Heesemann "MFA Impression CLLef DB-S" 53" 4 Head Wide Belt Sander (2020)  Ended

Ended

Group Delphi - Complete Plant Closure - Day 1 - Alameda, Ca

- Winning Bid : $126,151.00 USD Sold

- 102 Bid(s)

- High Bidder: m****s

Group Delphi - Complete Plant Closure - Day 1 - Alameda, Ca ( Closed #33286817 )

Day 1 - Lots 001-299

Open House will be April 20-21, 2022 - 8AM to 4PM local time. Open House Manager - Jack Ragan - 503-806-4611 - [email protected]

For Rigging/Loading quotes, Please Contact: Marco Salinas @ West Coast Movers, 323-588-3533 or [email protected]

-

Pick Up Location

950 W Tower Ave STE 5049 Alameda, Ca 94501

-

Make

Heesemann

-

Model

MFA Impression CLLef DB-S

-

Serial Number

2020.02.211

-

Year

2020

-

Phase

3 PHASE

-

Voltage

480 VOLT

-

Load Out Period

Please see Home Page for Final Removal Date Information

-

Estimated Dimensions

128" X 90" X 96"

-

Estimated Weight

-

Seller Comment

Aaron @ All-Ways Trucking @ 541-608-6532 or John @ NCL Trucking @ 615-452-7651

-

Load Fee

A rigger is required for this lot. Please Contact: Marco Salinas @ West Coast Movers, 323-588-3533 or [email protected]

-

page views

5628

New in 2020!

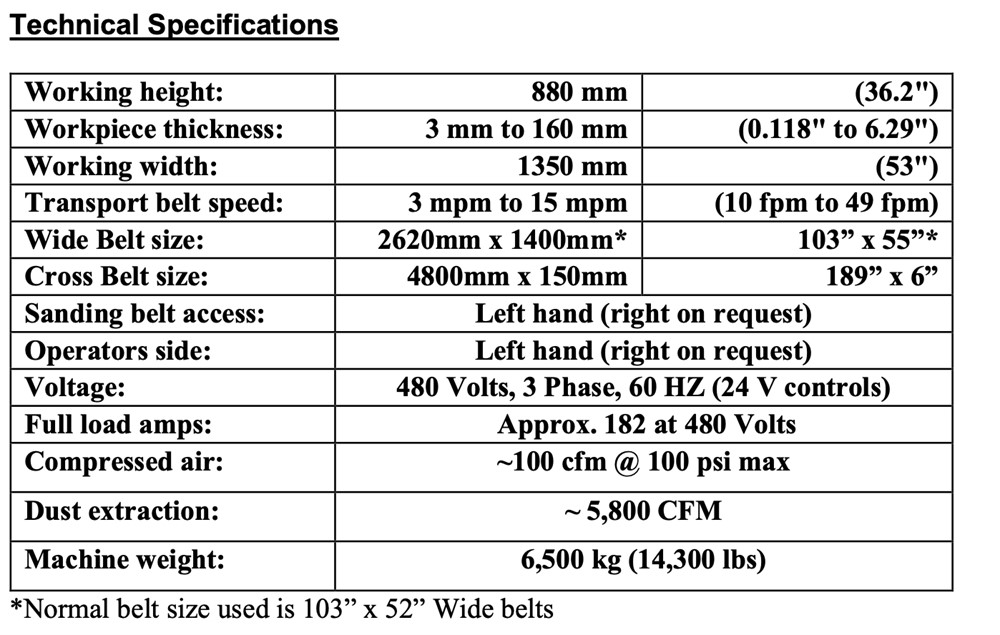

See original Quote attached with Specs ABOVE.

