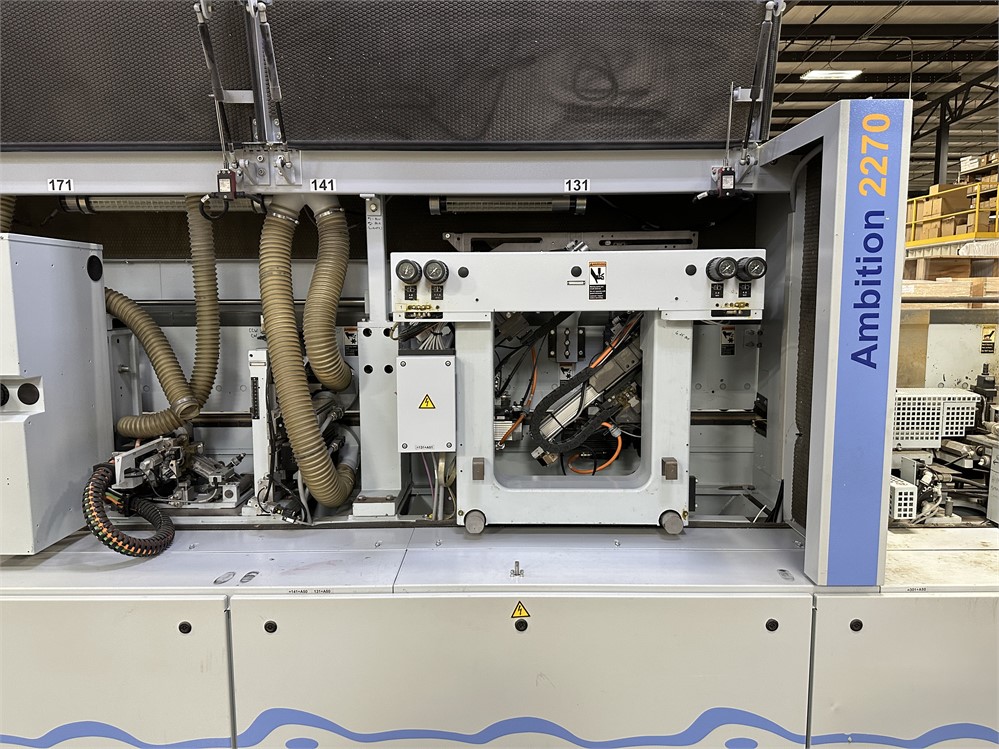

Homag "KAL210" Ambition 2270 Edgebander  Ended

Ended

Woodworking machinery no longer required for continuing operations

- Winning Bid : $5,000.00 USD Sold

- 24 Bid(s)

- High Bidder: p****e

Woodworking Machinery Auction - Suring, WI ( Closed #52061551 )

A well-known furniture manufacturer in Suring, WI is auctioning Sorbini panel cleaner, Busellato CNC, Homag edgebander, Giben beam saw, Cattinair panel cleaner, and several other woodworking machines no longer required for continuing operations.

