Holz-Her "Sprint 1416" Edgebander  Ended

Ended

Biesse CNC and Holz-Her Edgebander - Lancaster, NY

- Starting Bid : $250.00 USD

- 0 Bid(s)

Biesse CNC and Holz-Her Edgebander - Lancaster, NY ( Closed #30614528 )

Woodworking company in the Buffalo, NY area is auctioning its Biesse CNC and Holz-Her edgebander that are no longer required for continuing operations.

-

Pick Up Location

19 Palmer Pl. Lancaster, NY 14086

-

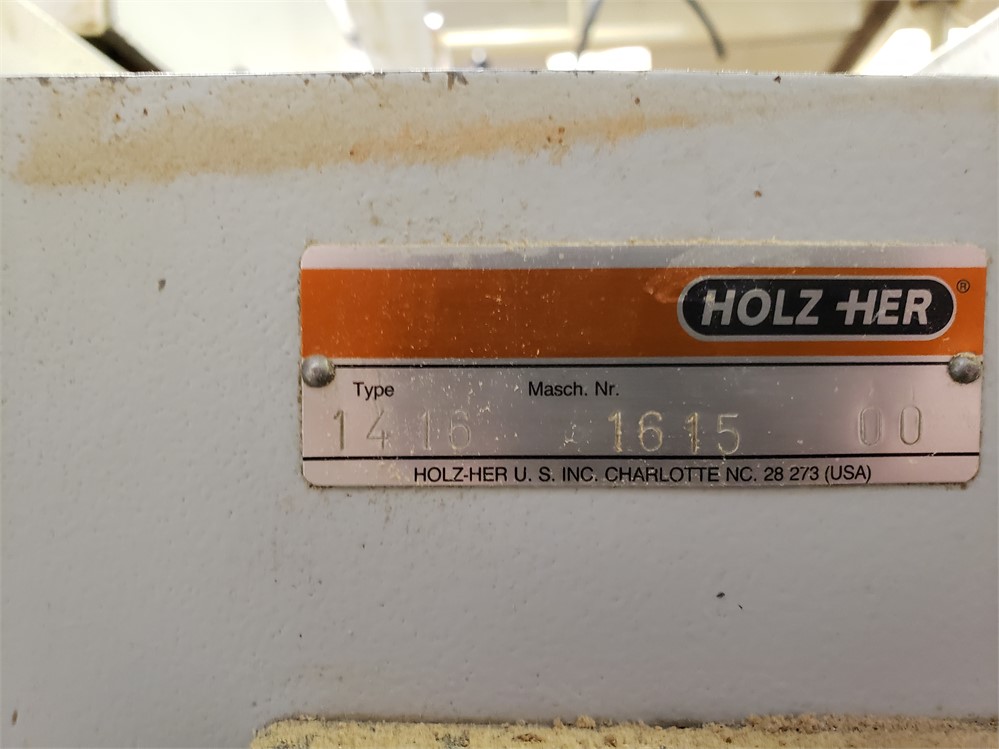

Make

Holz-Her

-

Model

Sprint 1416

-

Serial Number

1615

-

Year

2000

-

Phase

3 PHASE

-

Voltage

220 VOLT

-

Load Out Period

November 19, 2021 @ 9:00 AM Pacific

-

Estimated Dimensions

See photos and description

-

Estimated Weight

See photos and description

-

Seller Comment

Seller has forklift for loading, $200 loading fee, packaging, crating or other services at additional cost

