Giben "KG 365" Edgebander  Ended

Ended

Tracy Warehouse Auction 131 - Tracy, Ca

- Winning Bid : $5,400.00 USD Sold

- 51 Bid(s)

- High Bidder: j****9

Tracy Warehouse Auction - Tracy, CA ( Closed #39326624 )

Nice selections of late model machinery, featuring: 2017 CPC Action FL Case Clamp, Striebig Compact Vertical Panel Saw, Northfield Double Sided Planer, Weinig Unimat 500 Moulder, Plus much more!

-

Pick Up Location

1905 N Macarthur Dr STE 110 Tracy, Ca 95376

-

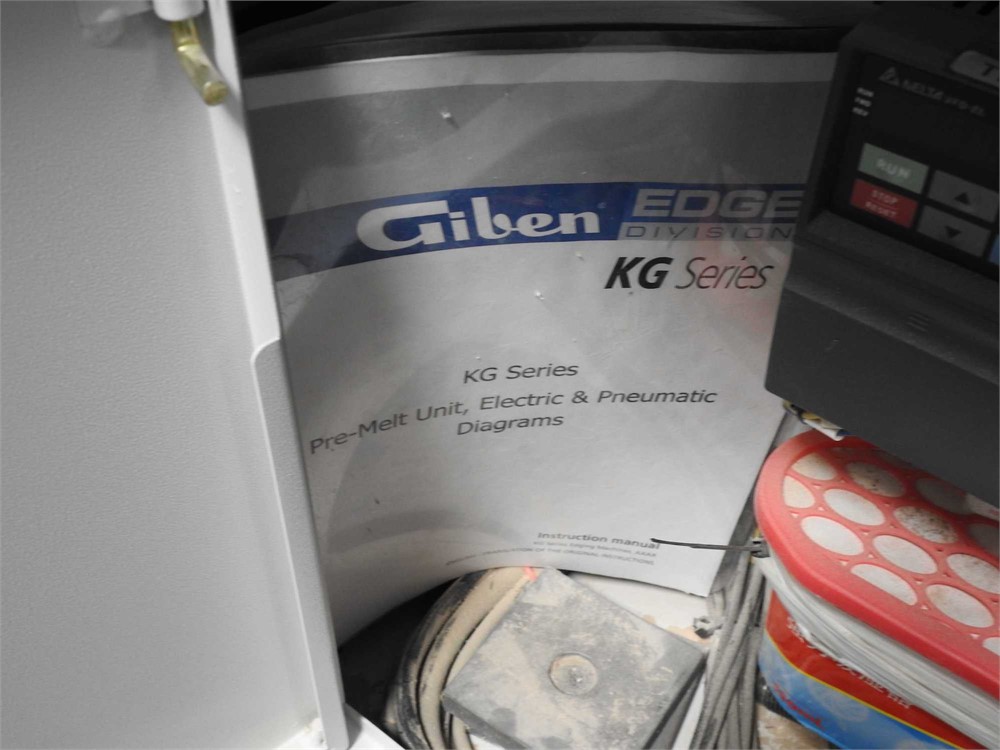

