(2020) Stefani "KD FRT" Edgebander  Ended

Ended

Tracy, Ca Warehouse Auction, Tracy, Ca

- Winning Bid : $47,150.00 USD Sold

- 105 Bid(s)

- High Bidder: J****0

Tracy Warehouse Auction - Tracy, CA ( Closed #54113029 )

All assets moved to Tracy CA warehouse for convenience of buyers. Items include Unique 250 GT Machine, Castaly Dovetail Machine, Tiger Apex PRO XXL 3d Printer, (4) Late Model Denray DownDraft Tables and much more. For additional questions or to view machines prior to auction close, contact [email protected] or 925-250-8248.

-

Pick Up Location

2203 N Macarthur Dr Tracy, Ca 95376

-

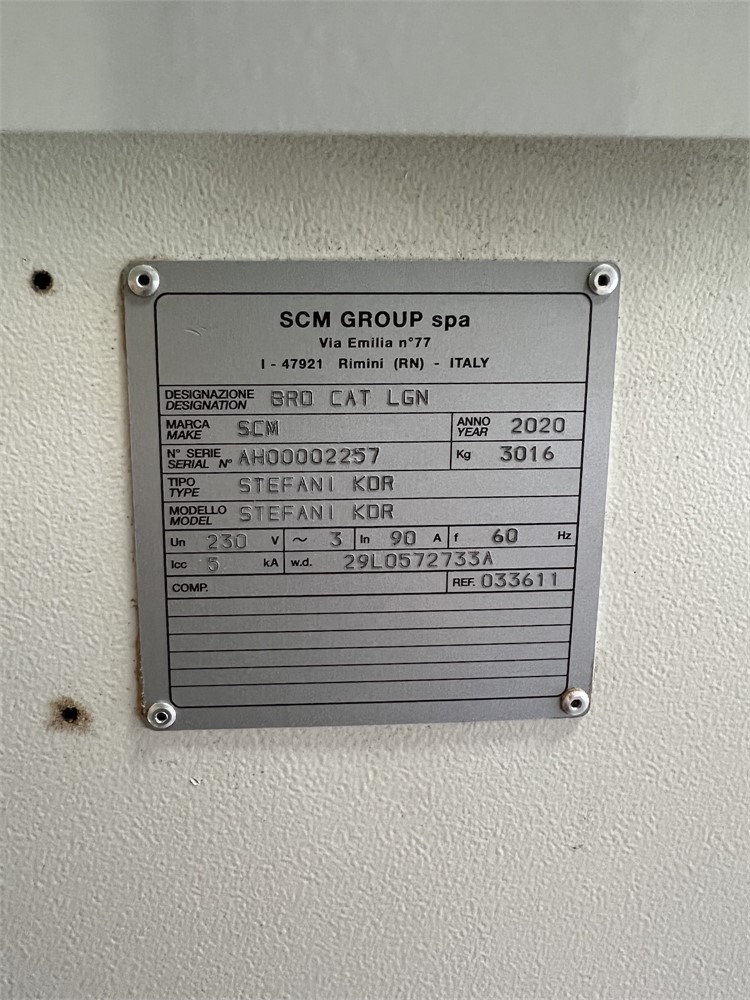

