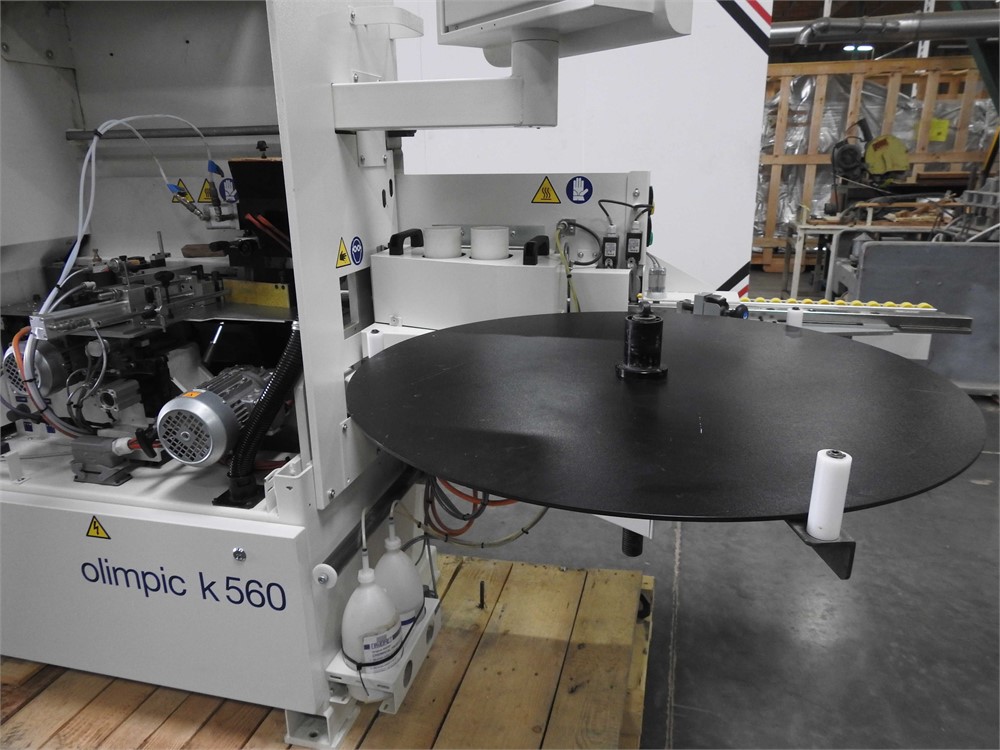

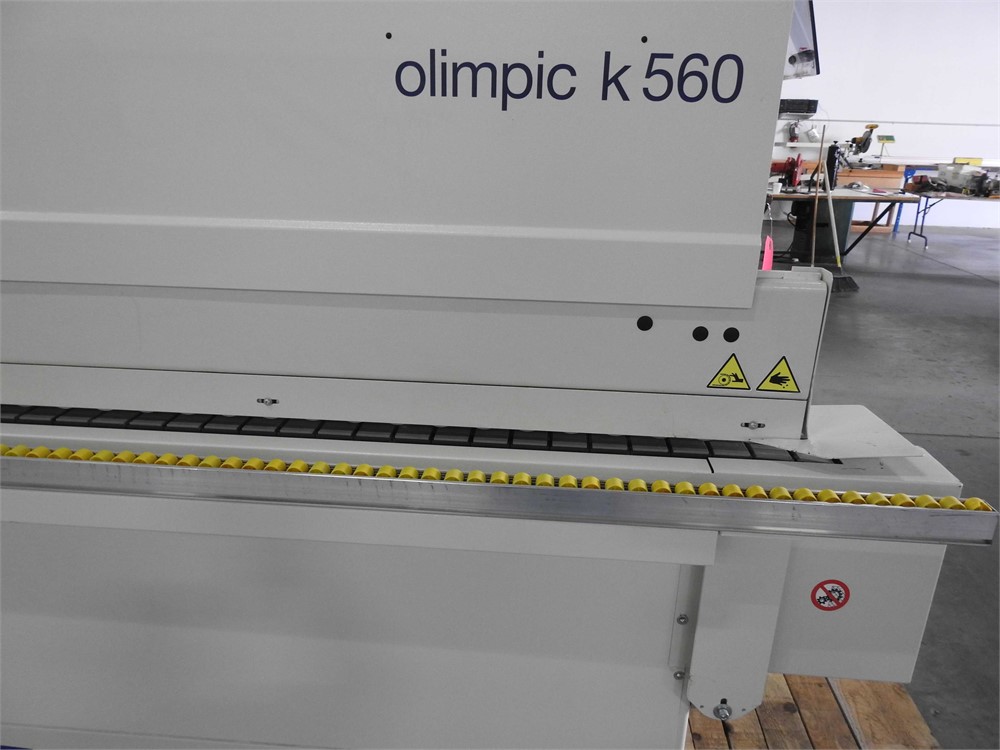

SCM Group "K560 ERT/HP/SGP" Automatic Edgebander, Year 2018  Ended

Ended

Large Woodworking and Warehouse Auction - Tracy CA

- Winning Bid : $33,000.00 USD Sold

- 94 Bid(s)

- High Bidder: m****y

Tracy CA Warehouse Large Auction, Over 150 Lots - Tracy, CA ( Closed #36721391 )

Over 150 Lots up for auction, including 2018 SCM K560ERT/HP/SGP Automatic Edgebander, Tiger Stop Systems and new Accessories, Industrial Showroom Display Case, Large Assortment of SAC Parts and Vitap Parts, Lumber Racks, Pallet Racks, Tooling, HolzHer Vertical Saw, Dust collectors, Power tools, Storage Cabinets, Carts, and much much more. Please contact Kirk @ 925-250-8248 or Sabrina at 209-839-7707 with questions or if you would like to view lots prior to auction close. Auction closes on Tuesday June 28th and all items need to be removed by July 6th.

-

Pick Up Location

1905 N. MACARTHUR DRIVE, SUITE 110, TRACY CALIFORNIA 95376

-

Make

SCM Group

-

Model

Olimpic K560 ERT/HP/SGP

-

Serial Number

AH/120935

-

Year

2018

-

Phase

3 PHASE

-

Voltage

230 VOLT

-

Load Out Period

July 6th, 2022

-

Estimated Dimensions

15' x 48" x 67"

-

Estimated Weight

Approximately 4200 lbs.