Make

Giben

-

Model

KG 365

-

Serial Number

3629310011

-

Year

2013

-

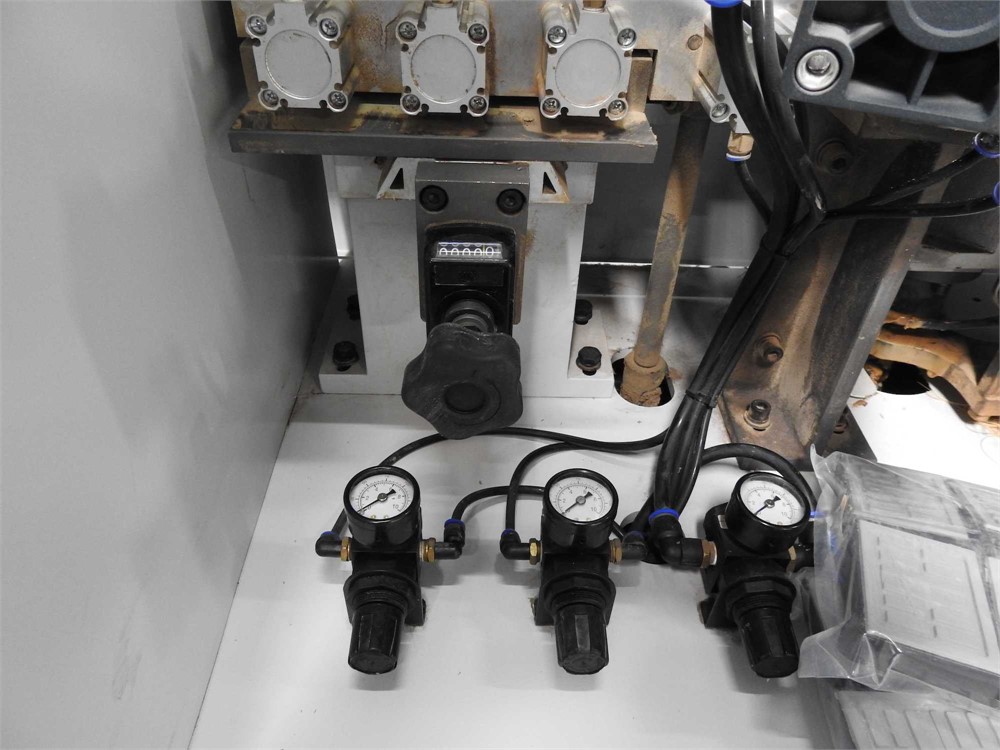

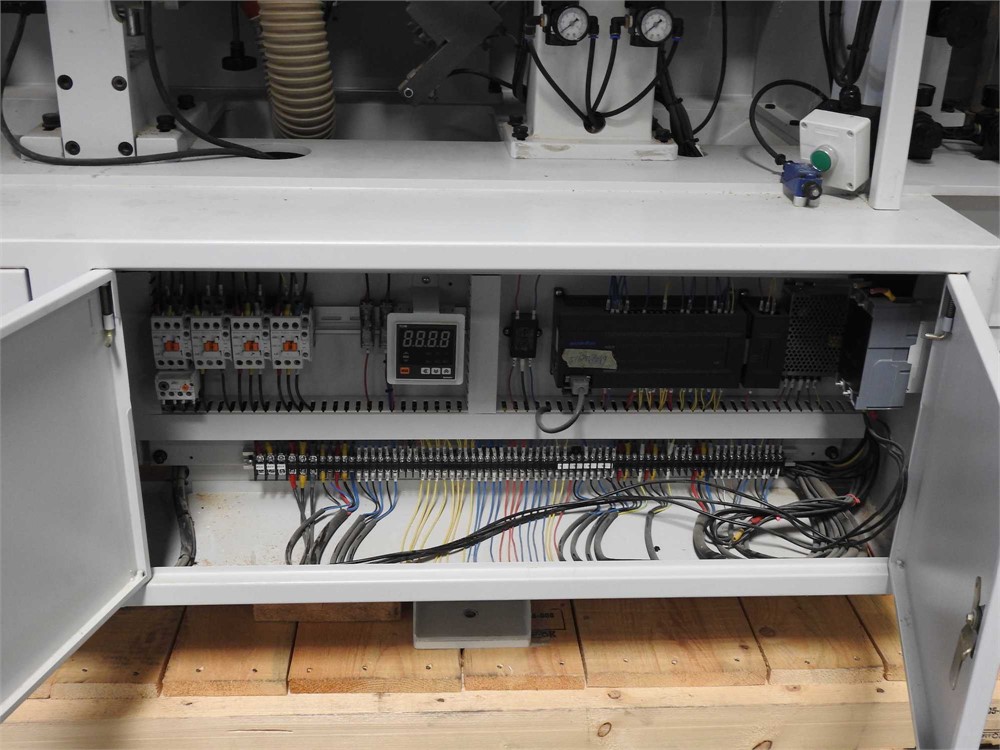

Phase

3 PHASE

-

Voltage

230/460

-

Load Out Period

September 23, 2022

-

Estimated Dimensions

-

Estimated Weight

-

Seller Comment

-

Load Fee

$200

-

page views

1848

**Specs. as per manufacturer website. Please do own due diligence as to exact specifications on this machine.

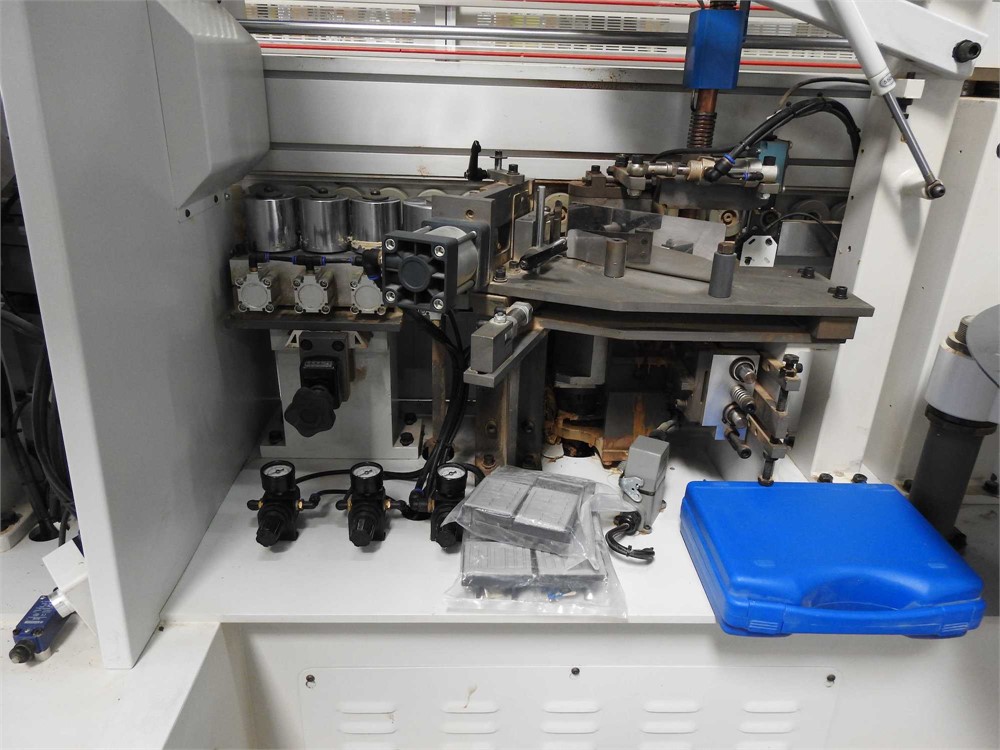

Giben features automatic loading of edgebanding material in rolls and glue application. Additionally the KG 365 is ideal for the application of veneer and coiled PVC from 0.4 up to 3 mm of thickness and strips up to 5 mm of thickness.

Standard Configuration:

- Speed 12-20 m/min. (may vary depending on additional groups)

- Chain drag with manual lubrication of the sliding guides

- Support bar at 700 mm. extractable

- Maximum panel height 60 mm.

- Maximum edge thickness 3 mm.

- Minimum length 120 mm.

- Minimum width 80 mm.

