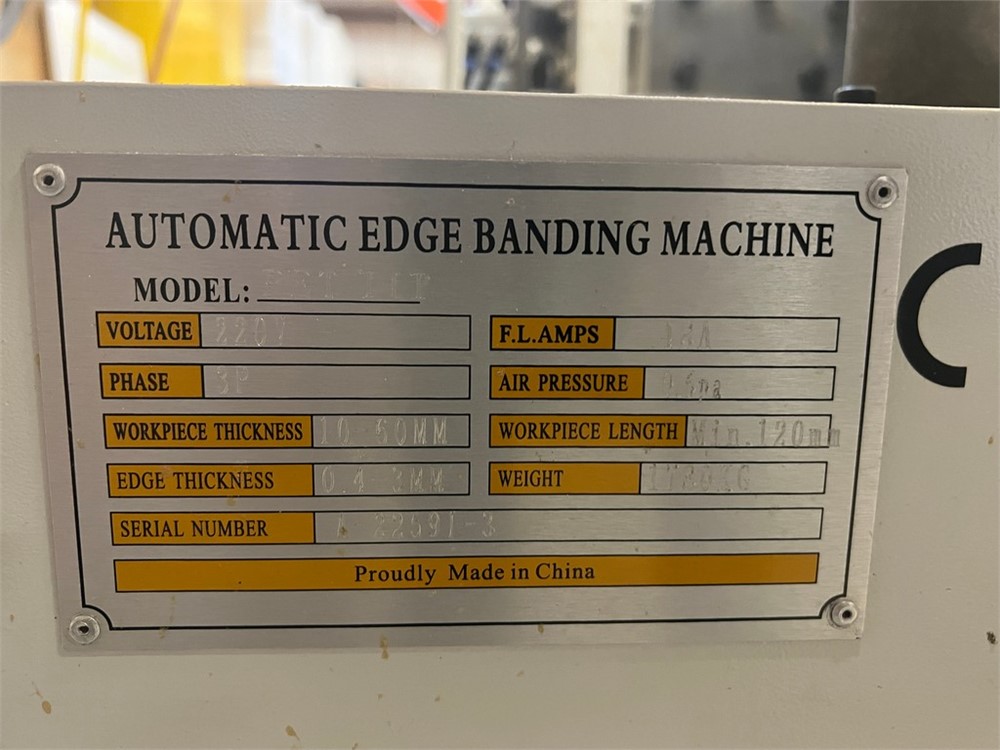

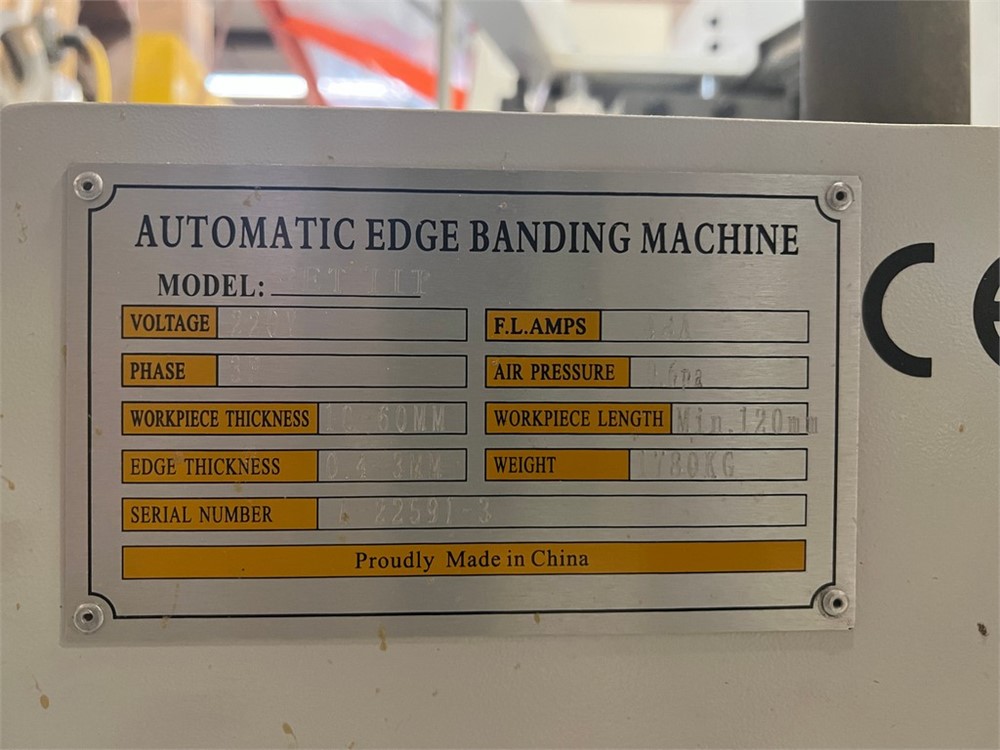

Pro-Edge Technology "PET III" Edgebander - Pre-Mill  Ended

Ended

Pro Closet - Ocala, FL

- Winning Bid : $6,500.00 USD Sold

- 61 Bid(s)

- High Bidder: M****e

Pro-Closet - Replacing machinery with New! - Ocala, FL ( Closed #45108410 )