-

Seller Comment

-

Load Fee

$250 Load Fee

-

page views

2972

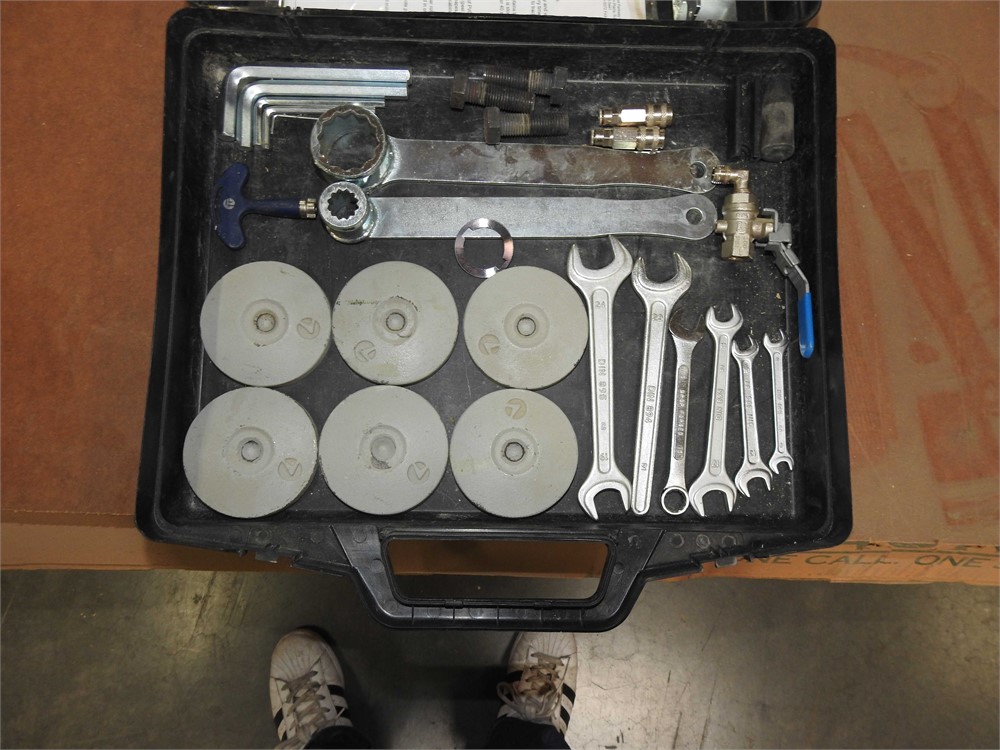

SCM GROUP MODEL #K560-ERT/HP/SGP Glue Pot AUTOMATIC EDGEBANDER

YEAR 2018 MANUFACTURED MACHINE

230 VOLT, 3-PHASE

SERIAL #AH/120935

SGP Glue Pot System

HP Servo Motor System

K 560 HP/ERT – Single Sided Edgebander

Automatic single sided edgebander designed to be used for edgebanding straight vertical profiles with coiled material (veneer and PVC) and with strips (high-pressure laminate and solid wood) with a maximum thickness of 8mm.

Machine Base

The machine base is made of a tubular steel structure and is designed to assure maximum stability and accuracy.

Electronic Top Pressure Beam

All operating units raise and lower simultaneously when the pressure beam is adjusted. No adjustment is required for the glue roller when changing panel thickness. The pressure beam has two rows of staggered pressure rollers with steel bearings.

Capacities and Speed

Glue Station

-

Edgebanding thickness: .4mm - 8mm (.016-5/16”)

-

Guillotine capacity: 3mm

-

Feed speed: 40/60 ft/min.

-

Panel height: 3/8” min – 2 1/8” max

-

Minimum panel length: 5 1/2”

-

Minimum panel width: 2 3/8”

-

Minimum distance between panels: 20”