Guide for Effective Length 400mm

- In tempered iron steel

- Safety device for remote input panels by mechanical locking

- PLC FOR THE ADJUSTMENT OF GROUPS

- Control of each unit on/off speed

- For banding ABS and PVC edges or similar materials

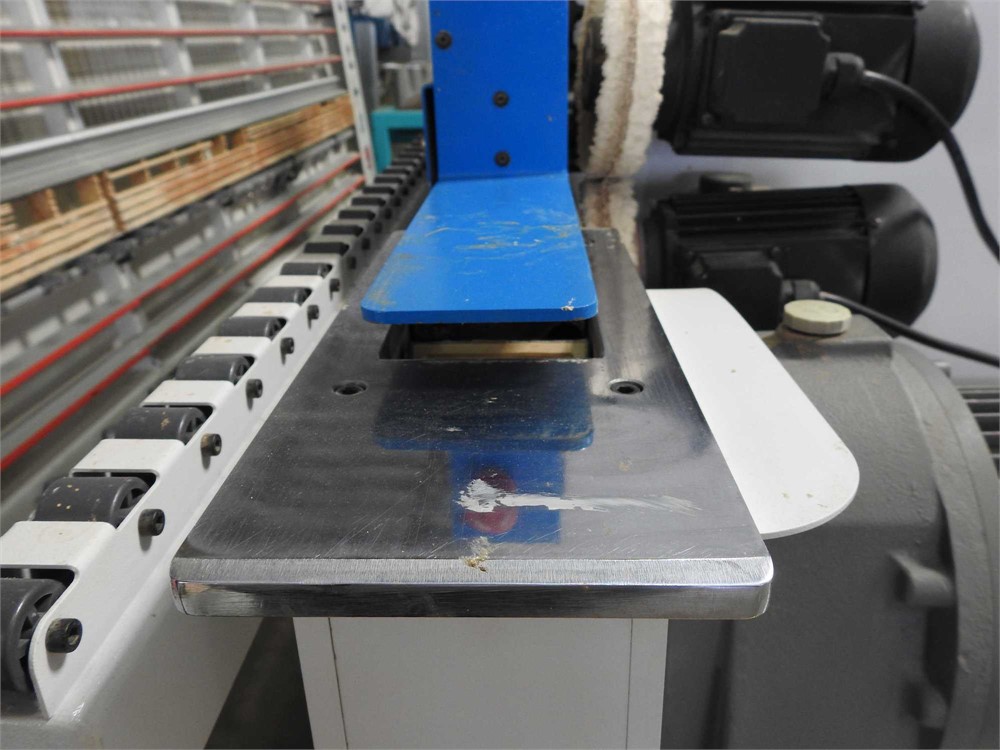

Plate for Edge Roll

- Autoloader with curled roller.

- Introduction of PVC and ABS edges.

- Shearing machine for cutting roll edges max 3 mm. thick.

Glue Group

- Automatic loading of edgebanding material in rolls and applying glue onto the panel. Glue pot for melting with fast heating; application roller with device to adjust the glue quantity that is applied on the panel; dual digital electronic control of the temperature in the tank and on the roller.

- 2 liter capacity roller height 65 mm.

- 2 resistors: one on roller 250 W and the second in a glue tank 1500 W.

- Temperature sensor roller.

Pre-Melting Glue System

- Quick change glue pot (top pot capacity 5KG lower pot capacity 2KG.