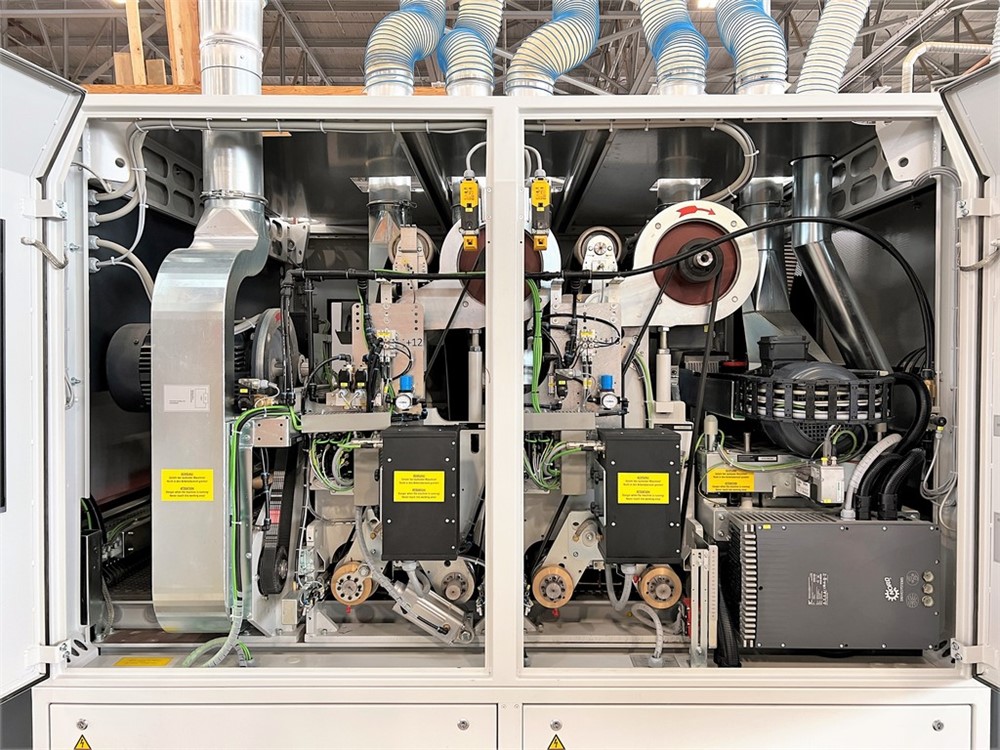

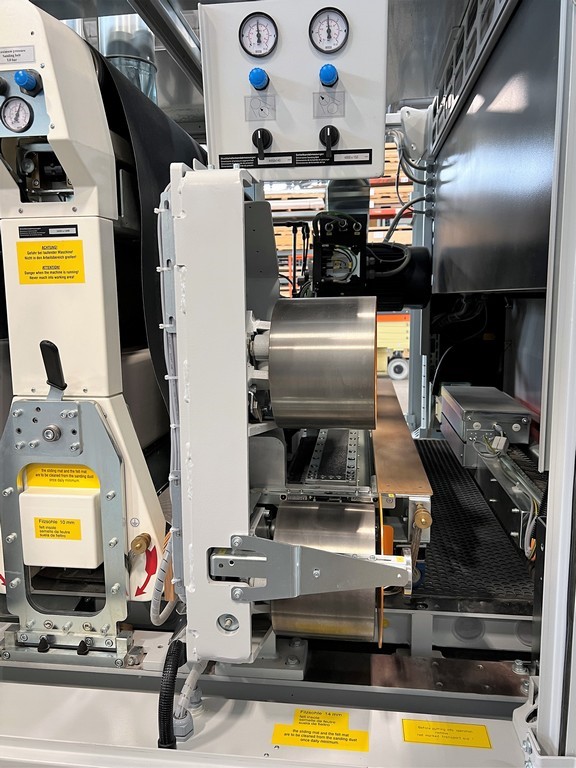

Heesemann MFA Impression Frame

Heesemann is known for manufacturing long-lasting sanders that begin with a durable welded steel structural frame as well as a heavy gauge formed and welded steel housing. Heesemann’s unique frame design uses I-beams to lift the sanding units and is driven by a drive shafts system for fast, accurate and stable height adjustment and maximum machine stability. Each sanding head has its own structural frame, making the machine extremely rigid. The MFA Impression comes standard with:

• Thickness adjustment of sanding units from 3-160mm (1/8” -6 1⁄4”) • Constant pass line height with no pinch points

• An over-thickness control system

• An emergency stop at machine infeed and outfeed

• A hold-down roller system at the machine infeed machine to safely transport thin and warped workpieces into the sander

Heesemann's MFA Impression transport conveyor features:

-

V ariable speed drive system

-

Variable feed speed 3 to 15 mpm (10 to 49 fpm)

-

Sanding width 1350mm (53 inches)

-

A transport belt with 1⁄2" diamond profiles and one-piece construction

-

Automatic tensioning & tracking

-

Clean out ports located on feed bed for easy access and cleaning

Press on Roller 50mm

A press on roller at machine infeed pushes down workpieces and controls for excessive workpiece thickness.

