Biesse "Roxyl 5.5" Edgebander  Ended

Ended

Biesse "Roxyl 5.5" Edgebander and Other Machinery - Ontario, CA

United States, CA

- Winning Bid : $7,601.00 USD Sold

- 74 Bid(s)

- High Bidder: l****k

Biesse "Roxyl 5.5" Edgebander and Other Machinery - Ontario, CA ( Closed #59508851 )

Store fixture manufacturer in Southern California is updating their shop and auctioning a Biesse edgebander and other machinery no longer required for continuing operations.

-

Pick Up Location

2314 E. Locust Ct. Ontario, CA 91761

-

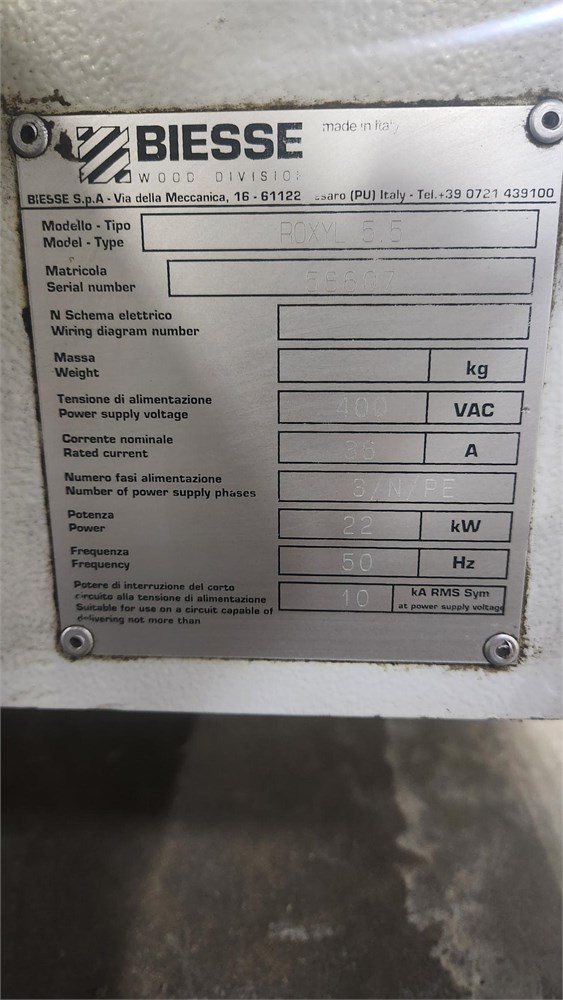

Make

Biesse

-

Model

Roxyl 5.5

-

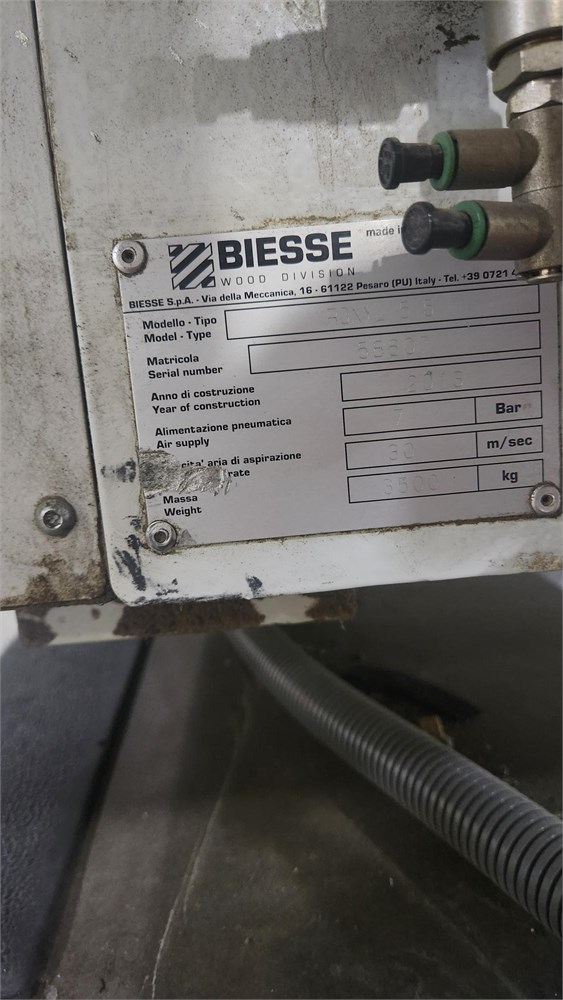

Serial Number

58607

-

Year

2013

-

Phase

3 PHASE

-

Voltage

208-230/460

-

Load Out Period

December 11 - December 22, 2023 (by appointment)

-

Estimated Dimensions

260" L x 48" W x 72" H

-

Estimated Weight

8,000 Pounds

-

Seller Comment

Seller will disconnect and load onto buyer's flatbed truck/trailer for non-negotiable $250 loading fee. Palletizing, crating or other services may be available at an additional cost.