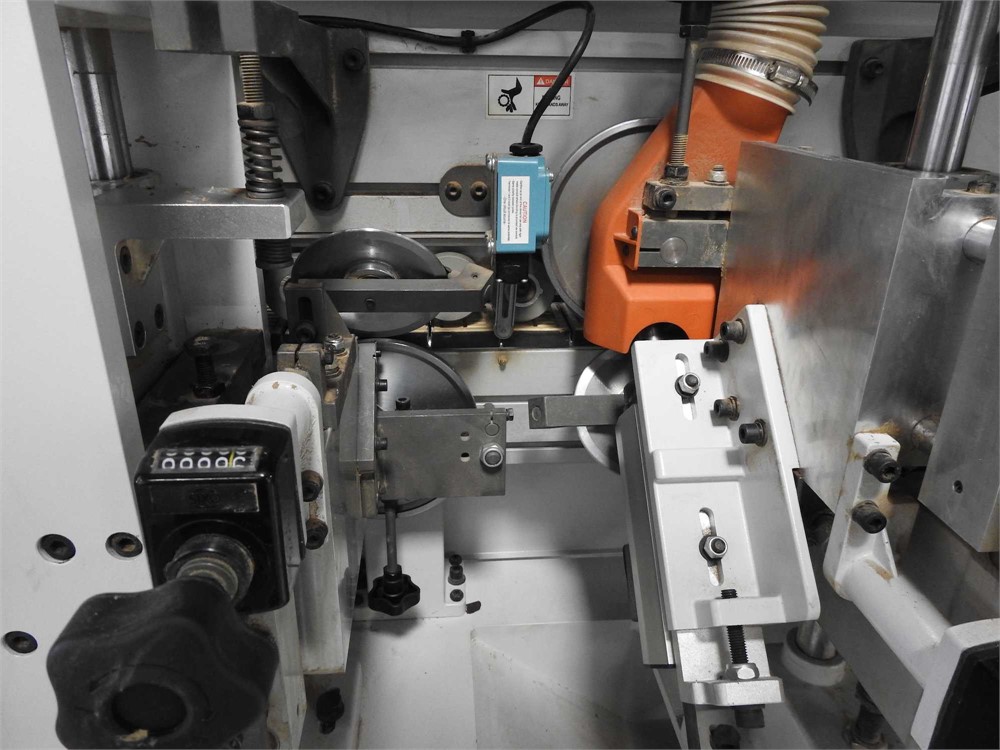

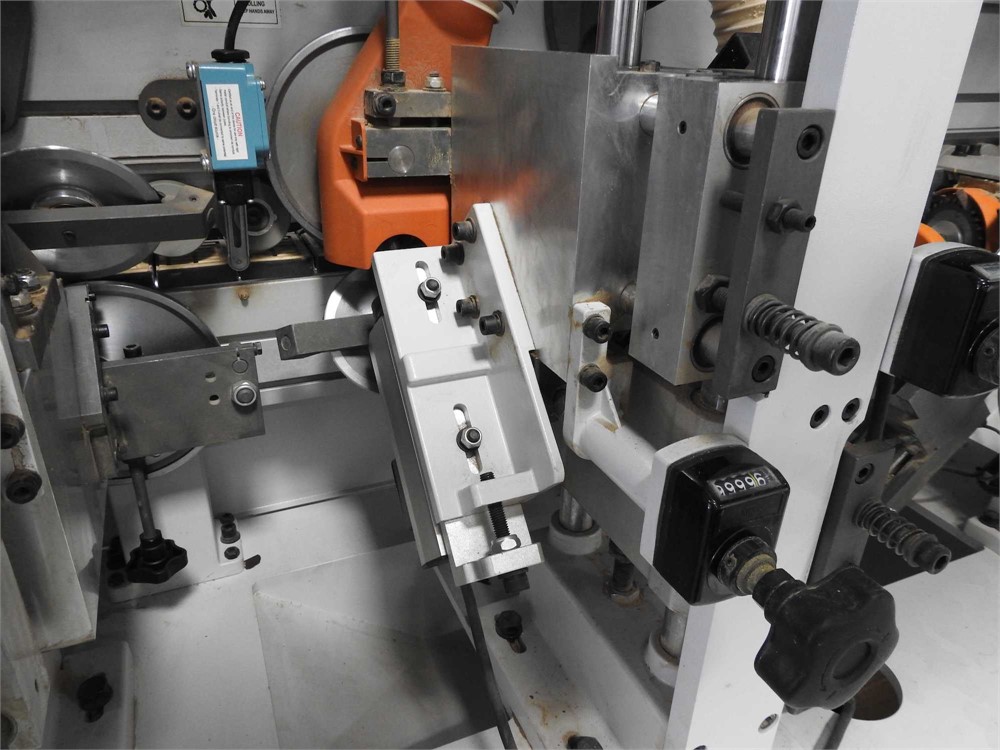

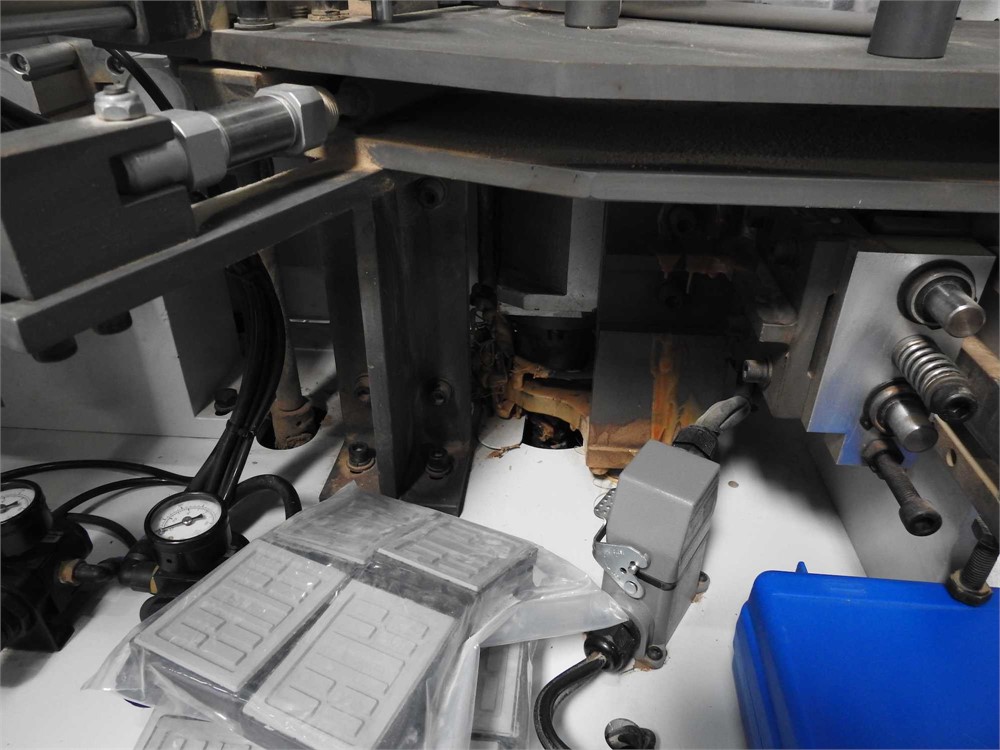

Profile Scraper:

- Removal of material to clean the profile shape from possible imperfections from the trimmer tooling.

- Tools included.

- Structure in cast iron solid base and vertical development.

