Altendorf "WA-80X" Series Heavy Duty Sliding Table Saw  Ended

Ended

Altendorf WA-80X Sliding Table Saw Auction - Sparks NV

- Winning Bid : $14,750.00 USD Sold

- 55 Bid(s)

- High Bidder: D****s

Altendorf WA 80X Sliding Table Saw Auction - Sparks, NV ( Closed #53192137 )

Altendorf Sliding Table saw no longer needed for continuing operations of local Sparks Nevada display and manufacturing company. For additional questions contact Kirk at [email protected] or via phone/text to 925-250-8248.

-

Pick Up Location

676 Dunn Cir., Sparks Nevada 89431

-

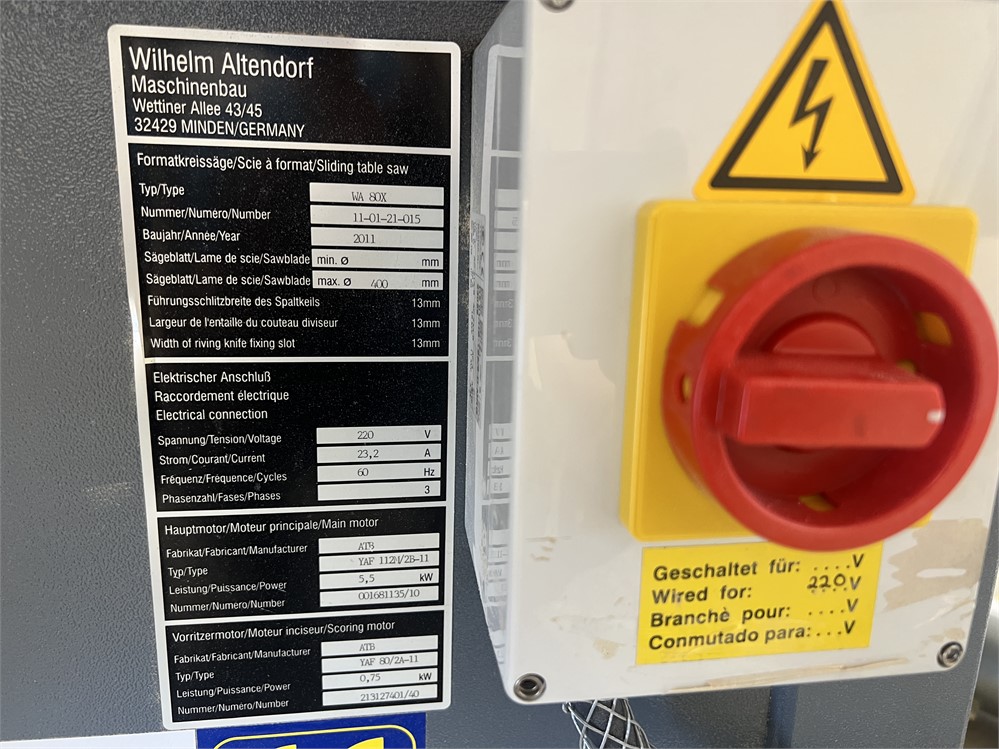

Make

Altendorf

-

Model

WA-80X

-

Serial Number

11-01-21-015

-

Year

2011

-

Phase

3 PHASE

-

Voltage

230 VOLT

-

Load Out Period

By Appt. Only, Please contact Sabrina at 209-839-7707

-

Estimated Dimensions

-

Estimated Weight

-

Seller Comment

-

Load Fee

$300.00 Prep and Load Fee

-

page views

2584

Manufactured at Altendorf’s German headquarters, the WA 80 X builds on the standard features found on the WA 80 TE model but includes powered rip fence positioning and ergonomic eye-level control. The WA 80 X has been designed for continual production use and engineered for years of trouble free precision cutting. Configure your ideal Altendorf from the expansive choice of optional equipment to meet your own exact requirements whether cutting panels, composites, solid wood or non-ferrous metal.

Control

A total of 3 separate motorised axis can be controlled from the eye-level control panel; rise and fall of the main blade, tilt, and rip fence positioning. The panel pivots to be positioned conveniently for the operator if standing on either side of the sliding table. An electronic digital readout displays the angle position of the blade and fence position. Optional start stop controls are also available on the end of the sliding table, particular useful when handling full size sheets.

Sliding table

One of the most critical aspects of a panel saw is the sliding table, and Altendorf have poured over 111 years of research and development into their uncompressing solution. Dumbbell style rollers ride on hard wearing chromed guidance track resulting in silk like movement for reliable and accurate cutting. Cleaning brushes mounted to the upper section of table, continually remove dust and debris from the guidance rails with no need for lubrication.

The aluminium table features multi-chamber construction for optimal tension and rigidity. Surface ground tables can create a suction effect when equally flat panels are placed on top making it hard for the operator to manoeuvre the material – think about two planes of glass stuck to one another. To overcome this, Altendorf take considerable time in planing each table creating a precision ripple effect on the surface allowing panels to run smoothly across the table.