-

Load Fee

250

-

Lot Notes

-

page views

444

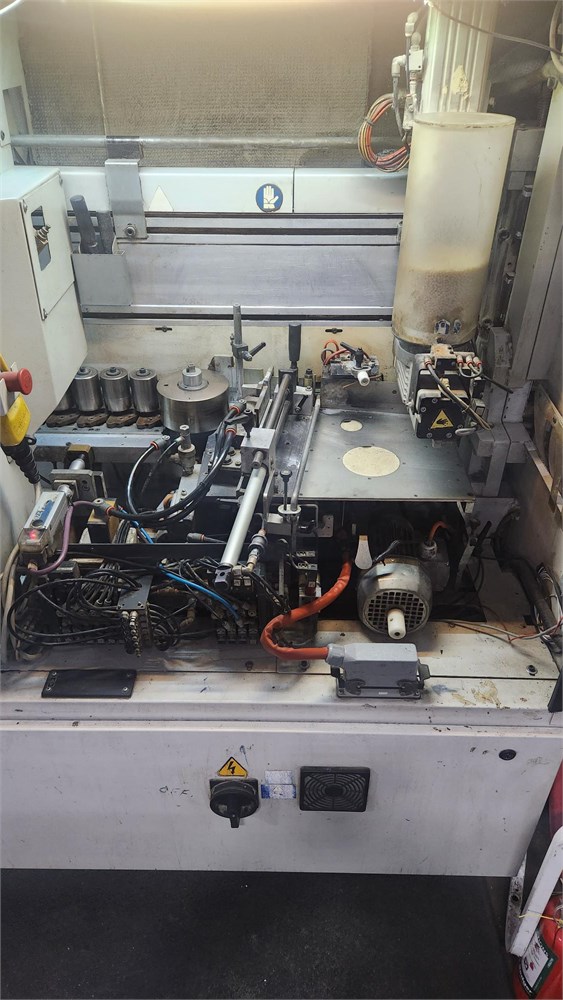

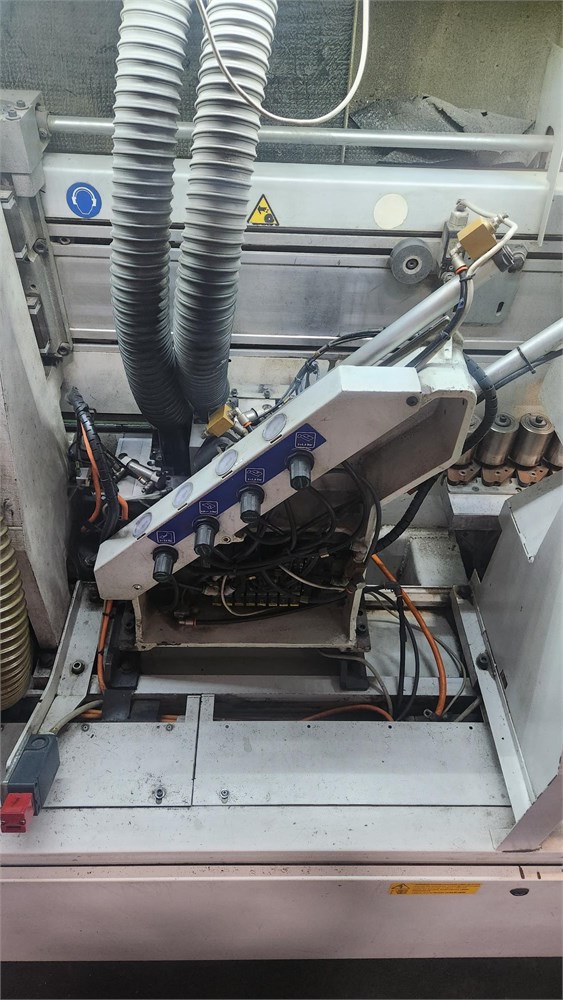

Biesse "Roxyl 5.5" Edgebander

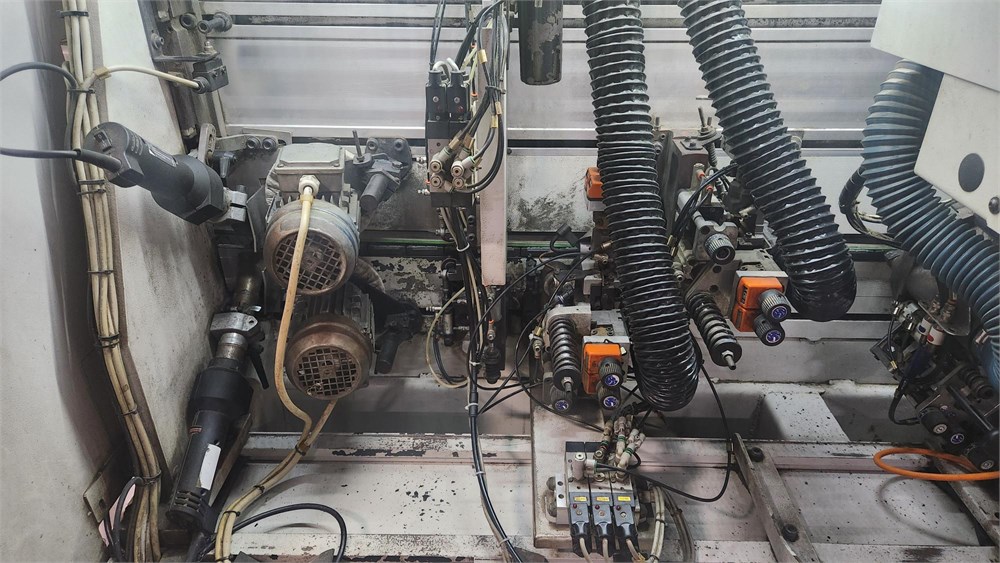

See video of machine in operation

Edge thickness for strips min./max. 0.4 - 22 mm (0.02" - 0.87"), coiled material from 0.4 - 3 mm (0.02 - 0.12")

Panel thickness from 10 - 60 mm (0.39 - 2.36")

Work piece width min. of 85 mm (3.34"

Work piece length min. 140 mm (5.51")

Feed speeds 10 - 14 - 18 - 20 MPM (33 - 46 - 59 - 65 FPM)

"Roxyl-Matic" automated machine setup, MS/Windows XP Operating System, floppy drive, and 4 GB HD; USB port, keyboard, and mouse interface. Remote control pendant.

Flat Screen (17") with color graphics interface: Programs can be easily created and recalled at will; Graphic interface makes programming easy, icon of each unit may be brought up on the screen to show the operator the status of the unit and the parameters, which can be programmed; Edgebander may be operated manually when required, without necessity to write a program.

Edge Magazine: Automatic for processing coiled and strip edge banding material.

Adjustable infeed fence

EVA (Hot Melt) "QM-705": Quick pre-melting granulate with glue roller applicator to cover conventional edge banding material.

