Leadermac "518S" SmartMac 7" 5 Head Moulder  Ended

Ended

New machinery Never Used! - Miami, FL

- Winning Bid : $18,500.00 USD Sold

- 65 Bid(s)

- High Bidder: A****m

New Machinery Never Installed! Miami, FL ( Closed #39818781 )

By order of secured creditors! Featuring 2019 Leadermac 518S 5 Head Moulder, 2019 Cantek MRS-300 Gang Rip Saw, 2019, 2021 Cantek P630HV 24" Helical Head Planer, Plus Much More!

-

Pick Up Location

-

Make

Leadermac

-

Model

518S

-

Serial Number

2010003

-

Year

2020

-

Phase

3 PHASE

-

Voltage

230/460

-

Load Out Period

-

Estimated Dimensions

-

Estimated Weight

-

Seller Comment

-

Load Fee

$1000

-

page views

2746

SPECIFICATIONS

Thickness Material .4”(to 1/4” optional) to 5”

Width Material .6” to 7” (8” optional see optional cutterheads - below)

Min length of material 8” (Butt fed)

Axial adjust. side heads .8” (20mm)

Axial adjust. top/btm heads .8” (20mm)

Feed Speeds to 20-85 FPM (6-24 MPM)

Net weight approx. 8,200 lbs.

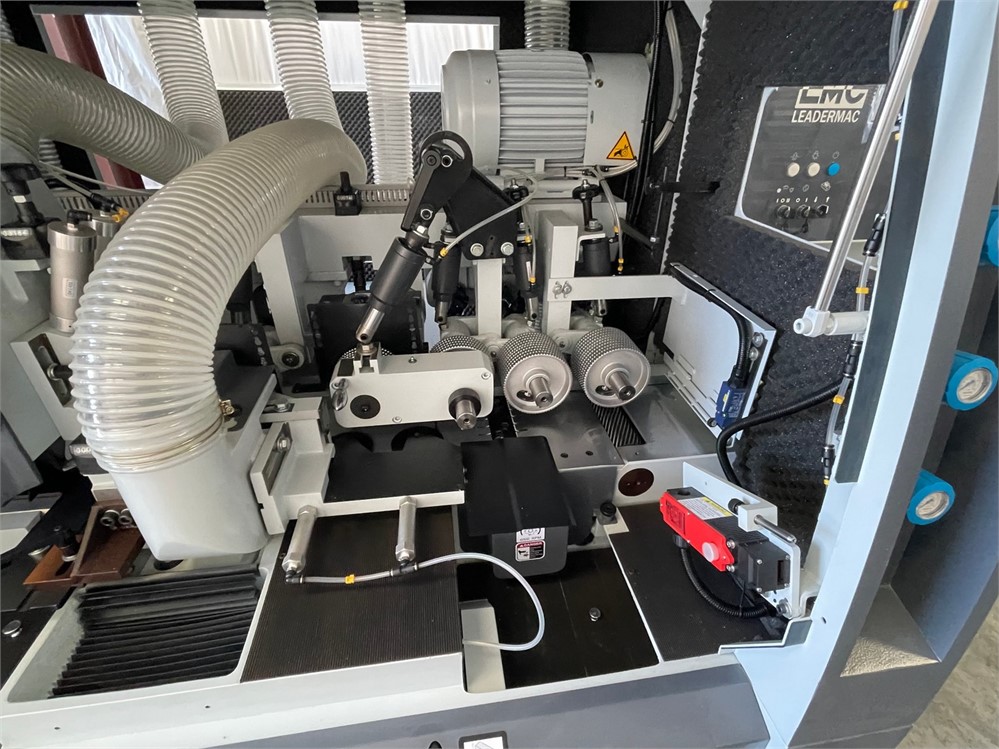

Maintenance free Full Cardan Shaft Drive to feedworks for balanced drive performance, with individual worm reduction gear box to each feed roller station

Powered rise and fall to extra heavy feed support beam by 1 hp/.75 kw motor.

Upper support Beam supported on large center column for most rigid upper beam support.

All feed rolls and pressures move with top beam rise and fall, including safety switches at extreme points.