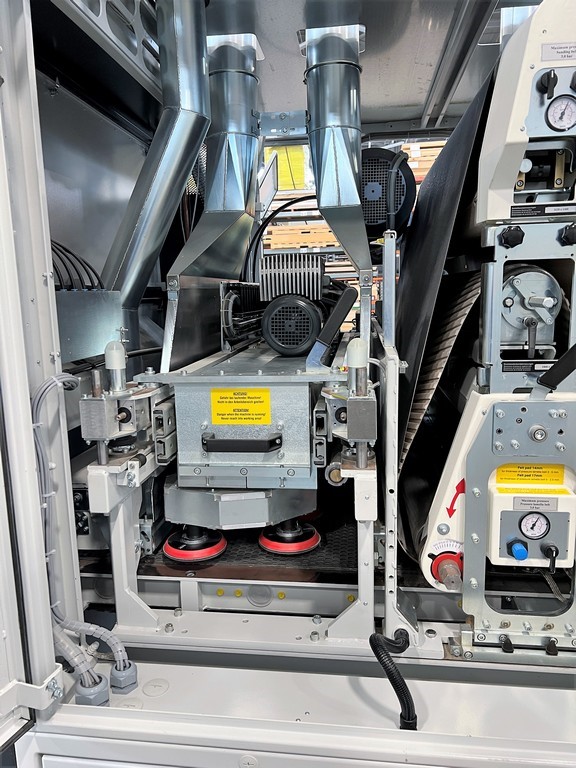

Vacuum Hold Down

This sander is equipped with vacuum hold down for safe movement of workpieces shorter than 500 mm (19.7") in feed direction. Heesemann’ s unique frame design integrates rigid vacuum plenums for maximum vacuum hold down force and eliminates hoses that are traditionally found on vacuum hold down systems. Heesemann also has a special vacuum table design to help evacuate dust and maximize vacuum suction – producing the strongest vacuum hold down in the industry.

Binding Posts

This machine is equipped with interlocking of emergency stop and feed, which is necessary when linked in a line of machines.

Emergency Stop

Emergency stop buttons are located at the machine outfeed, with one located on the right side and one located on the left side of the machine.

Doors with Glass

Doors have glass inserts for visual inspection while machine is operating

Industrial PC

This sander is equipped with a 21.5" high resolution touch screen / industrial PC and features: • High resolution display

• CFcard1GB

• Windows® embedded operating system

• Pendent mounted with adjustable viewing position • Ethernet connection

• Configured as web address for easy network access • Automatic on-screen diagnostics