Make

Stefani

-

Model

KD FRT

-

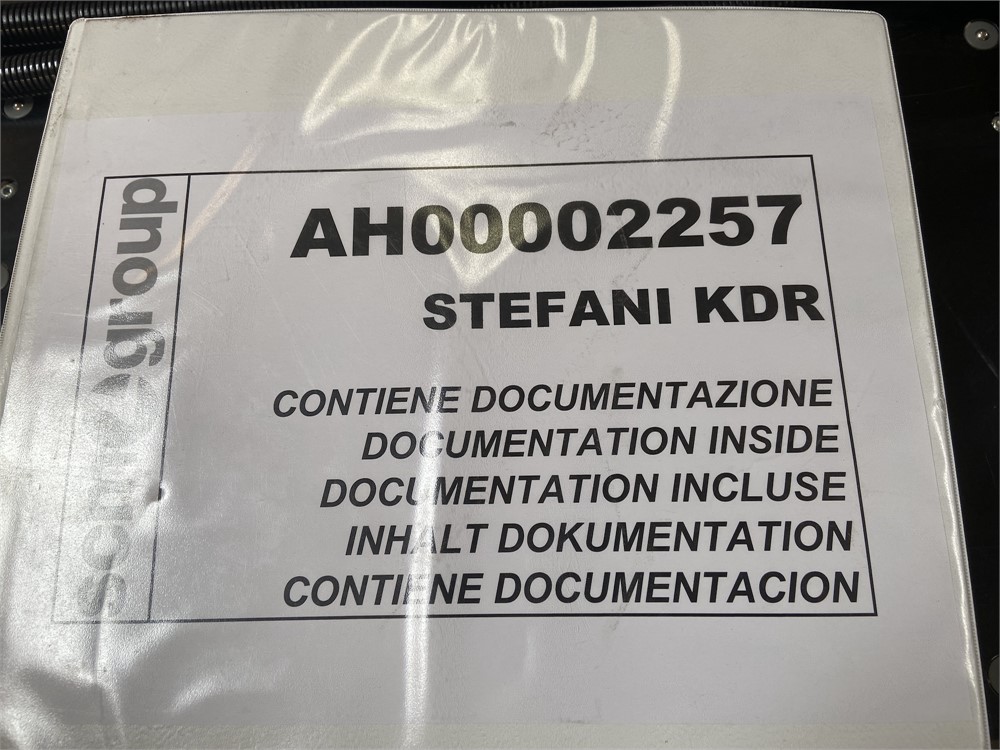

Serial Number

AH00002257

-

Year

2020

-

Phase

3 PHASE

-

Voltage

230 VOLT

-

Load Out Period

-

Estimated Dimensions

20'L x 4'W x 6'H

-

Estimated Weight

-

Seller Comment

Non Negotiable Load Fee $400

-

Load Fee

$400

-

page views

1950

SCM "Stefani KD-FRT" Edgebander (2019)

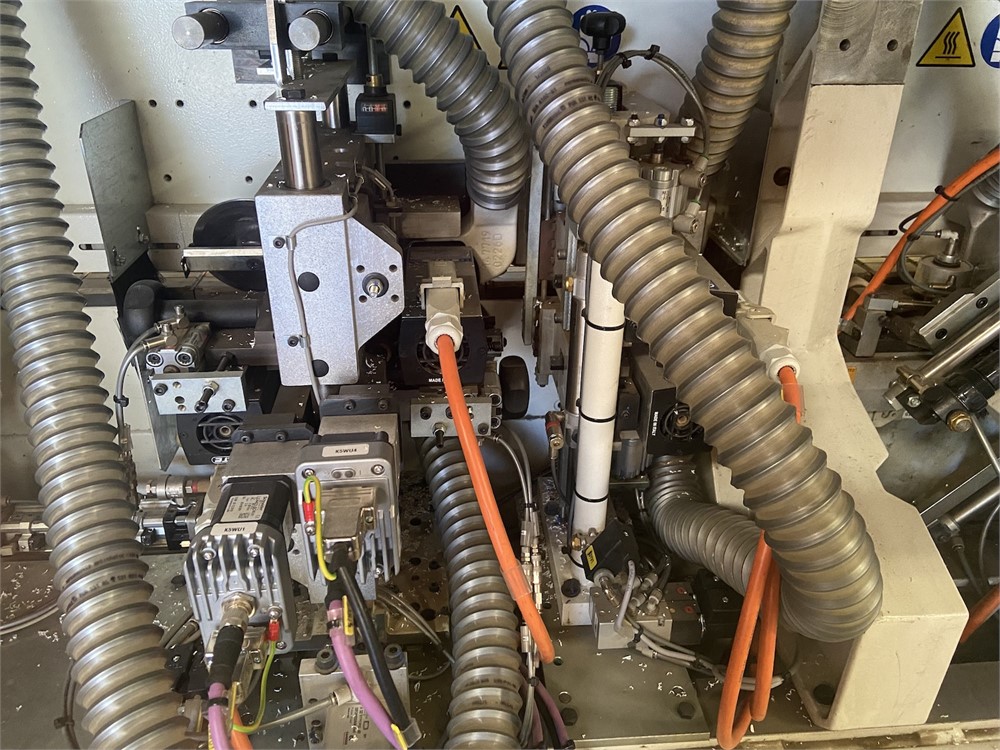

Automatic single sided edgebander designed to be used for edgebanding straight vertical profiles with coiled material (veneer and PVC) and with strips (high-pressure laminate and solid wood) with a maximum thickness of 12mm.

