Giben "Smart SP" Automatic Beam Saw, Year 2010  Ended

Ended

Giben Beam Saw Auction - Baytown TX

- Starting Bid : $1,000.00 USD Reserve Price Not Met

- 0 Bid(s)

Giben Smart SP Automatic Beam Saw - Baytown, TX ( Closed #32000390 )

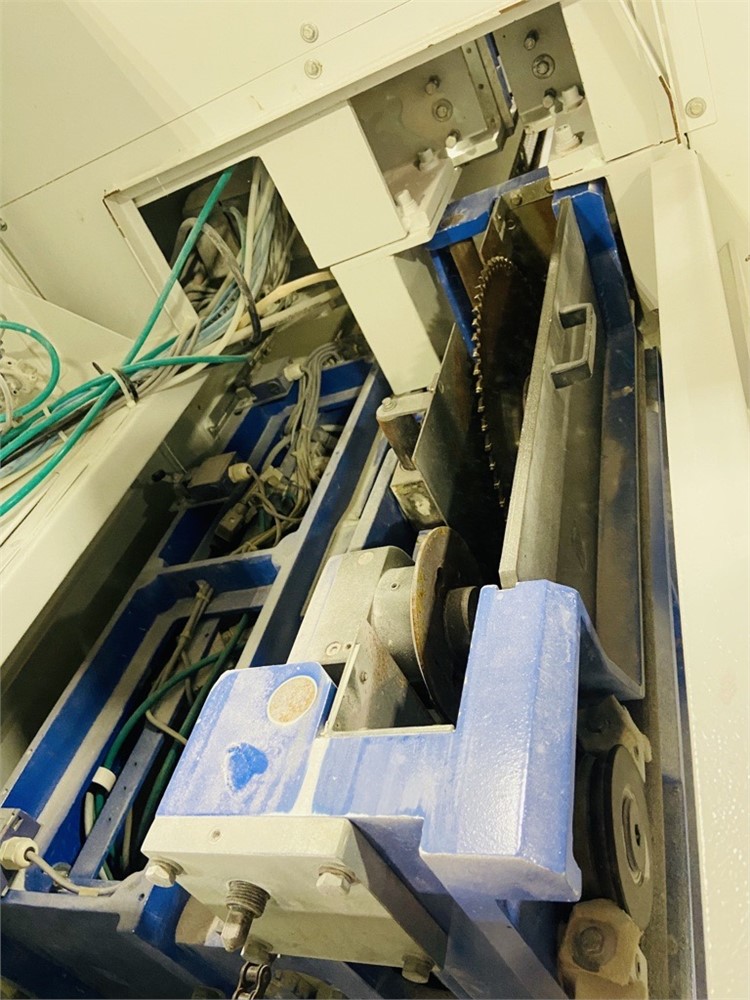

2010 Giben Smart SP Automatic Beam saw no longer needed for production of plastics and foam manufacturing company located in Baytown, TX.

-

Pick Up Location

4210 FM 1405 Baytown, Texas 77523 - U.S.A.

-

Make

Giben

-

Model

SP

-

Serial Number

910012

-

Year

2010

-

Phase

3 PHASE

-

Voltage

480 VOLT

-

Load Out Period

FEBRUARY 17th, 2022

-

Estimated Dimensions

-

Estimated Weight

-

Seller Comment

-

Load Fee

Rigger Required for Removal

-

page views

1785

149.6" (3,800 mm) Overall cutting length, 118.1" (3,000 mm) pusher stroke pull-back.

3.1" (80 mm) Max. saw blade projection, 15 HP (11 KW) main saw motor, 2.4 HP (1.8 kW) scoring saw motor.

Variable saw carriage forward speed 3 - 262 FPM (1 - 80 MPM), return speed 262 FPM (80 MPM).

Rack & pinion drive, driven by AC brushless Servo motors.

Electronically controlled overhead program fence with (7) pneumatic gripper clamps, max clamp opening 2.35" (60 mm).

Variable forward pusher speed 3 - 197 FPM (1 - 60 MPM), return speed 197 FPM (60 MPM).

Pusher driven on round bar-ways by AC brushless Servo motors.

PC front end with Giben "G-Vision" + Windows operating system with multitasking & easy programming of very complex cutting patterns.

15" Flat screen monitor displays REAL-TIME graphics of cutting dimensions & patterns, program cutting list, manual cuts, diagnostic & on-line help.

Data input by adjustable key pad pendant, standard industrial keyboard & mouse direct downloading from office PC is possible.

Giben "G-Vision" Automatic management of cutting patterns by optimizing all machine movements (pressure beam, saw carriage and side aligner pusher positioning, etc.).

The numerical control adjusts the optimum saw blade projection for the stack of panels being cut and sets the most appropriate cutting speed, in relation to the stack itself, and when necessary to the width of trim cut too.

(9) Rear support rails with 80 mm dia roller modules; rear of machine enclosed for safety.

(2) Front mounted air flotation table 20" x 78" & (2) Front mounted air floatation table 20" x 60" (approx).

The information provided in this lot was gathered from literature, internet & physical inspection. It is thought to be accurate; but not guaranteed. Bidders are urged to use the open house or private inspection periods to inspect and verify.

The listed specifications & information were taken from the manufacturer’s published information, internet research, or seller’s description.

The specifications & information are assumed to be correct; however, in no way, guaranteed. Bidders are encouraged to inspect the machine, call with questions, or contact the manufacturer for more information.

Please log in to view the bid history

LoginA local rigger will be required for removal of this machine. Winning bidder will be responsible for removal.

All buyers agree to make full payment to MachineryMax, Inc. within 48 hours of the online closing date for the auction lots purchased. All invoices over $1,500.00 are to be made by bank wire transfer or cashier’s check payable to MachineryMax, Inc. Purchases under $1,500.00 may be made using Visa MasterCard, or American Express (2% credit card processing fee will be added to the invoice). All payments are to be made in USD currency only. Bidder represents and warrants to MachineryMax, Inc. that such bidder has immediately available funds to fully pay for its successful bids within 48 hours of the online closing date. All payment questions should be directed to Sabrina Burns at 209-839-7707 or [email protected] All buyers agree that there will be a 15% Buyers premium that will be added to the final invoice.