SCM "MiniMax ME 40ET" Edgebander with Premilling  Ended

Ended

SCM "MiniMax ME-40ET" Edgebander with Premilling - Vacaville, CA

- Winning Bid : $13,151.00 USD Sold

- 68 Bid(s)

- High Bidder: W****y

SCM "MiniMax ME-40ET" Edgebander with Premilling - Vacaville, CA ( Closed #48571474 )

Custom cabinet shop in Vacaville, CA bought a new machine and is offering this machine for auction.

-

Pick Up Location

Vacaville, CA

-

Make

SCM

-

Model

MiniMax ME 40ET

-

Serial Number

AB00007062

-

Year

2018

-

Phase

3 PHASE

-

Voltage

230 VOLT

-

Load Out Period

May 8th - May 19th 2023 (by appointment)

-

Estimated Dimensions

136" L x 30" W x 60" H

-

Estimated Weight

2,000 Pounds

-

Seller Comment

A non-negotionable loading fee has been established. This includes loading onto a flat bed trailer. Requests for additional labor, crating or pallatization will be extra.

-

Load Fee

100

-

page views

2493

SCM "MiniMax ME 40ET" Edgebander with Premilling

190 mm minimum part length

110 mm minimum part width

0.4 mm - 3 mm coiled edgbanding capacity

5 mm maximum strip edgebanding capacity

PLC CONTROL SYSTEM

The control system for the Minimax ME 40 is a simple and intuitive use of the error-free machining and is ensured by the control positioned on the front of the edge bander which allows an easy selection of all of the main functions. These functions include the operating unit switching on/off and the PLC unit which guides the operator during maintenance, cleaning, diagnostic operations and much more.

TRACK FEED SYSTEM

The Minimax ME 40 track feed movement system is designed for a perfect finish that eliminates transfer marks onto the work piece. 9 meter/min panel feed speed with track movement for increased productivity. Monitoring of the panel position is done by an encoder for total work cycle control.