-

Pick Up Location

300 Krueger St, Suring, WI 54174

-

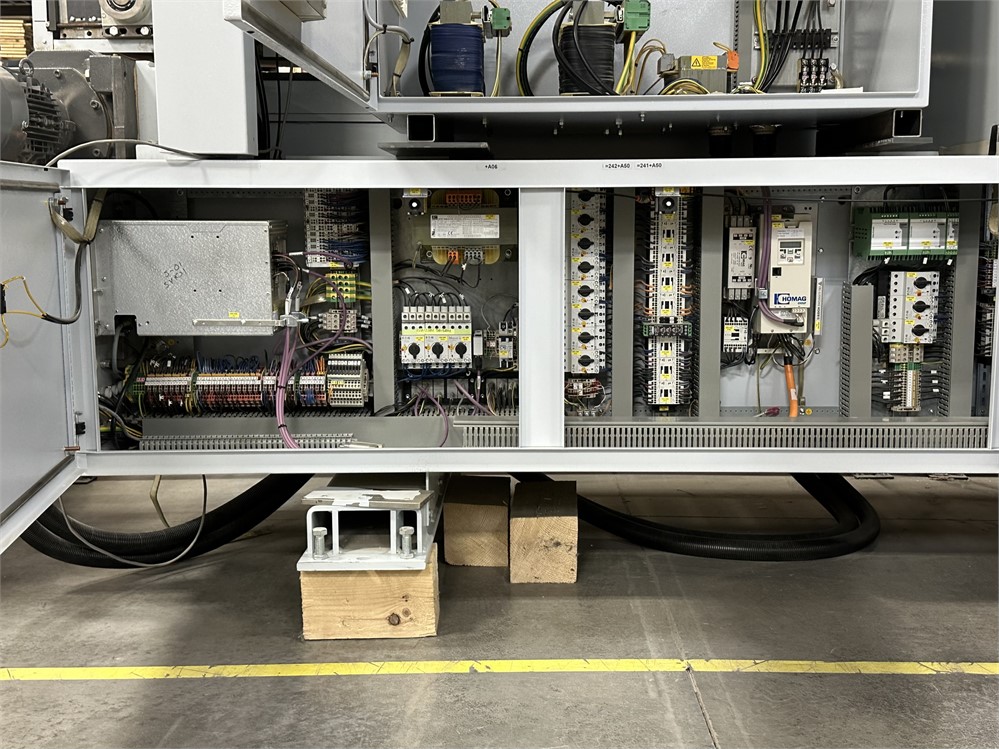

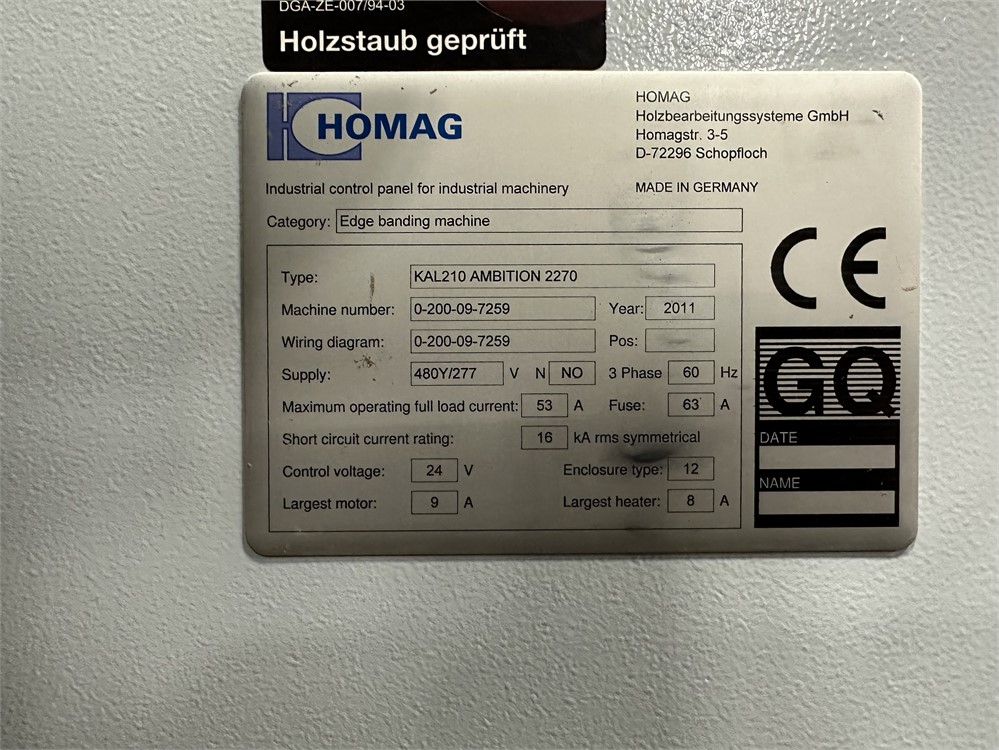

Make

Homag

-

Model

KAL 210 Ambition 2270

-

Serial Number

0200097259

-

Year

2011

-

Phase

3 PHASE

-

Voltage

480 VOLT

-

Load Out Period

July 13th - July 20th, 2023 By appointment only

-

Estimated Dimensions

-

Estimated Weight

-

Seller Comment

Rigger is required. Please see Home Page for Rigger contact information

-

Load Fee

Rigger is required.