-

Load Fee

200

-

page views

2755

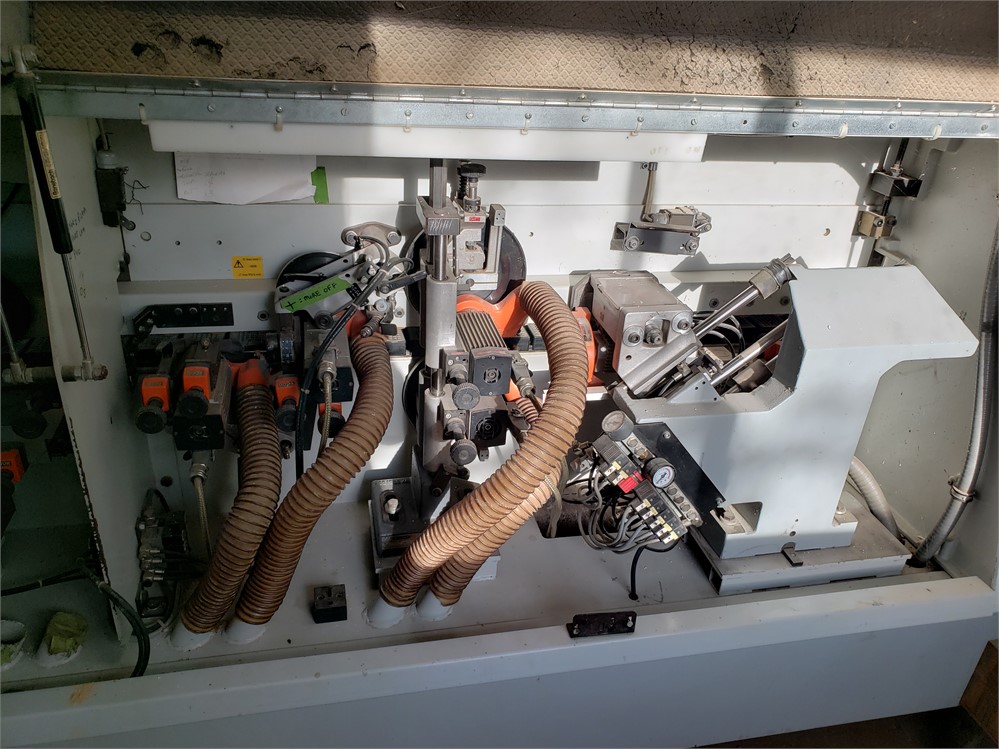

Holz-Her "Sprint 1416" Edgebander

See video of machine in operation

MODEL 1901 EDGESTRIP MAGAZINE

- 1 (one) universal magazine for solid edges, strips, and coiled material.

- Utilizes motion detector to ensure accurate, trouble-free positioning of edge material.

- Exclusive “TRACTOR-BELT FEED SYSTEM” to ensure accurate, trouble-free feeding of edge material, as well as optimum operator safety.

- Angled strip gate to prevent double feeding of strips.

- Magazine table on rollers for smooth feeding of coiled material.

- Edge guide equipped with automatic guillotine lock-out for safety.

- “3 DEGREE APPROACH ANGLE” allows easy feeding of large wood edges.

- Automatic guillotine for coiled material up to 4.0 mm.

MODEL 1906 GLUING STATION - “CARTRIDGE SYSTEM”

- Equipped with HOLZ-HER'S exclusive patented "CARTRIDGE" glue system. This is a CLOSED APPLICATION SYSTEM in which the glue is enclosed in an air- tight chamber and cannot oxidize, discolor, burn, or become contaminated with wood dust. This allows for optimum glue adhesion.

- Glue applied to panel by patented GLUE NOZZLE from 6-45mm workpiece thickness.

- Precise control of all functions including begin and end of glue line, height of glue line, bottom of glue line, volume of glue and face melt temperature.

- Less maintenance - no glue pot to clean, fewer parts.

- Efficient glue consumption - virtually no waste.

- Efficient power consumption - uses less than half that of conventional glue pots.

- Fastest & easiest glue color change, 5-10 min.

- Fastest heat-up time in the industry, less than 3 min.

- No fumes or other environmental hazards.

- Machine can be used for trimming without heating up the glue section.

