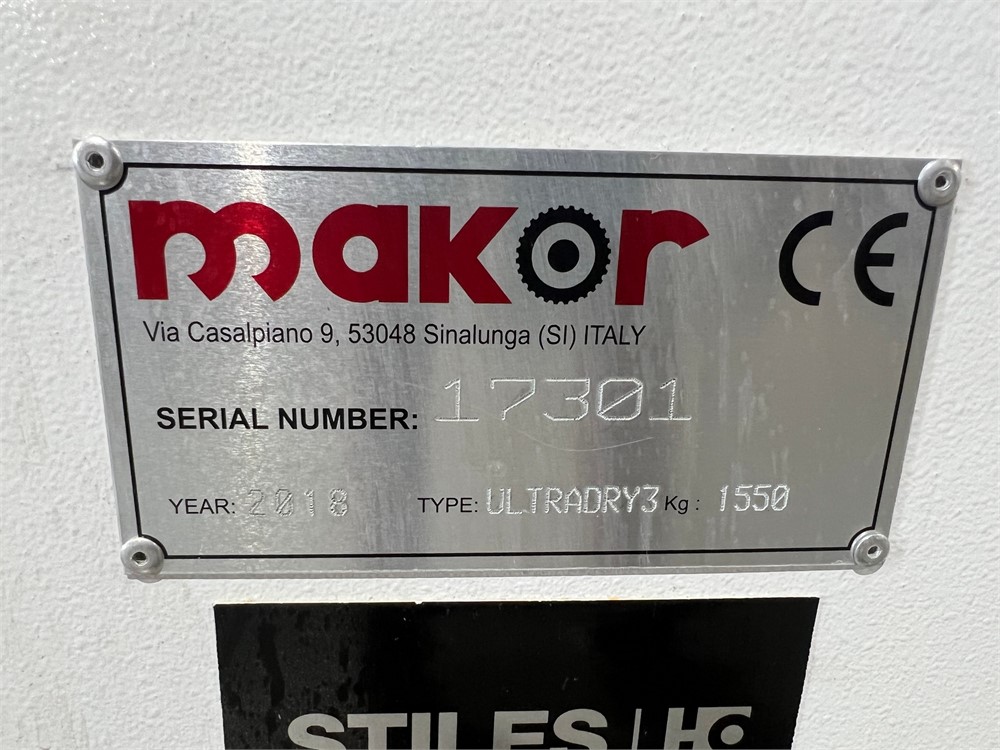

Makor "Ultradry 2/SCR" UV Drying Oven (2018)  Ended

Ended

Late Model Finishing Machinery - Covington, GA

- Winning Bid : $28,250.00 USD Sold

- 39 Bid(s)

- High Bidder: W****s

Makor Finishing Line & Butfering Sander - Covington, GA ( Closed #52832944 )

Makor Finishing Line & Butfering Sander - Atlanta, GA area

-

Pick Up Location

Covington, GA

-

Make

Makor

-

Model

"Ultradry 2/SCR"

-

Serial Number

17301

-

Year

2018

-

Phase

3 PHASE

-

Voltage

480 VOLT

-

Load Out Period

see Homepage

-

Estimated Dimensions

225" x 108" x 96"

-

Estimated Weight

-

Seller Comment

A rigger is required. Buyer's Responsibility for Break-down, loading and removal.

-

Load Fee

Buyer's Responsibility for Break-down, loading and removal.

-

page views

900

Makor "Ultradry 2/SCR" UV Drying Oven

Flexible production, less available space, and the necessity to respect environmental rules

require the use of fast-drying coatings. The ideal solution for this is the drying technology that

uses Ultraviolet lamps (UV) at direct radiation.

The ULTRADRY oven system instantly dries mono and bi-component UV paints, clear and

pigmented, matte or glossy. Its modularity allows obtaining different configurations,

guaranteeing perfect drying of flat and shaped panels, including edges.

Transport System

- Panels are moved by a series of idle rollers motorized by a double row of parallel chains

- The painted steel bars are made of material resistant to high temperatures

- Inverter-controlled speed is infinitely variable

- A 2-meter extension is located at the exit for manual off-loading

UV Lamps

- The two (2) upper lamps are positioned obliquely in respect to the transport system and can be adjusted on the lamp axis in order to aim the UV rays on the upper side of the panels and on their edges, guaranteeing total curing • each lamp is placed inside its own structure and has an independent ventilation device that keeps the bulbs at an ideal temperature, providing longer life and better performance.