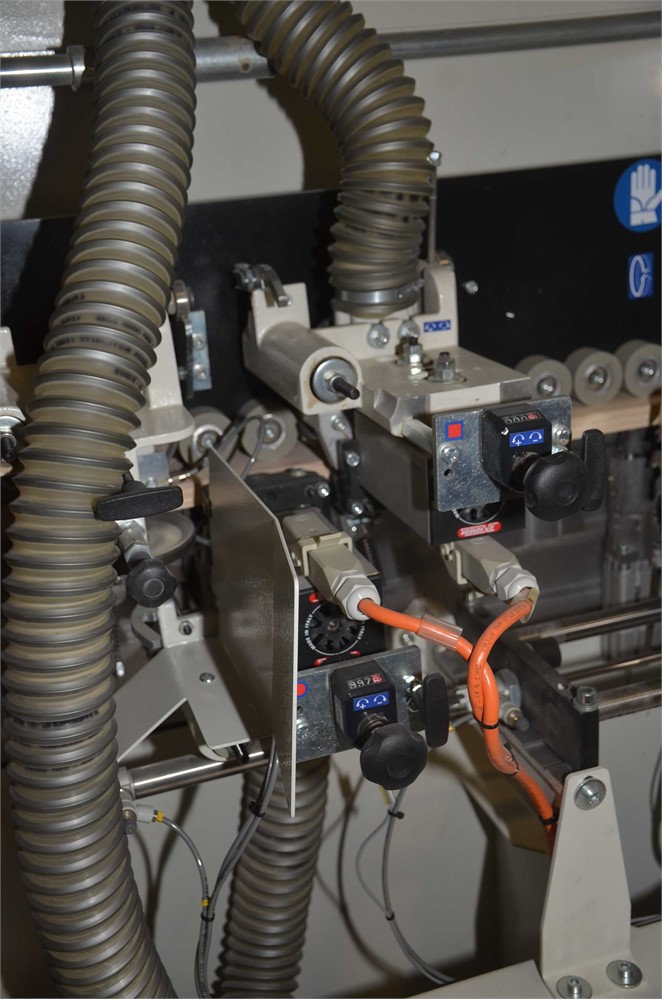

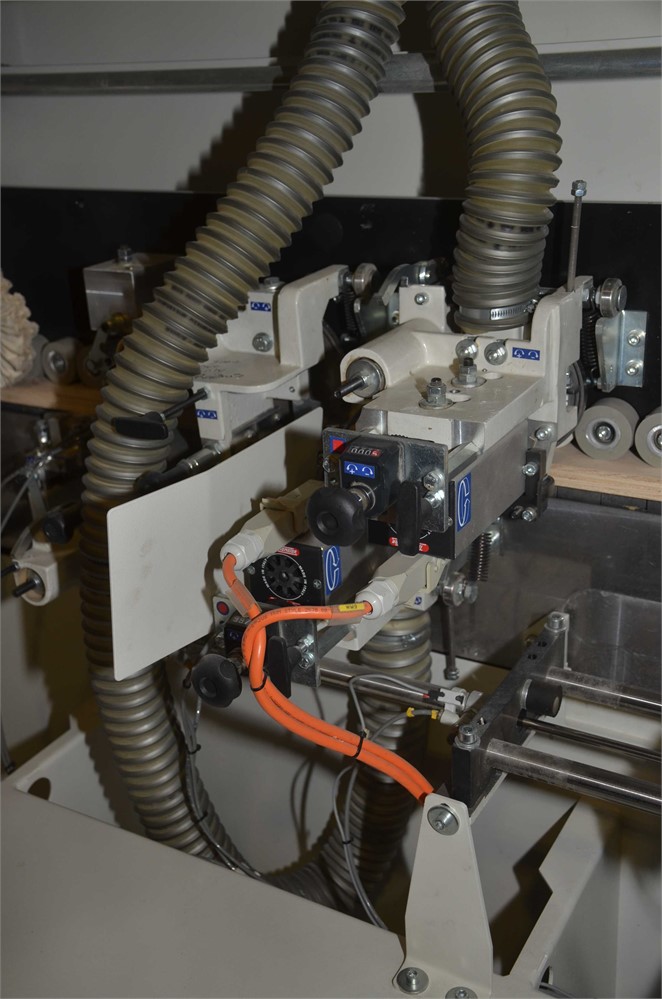

DIGITAL MECHANICAL READOUTS

Each station on the edge bander is easily adjustable and repeatable through the use of these digital mechanical readouts. Easily input the dimensions you are processing, and fine tune them simply. By taking note of the positions for the different panels you run, you can easily change the settings on the fly for any change in operation.

HIGH FREQUENCY MOTORS

Thanks to the high frequency motors of the end cutting unit and of the in-line trimming unit, the reliability of the Minimax ME 40 is unmatched. The maximum in precision, an optimal finishing level to an applied edge is always attained. With the absence of belts or other conventional driving systems, we have engineered less vibration into the unit, increasing reliability and high precision over the life of the machine.