Machine Base

The machine base is a rigid, ribbed steel structure and is designed to provide maximum support for the working units. The ribs provide stability and, at the same time, provide openings in the base to facilitate removal of the chips/dust.

Capacities And Speed:

Edgebanding thickness: .4mm - 12mm (.016-1/2”) Guillotine capacity: 3mm

Feed speed: 33-60 ft/min.

Panel height: 3/8” min – 2 3/8” max Minimum panel length: 5 1/2”

Minimum panel width: 2”

Minimum distance between panels: 24"

PC 21” Controller

The FRT Stefani comes equipped with the Maestro Pro Edge controller, a 21” industrial multi touch screen. Comes standard with a Windows operating

system. Capable of storing an unlimited number of programs. Monitors statistical data, as well perform diagnostic functions and program functions. 1920 x1080 resolution, intuitive interface. Monitors the number of panels processed, the amount of material applied, the number of hours run, the

distance the feed track has turned, etc. Maintenance schedules are monitored for various stations throughout the machine. Swivels 270 degrees for easy

access..

The Stefani KD comes equipped with the new "Startouch" controller. This controller features a 12" touch screen display. Capable of storing 100 programs, 6 at the touch of a single key. Color graphic display of all the

working units. Tracks production information, diagnostic information and monitors maintenance schedules. Choose mm's or inches, as well as 5

different languages. Swivels 270 degrees and tilts for easy access.

Lighted Sound Enclosure With Acoustical Hoods

Machine comes standard with a lighted sound enclosure making it easier for the operator to perform his daily functions. It is also equipped with an acoustical

sound enclosure that covers the entire machine and reduces the noise level.

Electronic Positioning Of The Top Pressure Beam

All operating units raise and lower simultaneously when the pressure beam is adjusted. No adjustment is required for the glue roller when changing panel thickness. The pressure beam has two rows of staggered pressure rollers with steel

bearings. The height of the pressure beam is electronically programmable through the controller.

Anti-Adhesive

The machine comes equipped with an anti-adhesive unit positioned prior to the pre milling unit. It prevents the buildup of glue on the top and bottom of the panel. The unit

comes with two independent nozzles and a tank of anti-adhesive liquid.

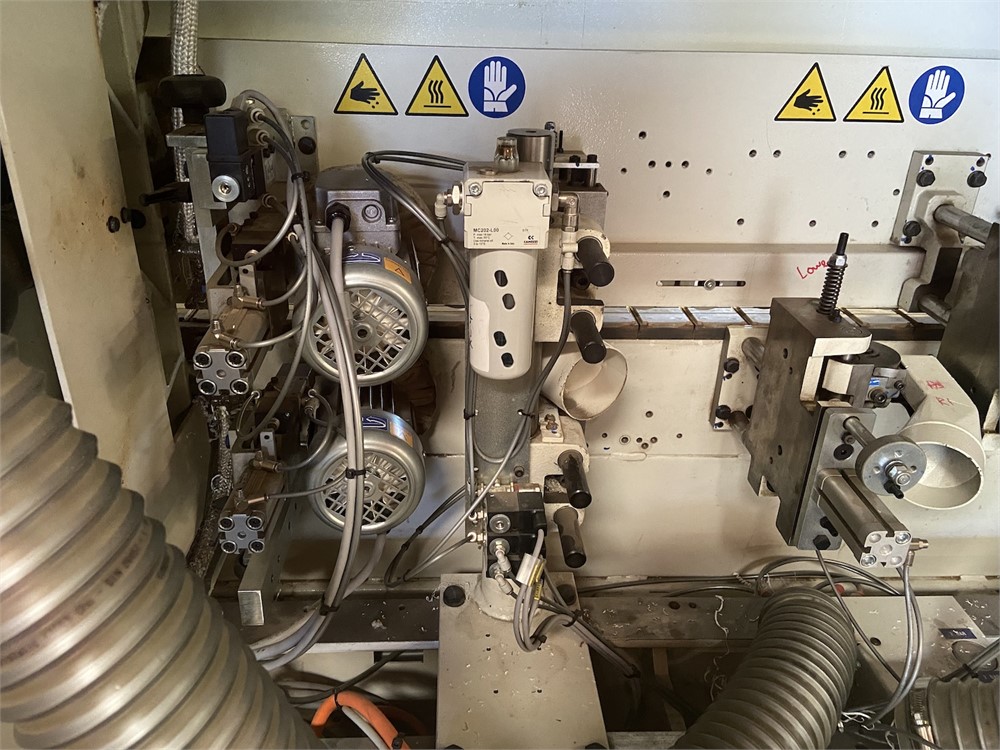

“QMS” Glue Station

Automatically supplies the glue pot with the proper amount of glue on demand. The level of the glue in the glue pot is monitored by a sensor insuring the proper level. The pot is smaller, the glue is turned over faster as a result. The hopper holds in excess of 10 lbs.