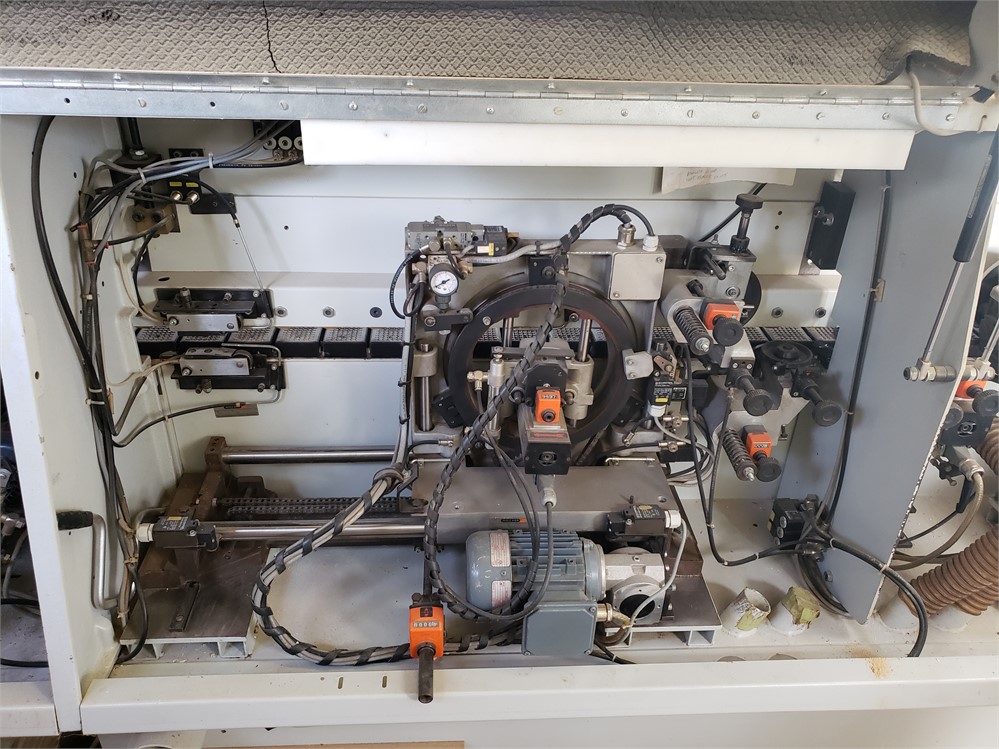

MODEL 1913 - P PNEUMATIC PRESSURE UNIT

- Large electronically-driven roller synchronized with feed speed.

- Two additional rollers are cantered enabling high gluing pressure and precise banding.

- Quick adjustment of pressure section to edge thickness by means of speed wheel and scale.

MODEL 1918 END TRIM UNIT

- Heavy duty finish with linear guide bars for precision and trimming.

- Two high frequency motors for cutting the leading and trailing edges with draw cuts. (up to 8 mm)

- Mounted with uni-point axis enabling quick change for chamfer trimming up to 10°.

- Mechanically indexes ends for a perfect finish.

- Motors: 2 x .22 KW Speed 9,000 RPM.

- Maximum edge thickness up to 13mm.

- “PCS” Pneumatic Changeover System included as standard

MODEL 1823 FLUSH TRIM UNIT

- Two high frequency motors for top and bottom rough trimming

- Vertical Tracing Wheels

- Maximum Edgestrip Thickness: 13mm

- Motor: 2 x 0.6 KW (.82 HP), 300 HZ, Speed 18,000 RPM

MODEL 1942-M COMBINATION FLUSH, CHAMFER & RADIUS TRIM UNIT

- Two high frequency motors for edge trimming 0 to 15 degrees.

- Vertical and horizontal tracing with uni-point design for no second adjustment when changing the degree of bevel.

- Maximum edgestrip thickness: 8 mm.(Standard) 13 mm with optional straight tooling.