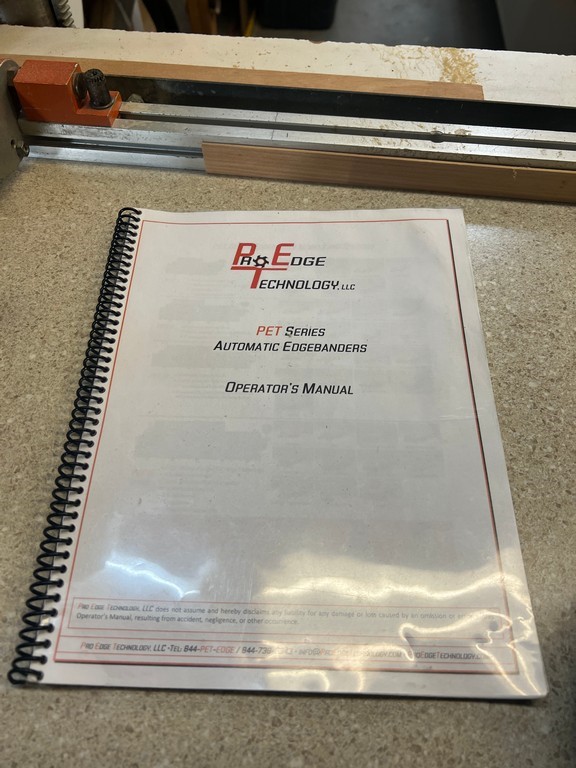

Machinery is still in use and fully functioning...Please see videos. Featuring Omnitech Select /PAL CNC Router, 2016 Pro Edge Technologies PET III Edgebander w/ Premill, Gorbel Vacuum Lift, Plus Much More!

