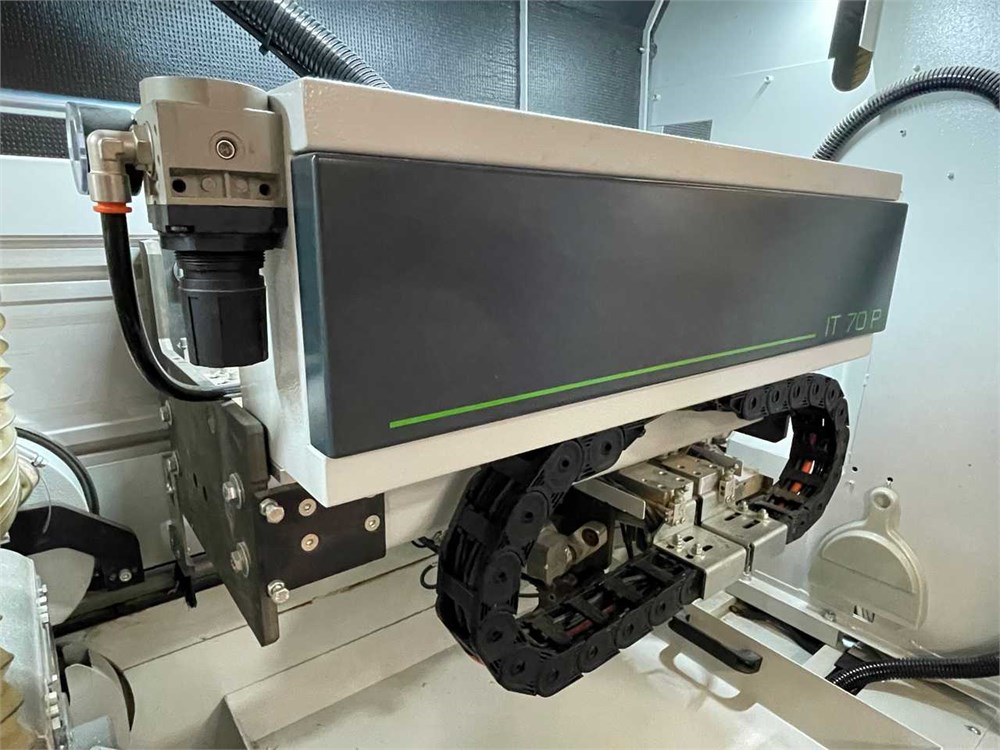

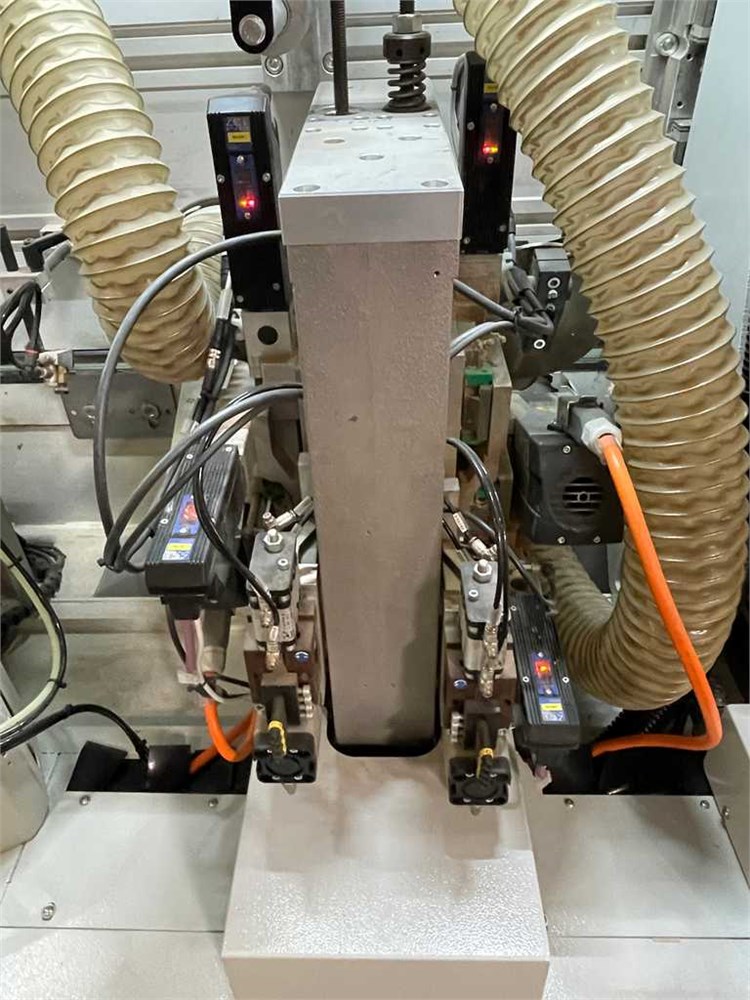

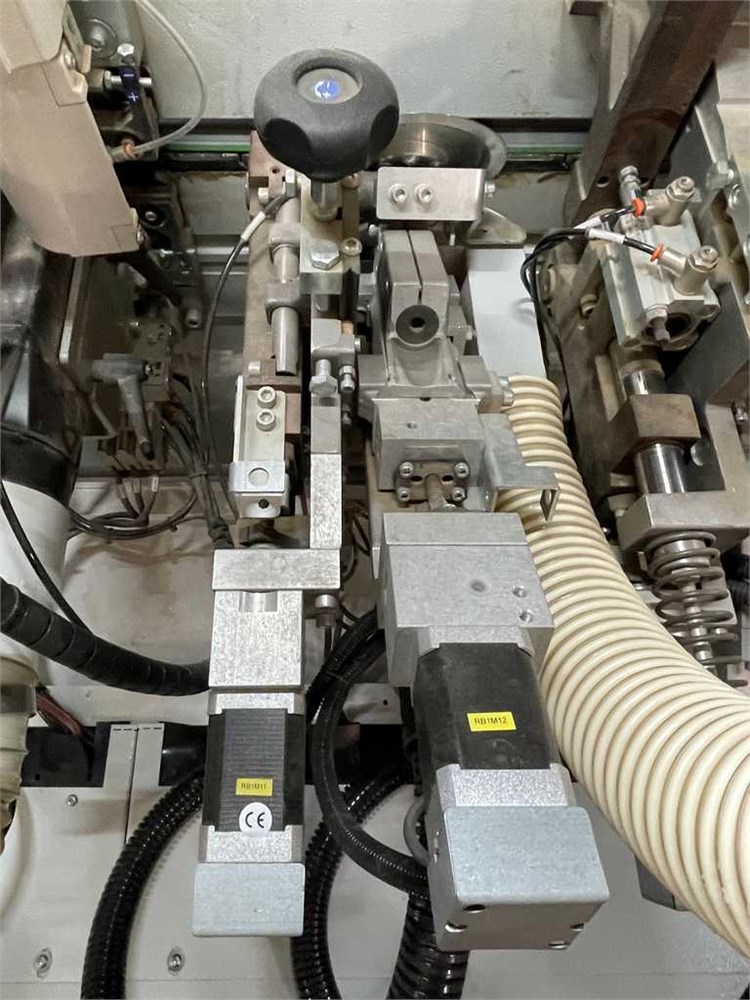

"IT-70-P" linear drive two (2) motor end trim unit

1 HP, 12000 RPM

0 - 15 degree tilting

NC control for automatic adjustment of copiers and tools

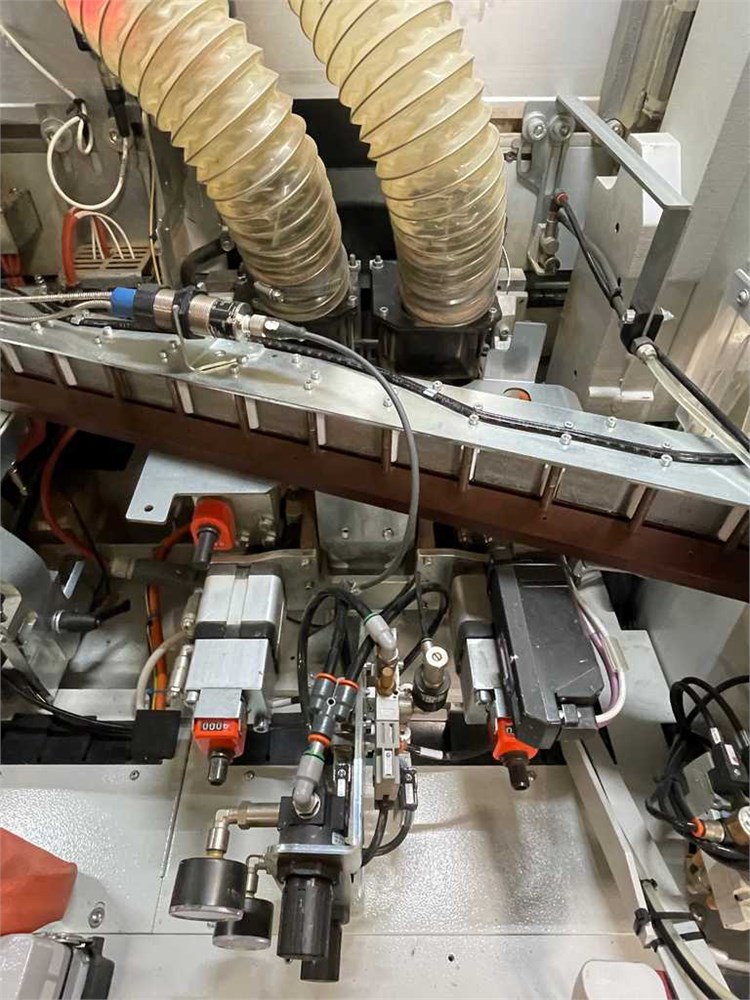

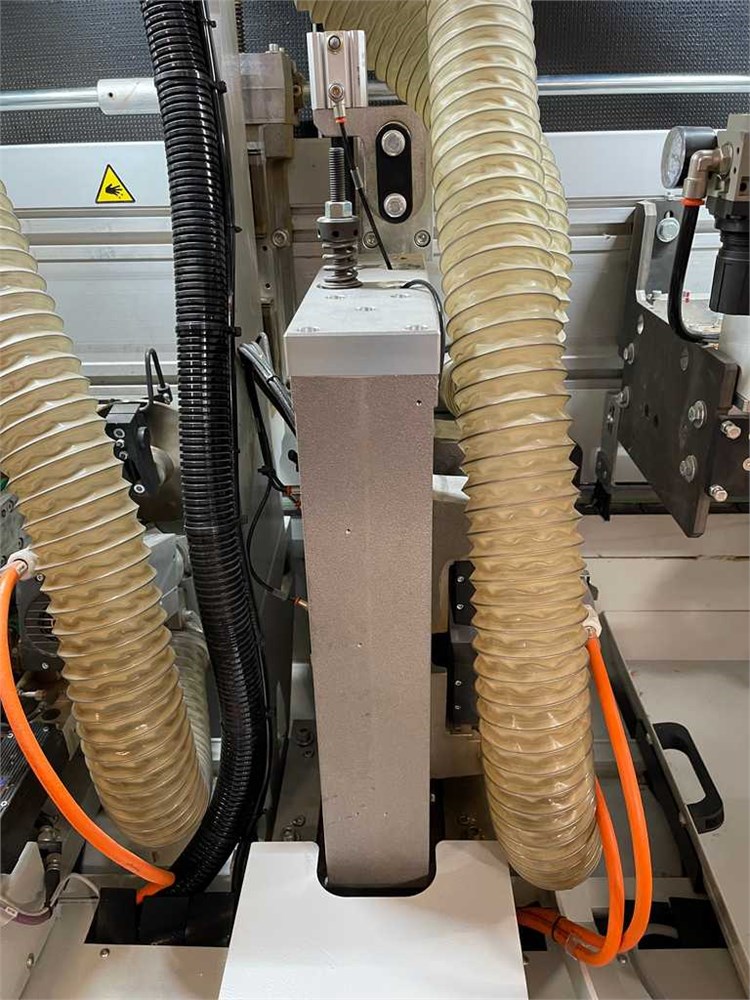