of glue and has sight glass to see what the level is. Teflon coated glue pot to facilitate glue changeover. Warm up time is approximately eight to ten minutes.

SGP Glue Pot with CNC Control of the Glue

Quick heat up time due to the small glue pot. Reverse rotation of the glue roller for the application of solid wood. Double Thermo Regulation for easy use of both EVA

and PUR glue. Color change and glue pot cleaning are able to be completed in minutes, as opposed to hours. CNC control of the amount of glue being applied,

specific to the program, is standard. Through the controller the operator can change the amount of glue being applied depending on the substrate of the panel. The

purging process is CNC controlled as well when changing glue colors or going from EVA to PUR glue.

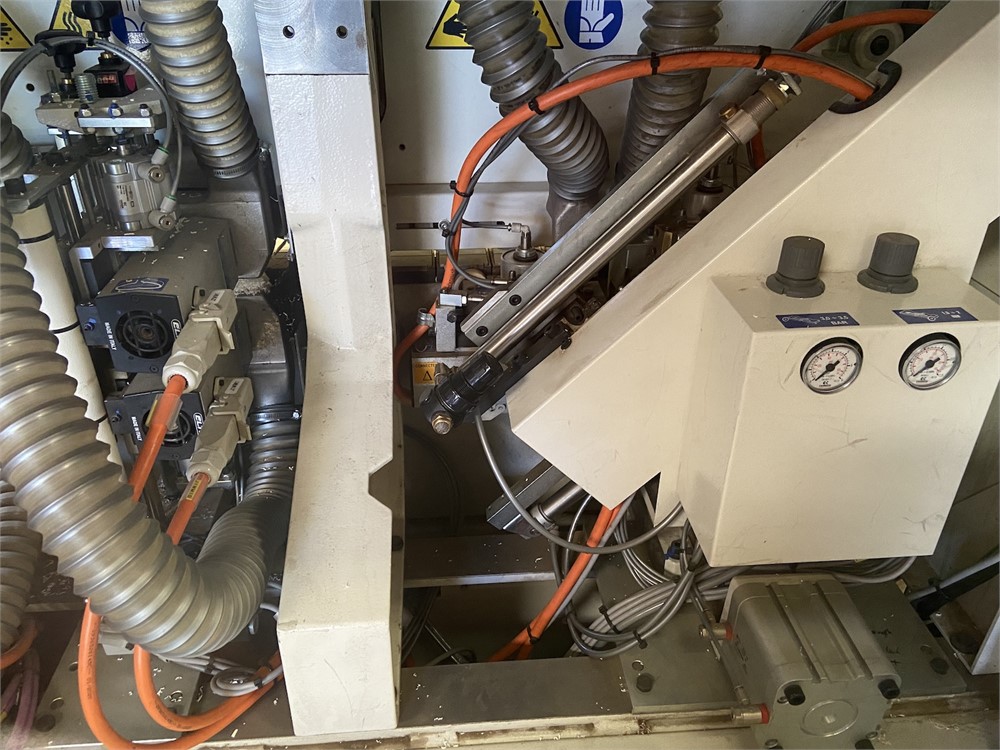

Servo Driven Pressure Section

There are a total of four pressure rollers for pressing the banding to the workpiece edge. The first roller is powered and applies pressure pneumatically. It is also Teflon coated to

prevent the banding material from slipping. The three idle rollers have opposing one- degree tilt to provide extra pressure along the top and bottom edge. The unit comes

standard with a servo driven motor for positioning. This eliminates the need for the operator to manually adjust the unit and helps reduce changeover time. The pressure section is also equipped with pneumatic jumping so the unit activates exactly on the leading/trailing

edges. Standard is the edge detecting sensor that will shut down the feedtrack when there is no material present to be applied. Equipped with I-Glue, locks the glue roller in place at the end of the panel eliminating any excess glue.