• Metric or English input • 100 memory addresses

• Alpha/numeric format

• Password protected • Digital keypad input

• Workpiece thickness

• Conveyor belt feed speed • Sanding pressures

• One button start

Battery Backup

For abrasive belt oscillation

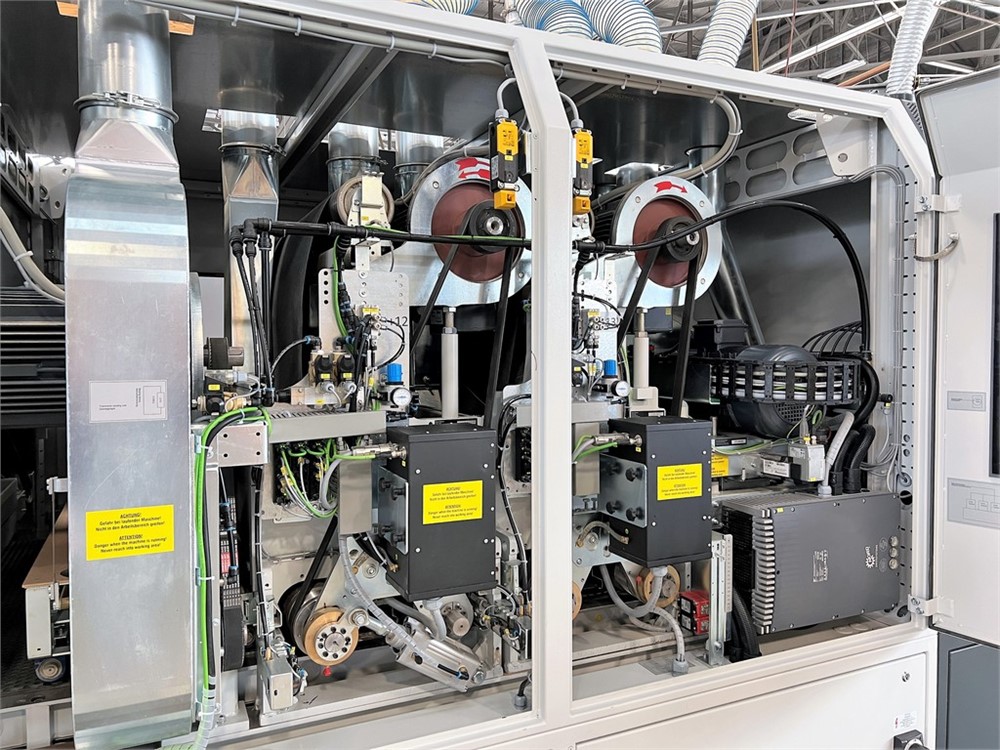

Head 1: C Head – Cross Sanding Unit

Heesemann's cross sanding head unit removes fiber from solid wood or can be used to remove tape from veneer in preparation for finishing. This C head features:

• CSD® segmented pad system

• A pinch roll system, rubber covered and adjustable

• An automatic infra-red belt control

• Servo cross belt tracking adjustments, for quick and easy belt centering when loading • Internal drive motor with electronic braking and adjustable tensioning; also includes:

• C-Flange mounted

• "Poly-V" one piece drive belt

• Pneumatic abrasive belt cleaning at bottom that is timed with workpiece

Variable Speed Belt

• This sanding unit is equipped with an inverter motor which allows for variable abrasive belt speeds, ranging from slow to fast belt speeds.Sanding belt size: 4800 mm x 150 mm Sanding belt speed: 2 to 20 mps Drive size:17.4 kW