- Lamp power is variable from 0 to 120 Watt/cm

- Possible to install two different types of lamps: Ga Gallium, with high penetration capacity suited for pigmented paints Hg Mercury, the proper wave length for clear paints

- If the line stops, a shield rotation system avoids radiating the workpieces, and an energy-saving system automatically reduces lamp power to a stand-by setting

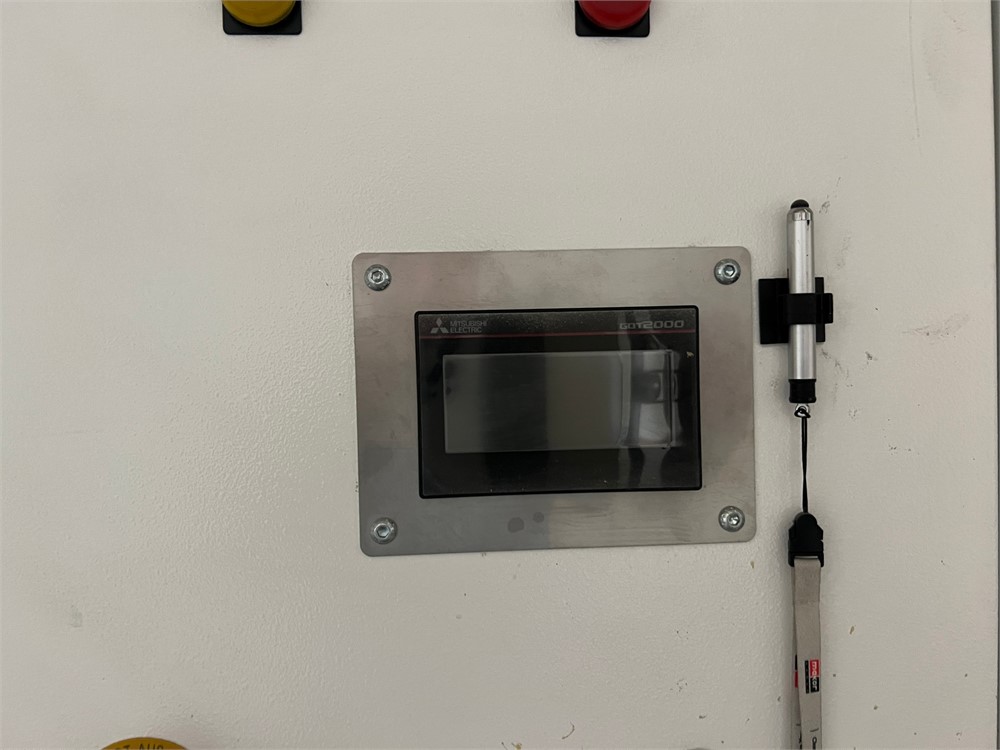

Control System

- PLC logic manages various working phases of each lamp: stand-by, radiation intensity, and safety systems also displays production and maintenance parameters

Technical Specifications

- Workpiece length min 300 mm (11-3/4") max unlimited

- Workpiece width min 25 mm (1") max 1300 mm (51")

- Workpiece height min 5 mm (3/16") max 50 mm (2")

- Feed speed 1.9 to 11 m/min (6.2 to 36 ft/min)

- Working height ± 50 mm 900 mm (35-1/2")

- Bulb working length 1600 mm (63")