-

page views

1591

Homag "KAL210" Ambition 2270 Edgebander

Working Capacity

Coiled stock min/max edge thickness 0.3 - 3 mm (0.016. - 0.118")

Strip material min/max edge thickness 0.4 - 20 mm (0.16 - 0.787")

Panel stock min/max thickness 12 - 60 mm (0.472" - 2.375")

Panel Over-Hang 30 mm (1.18")

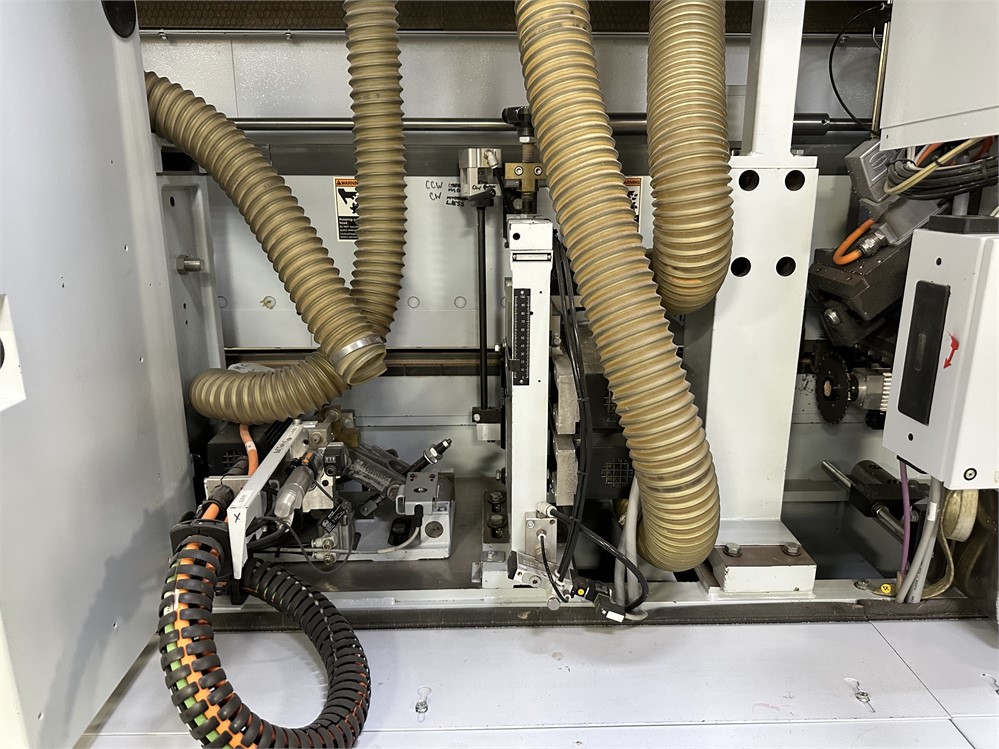

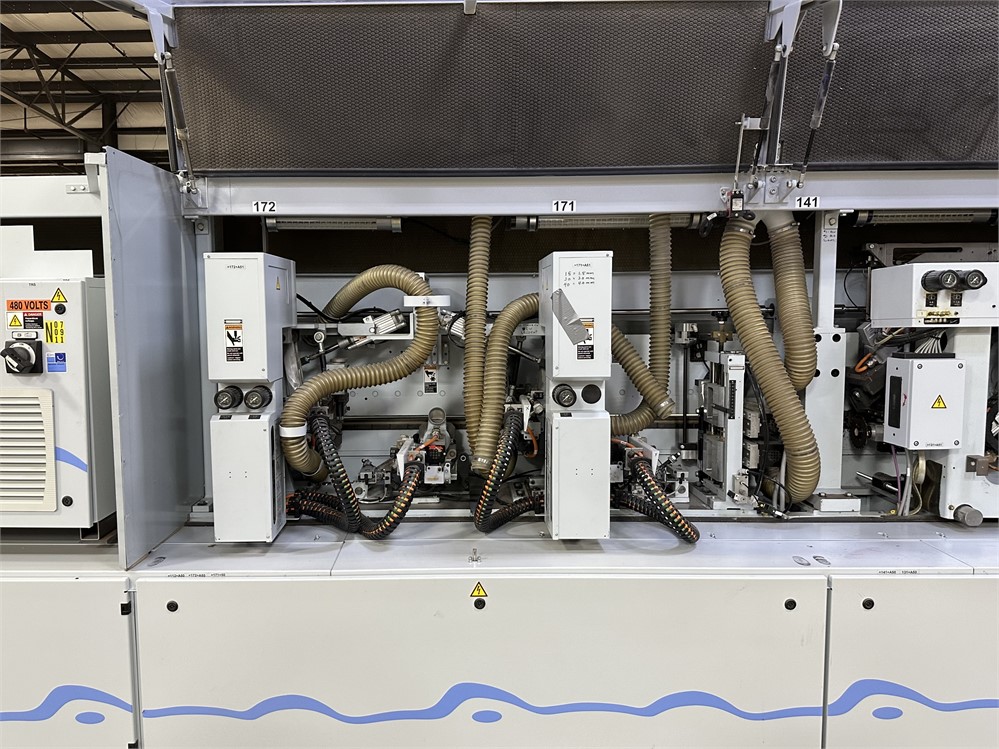

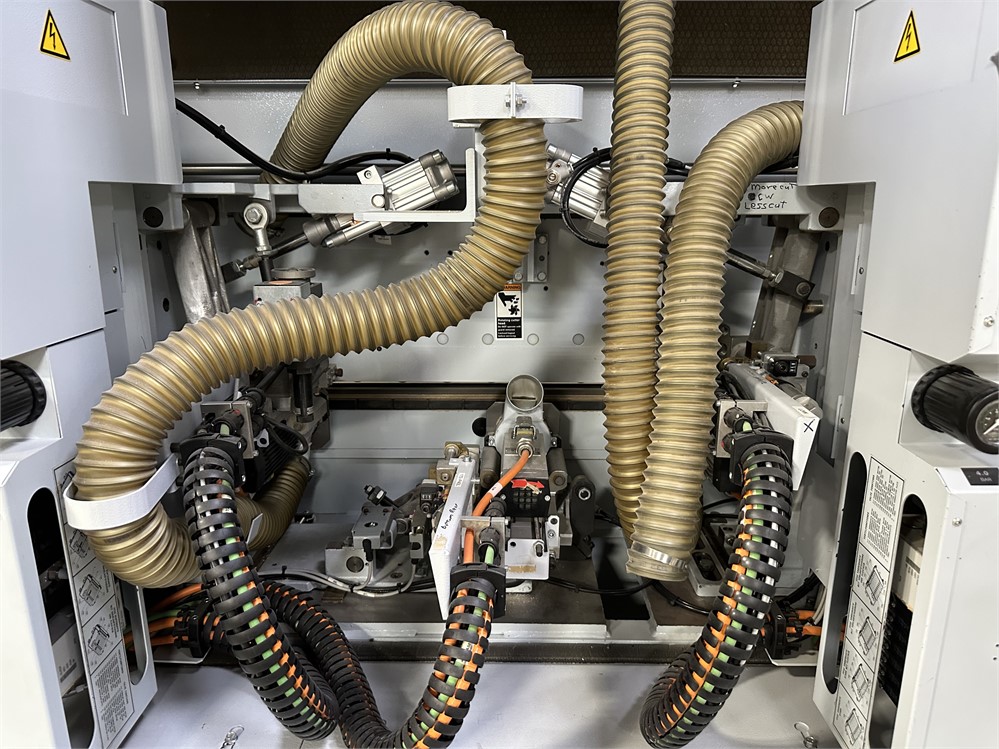

Two (2) motor premilling station

4 HP motors operating at 12,000 RPM

Panel Pre-Heater: Pre-heating the panel brings the panel to an appropriate temperature for better adhesion.This is especially beneficial in cooler temperatures. Quartz lamp for heating substrate edge before glue application improved edge quality and optimum bonding.

Multi-Purpose Magazine: A multi-purpose two (2) 2-coil magazine expands capability by running coiled material, strips and solid wood bands. Magazine height adjustment allows for greater usage of varying panel heights by raising and lowering the magazine table, allowing the operator to center the panel on the edgebanding.

