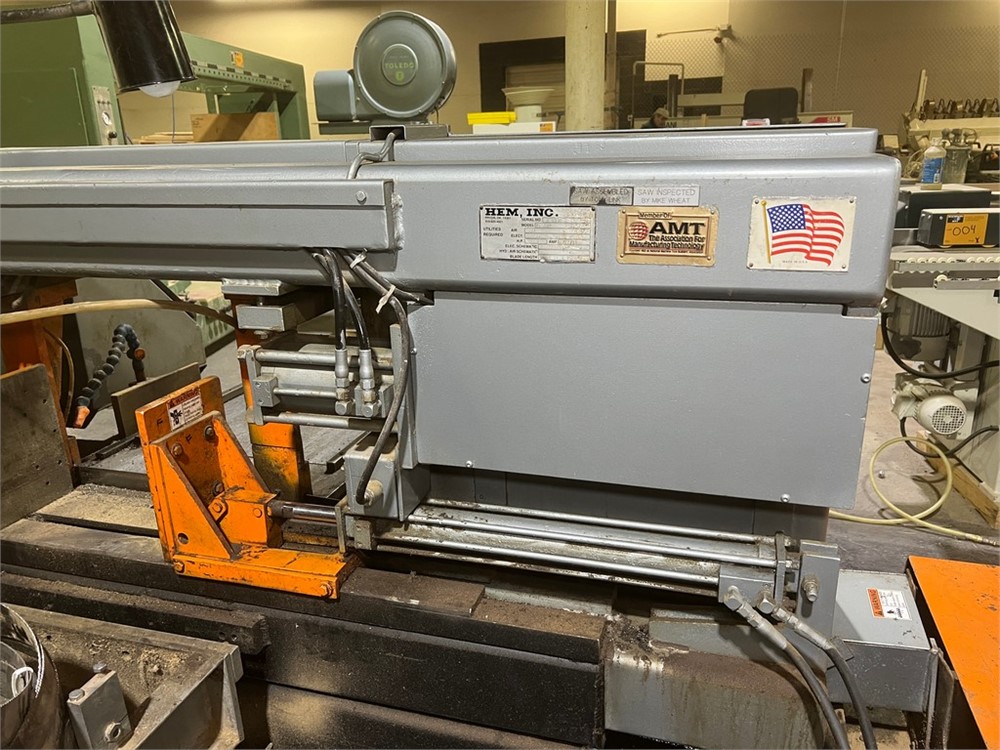

Hemsaw "H130HM" Metal Cutting Horizontal Bandsaw  Ended

Ended

GW Manufacturing - Poughkeepsie, NY

- Winning Bid : $1,000.00 USD Sold

- 1 Bid(s)

- High Bidder: A****d

GW Mfg. - Panel Division Closure - Poughkeepsie, NY ( Closed #31500456 )

Rigger: Preston Machinery, Tom Preston, 269-685-7591, [email protected]

-

Pick Up Location

Poughkeepsie, NY

-

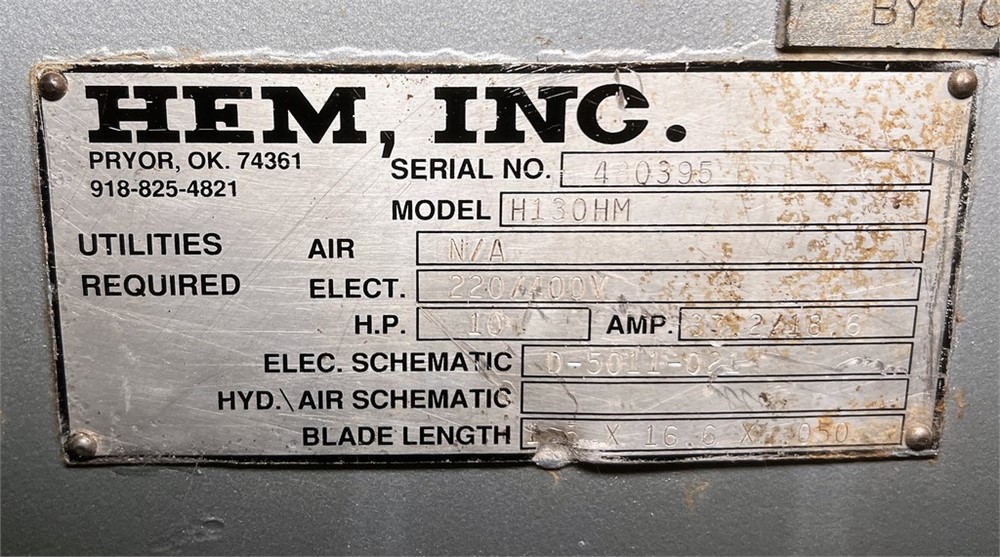

Make

Hemsaw

-

Model

"H130HM"