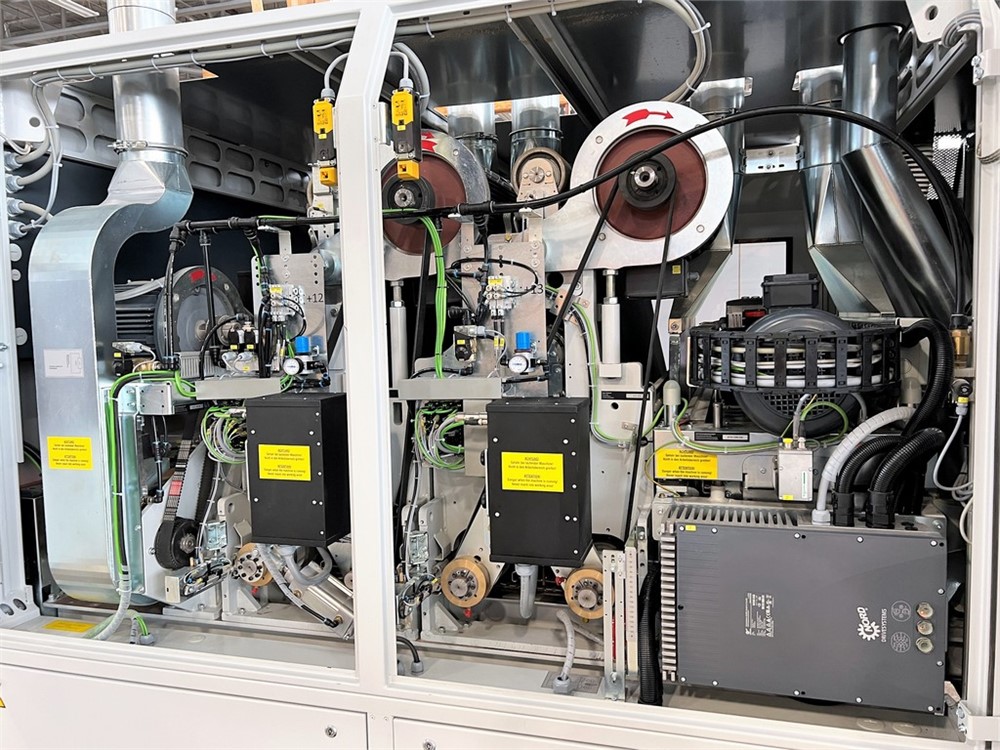

Head 2: L Head – Combi Longitudinal Sanding Unit

Heesemann's Longitudinal “L” head is suitable for finish sanding or light calibration. This head includes:

• Sanding belt running against feed direction

• CSD® segmented pad system

• Eccentric bearing for the front high speed drive roller for light calibration

• Automatic sanding belt grit compensation (for calibration) controlled via controller • A pinch roll system, rubber covered and adjustable

• An automatic infra-red belt control

• Internal drive motor with electronic braking and adjustable tensioning; also includes:

• C-Flange mounted

• "Poly-V" one piece drive belt

• Pneumatic abrasive belt cleaning at bottom that is timed with workpiece

• Sealed cleaning tube

Variable Speed Belt

This sanding unit is equipped with an inverter motor which allows for variable abrasive belt speeds, ranging from slow to fast belt speeds. Sanding belt size:2620 mm x 1400 mm Sanding belt speed:1.8 to 18 mps Drive size:17.4 kW

Contact Roller on Combi Head

Steel roller for calibration – helically grooved • 130mm diameter

Head 3: Lef Head – Longitudinal Sanding Unit with Inner Pressure Belt

Heesemann's longitudinal enhanced finish Lef head features an inner chevron belt to allow for fine sanding of the workpiece. This head includes:

• Internal pressure segment belt

• Sanding belt running against feed direction

• CSD® Segmented pad system

• Eccentrically adjustable drive drums for facilitating adjustment of the sanding unit for

different chevron belt thicknesses, as well as for operation without chevron belt if desired

• A pinch roll system, rubber covered and adjustable

• An automatic infra-red belt control

• Internal drive motor with electronic braking and adjustable tensioning; also includes:

• C-Flange mounted

• "Poly-V" one piece drive belt

• Pneumatic abrasive belt cleaning at bottom that is timed with workpiece

• Sealed cleaning tube

Variable Speed Belt

This sanding unit is equipped with an inverter motor which allows for variable abrasive belt speeds, ranging from slow to fast belt speeds.

