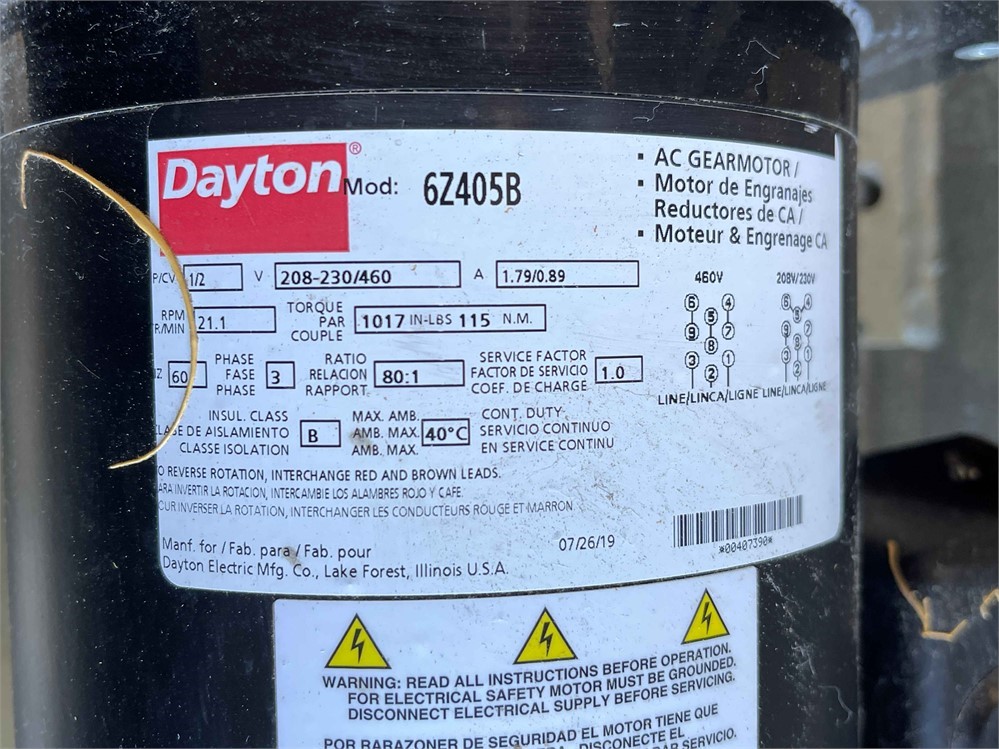

(2019) Triad "MultiBridge" Wall Panel Automation Line  Ended

Ended

Complete Woodworking Facility Auction - Spokane, WA

- Starting Bid : $5,000.00 USD

- 0 Bid(s)

Triad "MultiBridge" Wall Panel Automation Line (2019) - Spokane, WA ( Closed #54364710 )

Original cost in 2019 $345,000.00. By order of secured creditors an absolute auction is to take place. Machine has been professionally dismantled and prepped for shipping

