Shaw Almex "TL-6-4-9" Thermoforming Membrane Press  Ended

Ended

Items located in Kansas City metro

- Winning Bid : $750.00 USD Sold

- 10 Bid(s)

- High Bidder: f****1

DMC 4 head widebelt & Almex membrane press - Kansas City, MO ( Closed #54913308 )

Cabinet shop in KC metro is offering these 2 machines they do not use for their current production.

-

Pick Up Location

1308 W 9th Kansas City, MO 64101

-

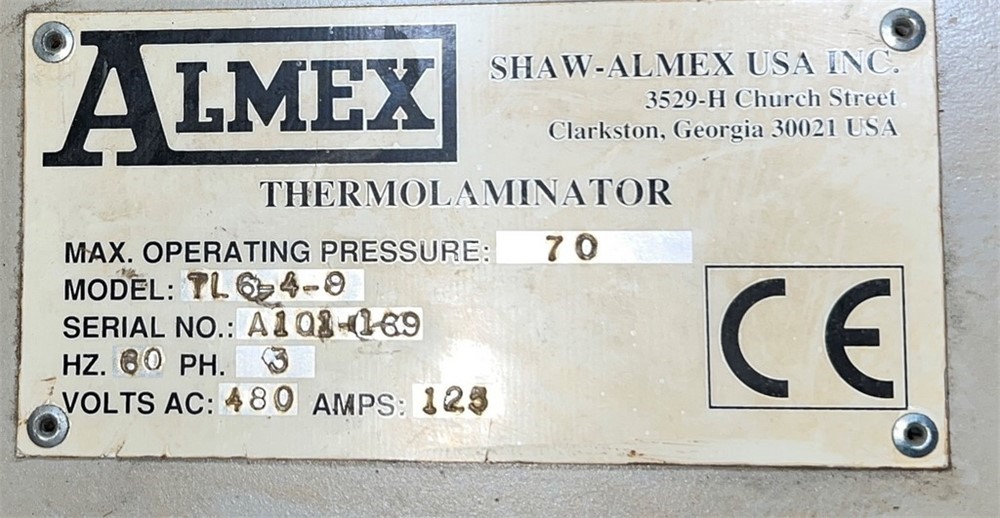

Make

Shaw Almex

-

Model

TL-6-4-9

-

Serial Number

A101-169

-

Year

-

Phase

3 PHASE

-

Voltage

480 VOLT

-

Load Out Period

See main page for loading dates

-

Estimated Dimensions

96" x 144" x 102" Mahine only size

-

Estimated Weight

-

Seller Comment

Buyer responsible for prep, loading, and shipping or hiring a rigger to do so.

-

Load Fee

-

page views

1791

Thermo-Laminating Press, membrane or "membraneless" operation for vinyl, heat transfer foils & veneer products; by the flip of a switch at the control console it changes from membrane to membraneless pressing. It uses "high volume" air pressure and a powerful instant vacuum creating suction and pressure at the same time.

Works without hydraulic cylinders: A platen size rubber pressure air bag under the lower platen (bolster) inflates and can withstand pressure up to 200 PSI; by in- & deflating it opens-and-closes the Press; a 240-gal. air tank supports the in/out high volume air movement.

The vacuum that sucks down the overlay to the substrate is generated by a 5 HP vacuum pump and supported by 240-gal. vacuum tank for instant vacuum power.

Double shuttle tray system, each tray 46" x 100" x 1-1/4" deep, they shuttle in-and-out of press on track guided casters for loading-and-unloading.

54" x 108" Aluminum top platen with a standard 3 mm thick silicone membrane (currently not being used); a small vacuum is used to draw the membrane up against the upper heated platten.

46" x 100" Max. part size for full wrap, 2" max. part thickness and a 2-1/4" max. chamber height; 84 PSI max. laminating pressure.

Top platen & infeed lower tray (platen): Both with resistance silicone heater elements, 150° - 350° F max. temperature with infinite control, 21 kW heating elements in each platen.

The information provided in this lot was gathered from literature, internet & physical inspection. It is thought to be accurate; but not guaranteed. Bidders are urged to use the open house or private inspection periods to inspect and verify.

The listed specifications & information were taken from the manufacturer’s published information, internet research, or seller’s description.

The specifications & information are assumed to be correct; however, in no way, guaranteed. Bidders are encouraged to inspect the machine, call with questions, or contact the manufacturer for more information.

Please log in to view the bid history

LoginNo information available