Adjustable infeed fence

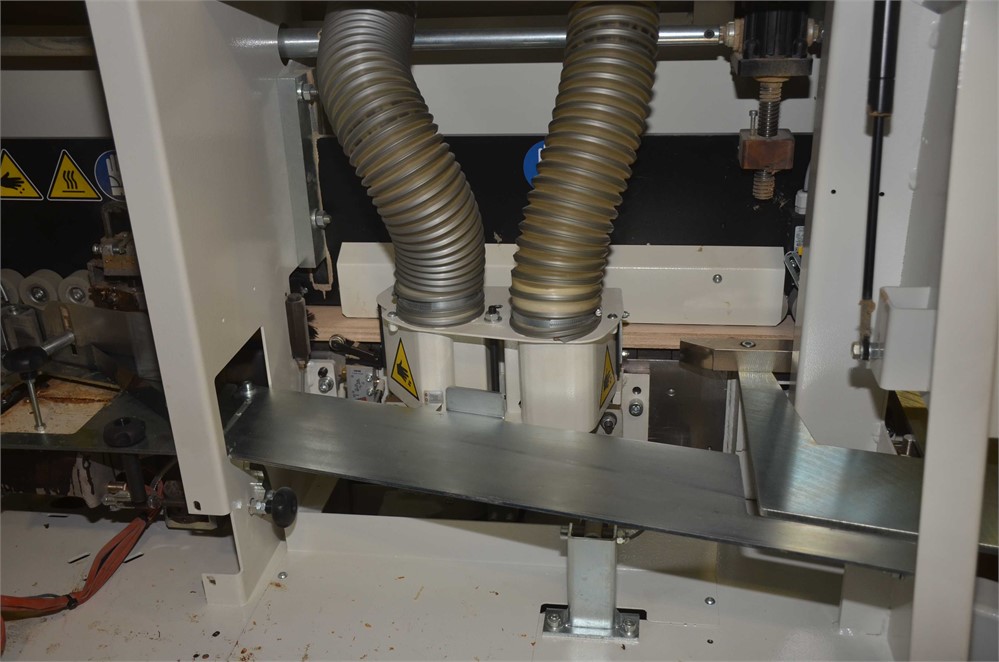

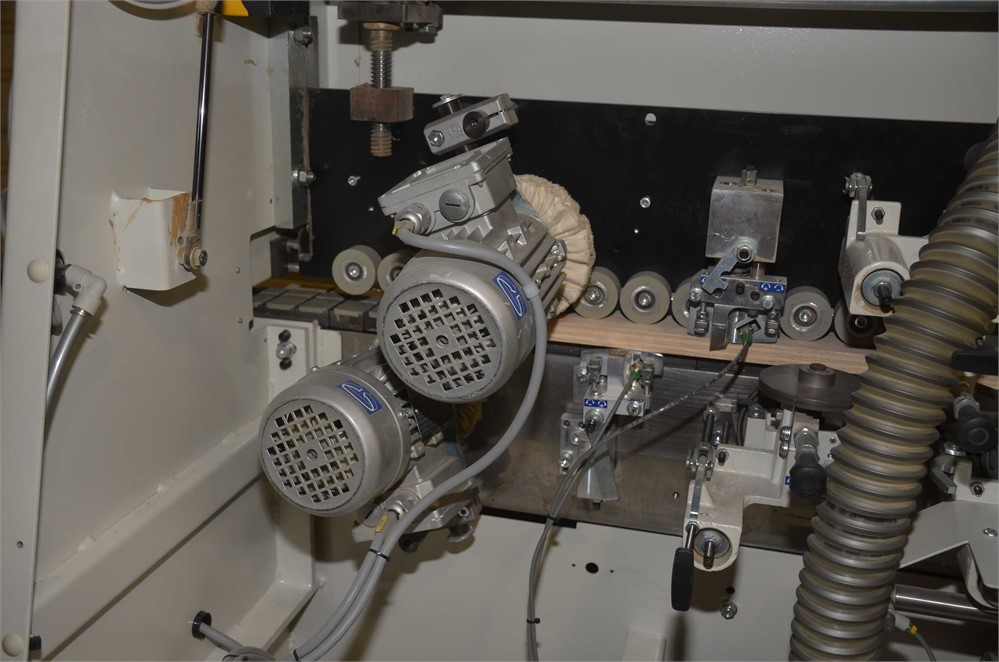

DUAL DIAMOND CUTTERHEAD PRE-MILLING UNIT

The Minimax ME 40 Pre-mill unit utilizes two 80mm diameter diamond tools with opposing rotation and timed intervention that, through the removal operation corrects any panel imperfections caused by the saw cutting process and panel storage. This allows for a clean edge and a good lineal finish during the pre-mill process. Pre-milling comes with an independent exhaust and air blower for cleaning of the panel during the process. You can carry out vertical adjustments of the tools for use even into the final sharpening phase. Allowing four levels of removal (0.5, 1, 1.5, and 2mm). 3 HP motors operating at 7,200 RPM.