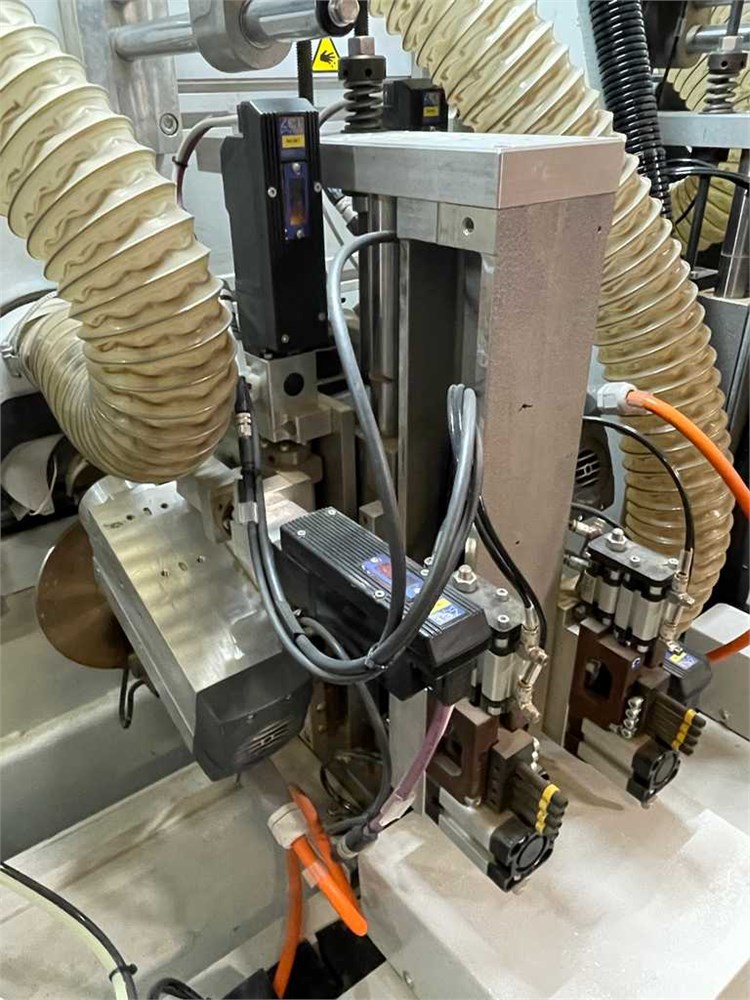

"RS-100" Top/bottom rough trim unit

2.7 HP, 12000 RPM

Can be tilted up to 1 degree

Two (2) position pneumatic exclusion

Pro-nesting kit with two (2) bearing copiers

"RF-400" Top/bottom fine trim unit

2.7 HP, 12000 RPM

0 - 45 degree tilt

NC control of four (4) axes

Pro-nesting kit with two (2) bearing copiers