-

Pick Up Location

4501 E. Trent Ave. Spokane, WA 99212

-

Make

Triad

-

Model

MultiBridge

-

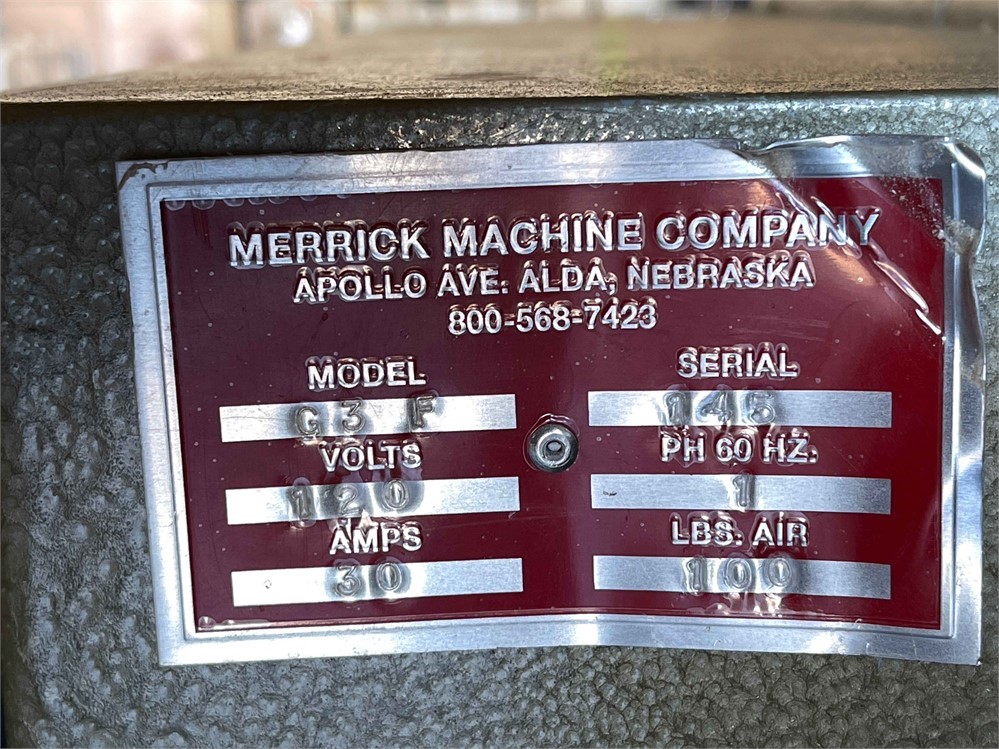

Serial Number

127 (bridge 1), 145 (bridge 2)