Infeed Fence

The infeed fence has a mechanical digital indicator to position the fence and determine the stock removal. It is also equipped with a

pneumatic panel spacing device to prevent the operator from feeding the panels to close to one another.

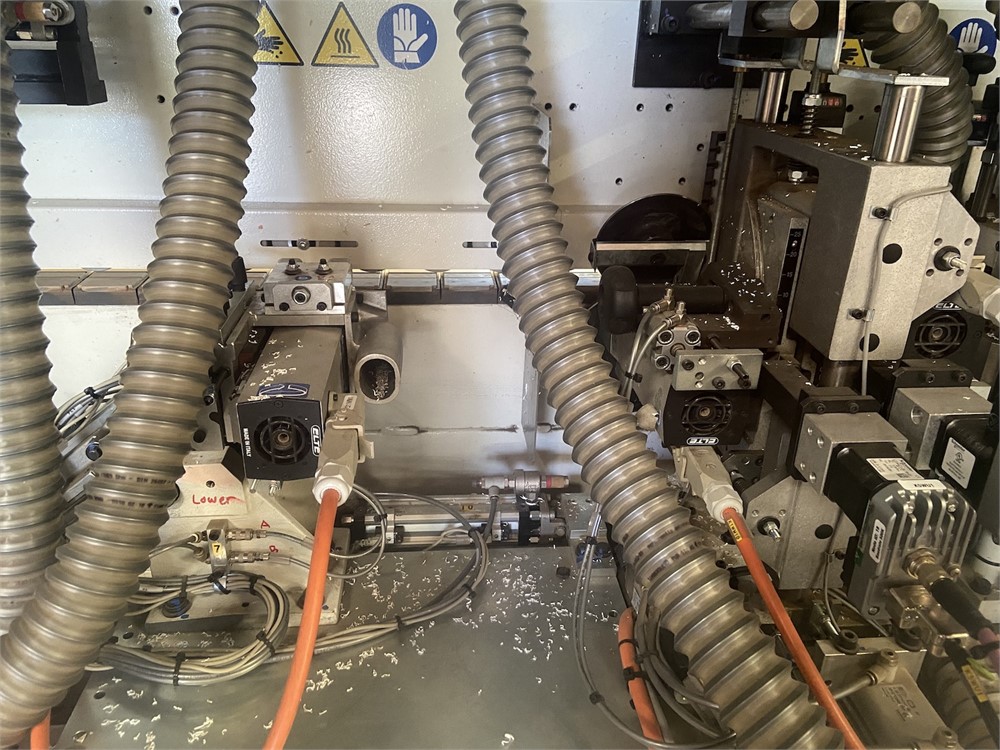

“RT-E” Pre-Milling Station:

To rectify/clean panels already sized and squared before the edge is applied. The unit is composed of two high frequency motors with

jumping action controlled through the PLC. The cutting heads are adjustable vertically. The unit is equipped with copying devices which

guarantee that material removal is consistent on long or slightly out-of- square panels. 64mm tall diamond premill cutters with replaceable

inserts come standard.

This unit is composed of two independent .50 hp motors mounted on THK guides. End trim utilizes a draw cut system for reduced blade projection on thick panels. The unit comes standard with automatic tilting of the unit from the control panel with two preset

positions. When operating in conjunction with the corner rounding station the unit is equipped with two position pneumatics to leave

the material long, thus allowing the corner rounding unit to have a seamless finish.

Flush Trimming Station:

Two independent 1.0 hp motors operating at 12,000 rpm. The unit comes standard with two position pneumatics and is capable of cutting flush or leaving an overhang.

Equipped with vertical copy shoes with digital indicators. Motors have quick release plugs to facilitate tooling changes. Pneumatic in/out positioning is standard.

Edge Trimming Station Servo Driven:

The top and bottom trim station has two independent 1.0 hp motors operating at 12,000 rpm. Large diameter vertical and horizontal copying devices with precise digital

indicators. The unit is equipped with a servo driven motor to go from one material thickness to another through the controller. Top trim unit three roller nesting kit comes standard, beneficial when running panels with grooves and/or 35mm hinge holes.