-

Serial Number

480395

-

Year

-

Phase

3 PHASE

-

Voltage

230/460

-

Load Out Period

-

Estimated Dimensions

120" x 84" x 60"

-

Estimated Weight

2,500 Lbs

-

Seller Comment

Aaron @ All-Ways Trucking @ 541-608-6532 or John @ NCL Trucking @ 615-452-7651

-

Load Fee

$195- non-negotionable loading fee has been established. This includes loading onto a flat bed trailer. Requests for additional labor will be extra.

-

page views

1242

Dual Column, Metal-Cutting Production Band Saw

Capacity: 20" W x 20" H

Blade: 1.5" x 19'0" x .050"

Motor: 10 HP

Hydraulics: 2 HP

Swing-Away Control Console

The Control Console is located on the front of the saw, in a swing-away console, for operator convenience.

24" Solid Discharge Table

A standard solid discharge table provides easier handling after the cut. The table is 24" in length and is fully coolant panned.

Full Stroking Main Vise

A Full-Stroking Main Vise clamps material at the turn of a switch and holds the material in place to ensure accurate cuts. The clamping pressure is easily adjusted to clamp various materials.

Carbide Blade Guides & Lead In/Lead Out Roller Guides

A blade guide system is composed of side and back blade guides which are flat carbide inserts. In addition to precision-ground flat carbides, roller guides are used to reduce vibration when cutting hard materials.

Built-In Flood Coolant System

The saw has a totally built-in coolant system with sealed coolant pump with coolant that is dispensed through the guides on each sides of the cut.

Adjustable Feed Rate & Cut Pressure

The saw arm Feed Rate can be adjusted from zero to 3 inches per second. Cutting pressure can be adjusted for effective metal removal rates.

Blade Brush

A shaft-driven Blade Brush is standard for positive removal of metal chips that lodge in the blade gullets. This system ensures a cleaner blade, more accurate cuts and prolonged blade life.

Push button Blade Speed

Blade speed can be adjusted with an infinitely variable speed drive from the console with push button controls. The blade speed is shown on the console with LED Readout.

Powered Guide Arm

The Powered Moveable Guide Arm provides optimum blade support as material size changes. It quickly adjusts the guides that hold the blade securely, providing straighter cuts and longer blade life.

Powered Blade Tension

The Powered Blade Tensioner maintains proper blade tension at all times during the cut, compensating for blade stretch. Changing blades on the saw is done in minutes with the use of the Powered Blade Tensioner.

The information provided in this lot was gathered from literature, internet & physical inspection. It is thought to be accurate; but not guaranteed. Bidders are urged to use the open house or private inspection periods to inspect and verify.

The listed specifications & information were taken from the manufacturer’s published information, internet research, or seller’s description.

The specifications & information are assumed to be correct; however, in no way, guaranteed. Bidders are encouraged to inspect the machine, call with questions, or contact the manufacturer for more information.

Please log in to view the bid history

LoginPick-ups are to be scheduled by appointment only. Please contact Sabrina Burns at 209-839-7707 or [email protected] to schedule an appointment. For freight quotes please contact Aaron at All-Ways Trucking at 541-608-6532. Buyer bears all costs to remove and load this lot. Buyer must remove entire lot purchased. Anyone removing non-hand carriable lots must provide MachineryMax, Inc. with a certificate of insurance (COI) before purchased items can be removed.

Rigger: Preston Machinery, Tom Preston, 269-685-7591, [email protected]

All buyers agree to make full payment to MachineryMax, Inc. within 48 hours of the online closing date for the auction lots purchased. All invoices over $1,500.00 are to be made by bank wire transfer or cashier’s check payable to MachineryMax, Inc. Purchases under $1,500.00 may be made using Visa, MasterCard, or American Express (2% credit card processing fee will be added to the invoice). All payments are to be made in USD currency only. Bidder represents and warrants to MachineryMax, Inc. that such bidder has immediately available funds to fully pay for its successful bids within 48 hours of the online closing date. All payment questions should be directed to Sabrina Burns at 209-839-7707 or [email protected] All buyers agree that there will be a 15% Buyers premium that will be added to the final invoice.