Edgebanding infeed table

Guillotine

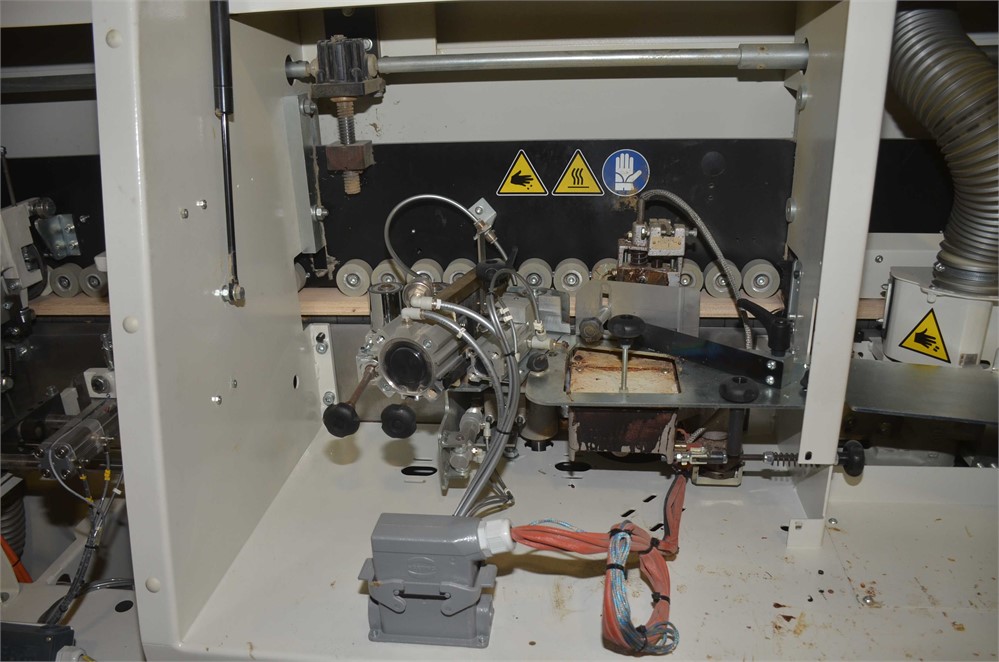

INTERCHANGEABLE GLUE POT UNIT

The Minimax ME 40 edge bander features an interchangeable glue pot with a quick heat-up system. The glue pot is Teflon coated to allow for easy clean up and easy glue replacement. The system easily applies the glue to the panel with a vertical glue spreading roller, and the temperature is adjustable via the PLC control. This machine also has a device to automatically recover any unused glue.