- # of upper lamps 2

- Lamp specific power 0 to 120 W/cm

- Lamp power 13 kW

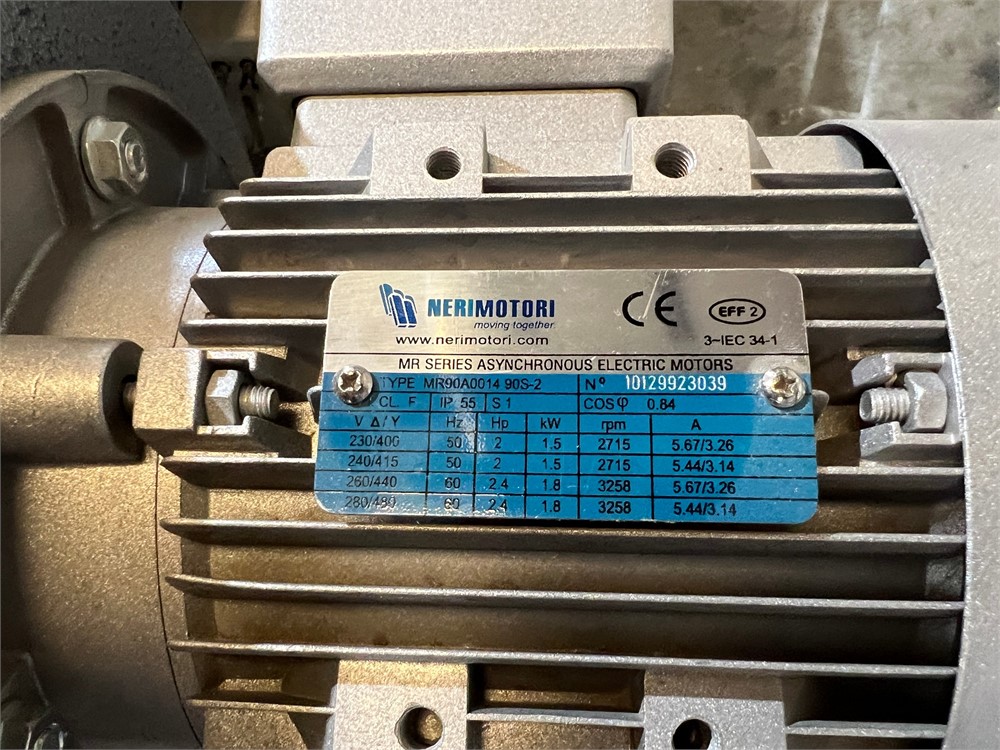

- Feed motor power 0.55 kW

- Suction motor power 2 x 1.5 kW

Electrical

- Operating voltage 480 V / 3-phase/ 60 Hz

- Total connected load 32 kW*

Air

- Exhaust air volume 4,800 m3/hr (2,825 cfm)

- Air make up required 4,800 m3/hr (2,825 cfm)

- Connection diameter 200 mm (7-7/8")

- Compressed Air pressure required 87 psi

- Consumption / volume (0.18 cfm)

- Electrical equipment installed according to UL regulations. Voltage supplied must not fluctuate in excess of +/- 5% of its stated value.

The information provided in this lot was gathered from literature, internet & physical inspection. It is thought to be accurate; but not guaranteed. Bidders are urged to use the open house or private inspection periods to inspect and verify.

The listed specifications & information were taken from the manufacturer’s published information, internet research, or seller’s description.

The specifications & information are assumed to be correct; however, in no way, guaranteed. Bidders are encouraged to inspect the machine, call with questions, or contact the manufacturer for more information.

Please log in to view the bid history

LoginPick-ups are to be scheduled by appointment only. Please contact Sabrina Burns at 209-839-7707 or [email protected] to schedule an appointment. For freight quotes please contact Aaron at All-Ways Trucking at 541-608-6532. Buyer bears all costs to remove and load this lot. Buyer must remove entire lot purchased. Anyone removing non-hand carriable lots must provide MachineryMax, Inc. with a certificate of insurance (COI) before purchased items can be removed.

All buyers agree to make full payment to MachineryMax, Inc. within 48 hours of the online closing date for the auction lots purchased. All invoices over $1,500.00 are to be made by bank wire transfer or cashier’s check payable to MachineryMax, Inc. Purchases under $1,500.00 may be made using Visa, MasterCard, or American Express (3% credit card processing fee will be added to the invoice). All payments are to be made in USD currency only. Bidder represents and warrants to MachineryMax, Inc. that such bidder has immediately available funds to fully pay for its successful bids within 48 hours of the online closing date. All payment questions should be directed to Sabrina Burns at 209-839-7707 or [email protected] All buyers agree that there will be a 15% Buyers premium that will be added to the final invoice. Applicable State & local tax will be added in.