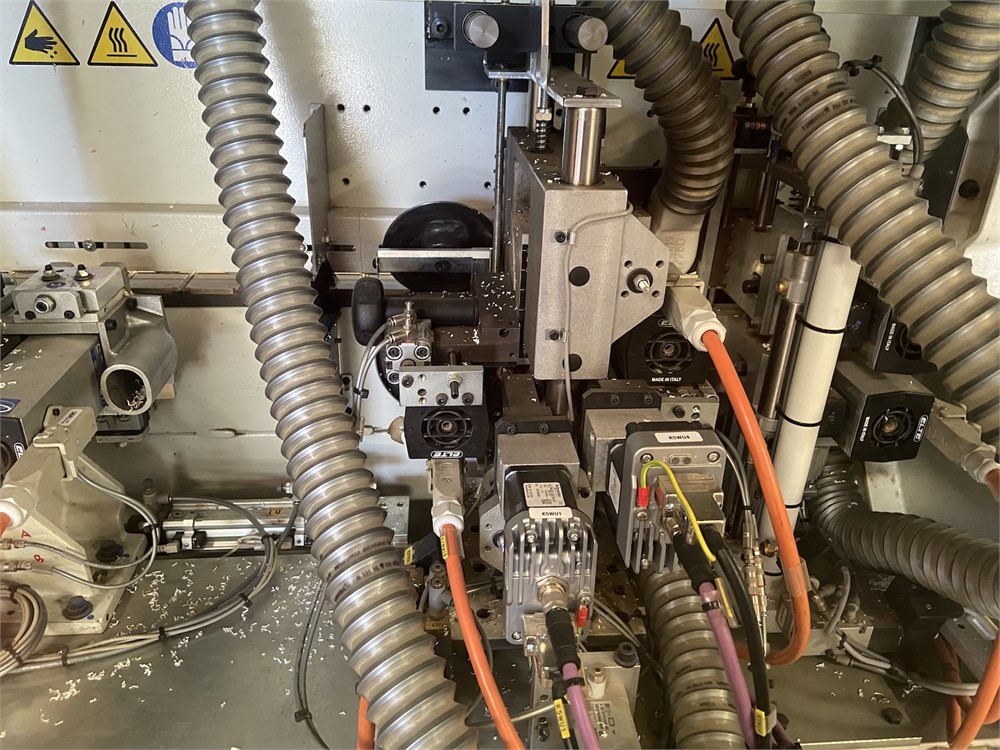

“ROUND-K” Corner Rounding Unit:

Two independent .80hp motors that slide on THK guides ensuring the highest quality finish. Unit is designed to work as an additional set of trimmers for rounding the top/bottom as well as the front/rear corners of work piece with 3mm PVC edges. The unit is equipped with front and

lateral copying devices and pneumatic blowers to clean the panel. Dust shrouds surround the cutter and travel with the unit as it trims. The unit

can go from thin tape to 3mm PVC, through the controller, with no manual adjustments by the operator.

“RAS/1000” Profile Scraping Station

The profile scraping station designed to remove knife marks from thick PVC. The unit is equipped with pneumatic in/out positioning through the controller. It has a large diameter horizontal copy wheel and side copy wheel device with digital indicators. It

features a quick knife replacement system and comes with 3mm knives. The unit is also equipped with dust extraction. Top scrape unit three roller nesting kit comes

standard, beneficial when running panels with grooves and/or 35mm hinge holes.

“RC-V” Glue Scraping Station

The glue scraping unit is for the finishing of thin PVC. It is equipped with two throwaway knives, vertical rotating copiers and blowers for tool cleaning.

The unit is equipped with on/off pneumatic exclusion.