The standard table on the WA 80 X is 3000mm but can be reduced to 2250mm if space is tight, or increased to 3200mm, 3400mm, 3800mm and 4300mm lengths.

Rip fence

Reduce set up times and improve accuracy. Moving at 250 mm/sec the CNC powered rip fence quickly adjusts with an accuracy of +/- 1/10mm. The high precision ball spindle and motor are incorporated into the aluminium front section keeping them protected. The fence recognises when it is in the standard upright, or flat position and compensates accordingly.

The standard fence capacity for the WA 80 X is 1000mm but can be reduced to 800mm or increased to 1300mm if required.

Crosscut fence

As standard the WA 80 X is supplied with a fixed 90° crosscut fence and can be quickly positioned either at the front or back of the cross-slide support. Two ‘zero play’ flip over stops can be independently set using the incremental scale with telescopic extension up to 3200mm.

For mitre work the optional crosscut-mitre fence is available with a working range of 0 – 49°. Integrated length compensation means that the distance from the saw line to the flip over stops remains accurate when the fence is angled.

Additional options for DIGIT L and DIGIT LD add electronic digital readouts to the flip over stop position and fence angle with a repeatable accuracy of 1-10mm on length +/- 1/100° for angles.

Saw unit

The Altendorf saw unit is the heart of the machine. The latest manufacturing techniques are used to ensure high precision movement, and reliable performance. The electronically balanced saw shaft runs smoothly with extensive use of cast iron components for vibration free cutting.

The WA 80 X now features an increased cutting depth of 150mm. Blade diameters up to 450mm can be fitted using the quick change AKE tool clamp system. The standard single speed (4000 rpm) 4 kW (5.5 HP) motor can be increased to a three speed (3/4/5000 rpm) 5.5 kW (7.5 HP) or 7.5 kW (10 HP) motor as required.

A dedicated scoring saw unit can be added to the Altendorf WA 80 X to prevent breakout on the underside of laminated materials. Powered by an independent 0.75 (1 HP) motor, the scoring saw automatically raises to its working height when started, and retracts beneath the table when stopped.

Optional equipment

In addition to the optional features already described above, the Altendorf WA 80 X can also be equipped with the following;

RAPIDO scoring system – this quick set scoring saw can be adjusted to match the main blade without the need to remove it from the machine. Compared to working with traditional shims the RAPDIO saves up to 10 mins taking about 3 minutes to set.

Parallelogram cross-slide – for regular mitre cutting this system allows the entire cross-slide to be angled with the fence ensuring optimal work piece support is maintained. An electronic digital display shows the angle position to an accuracy of 1-100°.

Single-sided mitre fence – this independent mitre fence locks quickly onto the sliding table for precise cutting of mitres.

DUPLEX double-sided mitre fence – a separate high precision mitre fence that can be quickly mounted to the WA6 sliding table with angle adjustment from 0 to 90°. When set at 45° mitre cuts can be made on both sides of the work piece without having to adjust the fence. Length compensation allows for precise measurements to be made from the saw line to the flip over stops.

DUPLEX DD double-sided mitre fence – in addition to the features found on the standard DUPLEX, the DD incorporates a large electronic digital display for the angle and stop positions for fast, high precision setting.

Laser cutting line – clearly displays the sawing line in front of the blade when cutting to marked jobs or adjusting material for trimming.

Palin – this additional side fence allows long, thin work pieces to be accurately set for parallel ripping or conical cutting.

Pneumatic pressure beam – long thin materials can be securely clamped along the length of the table, close to the saw line. It is pneumatically operated with two separate clamping zones.

Manual quick action clamp – easily positioned along the length of the sliding table firmly securing the work piece.

STEG second support – easily mounted on the side of the sliding table providing additional support for wider materials.

Infeed roller support – a 300mm wide infeed support roller that can be quickly folded away when not required. Useful when cutting longer materials against the rip fence.

**Specifications as per manufacturer website and brochures, please do own due diligence as to exact specs. on this machine.

Specification

| Maximum blade diameter | 450 mm |

| Sliding table length options | 2250 - 5000 mm options |

| Blade speeds | 3000/ 4000/ 5000/ variable rpm |

| Maximum depth of cut | 150 mm (with 450 mm blade) |

| Blade tilt | 0 - 45° |

| Saw to fence capacity options | 800/ 1000/ 1300 mm |

| Saw to crosscut fence | 3200 mm |

| Power | 3 phase |

The listed specifications & information were taken from the manufacturer’s published information, internet research, or seller’s description.

The specifications & information are assumed to be correct; however, in no way, guaranteed. Bidders are encouraged to inspect the machine, call with questions, or contact the manufacturer for more information.

Please log in to view the bid history

LoginNo information available