sanding belt size 2620 mm x 1400 mm

belt speed with pressure segment belt 1.8 to 9 m/s

belt speed without pressure segment belt 1.8 to 18 m/s

drive size 17.4kw

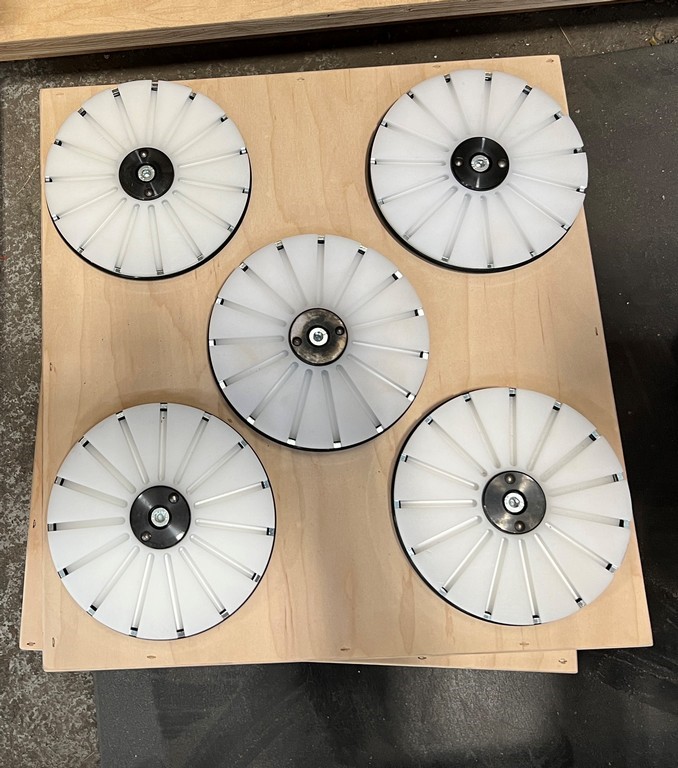

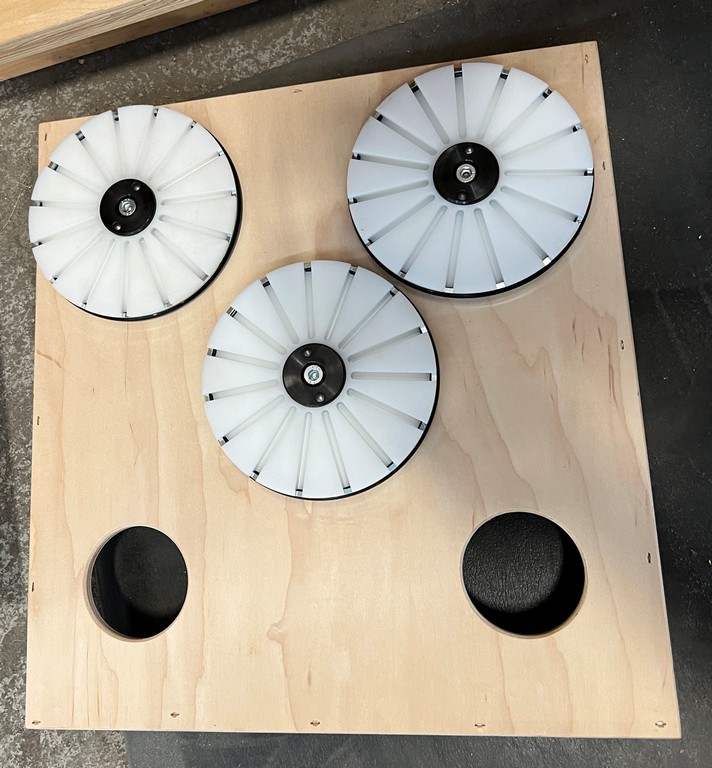

Head 4: DB-S Head – Rotating Planetary Sanding Unit

Heesemann's rotating planetary sanding unit incorporates sanding discs for the purpose of smoothing the work surface along with effects sanding. This head includes:

• 10 driven brush discs with quick changing device • Rotation in both directions

• Central height adjustment

• 4 kW (5.3 Hp) motor to power the discs

• 1.5 kW (2 Hp) motor gear box

• Brush trimming: Flex Trim

• Brush Diameter: 150 mm (6”) • Other brush discs available on demand

CSD® - Segmented Pad System (10 Year Warranty) (3x)

Only Heesemann features a state-of-the-art electro-magnetic segmented pad system with an interlocking design for consistent sanding of irregular shaped work-pieces. Heesemann's CSD® segmented pad system also includes:

• 100% electronic stepless pistons – pressure is applied smoothly to work-piece • Maintenance-free pistons – no oil, water or other materials to maintain

• A sealed enclosure keeps dust and other particles out

• Precise surface pressure control allows for a consistent finish

• Precise edge pressure control so pressure is applied to the work-piece consistently and evenly

• Edge pressure operates independently from the work-piece surface • Pressures that are stored and controlled in IPC

• Single or multi-track control of edge pressures

• Three (3) rollers per segment

• 21mm roller spacing

• Non-mechanical, magnetic switches activate the segmented pads are ideal as there

are no moving parts to worry about

• Thickness compensation; 2 mm within and 2 mm between work-pieces

• Adjustable sanding start/stop that can be administered from the controller • Interlocking phenolic segments

Segmented Workpiece Blasting Device

Rotating compressed air nozzles for blasting workpiece surface. Only operate if a workpiece is present.