-

Pick Up Location

Ocala, Fl

-

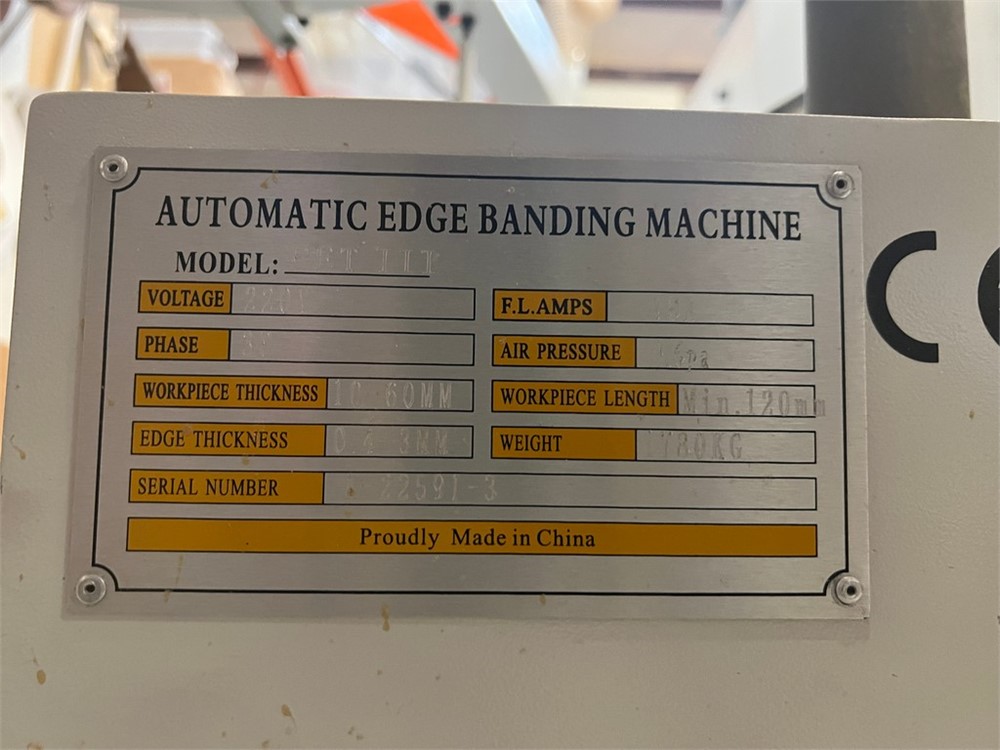

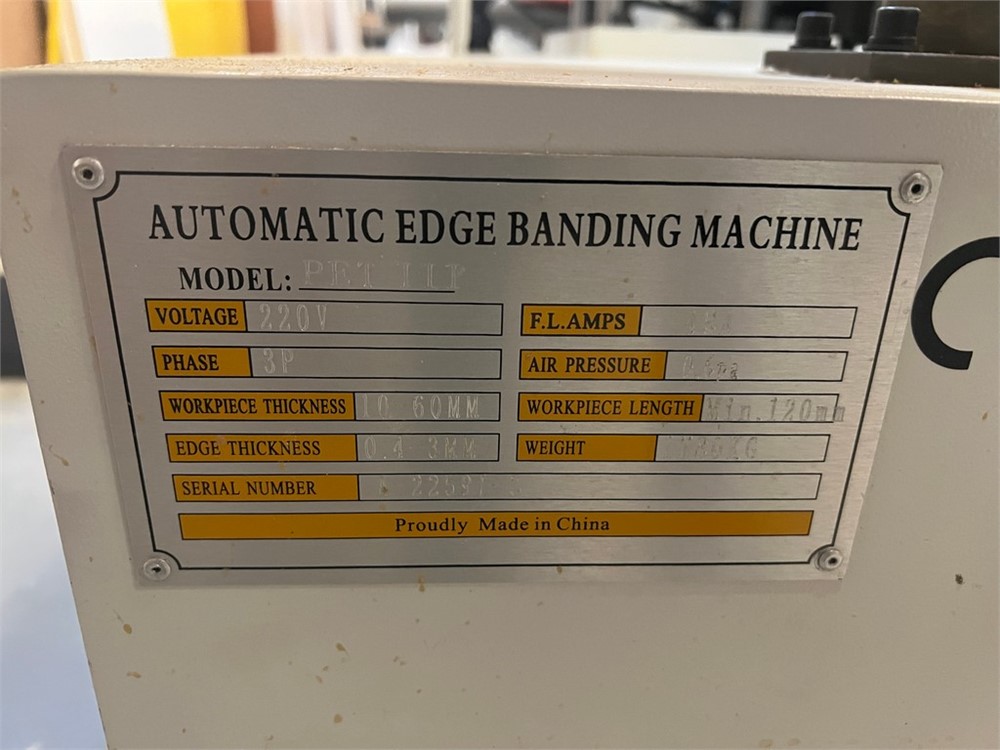

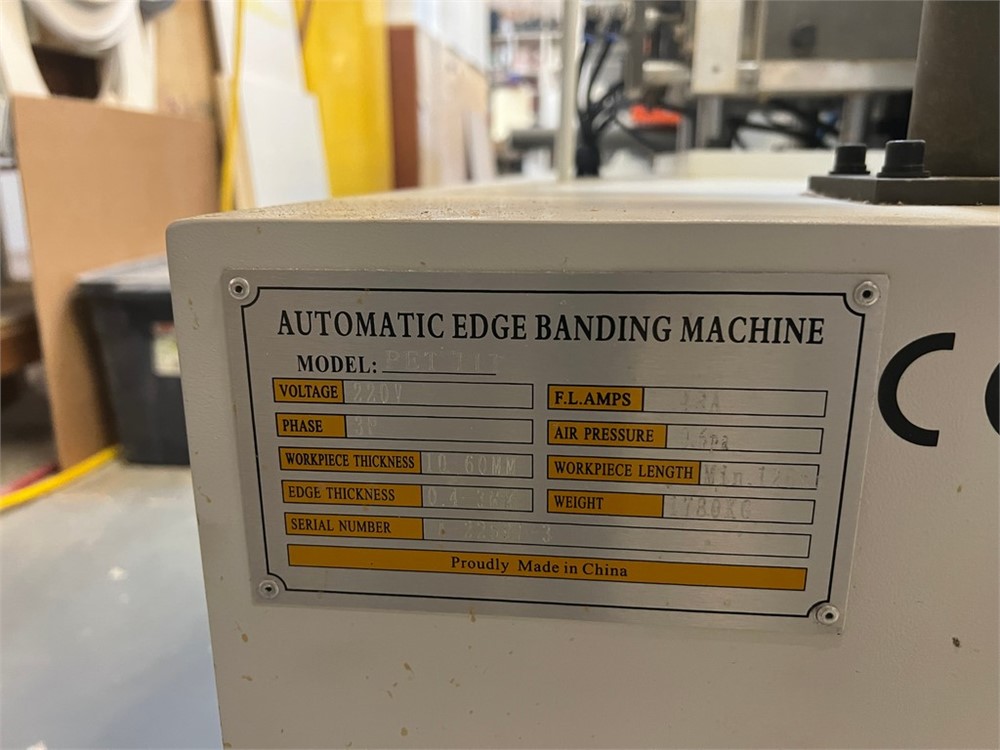

Make

Pro-Edge Technology

-

Model

"PET III"

-

Serial Number

A22591-3

-

Year

2016

-

Phase

3 PHASE

-

Voltage

220 VOLT

-

Load Out Period

See Home Page for Removal Dates

-

Estimated Dimensions

18' x 4' x 6'

-

Estimated Weight

4,000 Lbs

-

Seller Comment

A non-negotionable loading fee has been established. This includes loading onto a flat bed trailer. Requests for additional labor, crating or pallatization will be extra.

-

Load Fee

$995

-

page views

2963

Pro-Edge Technology "PET III" Edgebander - Pre-Mill

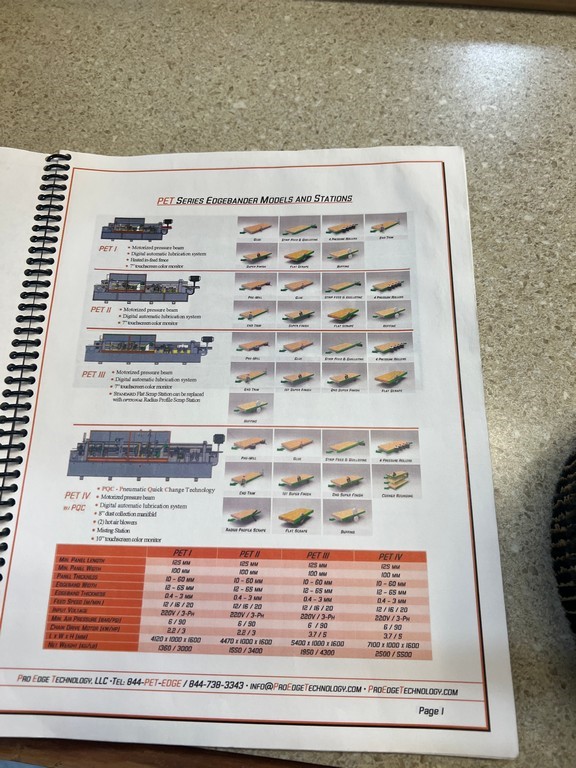

125mm Min. panel length, 100mm min. panel width, 10-60mm panel thickness, 12-65mm edgeband width, 0.4-3mm edgeband thickness, 12/16/20 mpm feed speed.