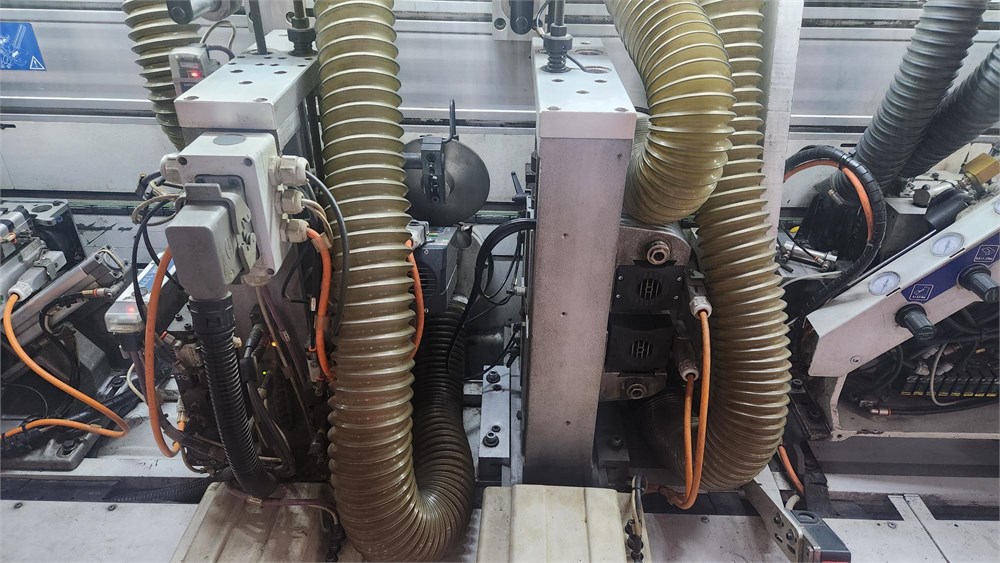

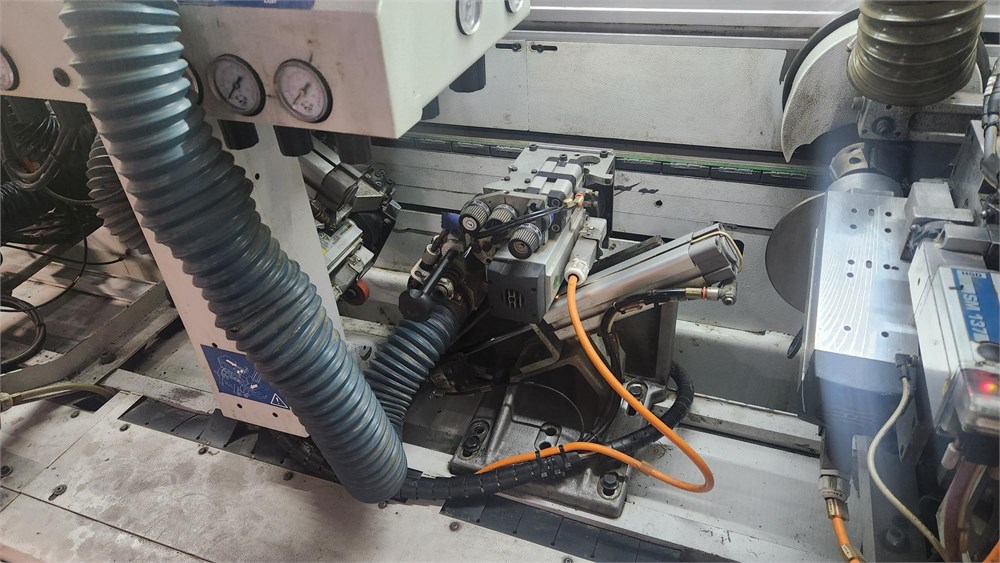

Pressure Section: Servo controlled programmable pressure section with (1) large driven roller and (4) idle rollers.

End Trimming Unit "IN-801": Front & rear trimming motors, uni-point swivel 0° - 15° bevel, programmable pneumatic change-over from flush to bevel.

Rough/Flush Trimming Unit "RS-701": Top/Bottom pre- or flush trimming motors.

Flush/Bevel/Radius Combination Trimming Unit "RF-400": Servo controlled, (2) Servo motors (one for horizontal tool position, one for tool up/down position); using combination bevel/radius/flush insert knives; pre-positioning of motors by pneumatic air cylinders.

Corner Rounding Unit "CR-202": (2) Motors for front/back corner and upper & lower edge profiling.

Profile Scraping Unit "RBK-503": Top/Bottom 2-axis NC programmable knife positioning (i.e. 2 - 3 mm radius) for PVC edges. External collection box.

Glue Scraping Unit "RCC-701": Flat, top/bottom, digital positioning indicators, pneumatic controlled for in/out position.

Buffing Station "SP-501": Top & Bottom buffing motors with 150 mm (6") cloth buffing wheel diameter; adjusts in multiple directions.

Hot air blowers

Motorized top beam positioning

Overhead belt hold down

Lighted sound enclosure

Outboard roller support

Centralized lubrication system

External electrical transformer

Dust pipe and flex hose NOT included

Listed specifications were taken from manufacturer's published information and is assumed to be correct but not guaranteed. Bidder is encouraged to inspect the machine, call with questions or contact the manufacturer for more information.

The listed specifications & information were taken from the manufacturer’s published information, internet research, or seller’s description.

The specifications & information are assumed to be correct; however, in no way, guaranteed. Bidders are encouraged to inspect the machine, call with questions, or contact the manufacturer for more information.

Please log in to view the bid history

LoginNo information available