- Manual tool adjustment.

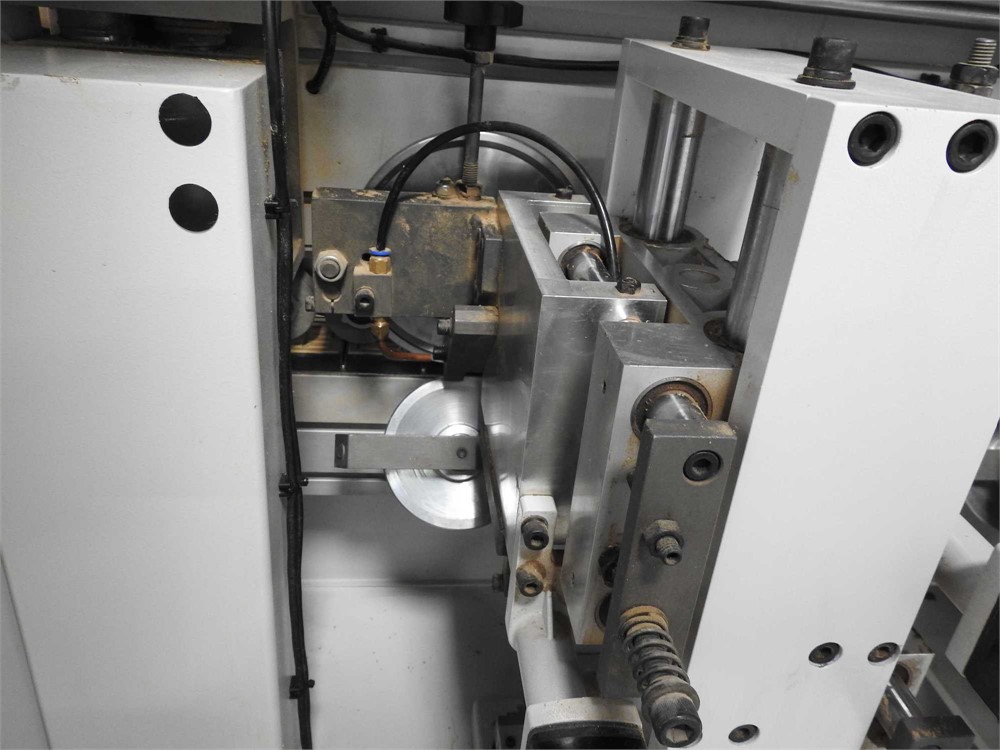

Cutting Head:

- Solid cast iron structure with vertical development and moving with motors on precision linear guides.

- 2 motors (0.35 kW) 12 000 min-1 200 Hz.

- Two position pneumatic adjustment (straight and angle).

- Blades (included):

- Diameter 104 mm.