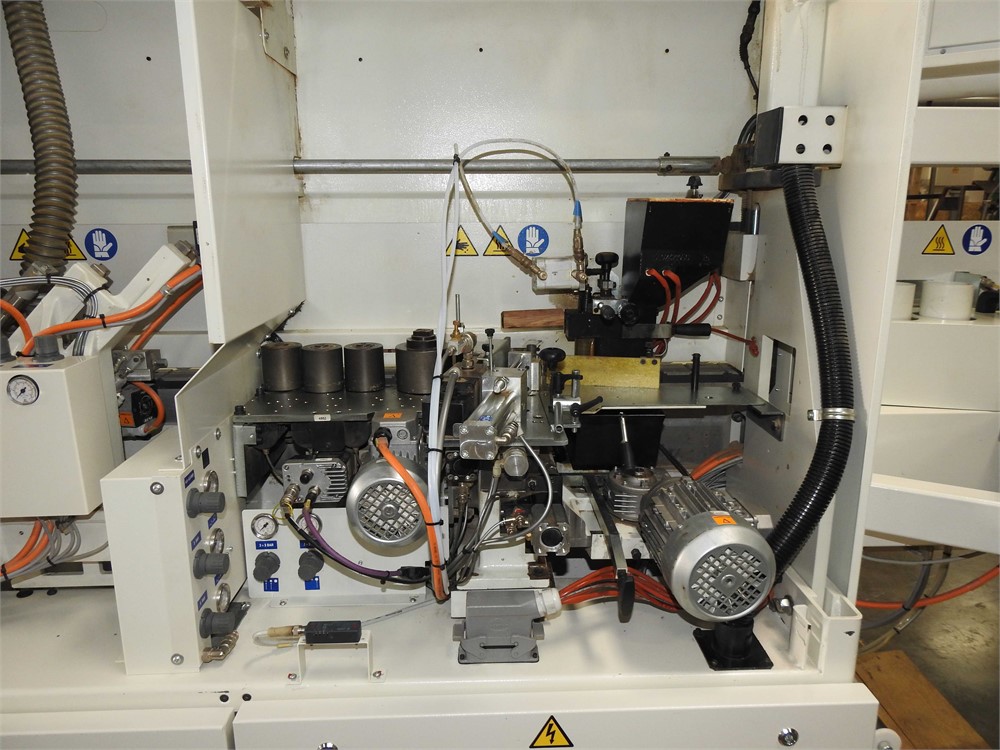

SCM Innovative "SGP" Smart Glue Pot System

Servo Driven Pressure Section

There are a total of four pressure rollers for pressing the banding to the workpiece edge. The first roller is powered and is also Teflon coated to prevent the banding material from slipping. The three idle rollers have opposing one-degree tilt to provide extra pressure along the top and bottom edge. The machine comes standard with an automatic strip magazine. Comes standard with servo driven positioning that requires no manual intervention from the operator. The glue pot is Teflon coated and has a 5.5lb. capacity. Comes equipped with a quick change feature that allows the operator to remove the glue pot in less than two minutes.

Startouch Controller

The K 560 comes equipped with the “Startouch” controller. This controller features a 12" touch screen display. Capable of storing 100 programs. Color graphic display of all the working units. Tracks production information, diagnostic information and monitors maintenance schedules. Choose mm's or inches, as well as 5 different languages. Swivels 270 degrees and tilts for easy access.

Anti-Adhesive

The machine comes equipped with an anti-adhesive unit positioned prior to the pre milling unit. It prevents the buildup of glue on the top and bottom of the panel. The unit comes with two independent nozzles and a tank of anti- adhesive liquid.

K560 HP/ERT

Adjustable Infeed Fence

The infeed fence is manually adjustable with a mechanical digital readout for determining stock removal.

