Brandt "Optimat KDN 520" Automatic Edgebander  Ended

Ended

Brandt "Optimat KDN 520" Automatic Edgebander - Rancho Cordova, CA

- Winning Bid : $2,050.00 USD Sold

- 26 Bid(s)

- High Bidder: i****h

Brandt "Optimat KDN 520" Automatic Edgebander - Rancho Cordova, CA ( Closed #52335210 )

Well-known, family-owned cabinet company in Sacramento, CA metro area is auctioning a Brandt Optimat KDN 520 edgebander no longer required for continuing operations.

-

Pick Up Location

3766 Omec Cir, Rancho Cordova, CA 95742

-

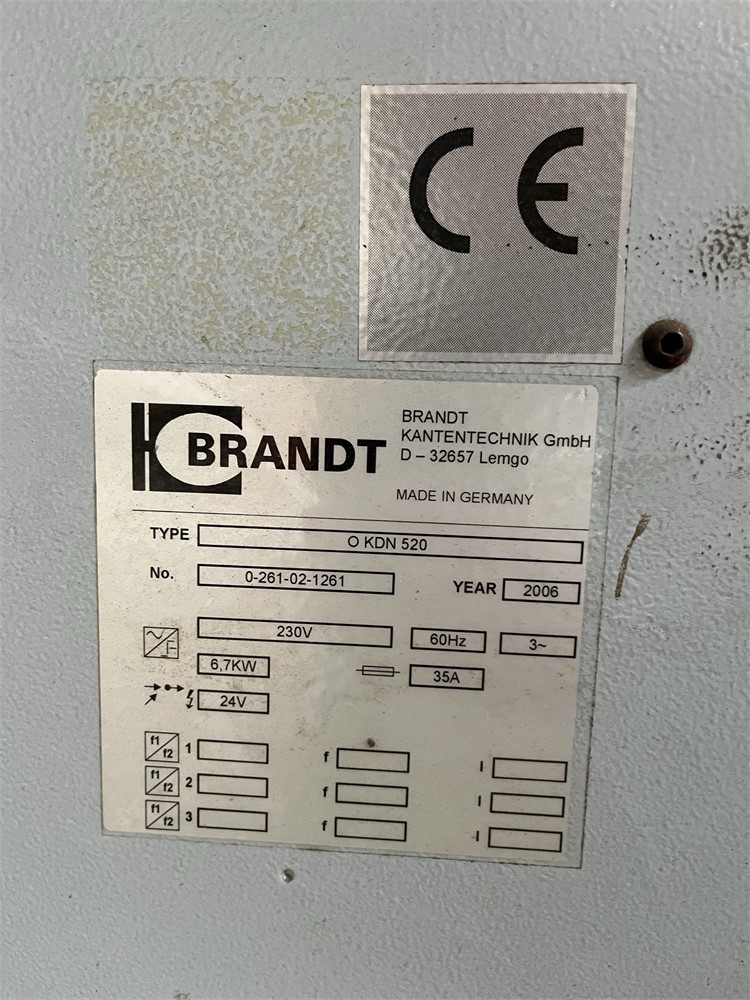

Make

Brandt

-

Model

KDN 520

-

Serial Number

0261021261

-

Year

2006

-

Phase

3 PHASE

-

Voltage

230 VOLT

-

Load Out Period

July 21st - July 28th, 2023 By appointment only

-

Estimated Dimensions

168" L x 51" W x 72" H

-

Estimated Weight

2,500 Pounds

-

Seller Comment

Seller will disconnect and load onto buyer's flatbed truck/trailer for non-negotiable $200 loading fee. Palletizing, crating or other services may be available at an additional cost.

-

Load Fee

200

-

page views

1390

Brandt "Optimat KDN 520" Automatic Edgebander

Edgeband thickness 0.4 - 8 mm (0.016" - .250") ( 5/16”)

Coil cutoff maximum 0.8 x 55 mm 3.0 x 30 mm (PVC)

Edgeband height 12 - 55 mm (1/2" – 2 3/16”")

Panel length min. 160 mm (6 3/8")

Panel width min. 65 mm (2 3/8")

Panel thickness - min. 8 mm (5/16") - max. 50 mm (2")

Feed speed 11 m/min (36 FPM)

Feed motor 2.2 kw (3 HP)

Automatic Magazine for Strip and Coil Feeding

Large coil table 31.5" (800 mm diameter) with built-in rollers to allow for 3 mm PVC coils

Edge strip capacity from 0.4 mm to 8 mm (0.016” – 5/16”)

Reversible glue roller rotation

Glue roller section is also retractable from fence line

One large driven pressure roller with pneumatic pressure control

Two secondary rollers, all with controlled side pressure

Setting of pressure zone equipped with digital counter accurate to .1 mm (.004")

Strengthened pre-cutter for cutting thick PVC edges from the coil; maximum 3 x 30 mm

Standard Gluing System, heat-up time is twelve minutes, quick-change glue tank for easy maintenance and glue color change

Glue temperature indication of both pre-melter and glue roller via LED thermostat display visible to operator

Automatic temperature reduction if not run within 15 minutes. This feature lowers the temperature automatically to 150 degrees C

End trim unit - two motors .18 kw (1/4 HP), 12,000 RPM, straight cut max. 8 x 45 mm (5/16" x 1 3/4")

Fine trimming unit .27 kw (1/3 HP), tilting range 0 - 15 degrees, 12,000 RPM, horizontal and vertical tracing with lateral location indexing via digital “Quickset” system calibrating to .1 mm (.004”)

Top/bottom scraping unit, program controlled pneumatic indexing

Top/bottom Buffing Unit, 2800 RPM, inclinable vertically and horizontally

Electronic frequency inverter

Integrated Electronic Line Control System for Increased Reliability and Diagnostic Assistance

PLC for machine setup and feedback

Outboard roller support

Sound Cover, equipped with two independent openings

Listed specifications were taken from manufacturer's published information and is assumed to be correct but not guaranteed. Bidder is encouraged to inspect the machine, call with questions or contact the manufacturer for more information.

The listed specifications & information were taken from the manufacturer’s published information, internet research, or seller’s description.

The specifications & information are assumed to be correct; however, in no way, guaranteed. Bidders are encouraged to inspect the machine, call with questions, or contact the manufacturer for more information.

Please log in to view the bid history

LoginIf a load fee is established for an individual lot, that fee will include loading onto a flatbed truck (only) by the seller. Any individual lot without a load fee will be the buyer's responsibility to remove and load (at buyer’s expense).

Payment is due within 24 hours of auction close. Payments must be made via bank wire transfer for any amount above $1,500. Credit cards may be used up to $1,500 (3% processing fee). Please Contact Sabrina Burns with payment questions at 209-839-7707 Any sales tax exemption documents are to be emailed to [email protected] at time of purchase/invoice for tax exemption consideration.