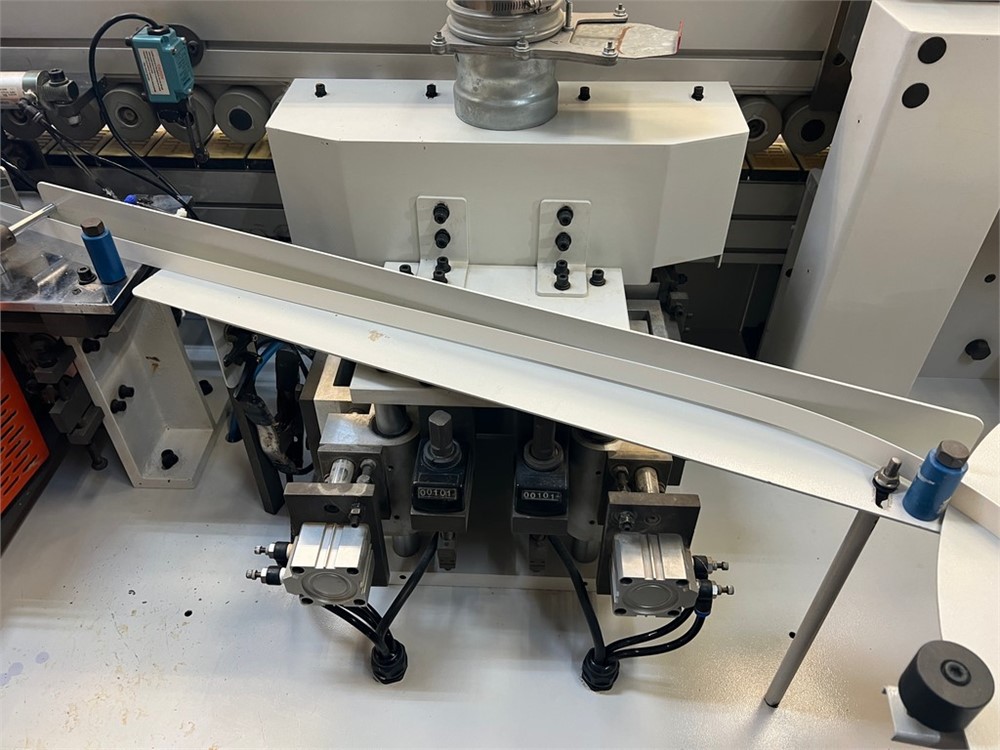

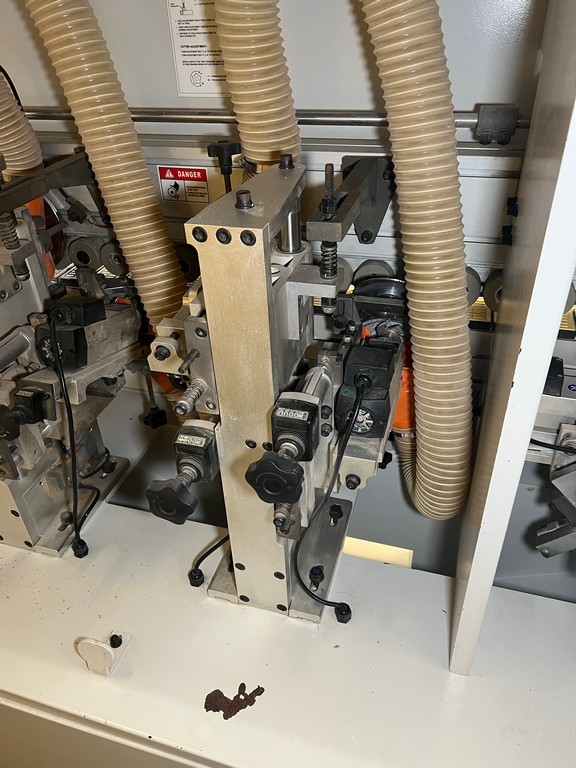

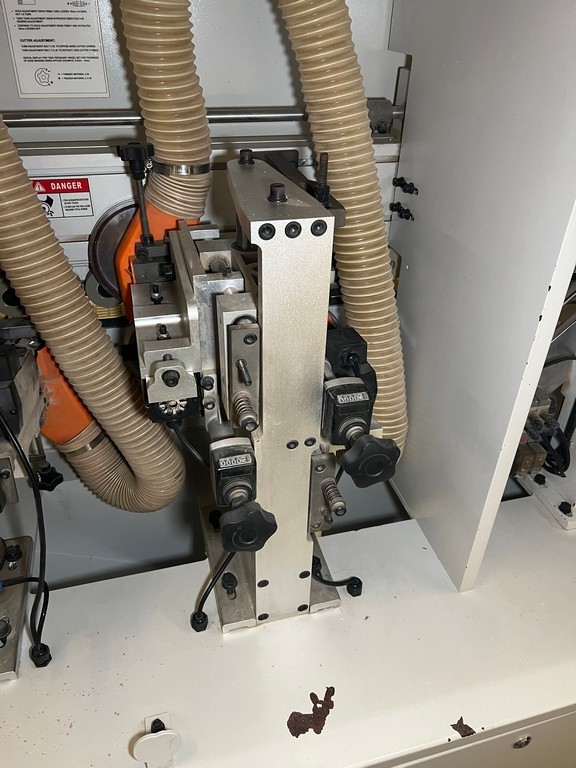

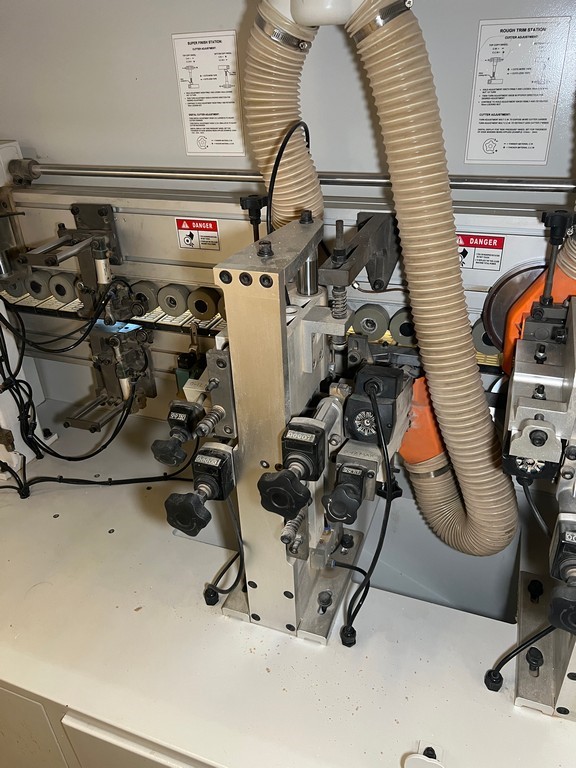

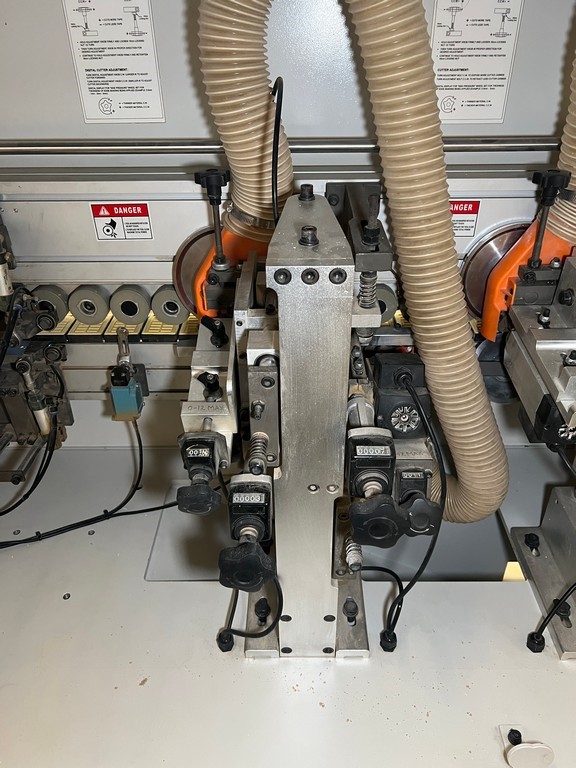

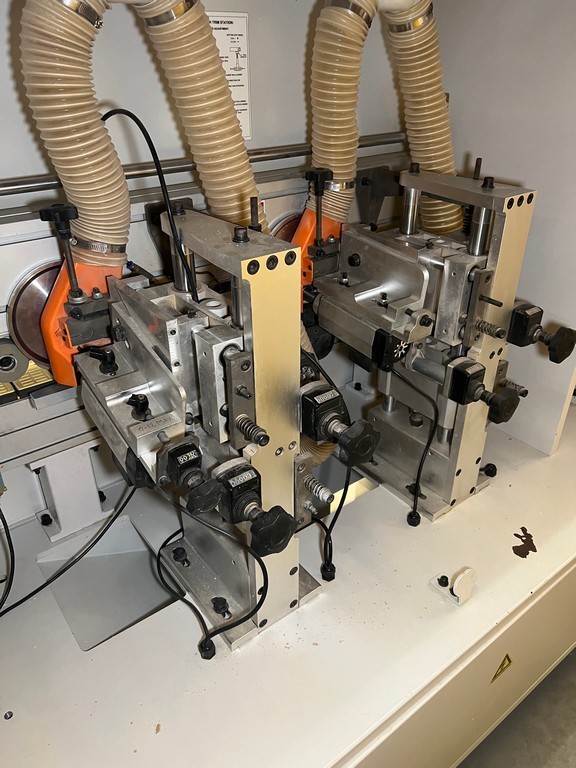

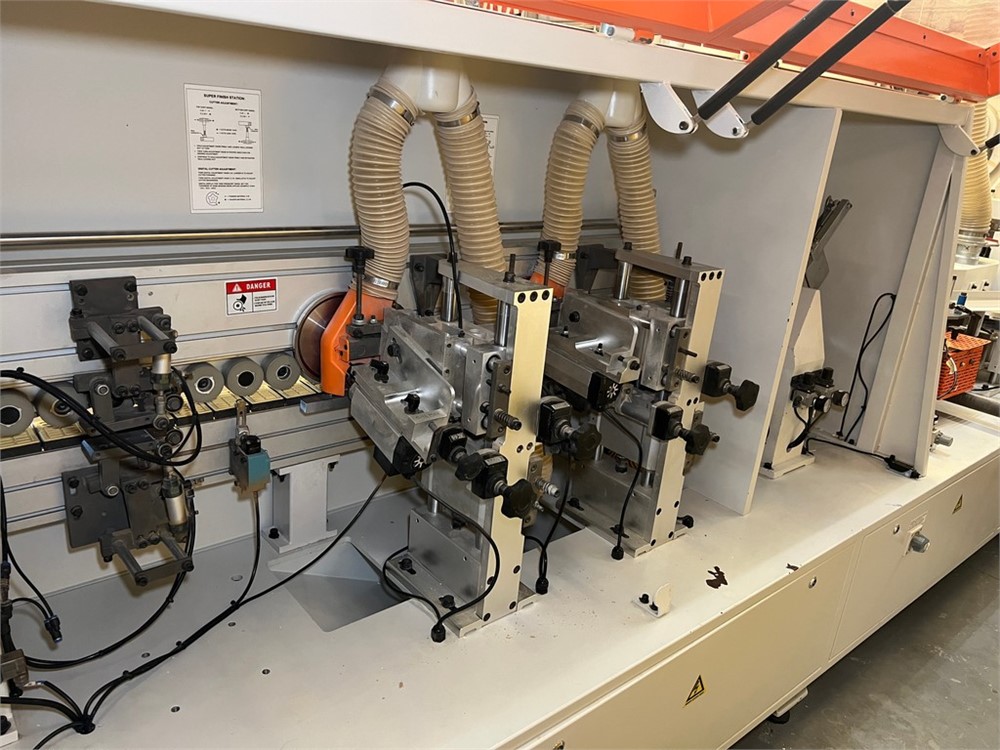

PREMILL STATION: The Premill Station comes standard with (2) compression diamond tipped milling heads. The compression diamond tipped milling heads are used to remove any tooling marks left from panel saws or other processing methods in order to achieve a better adhesive bond and a higher quality finish. Our high frequency counterrotating cutter heads run at a rate of 12,000 rpm with adjustable tracers and digital numerical positioning indicators. And a pneumatic plunge and retraction PLC controlled machining operation.