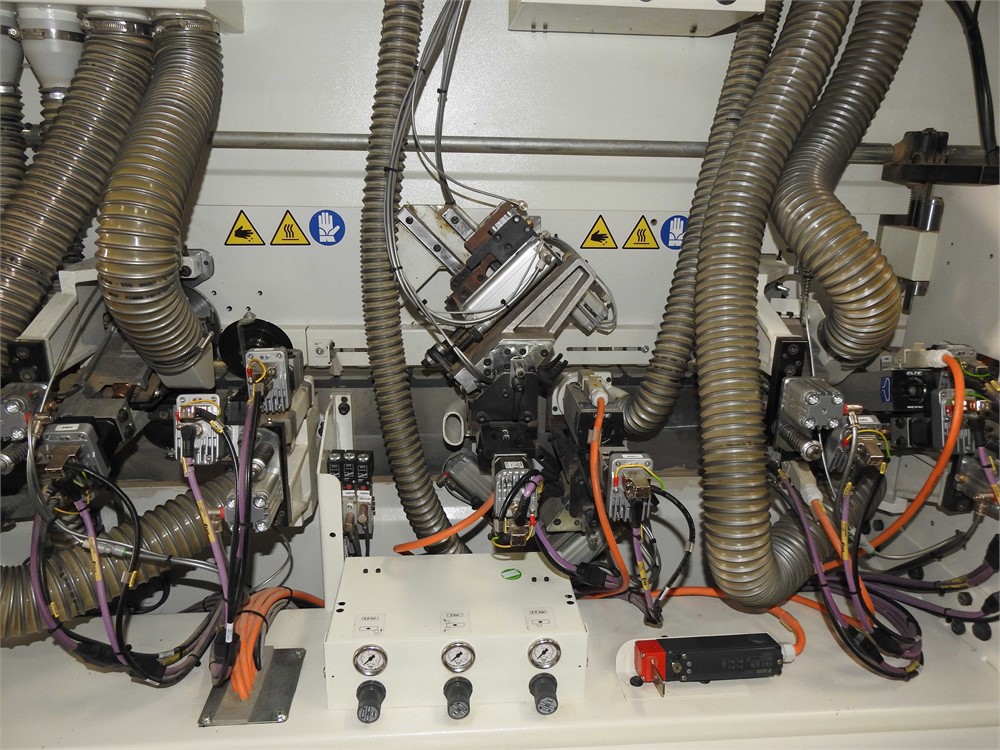

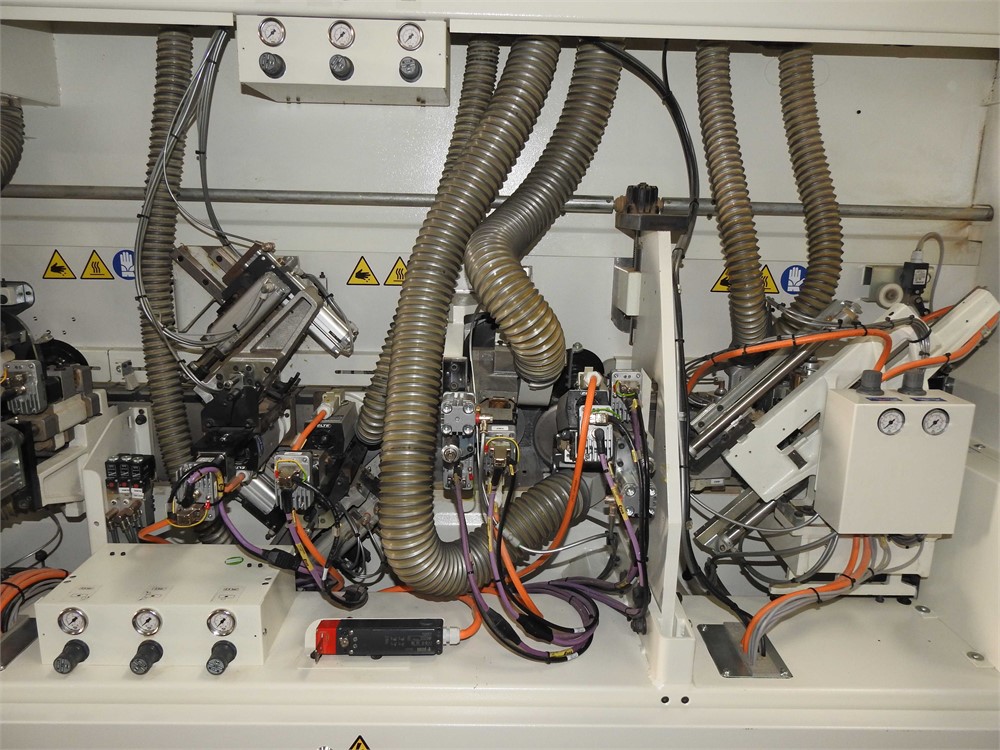

RT-V Pre-Milling Station:

To rectify/clean panels already sized and squared before the edge is applied. The unit is composed of two high frequency motors (2.0hp) with jumping action controlled through the PLC. The cutting heads are adjustable vertically. Diamond cutters are standard with 49mm height.

K-SEL 2” End Trimming Station

This unit is composed of two independent .50 hp motors mounted on THK guides. End trim utilizes a draw cut system for reduced blade projection on thick panels. The unit comes standard with automatic tilting of the unit from the control panel with two preset positions.