- Air jets for debris removal.

- Radius capability up to 3 mm radius.

- Motor: 2 x 0.6 KW (.82 HP), 300 HZ, Speed 18000 RPM.

- “PCS” Pneumatic Changeover System from flush to radius from control panel included as standard

- Digital counters included.

MODEL 1929 SCRAPER UNIT

- Uses reversible insert carbide scraping knives on the top and bottom edges.

- Normally equipped with radius tooling to finish and remove knife marks created by the top,bottom, and radius units on thick PVC edgings. (2,3 mm).

- Equipped with air-jet blowers.

- Vertical and horizontal copy wheels.

- “PCS” Pneumatic Changeover System moves Scraper Unit in and out from control panel.

- Equipped with digital readouts for all adjustment spindles.

MODEL 1983 CONTOUR TRIMMING UNIT, H.F. WITH AIR JET

- For rounding of corners: radius, chamfer, or flush trim.

- Possible radius: 2 mm and 3 mm.

- One motor, 1 x 0.6 KW, 300 HZ.

- Feed speed of 12 meters per minute. Max.

- Includes 7 Siko digitals for quick set-up.

- Equipped with reversible blade cutterhead with radius knives.

MODEL 1944K PLUNGE BUFFING UNIT

- Includes two motors with the possibility of adjustment in any direction.

- Incorporates “plunge control” to avoid rounding-over the leading and trailing edges, and ensure tight corners (thick PVC).

- Horizontal Swivel = 0 to 20 º.

- Equipped with cloth buffing wheels for smoothing the sharp edges of thin PVC band after trimming.

- Can be equipped with fine sanding wheels for finishing wood and laminate edges.

- Motor Speed = 1440 RPM.

TECHNICAL DATA:

Machine Dimensions:

Length: 3250 mm / 128 in.

Width: 1470 mm / 58 in.

Height: 1200 mm / 47 in.

Working Dimensions:

Edge Strip Thickness: 0.3 - 13mm

Edge Strip Width: 50mm

Edge Strip Length: 200mm minimum - Unlimited

Workpiece Width: Min. 60mm

Workpiece Length: Min. 180mm

Workpiece Thickness: 6 - 45mm

Feed Speed: 12 m/min

(12~16mpm with Optional Variable Track

Speed)

Air Requirement: 6 bar

Listed specifications were taken from manufacturer's published information and is assumed to be correct but not guaranteed. Bidder is encouraged to inspect the machine, call with questions or contact the manufacturer for more information.

The listed specifications & information were taken from the manufacturer’s published information, internet research, or seller’s description.

The specifications & information are assumed to be correct; however, in no way, guaranteed. Bidders are encouraged to inspect the machine, call with questions, or contact the manufacturer for more information.

Please log in to view the bid history

LoginPick-ups are to be scheduled by appointment only. Please contact Sabrina Burns at 209-839-7707 or [email protected] to schedule an appointment. For freight quotes please contact Aaron at All-Ways Trucking at 541-608-6532. Buyer bears all costs to remove and load this lot. Buyer must remove entire lot purchased. Anyone removing non-hand carriable lots must provide MachineryMax, Inc. with a certificate of insurance (COI) before purchased items can be removed.

All buyers agree to make full payment to MachineryMax, Inc. within 48 hours of the online closing date for the auction lots purchased. All invoices over $1,500.00 are to be made by bank wire transfer or cashier’s check payable to MachineryMax, Inc. Purchases under $1,500.00 may be made using Visa, MasterCard, or American Express (2% credit card processing fee will be added to the invoice). All payments are to be made in USD currency only. Bidder represents and warrants to MachineryMax, Inc. that such bidder has immediately available funds to fully pay for its successful bids within 48 hours of the online closing date. All payment questions should be directed to Sabrina Burns at 209-839-7707 or [email protected] All buyers agree that there will be a 15% Buyers premium that will be added to the final invoice.