Pressure station

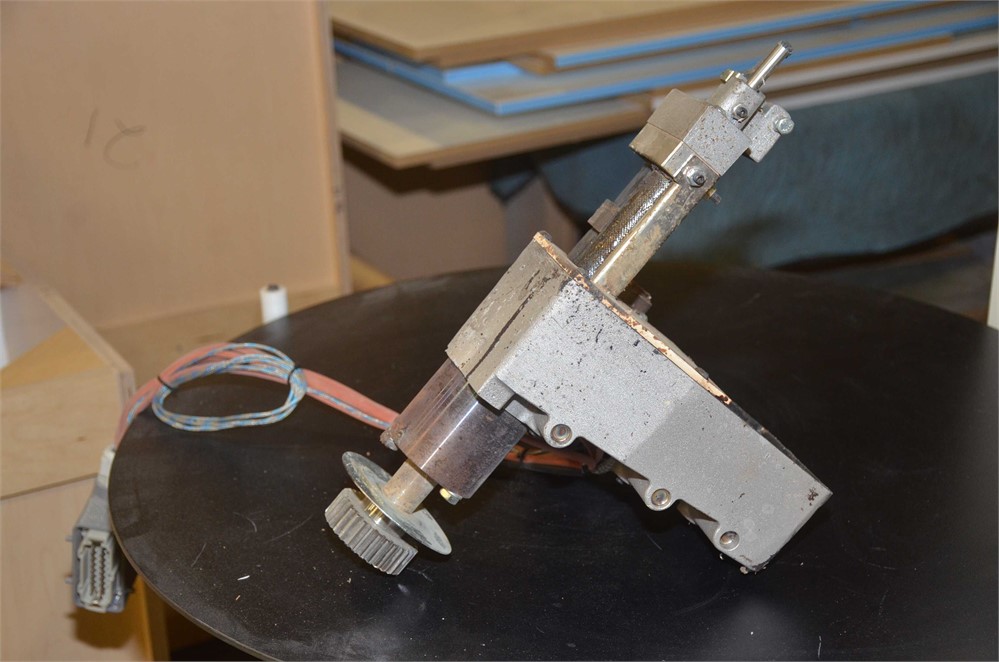

END TRIMMING UNIT

0.25 HP motors operating at 12,000 RPM

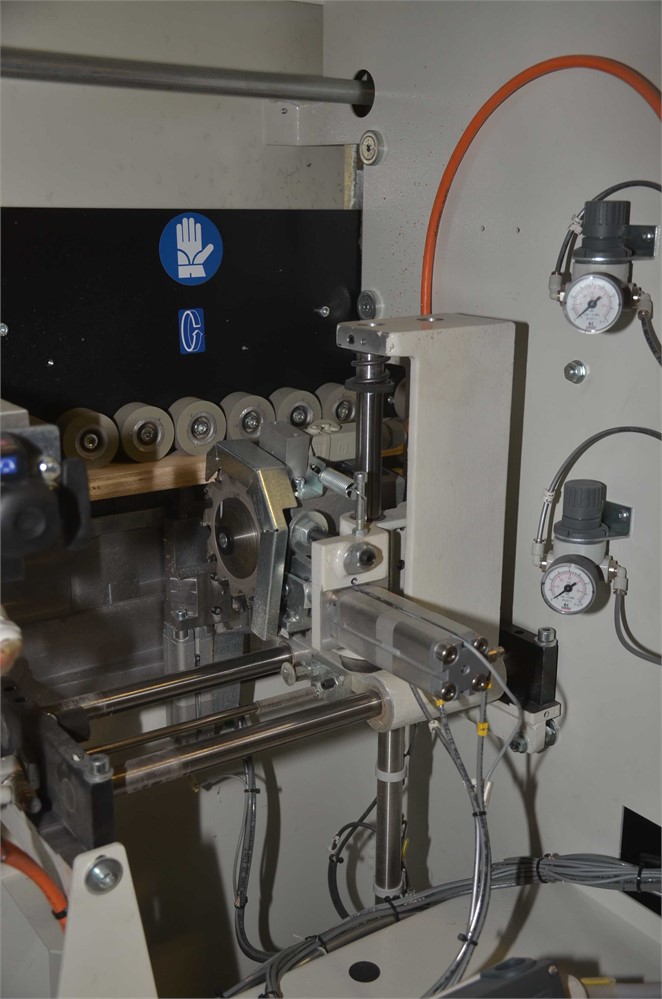

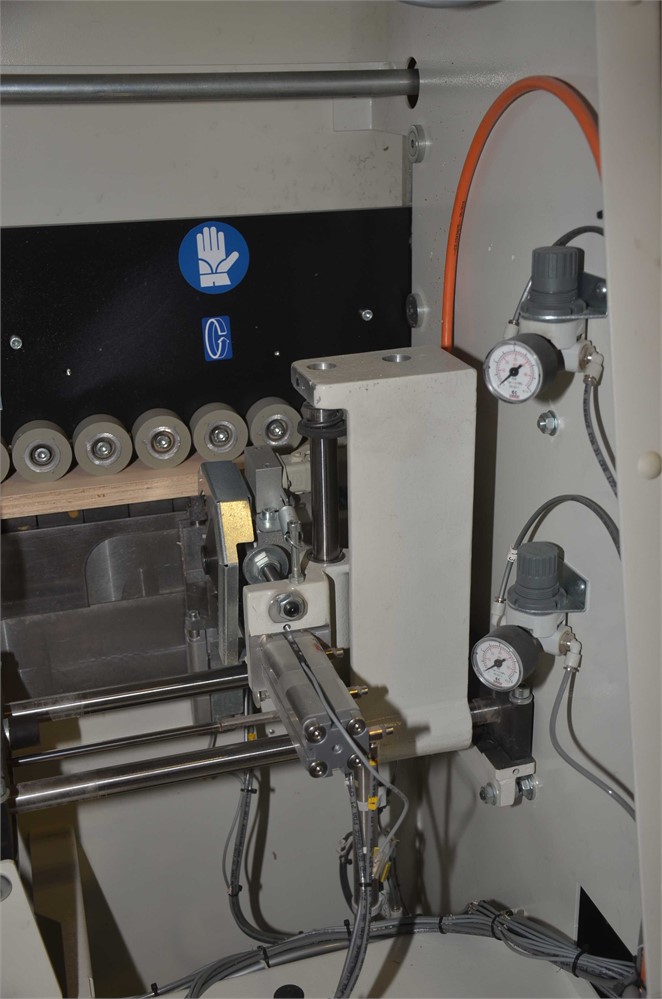

TOP AND BOTTOM TRIM UNIT

The Minimax ME 40ET has a very high edge quality finishing with the rotating copy wheels. The high frequency motors generate high cutter rotating speed, reducing to a minimum any marks left from trimming and guaranteeing the absence of vibrations. These cutters are designed for straight or radius trimming of any type of edge. The edge thickness is easily set by means of two numerical readouts. 0.5 HP motors operating at 12,000 RPM

EDGE AND GLUE SCRAPE UNITS, AND BUFFING UNIT

The Minimax ME 40 features scraping and buffing stations as standard for finishing of 3mm PVC/ABS edges. The scraping system assures an excellent finish, eliminating any excess glue on the panel or edge joint and keeping it free of chatter marks, thanks to the heavy-duty structure. The precise horizontal and vertical copying wheels have chrome plated surfaces and assure accurate positioning of the knives. The buffing station includes high frequency motors for cleaning and polishing the edge. This unit is tilted and vertically adjustable to optimize the polishing and cleanliness of the work piece. 0.2 HP motors operating at 2,800 RPM

Sound enclosure

Outboard roller support

Forklift cutouts in frame

The information provided in this lot was gathered from literature, internet & physical inspection. It is thought to be accurate; but not guaranteed. Bidders are urged to use the open house or private inspection periods to inspect and verify.

The listed specifications & information were taken from the manufacturer’s published information, internet research, or seller’s description.

The specifications & information are assumed to be correct; however, in no way, guaranteed. Bidders are encouraged to inspect the machine, call with questions, or contact the manufacturer for more information.

Please log in to view the bid history

LoginNo information available