-

Year

2019

-

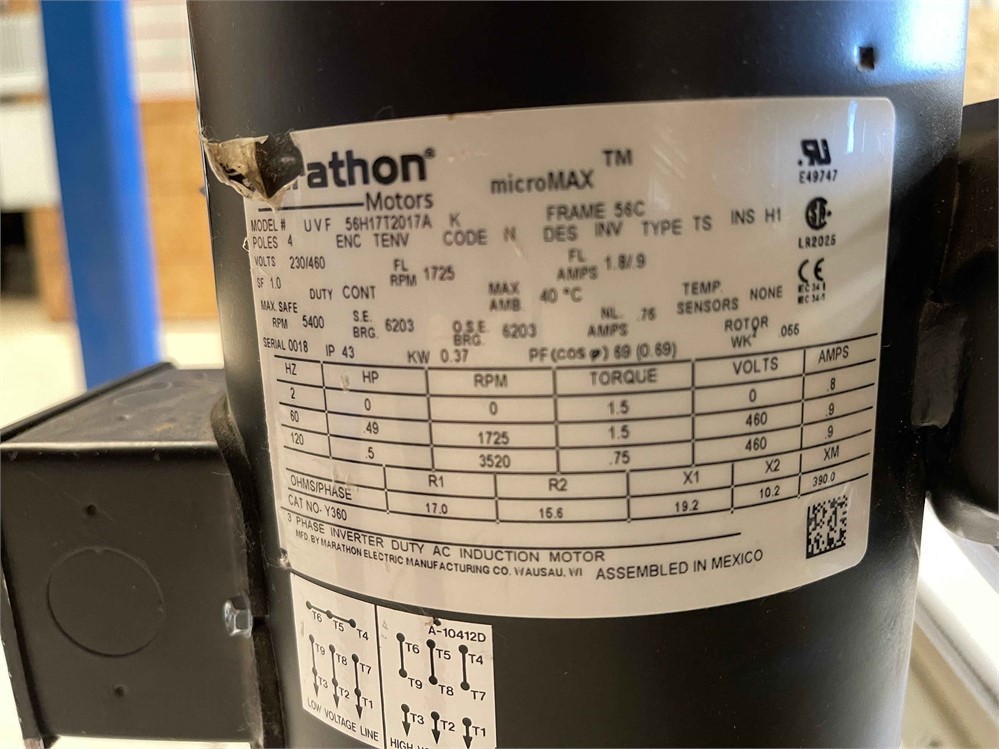

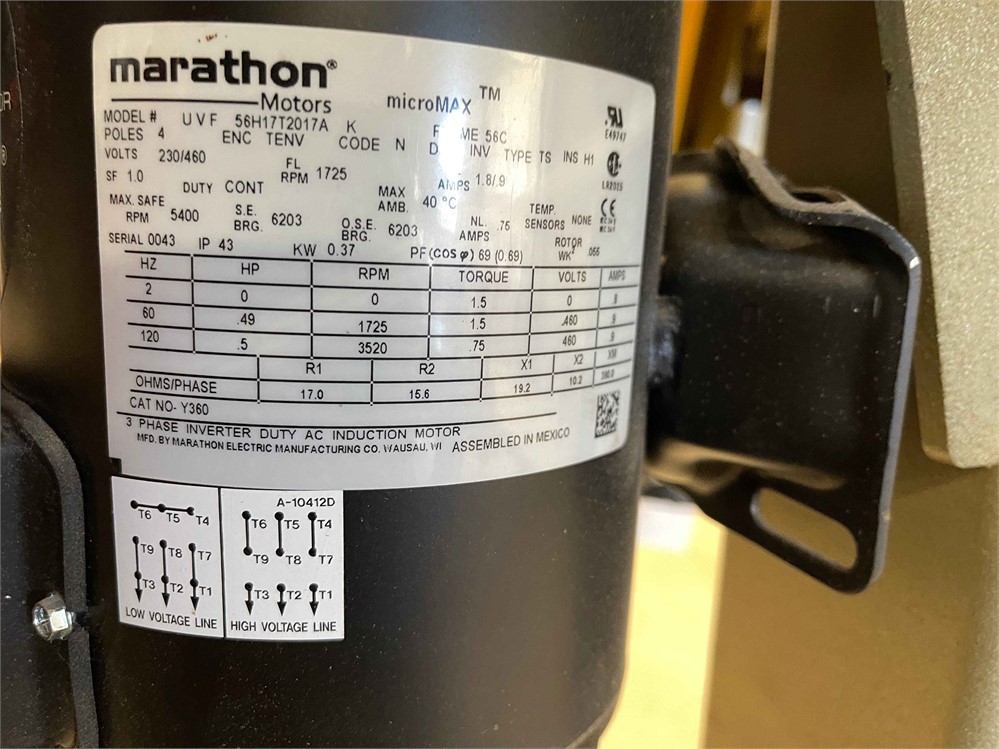

Phase

3 PHASE

-

Voltage

208-230/460

-

Load Out Period

See home page for details

-

Estimated Dimensions

422" L x 192" W x 72" H

-

Estimated Weight

20,000 Pounds

-

Seller Comment

-

Load Fee

Non Negotiable Load Fee $4,795.00

-

page views

628

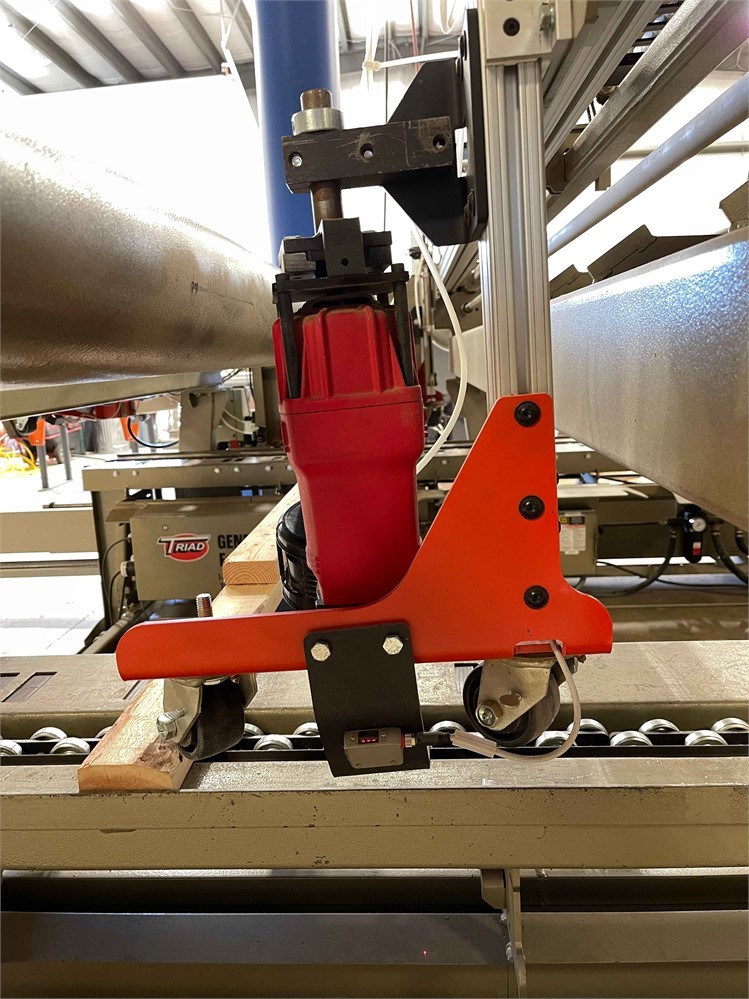

Triad "MultiBridge" Wall Nailing/Framing Line

MultiBridge

A Triad MultiBridge gives you TWO gantries with your choice of combined functionalities. So many great options! And the MultiBridge can be made to fit most Triad Framing Tables and/or Squaring-Sheathing Tables.

For example: A wood-timber builder might choose a Trident Bridge on one gantry, and a Router Bridge on the second gantry. That means the ability to nail the sheathing onto the studs, with three high-capacity nail guns & then (on the return trip) route out the window/door openings with the Router Bridge side. Automatic PlateFire guns are also available, adding a THIRD functionality to the MultiBridge. (PlateFire automatically nails the plates at your choice of nail spacing).

Other options: We have had builders purchase a nailing bridge on one gantry, and a panel stapler bridge for the second gantry – offering them versatility in fastener choices or sheathing material choices.

Generation Framing Table

Triad’s Generation 3 Framing Table is custom built for 16’ to 80’ long walls (your choice of maximum length), and offers the greatest wall height range of any Triad Framing Table: With wall heights from 3’9″ to 16’3″ you can do anything from knee walls to commercial building wall panels. Studs are placed between color-coded stud locators. With just a push of a button, the width adjustment clamp is activated to clamp and square all components at a rate 18% faster than our previous (Gen II) model. The Generation 3 Framer features a wider table top support surface, as well as an innovative, optional, Pop-up Power Chain Conveyor. The Generation 3 was designed with the framer in mind, with our new Slip-Resistant Surface that allows the operator to move about on the machine’s interior (when needed) on a comfortable and safe platform.