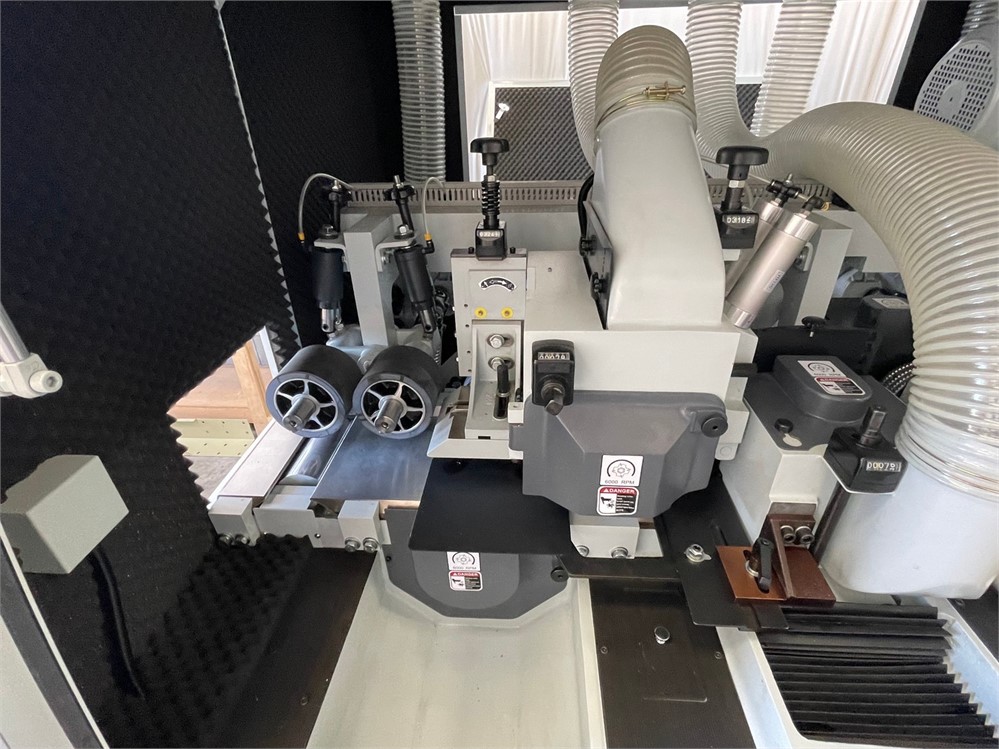

6 Top Driven Feed Roll Assemblies (each equipped with Multiple 2” wide rolls that can be quickly spaced/positioned or removed as desired)

2 Full Width Driven Bottom Feed Rolls

Top & Bottom rolls – before first bottom head

Full Width Bottom Driven Infeed Roll

Top/Bottom Full Width Powered Outfeed Rolls

Top Infeed Rolls with pneumatic rise and fall by switch

All Top Rolls are Pneumatically Tensioned.

Top Infeed driven serrated Steel feed rolls up to top head are hardened and satin chromed to resist wear and prevent chips and shavings from sticking to them

Polyurethane top feed rolls after top head

Intermediate short stock top driven feed roll station with pneumatic pressure for feeding minimum 8”(200mm) length work pieces. It is easily flipped up for rear side head removal.

Jog Forward & Jog Reverse to feed with duplicate remote located along the front of the moulder for fast and easy control – Remote includes Beam Up/Down

4 HP Variable Speed Drive to 20-85 FPM

All Heads are Standard 6000RPM and belt driven

40 mm diameter spindles

Edge reference straightening system

Adjustment of all spindles from front – Easy to operate stations

All spindles have horizontal and vertical adjustment, with mechanical digital readouts for fast and accurate setting, except 1st bottom head which has vertical only.

Vertical Spindle – Axial Adjustment – .8”

Horizontal Spindle – Axial Adjustment - .8”

Independent manual vertical adjustment to top head.

Siko Dual Counters on Near Side Head & Top Head Radial Adjustment for Quick Setup

Single Std Digital Counters included all Heads – other axis

Digital Readouts in Inch

1st bottom head supplied with spiral carbide cutterhead – with notching capability

- edge reference straightening system (including carbide insert knife head)

Set (of 4) Cutterheads Included, serrated back dual angle 10° / 20°

HEAD HP CUTTERHEAD SWING HOOD SIZE

1) Bottom Head 7.5 HP 5” to 6.3”(125 – 160 mm) 4.9” (125 mm)

2 & 3) Right Side/Left Side Heads 15 HP 4” to 7” (100 – 180 mm) 4.9” (125 mm)

4) Top Head 15 HP 4” to 8” (100 – 200 mm) 4.9” (125 mm)

5) 2nd Bottom Head 10 HP 4” to 8” (100 – 200 mm) 4.9” (125 mm)

Tables, Bedplates, Chipbreakers, Pressure Plate and Fences are Hard Chromed with approx. .012” - .014” chrome thickness(not flash Chromed) – giving you the best in wear resistance

Sectional Chip breakers before top heads with vertical screw adjustment and mechanical digital position readout