K560 HP/ERT

R-HP Multi Edge 2R Trimming Station

This unit is composed of two independent .7 hp motors operating at 12,000 rpm. It comes standard with servo positioning to process TWO different radii and infinite thin edges all through the controller. Independently controlled positioning, ie radius on top and straight edge on the bottom. Four different controlled axes adjustments. The unit has top/bottom/side copy wheels. The motors have quick release plugs to facilitate tooling changes. Unit comes equipped with the nesting package from the factory.

“ROUND-X” Multi Edge Corner Rounding Unit:

Two independent .50hp motors that slide on THK guides ensuring the highest quality finish. Servo positioning allows for the finishing of various thin edges and thick edge. Two controlled axes adjustments through the controller. Unit is designed to work as an additional set of trimmers for rounding the top/bottom as well as the front/rear corners of work piece with 3mm PVC edges. The unit is equipped with front and lateral copying devices and pneumatic blowers to clean the panel. Dust shrouds surround the cutter and travel with the unit as it trims. The unit can go from thin tape to 3mm PVC, through the controller, with no manual adjustments by the operator.

K560 HP/ERT

RAS Multi Edge 2R Profile Scraping Station

The profile scraping station designed to remove knife marks from thick PVC. The unit is equipped with servo positioning to process TWO different radii. Includes tool with two different radii, four controlled axes adjustments and the ability to independently control the top from the bottom. It has a large diameter horizontal copy wheel and side copy wheel device. Unit comes equipped with the nesting package from the factory.

K560 HP/ERT

RC-V Glue Scraping Unit

The unit eliminates any excess glue to help improve the quality of the glue joint. It comes standard with double copy wheels on the top and bottom of the panel, air blowers are standard to help keep the knives clean, the off fall is collected in the collection bin and it is pneumatically positioned through the controller.

SP-V Buffing Unit

The buffing unit has two .25 hp motors. It can also be tilted up to 12 degrees to provide a softer, more refined edge finish.

Acoustical Safety Enclosure

All working units are enclosed under an acoustical safety hood to reduce noise and prevent accidents. The hood has a safety microswitch which prevents the machine from operating when the hood is open.

Centralized Dust Extraction

Machine comes with two 3” ports for the premilling station, two 2” ports for the top and bottom trim station and one 3” port for the 3mm collection bin for extraction.

The listed specifications & information were taken from the manufacturer’s published information, internet research, or seller’s description.

The specifications & information are assumed to be correct; however, in no way, guaranteed. Bidders are encouraged to inspect the machine, call with questions, or contact the manufacturer for more information.

Please log in to view the bid history

LoginLoading Fees will be added to each auction item and will be posted on site. Loading fee is for side loading onto flat bed truck or trailer only. For items that Do Not having Loading Fees, Winning Bidder is responsible for Hand Load or Removal of items. Items like Storage Racks, Lumber Racks, Pallet Racks are to be loaded out by winning bidder.

Please note that all items need to be removed by July 6th.

Loadout Dates will be June 29th, 30th, July 1st, July 2nd(By appt. Only), and July 5th and July 6th. All items not removed by July 6th will be considered abandoned and no refunds will be issued.

All buyers agree to make full payment to MachineryMax, Inc. within 48 hours of the online closing date for the auction lots purchased. All invoices over $1,500.00 are to be made by bank wire transfer or cashier’s check payable to MachineryMax, Inc. Purchases under $1,500.00 may be made using Visa, MasterCard, or American Express (2% credit card processing fee will be added to the invoice). All payments are to be made in USD currency only. Bidder represents and warrants to MachineryMax, Inc. that such bidder has immediately available funds to fully pay for its successful bids within 48 hours of the online closing date. All payment questions should be directed to Sabrina Burns at 209-839-7707 or [email protected] All buyers agree that there will be a 15% Buyers premium that will be added to the final invoice.

Sales Tax: All purchases from this auction will be subject to 8.25% California / San Juaquin County Sales Tax unless the purchaser is exempt.

Sales Tax Exemption: All buyers claiming exemption from sales tax will need to provide MachineryMax INC with a properly filled out and executed California Sales Tax exemption certificate prior to buyers removal of purchased items.