IMA "Advantage 70" Edgebander (2009)  Ended

Ended

IMA "Advantage 70" Edgebander - Delta, BC

- Final Bid Price : $5,000.00 USD Reserve Price Not Met

- 2 Bid(s)

- High Bidder: d****4

-

Pick Up Location

8035 Alexander Road, Delta, British Columbia V4G 1C6

-

Make

IMA

-

Model

Advantage 70

-

Serial Number

50049

-

Year

2009

-

Phase

3 PHASE

-

Voltage

480 VOLT

-

Load Out Period

March 16 - 25, 2022 and by appt. only

-

Estimated Dimensions

228" L x 36" W x 60" H

-

Estimated Weight

7,500 Pounds

-

Seller Comment

For a shipping quote, please contact Aaron Hubbartt at All-Ways Trucking, [email protected] or (541) 779-9295

-

Load Fee

Seller has forklift for loading, $250 loading fee, packaging, crating or other services at additional cost

-

page views

2758

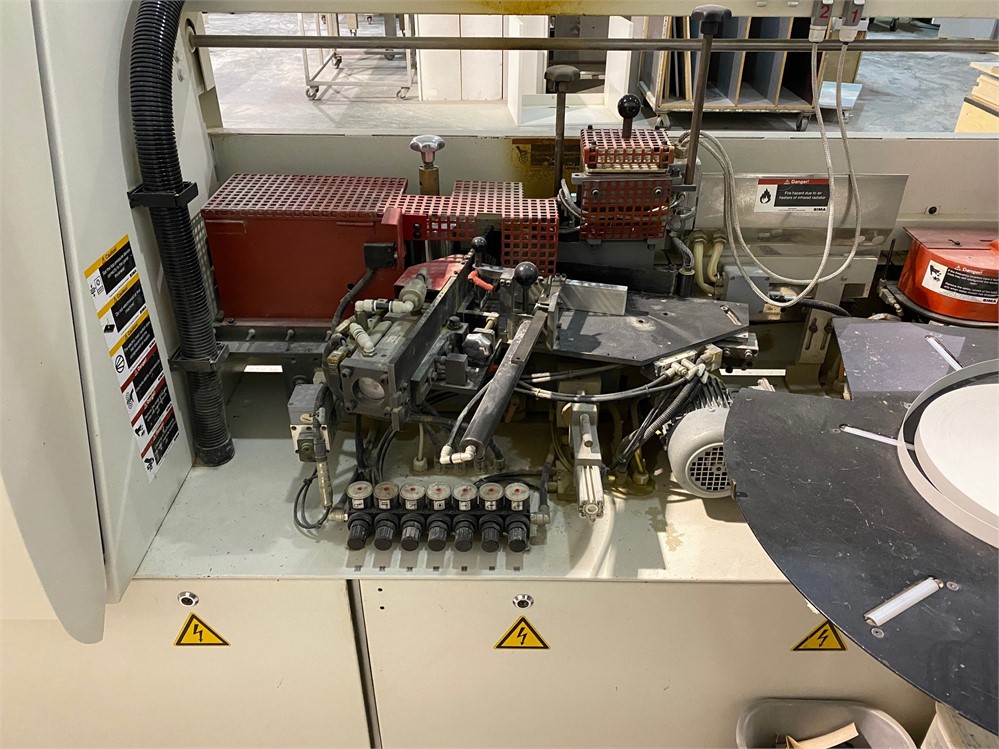

IMA "Advantage 70" Edgebander (2009)

Edgebanding capacity, 0.3 - 3 mm (0.012 - 0.118"), in coil and up to 12 mm (.47") in strip.

Panel thickness min./max. 8 - 65 mm (0.315 - 2.362").

Spraying Unit, anti-sticking solvent, top & bottom application.

Pre-Milling Unit, (2) 4 kW (5.3 HP) vertical joining spindles with SIKO digital readouts, particle & debris air jet blower.

Panel Pre-Heat Unit: Quartz Lamp for heating substrate edge before glue application.

Glue System to apply hot-melt glue.

Pressure Roll Section with (1) large dia. driven and (5) idle rollers.

End Trimming Unit: High speed, double motor, each 0.66 kW (0.88 HP) suspended from the hold-down beam, automatic chamfer adjustment 0° - 15° for speeds up to 32 m/Min (105 FPM).

Rough Trimming Unit: Top & bottom flush trimming, 1.0 kW (1.34 HP) - 12,000 RPM ea. motor, superimposed motors operate against the feed (up-milling), vertical & horizontal tracing wheels, digital readouts for adjustments.

Multi Function/ Corner Rounding Unit: Top & bottom 2-motor unit, 0.66 kW (0..89 HP) each motor.

Profile scraping unit top & Bottom profile scraper with 3 mm radius

Glue Scraping Unit: Flat, top & bottom self-tracing glue scraper, NC controlled.

Buffing Unit: Top & bottom 0.18 kW (0.25 HP) - 1,400 RPM each motor.

Control System ICOS EXPERT, Large color LCD display; displays stored data, on/off work station sequence, troubleshooting diagnostic; Data input by alphanumeric keyboard.

Microprocessor adjusts according to stored programs or input; Pressure section position & pressure control, vertical positioning of all hold-down beam mounted workstations.

Motorized central height adjustment of top pressure beam with double V-belt hold-down.

Sound enclosure, all stations, all trimming & milling motors DC electrical motor brakes for immediate stopping.

Machine has been relocated to rigger's warehouse. Buyer responsible for scheduling and paying loading fees directly with rigger.

The information provided in this lot was gathered from literature, internet & physical inspection. It is thought to be accurate; but not guaranteed. Bidders are urged to use the open house or private inspection periods to inspect and verify.

The listed specifications & information were taken from the manufacturer’s published information, internet research, or seller’s description.

The specifications & information are assumed to be correct; however, in no way, guaranteed. Bidders are encouraged to inspect the machine, call with questions, or contact the manufacturer for more information.

Please log in to view the bid history

LoginPick-ups are to be scheduled by appointment only. Please contact Eric Beach [email protected] to schedule an appointment. For freight quotes please contact Aaron @ All-Ways Trucking @ 541-608-6532 or John @ NCL Trucking @ 615-452-7651 . Buyer bears all costs to remove and load this lot. Buyer must remove entire lot purchased.

All buyers agree to make full payment to MachineryMax, Inc. within 48 hours of the online closing date for the auction lots purchased. All invoices over $1,500.00 are to be made by bank wire transfer or cashier’s check payable to MachineryMax, Inc. Purchases under $1,500.00 may be made using Visa, MasterCard, or American Express (2% credit card processing fee will be added to the invoice). All payments are to be made in USD currency only. Bidder represents and warrants to MachineryMax, Inc. that such bidder has immediately available funds to fully pay for its successful bids within 48 hours of the online closing date. All payment questions should be directed to Sabrina Burns at 209-839-7707 or [email protected] All buyers agree that there will be a 15% Buyers premium that will be added to the final invoice.