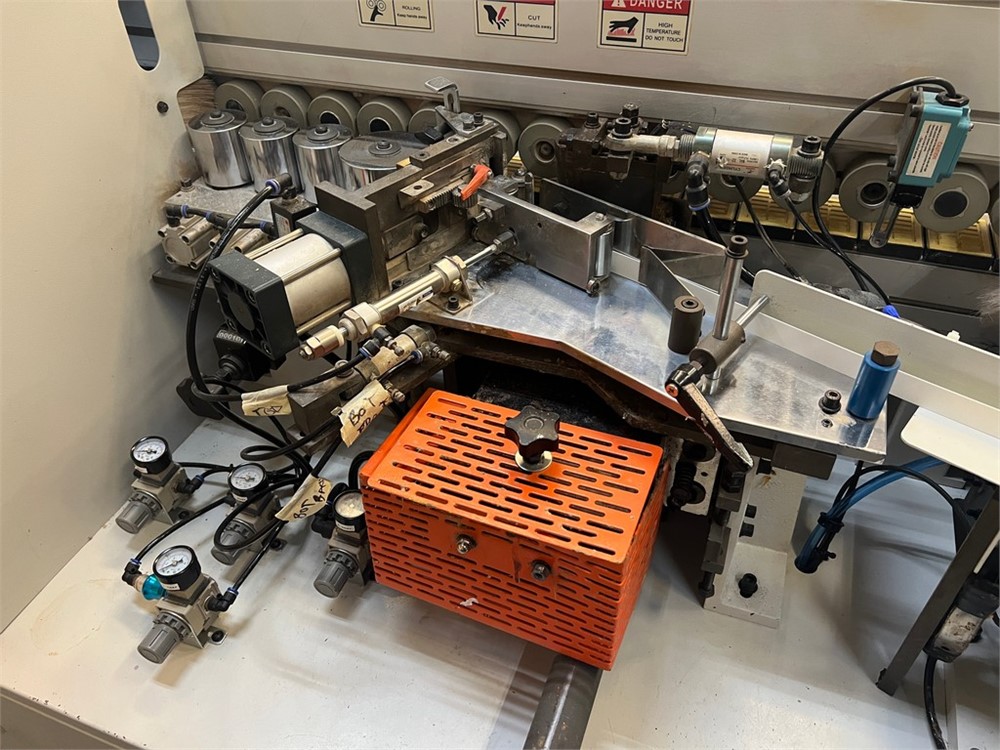

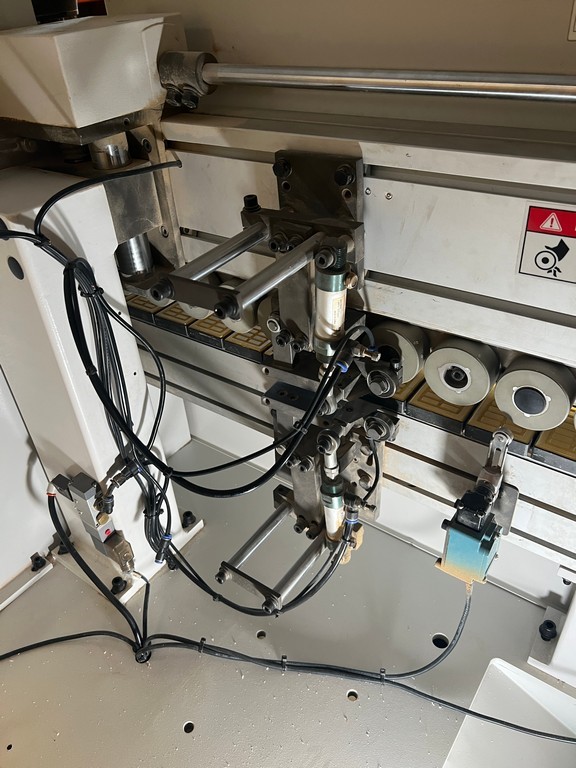

GLUE STATION: To ensure a precisely metered glue application on the edge of the panel, our heavy-duty, non-stick coated, glue pot comes with an independent variable-speed drive. The pneumatic controlled glue metering cylinder allows a more accurate amount of glue to the board’s edge. Our hardened glue application roller and the quick heat -up time ensures years of trouble-free service.