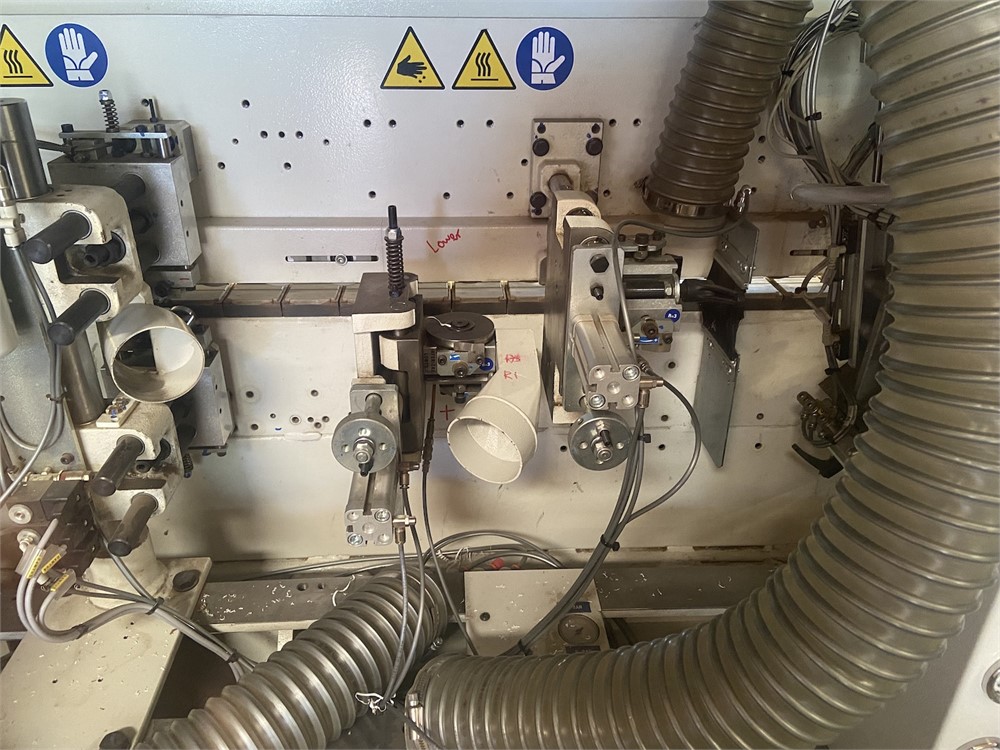

“SPN” Buffing Unit And Hot Air Blower

The buffing unit has two .25 hp motors. The unit cleans and polishes the panel edge. The unit oscillates to utilize the full width of the wheel and prevent rounding of the panel’s

leading edge.

The hot air blower is designed to brighten the edges of thick PVC that can sometimes discolor during the machining process. The unit consists of a single hot air blower with

adjustable heat range and a directional heat shield for coverage from the top to the bottom edge.

Acoustical Safety Enclosure

All working units are enclosed under an acoustical safety hood that is insulated to help reduce noise and prevent accidents. The hood has a safety microswitch which prevents the machine from operating when the hood is open. The

machine has a decibel rating of 86db when operating.

Dust Extraction

Working units are individually ported on the top of the safety enclosure for maximum efficiency, per the drawing.

Technical Specifications

Glue Pot Unit:

Heating Time

Glue Capacity Pre-milling Station:

Horsepower

RPM

Max. Stock Removal

Diameter/Bore/Height

End Cutting Trimming Station:

Horsepower

RPM

Tilting

Blade Diameter/Bore Flush Edge Trimming Unit:

Horsepower

RPM

Cutting Tools

Tiltable Edge Trimming Unit:

Horsepower

RPM

Tilting

Cutting Tools

Corner Rounding Unit::

Horsepower

RPM

Cutting Tools Scraping Unit:

Knife Radius Buffing Unit::

Horsepower

RPM

Diameter/Bore

Feed Motor Horsepower Feed Speed

Frequency Converter Pneumatic Operating Pressure

Machine weight: Electrical:

Dust:

Dimensions (LxWxH):

Approx. 8-10 min. 3.3 lbs.

3.0 HP ea. 12,000 RPM 60mm²

100mm/30mm/64mm

.50 HP ea. 12,000 RPM

0-15 degrees 100mm/32mm

1.0 HP ea. 12,000 RPM 70x20x16mm

1.0 HP ea. 12,000 RPM 0-15 degrees 70x20x16mm

3mm radius knives

.80 HP ea. 12,000 RPM

3mm inserts

2mm and 3mm inserts

.25 HP 3,000 RPM

152mm/17mm 2.5 HP

33-60 FPM 200 Hz

90 PSI 7,603lbs.

89 amps @ 230v three phase 3,500 cfm

239” x 65” x 62”

Air flotation tables

The information provided in this lot was gathered from literature, internet & physical inspection. It is thought to be accurate; but not guaranteed. Bidders are urged to use the open house or private inspection periods to inspect and verify.

The listed specifications & information were taken from the manufacturer’s published information, internet research, or seller’s description.

The specifications & information are assumed to be correct; however, in no way, guaranteed. Bidders are encouraged to inspect the machine, call with questions, or contact the manufacturer for more information.

Please log in to view the bid history

LoginNo information available