Capabilities

- Wider working surface

- Custom built from 12’ to 80’ lengths of walls

- Power width adjust for various wall lengths

- Cast iron counter-balanced stud locators

- Includes rails to accommodate optional dollies

- Continuous squaring lip for precision squaring

- Squaring stops

Feed through roller conveyors

Automated width open/close via two (2) motors and rack/pinion drive

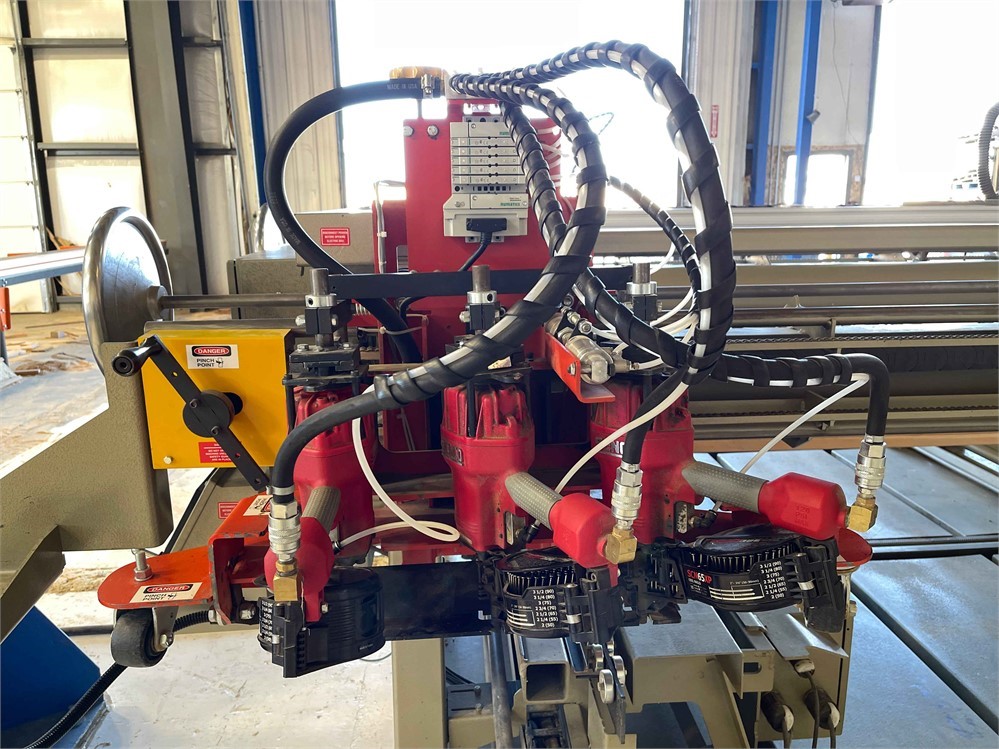

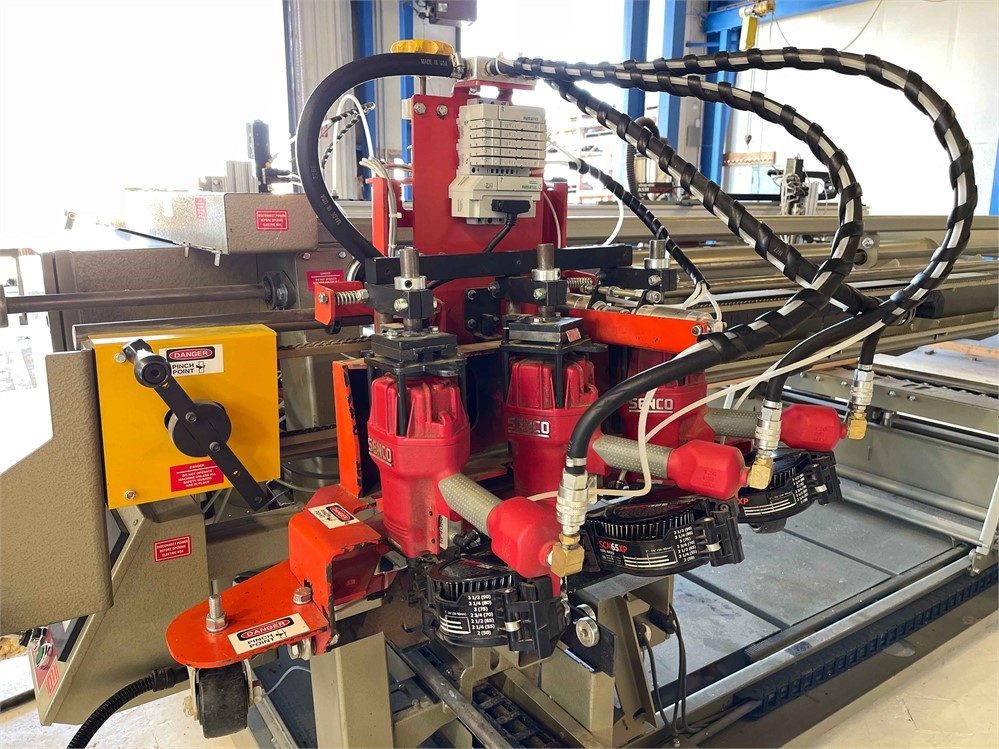

Bridge 1

NC positioning

One tool dolly with three (3) Senco pneumatic nailers

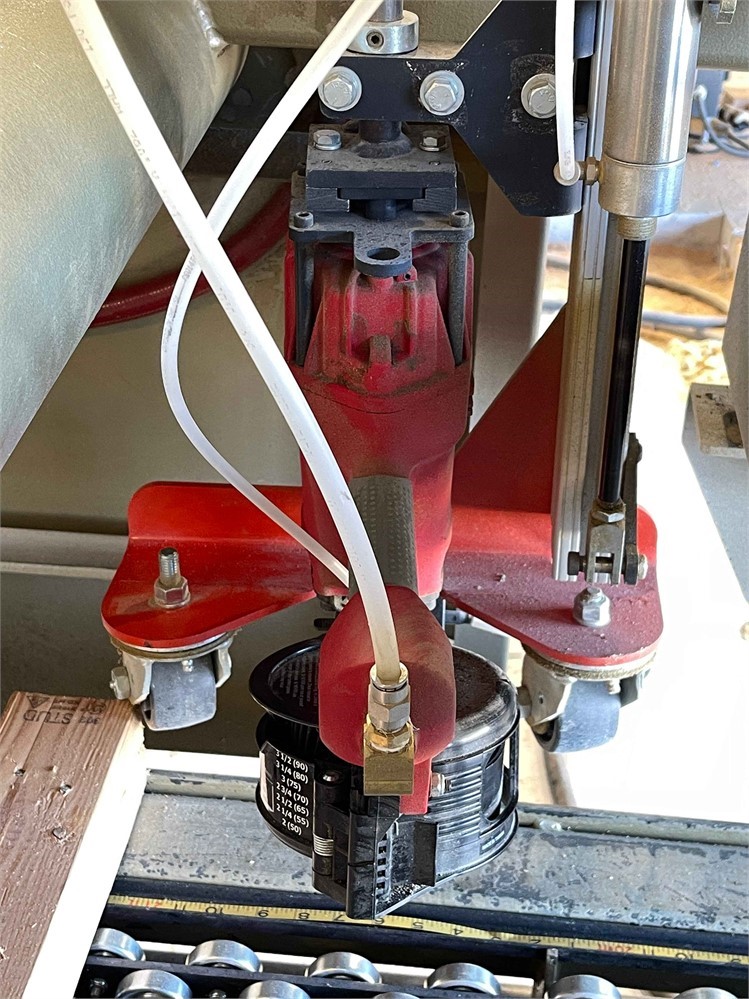

Bridge 2

NC positioning

Two (2) tool dollies with one (1) Senco pneumatic nailer each

Bridge 3

One (1) Porter Cable router

One (1) vacuum cleaner

Center support (not installed)

Touch screen PLC

Ten (10) extra Senco pneumatic nailers

Two (2) extra tool dollies with installed Senco pneumatic nailers

Listed specifications were taken from manufacturer's published information and is assumed to be correct but not guaranteed. Bidder is encouraged to inspect the machine, call with questions or contact the manufacturer for more information.

The listed specifications & information were taken from the manufacturer’s published information, internet research, or seller’s description.

The specifications & information are assumed to be correct; however, in no way, guaranteed. Bidders are encouraged to inspect the machine, call with questions, or contact the manufacturer for more information.

Please log in to view the bid history

LoginNo information available