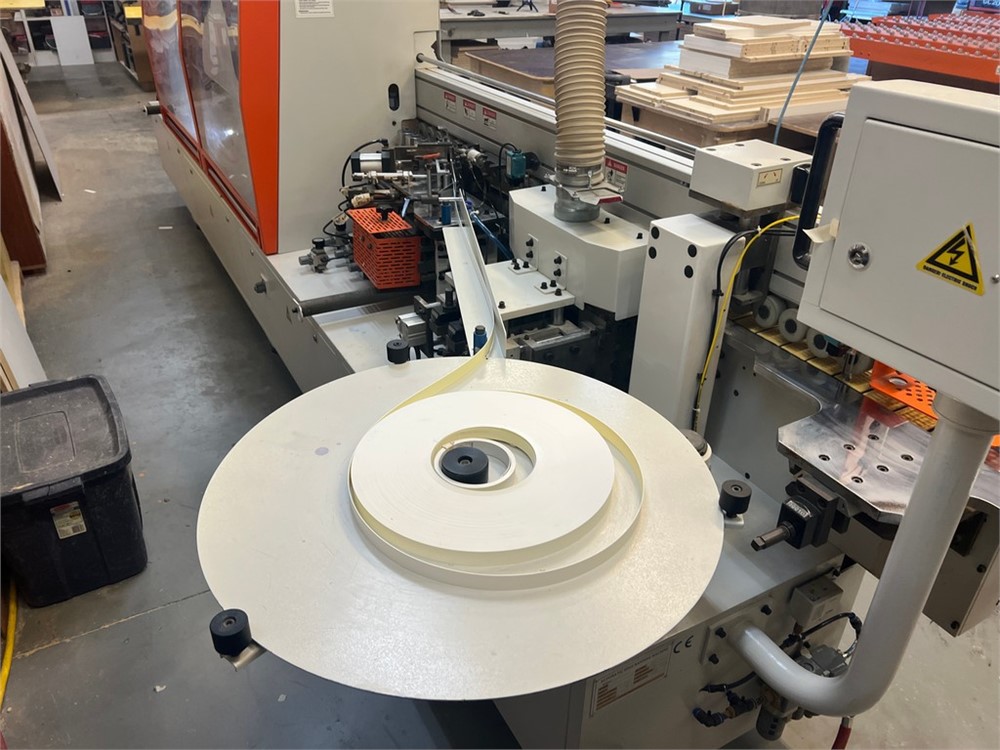

STRIP FEED SYSTEM: Our Strip Feed System was specially designed for a smoother intake of coil-type material ranging from 0.4mm to 3mm edge thickness, and stackable pre-cut material such as wood strips or plastic laminates. The Strip Feed has an independent cut-off switch when using long laminate strips or pre-cut material.

GUILLOTINE: An adjustable pneumatic controlled Guillotine with an independent switch for cutting PVC tape, 3mm PVC tape and all types of wood veneers and plastic laminates. The heavy-duty hardened knife ensures a longer life of quality cuts.

4-ROLLER PRESSURE STATION: The 1st roller applies even pressure across the entire edge of the panel; the 2nd and 3rd rollers are conically shaped to apply pressure on the top and bottom of applied edge; and the 4th roller reapplies even pressure across the entire edge of the panel. Each roller is pneumatically pressurized to ensure a strong adhesion between the panel to the glue and the glue to the edge banding. The heavy -duty drive transmission ensures the rotation speed of the 1st roller matches the feed speed of the machine.

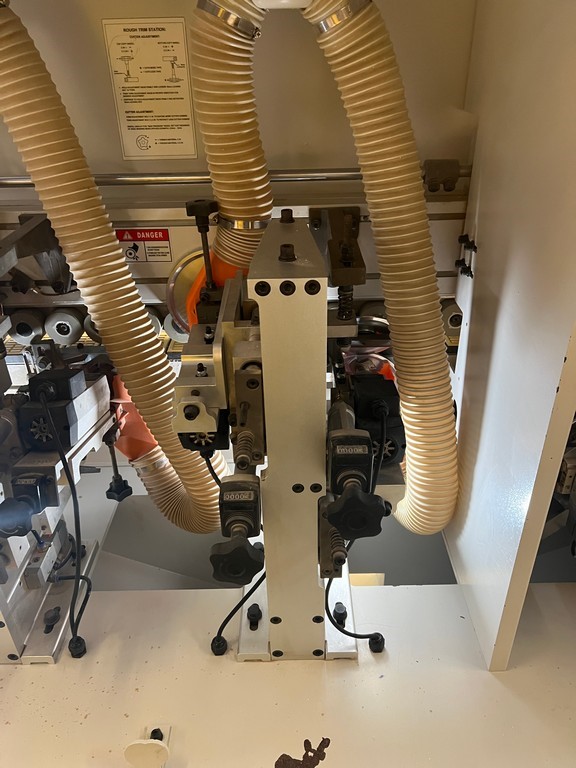

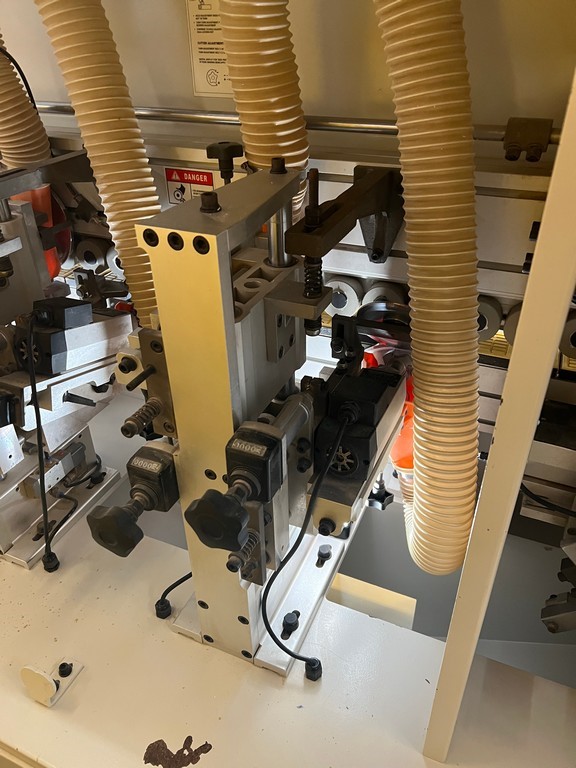

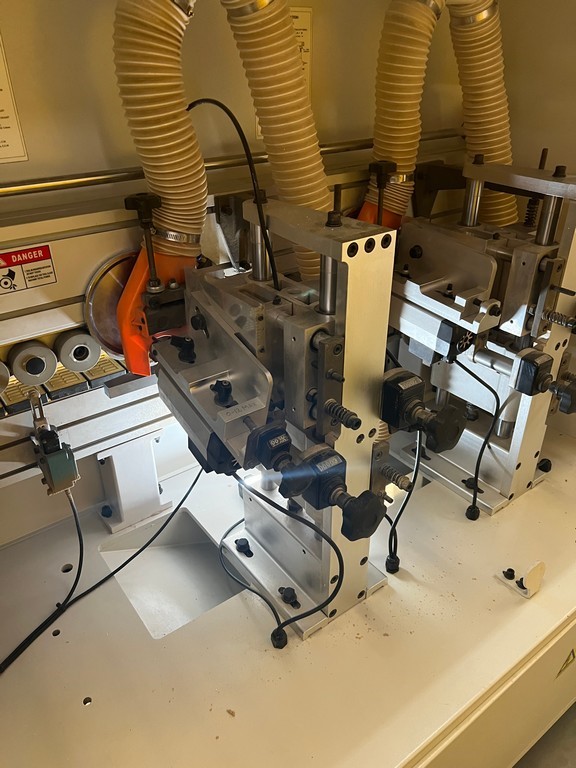

END TRIM STATION: (2) high frequency end trim motors sit in a secure machined way with manual locking devices ensuring an accurate vibration free end trim with a high quality cut on both thin and thick edges of banding. Precision linear prismatic bearing guides ensure a flawless end trim. Both motors can be independently tilted from a 0° to 15° bevel.