-

Each rotor is separately controlled according to part size to preserve compressed air

-

A conveyor belt cleaning program is included in the software, which lowers machine

height and cleans conveyor belt 1 complete rotation.

Energy Management System

This sanding machine is equipped with an automatic frequency inverter motor control system which allows for a system standby mode with the machine is not in use. Machine can idle and vacuum can turn off to preserve energy and avoid machine wear and tear, without required a separate machine startup when ready to run

-

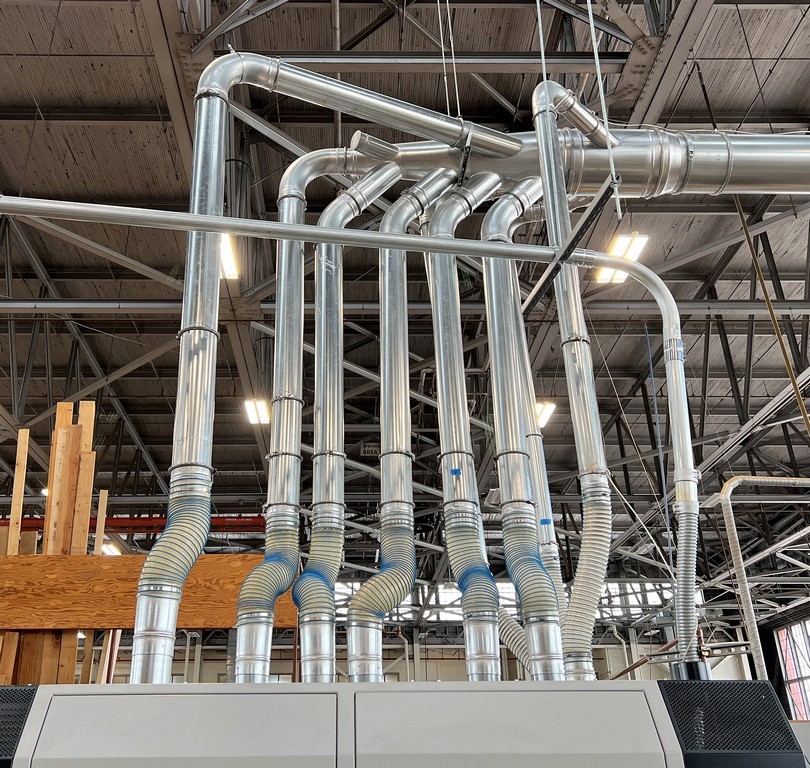

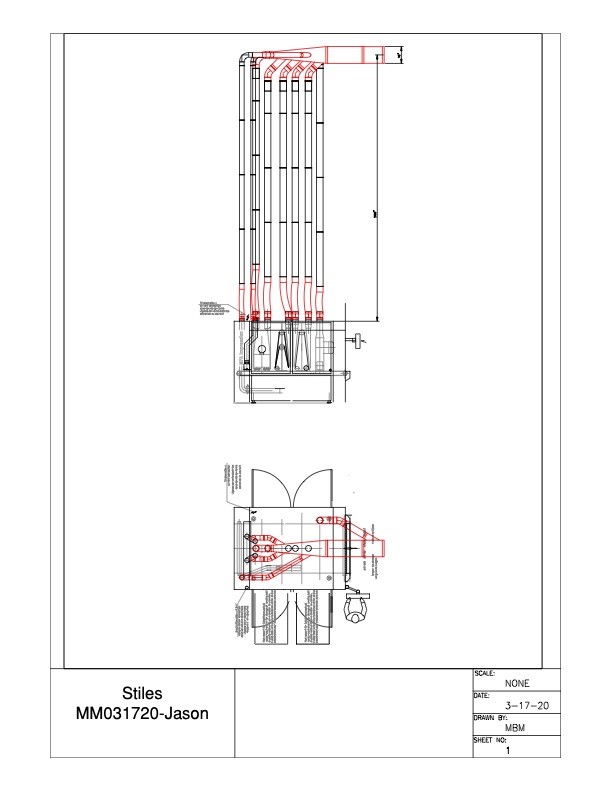

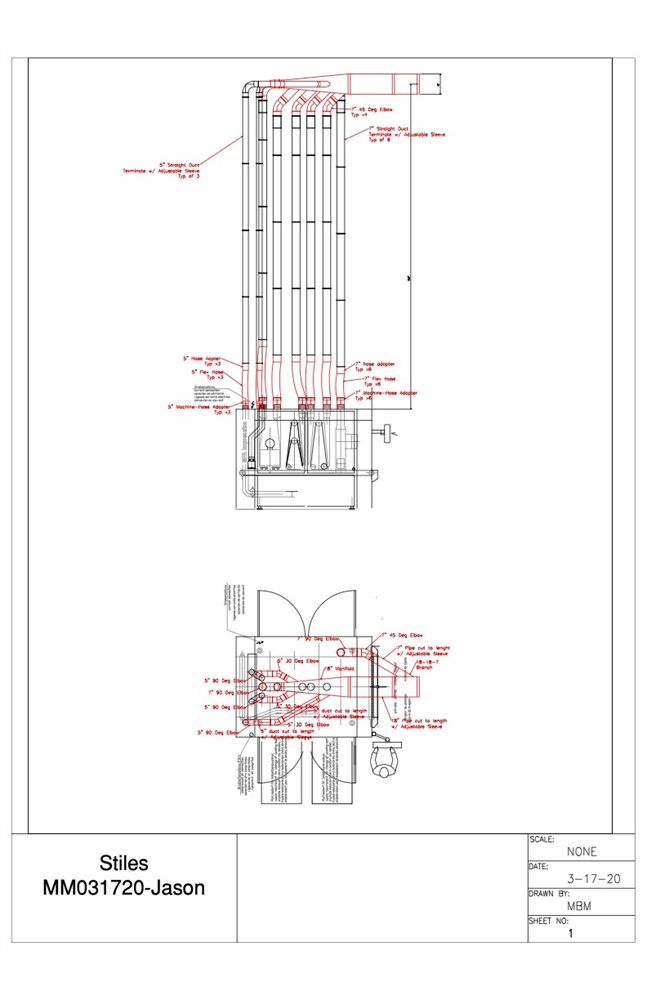

Dust Extraction Manifold/Flex pipe & Extra heads pictured are included.

The information provided in this lot was gathered from literature, internet & physical inspection. It is thought to be accurate; but not guaranteed. Bidders are urged to use the open house or private inspection periods to inspect and verify.

The listed specifications & information were taken from the manufacturer’s published information, internet research, or seller’s description.

The specifications & information are assumed to be correct; however, in no way, guaranteed. Bidders are encouraged to inspect the machine, call with questions, or contact the manufacturer for more information.

Please log in to view the bid history