Gluing station

Pre-melt hopper

Glue pot with application roller

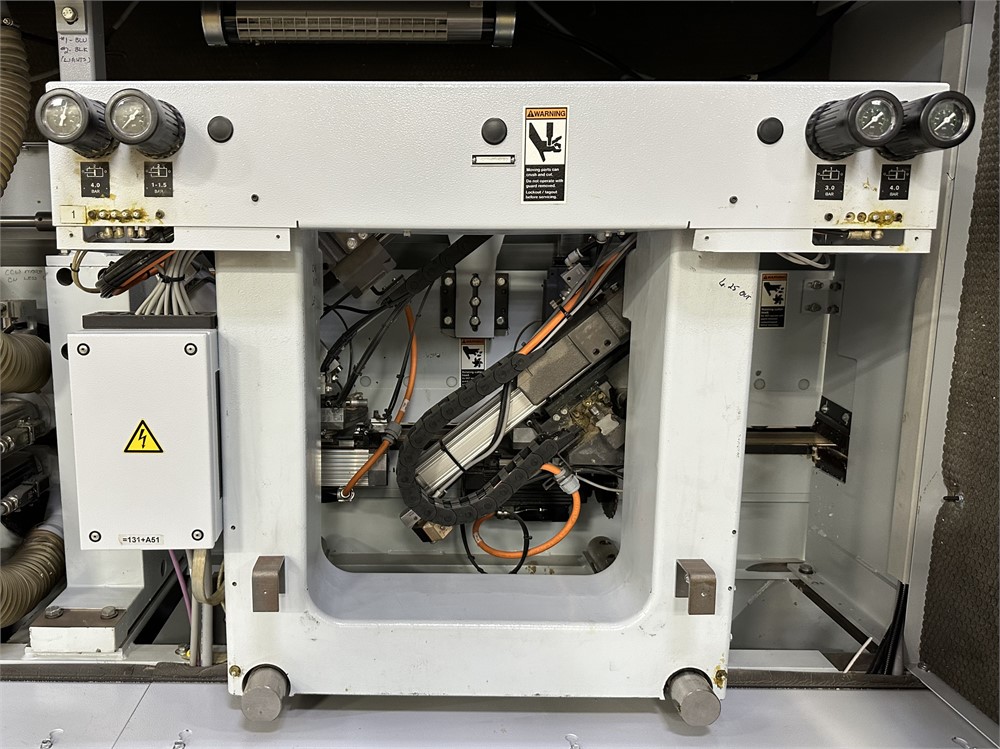

Pressure station

Servo controlled) with seven (7) pressure rollers

One (1) large 160 mm dia. driven

Six (6) 70 mm dia. idle rollers

Pneumatic pressure control depending on edgebanding material used

Two (2) motor end trimming station

1 HP motors operating at 12,000 RPM

Automatic pneumatic adjusting from chamfer 30° to straight cut

Top/bottom flush trimming station

0.75 HP motors operating at 12,000 RPM

Electronic speed control

Braking Control

Pneumatic adjustment

Height adjustment with the top pressure-beam and tilting range +/- 1°

Four (4) motor corner rounding station

0.6 HP motors operating at 12,000 RPM

Top/bottom profile scraping station

Top/bottom flat scraping station

Top/bottom buffing station

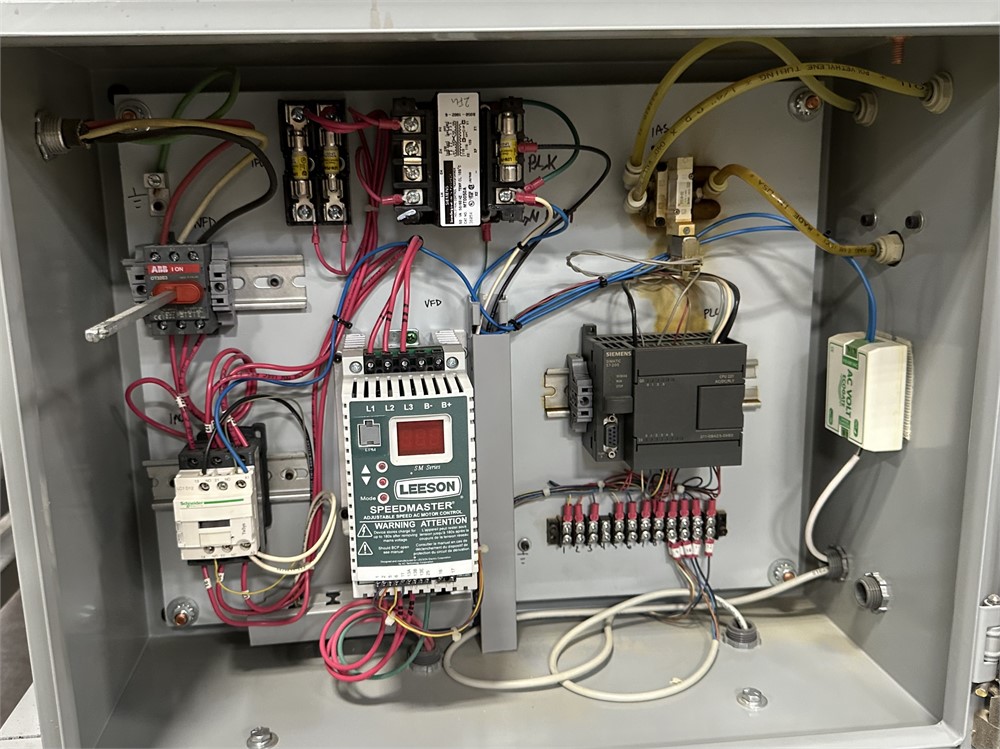

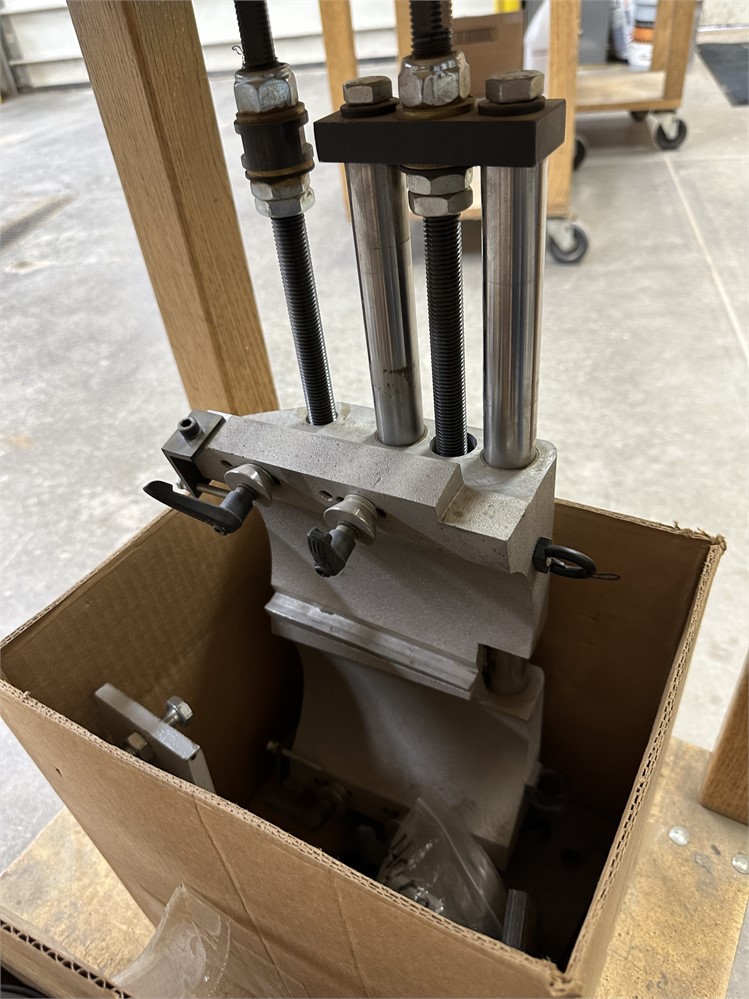

Spare parts as shown

Sound enclosure

Outboard roller track

Listed specifications were taken from manufacturer's published information and is assumed to be correct but not guaranteed. Bidder is encouraged to inspect the machine, call with questions or contact the manufacturer for more information.

The listed specifications & information were taken from the manufacturer’s published information, internet research, or seller’s description.

The specifications & information are assumed to be correct; however, in no way, guaranteed. Bidders are encouraged to inspect the machine, call with questions, or contact the manufacturer for more information.

Please log in to view the bid history

LoginIf a load fee is established for an individual lot, that fee will include loading onto a flatbed truck (only) by the seller. Any individual lot without a load fee will be the buyer's responsibility to remove and load (at buyer’s expense).

Payment is due within 24 hours of auction close. Payments must be made via bank wire transfer for any amount above $1,500. Credit cards may be used up to $1,500 (3% processing fee). Please Contact Sabrina Burns with payment questions at 209-839-7707 Any sales tax exemption documents are to be emailed to [email protected] at time of purchase/invoice for tax exemption consideration.