ROUGH / 1st SUPER FINISH TRIM STATION: (2) high frequency motors are manually adjusted to tilt from a 45° to 90° bevel for the final finish top and bottom trim of the panel. Manual adjustments are “locked” in place to ensure there is no movement from any vibration. This station is also equipped with an air blow-off on the top cutter and dust collection on both top and bottom cutters.

2nd SUPER FINISH TRIM STATION / PROFILING STATION for 2MM to 3MM EDGEBANDING : When machining 2mm to 3mm edge banding this 2nd top and bottom super / profiling station is used as the final finish station giving a high quality and accurate profiled edge. This station comes standard with (2) 6-tooth combination profiled/beveled diamond cutters. Both above mentioned stations can be tilted any angle between 90 and 45 degrees to accommodate any required combination cutters.

FLAT SCRAPER STATION: The Flat Scraper Station is used to remove any residual glue left on the panel caused by squeeze-out. The flat scraper ensures a clean joint on both sides of the panel surface.

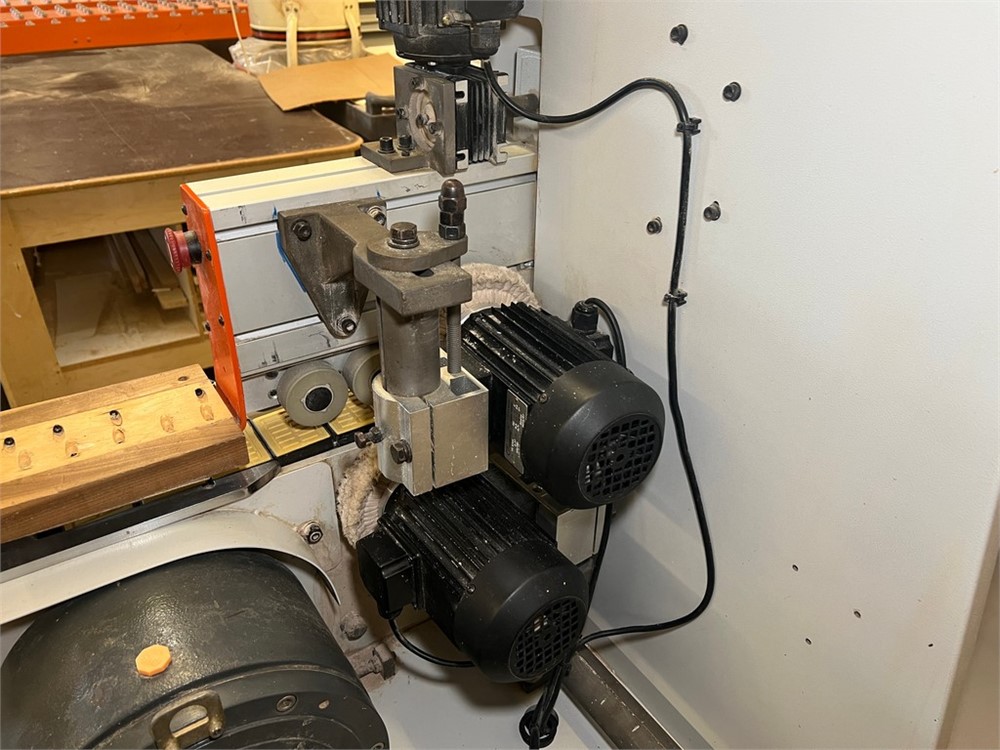

BUFFING STATION: (2) independent, heavy-duty 3-phase motors soften and polish the sharp edges on the panel. The Buffing Station has (2) fully adjustable universal mounts for easy adjustment. Buffers can be used with either cloth or abrasive discs.

DIGITAL AUTOMATIC LUBRICATION SYSTEM: For linear guide bearings on the end trim saws and the main track chain

The information provided in this lot was gathered from literature, internet & physical inspection. It is thought to be accurate; but not guaranteed. Bidders are urged to use the open house or private inspection periods to inspect and verify.

The listed specifications & information were taken from the manufacturer’s published information, internet research, or seller’s description.

The specifications & information are assumed to be correct; however, in no way, guaranteed. Bidders are encouraged to inspect the machine, call with questions, or contact the manufacturer for more information.

Please log in to view the bid history

LoginPick-ups are to be scheduled by appointment only. Please contact Sabrina Burns at 209-839-7707 or [email protected] to schedule an appointment. For freight quotes please contact Aaron at All-Ways Trucking at 541-608-6532 or or John @ NCL Trucking @ 615-452-7651 . Buyer bears all costs to remove and load this lot. Buyer must remove entire lot purchased. Anyone removing non-hand carriable lots must provide MachineryMax, Inc. with a certificate of insurance (COI) before purchased items can be removed.

All buyers agree to make full payment to MachineryMax, Inc. within 48 hours of the online closing date for the auction lots purchased. All invoices over $1,500.00 are to be made by bank wire transfer or cashier’s check payable to MachineryMax, Inc. Purchases under $1,500.00 may be made using Visa, MasterCard, or American Express (3% credit card processing fee will be added to the invoice). All payments are to be made in USD currency only. Bidder represents and warrants to MachineryMax, Inc. that such bidder has immediately available funds to fully pay for its successful bids within 48 hours of the online closing date. All payment questions should be directed to Sabrina Burns at 209-839-7707 or [email protected] All buyers agree that there will be a 15% Buyers premium that will be added to the final invoice. Applicable State & local tax will be added in.