LoginPick-ups are to be scheduled by appointment only. Please contact Sabrina Burns at 209-839-7707 or [email protected] to schedule an appointment. For freight quotes please contact Aaron at All-Ways Trucking at 541-608-6532. Buyer bears all costs to remove and load this lot. Buyer must remove entire lot purchased. Anyone removing non-hand carriable lots must provide MachineryMax, Inc. with a certificate of insurance (COI) before purchased items can be removed.

For Rigging/Loading quotes, Please Contact: Marco Salinas @ West Coast Movers, 323-588-3533 or [email protected]

All buyers agree to make full payment to MachineryMax, Inc. within 48 hours of the online closing date for the auction lots purchased. All invoices over $1,500.00 are to be made by bank wire transfer or cashier’s check payable to MachineryMax, Inc. Purchases under $1,500.00 may be made using Visa, MasterCard, or American Express (2% credit card processing fee will be added to the invoice). All payments are to be made in USD currency only. Bidder represents and warrants to MachineryMax, Inc. that such bidder has immediately available funds to fully pay for its successful bids within 48 hours of the online closing date. All payment questions should be directed to Sabrina Burns at 209-839-7707 or [email protected] All buyers agree that there will be a 15% Buyers premium that will be added to the final invoice.

Sales Tax: All purchases from this auction will be subject to 10.75% California / Alameda County Sales Tax unless the purchaser is exempt.

Sales Tax Exemption: All buyers claiming exemption from sales tax will need to provide MachineryMax INC with a properly filled out and executed California Sales Tax exemption certificate prior to buyers removal of purchased items.