Lubrication unit to enhance corner rounding finished appearance

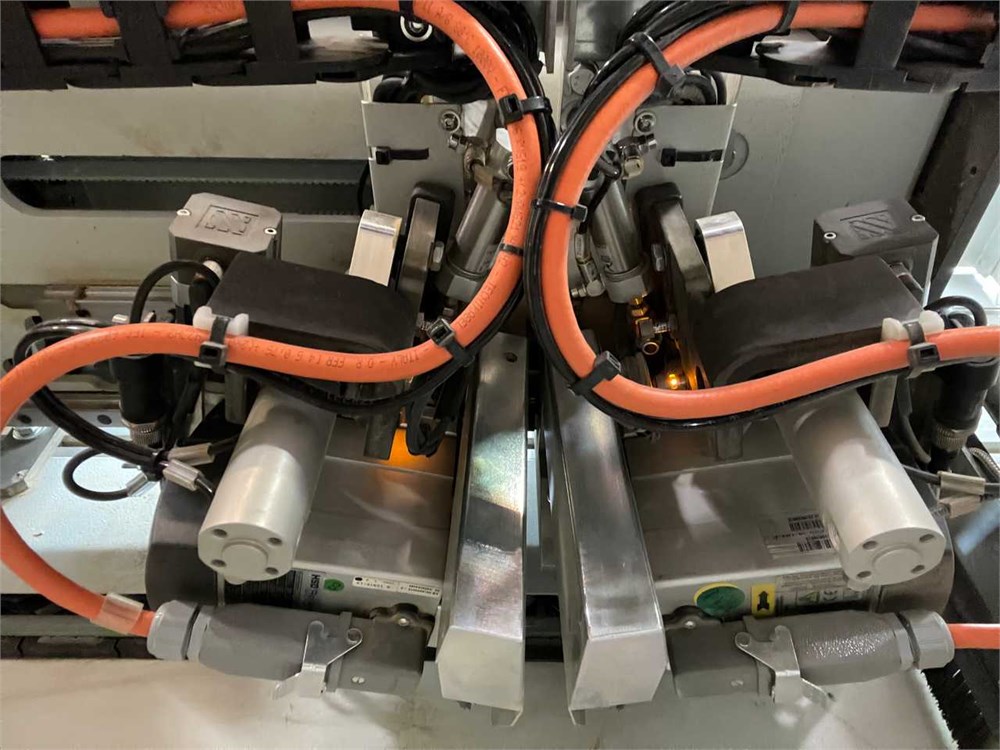

Two (2) motor corner round unit

12,000 RPM

NC adjustment

NC pneumatic exclusion

"RB-02 NC" Top/bottom profile scrape unit with external collection box

NC control of four (4) axes

NC pneumatic exclusion

Pro-nesting kit with two (2) bearing copiers

"RCC-701" Top/bottom flat scrape unit