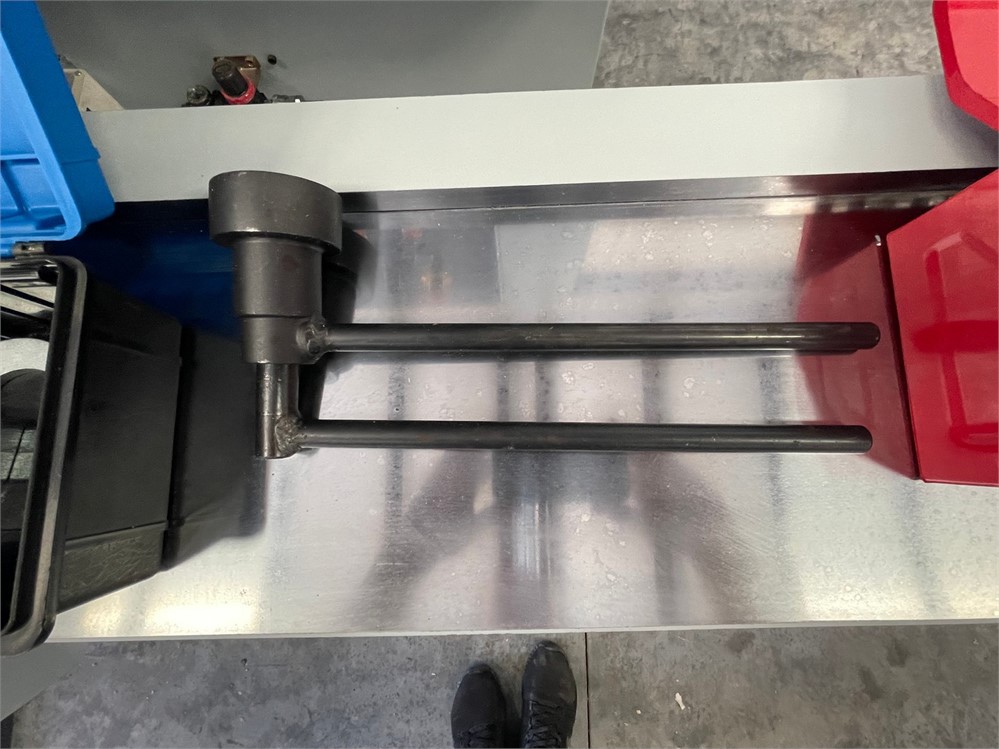

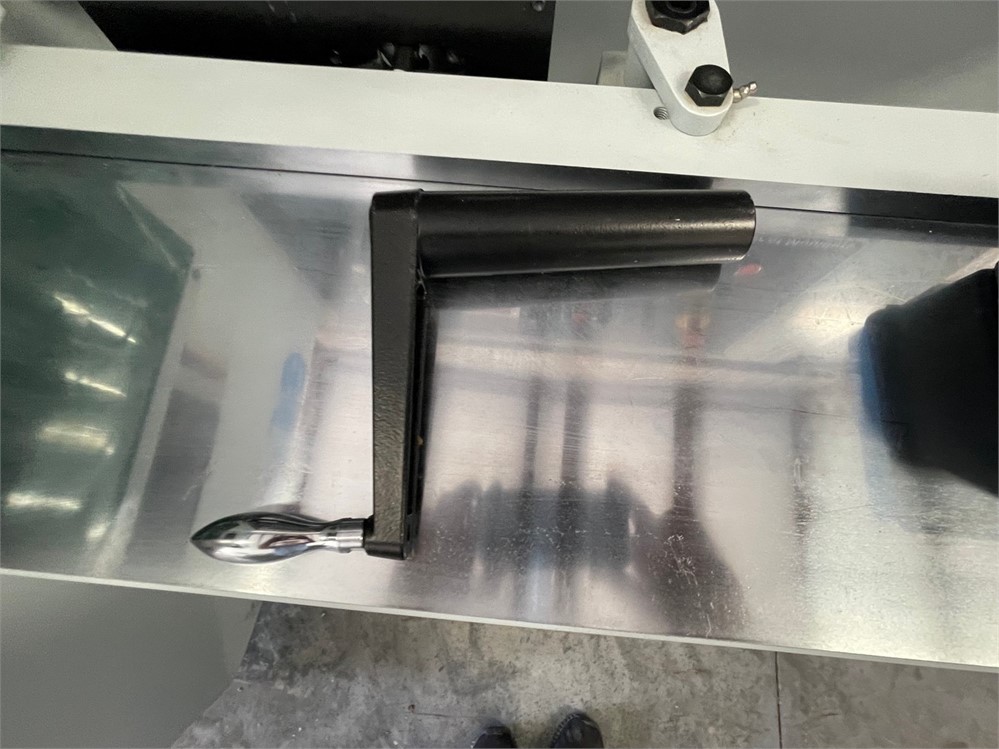

Hand pump bed lubrication system

Greasing of all critical points from central front of the moulder location(s)

Amperage Total – Amperage Total – based on 230 volt installation – 149 amps (460V – 75amps)

Control Voltage – 110 Volt

The listed specifications & information were taken from the manufacturer’s published information, internet research, or seller’s description.

The specifications & information are assumed to be correct; however, in no way, guaranteed. Bidders are encouraged to inspect the machine, call with questions, or contact the manufacturer for more information.

Please log in to view the bid history

LoginNo information available