- Internal diameter 32 mm.

- Thickness 2 mm.

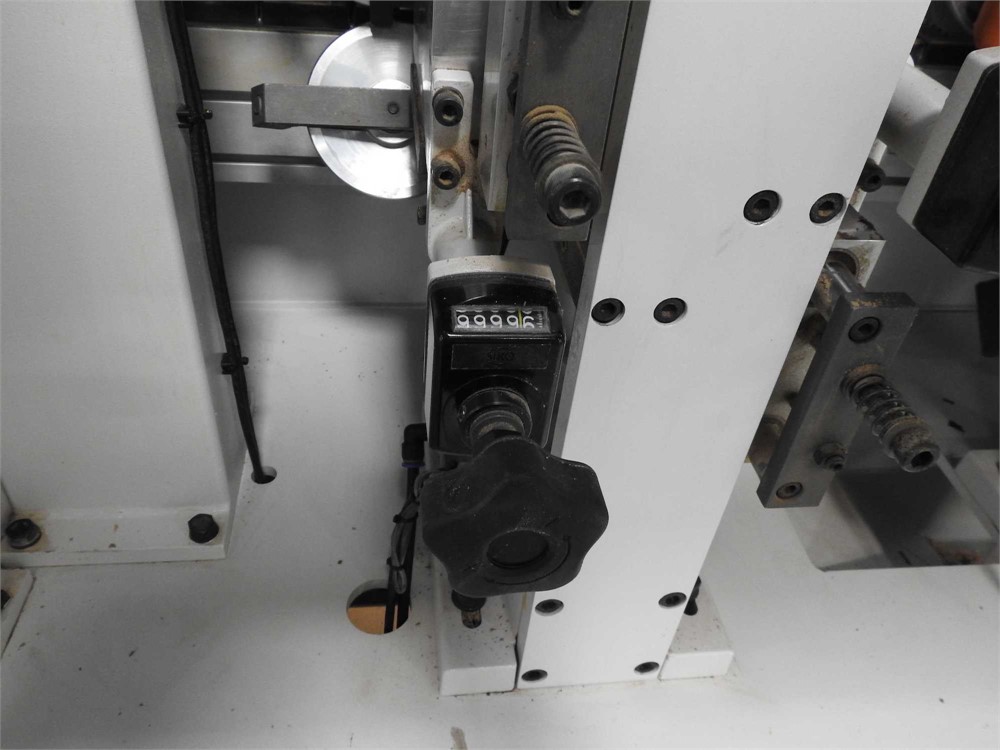

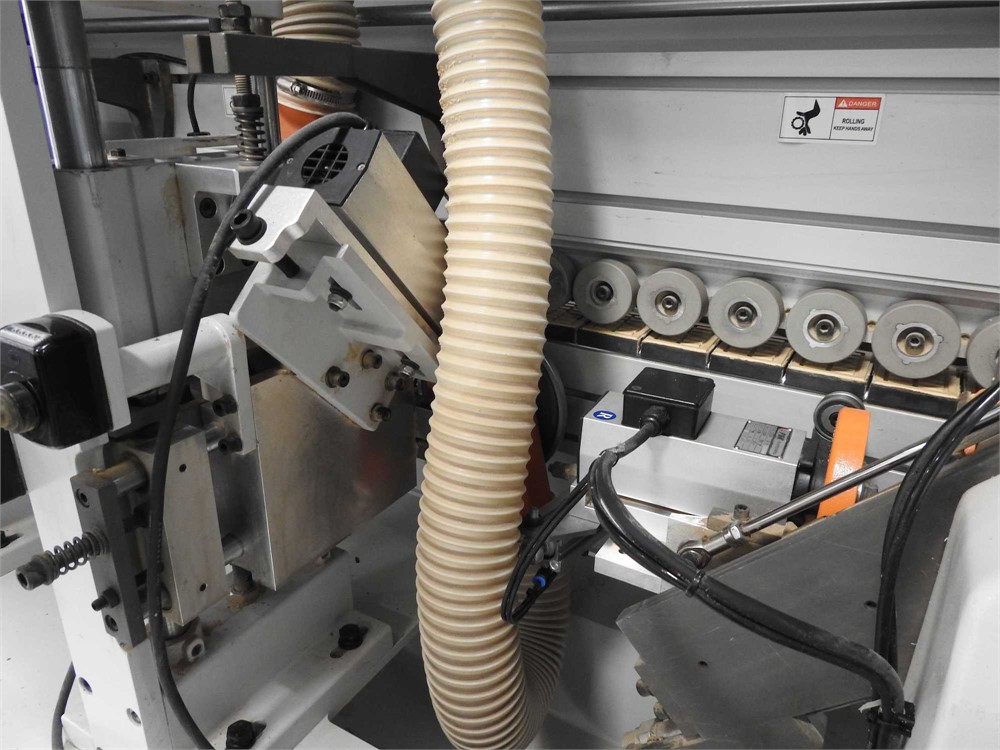

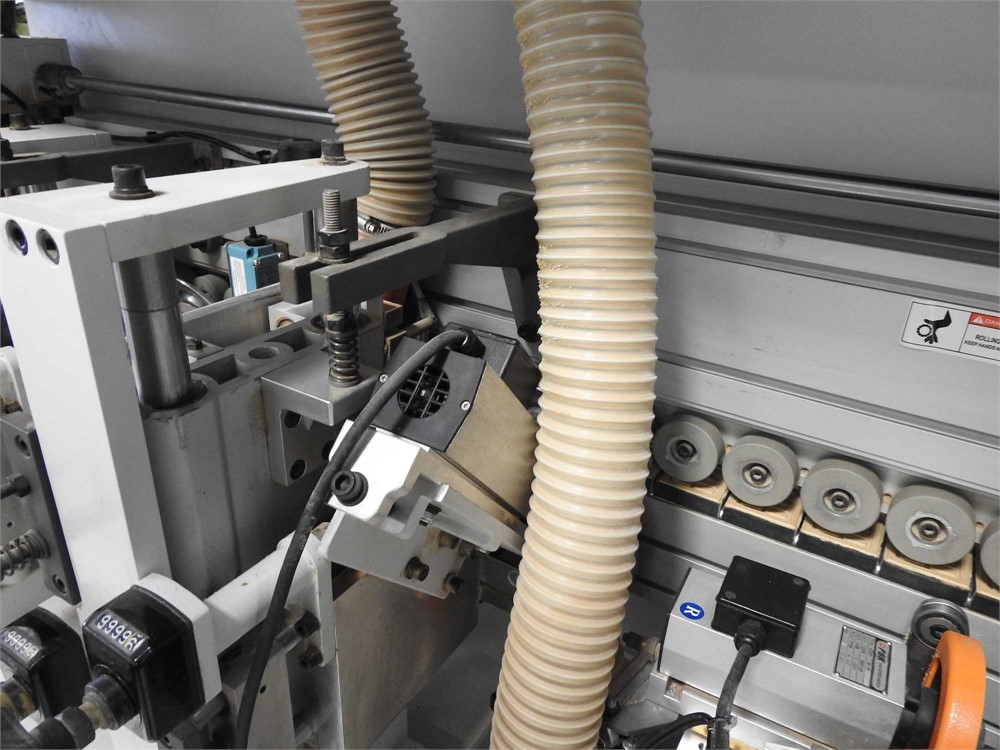

Top & Bottom Fine Trimming Group:

- 2 motors (0.7 kW) 18 000 min-1 300Hz

- each motor is equipped with manual groups adjustment.

- Tools with heads and cutters diameter 69 mm.

- Z6 with profiles on request.

- 3 mm tooling standard

Profile Scraper:

- Removal of material to clean profile shape from possible imperfections from trimmer tooling.

- Tools included.

- Structure in cast iron solid base and vertical development.

- Manual tool adjustment.

Buffing Unit:

- Two buffing wheels of resistant cloth for cleaning panels and boards.

- 2 motors (0.30 kW) 200 Hz 1 200 min.-1

The listed specifications & information were taken from the manufacturer’s published information, internet research, or seller’s description.

The specifications & information are assumed to be correct; however, in no way, guaranteed. Bidders are encouraged to inspect the machine, call with questions, or contact the manufacturer for more information.

Please log in to view the bid history

LoginNo information available