NC Pneumatic exclusion

Air blowers

"SP-501" Top/bottom buff unit

0.5 HP, 2800 RPM

Tiltable

Misting unit

"PH-700" Top/bottom hot air blower

PC control

Smart-Touch 23 numerical control

23" color touch screen

Windows operating system

Standard keyboard and mouse

Integrated hard drive, USB port

Remote control pendant

Lighted sound enclosure

Integrated electrical cabinet with air conditioning

Outboard roller support

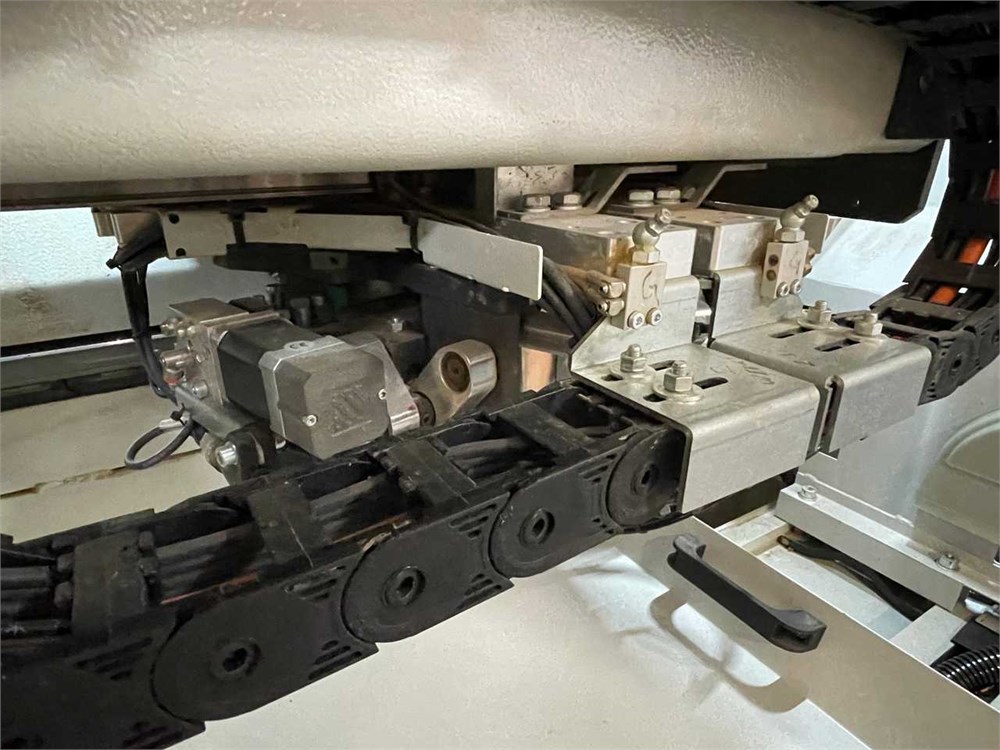

Automatic lubrication system

External electrical transformer

Custom dust manifold

Manuals

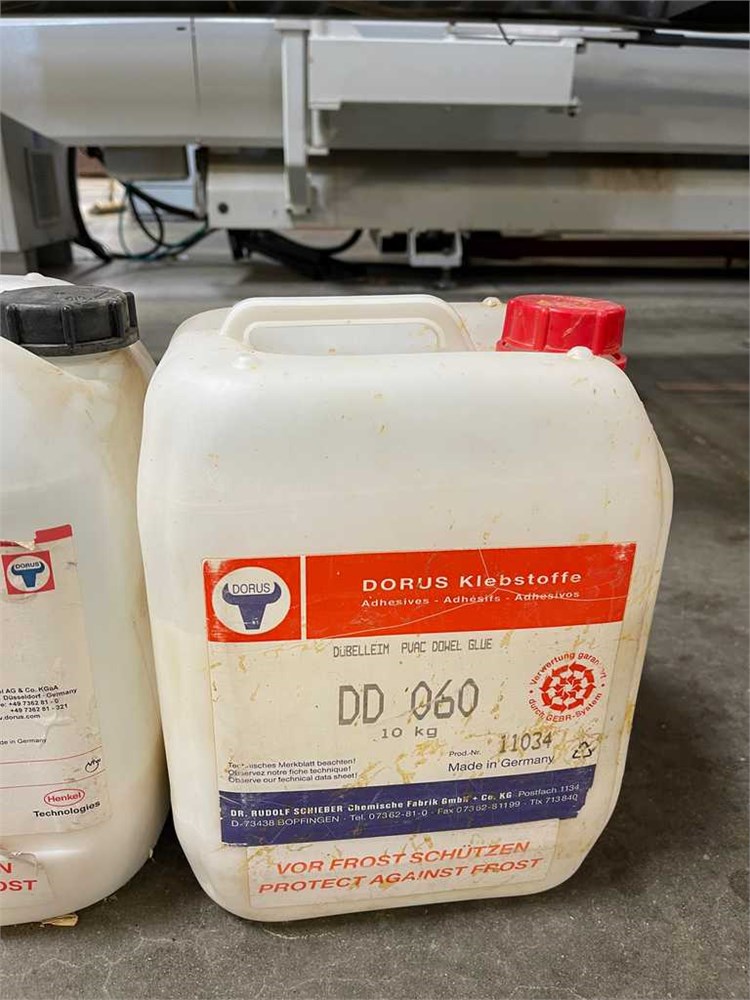

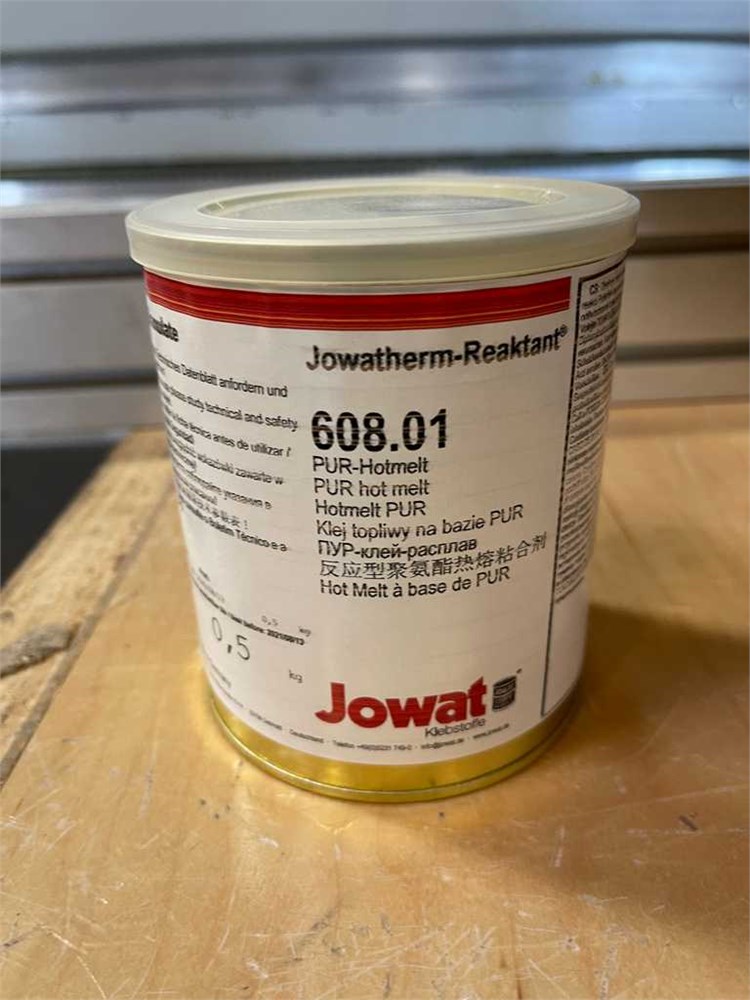

Chemicals and glue

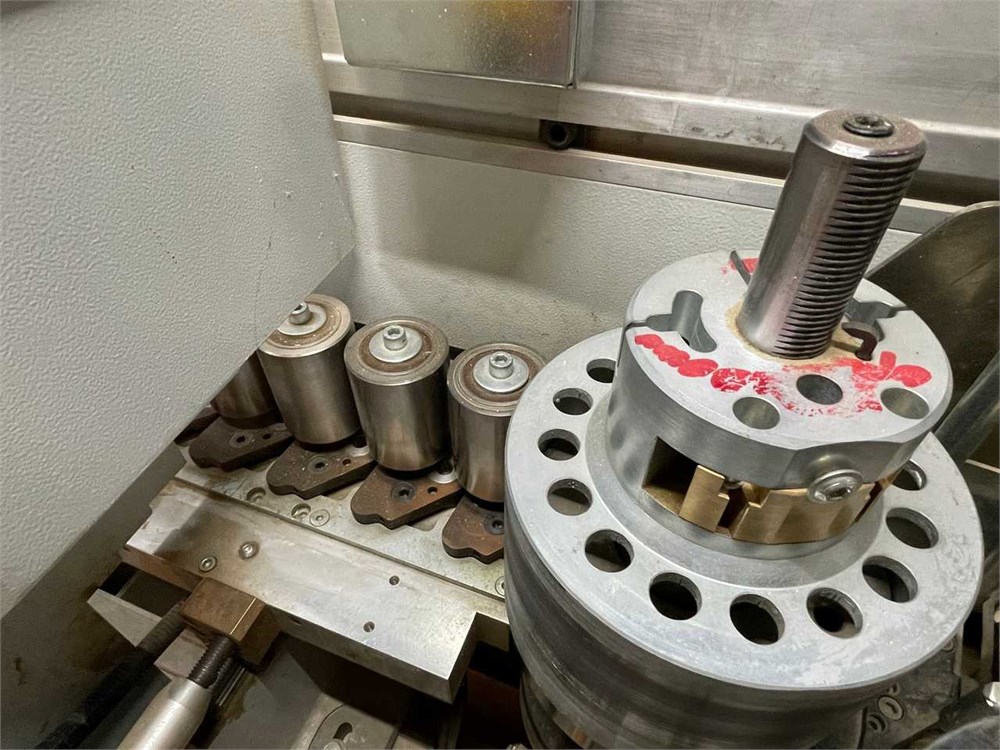

Accessories and tooling

Rigging/lifting bars

Return conveyor NOT included, offered in lot 002

Listed specifications were taken from manufacturer's published information and is assumed to be correct but not guaranteed. Bidder is encouraged to inspect the machine, call with questions or contact the manufacturer for more information.

The listed specifications & information were taken from the manufacturer’s published information, internet research, or seller’s description.

The specifications & information are assumed to be correct; however, in no way, guaranteed. Bidders are encouraged to inspect the machine, call with questions, or contact the manufacturer for more information.

Please log in to view the bid history

LoginNo information available