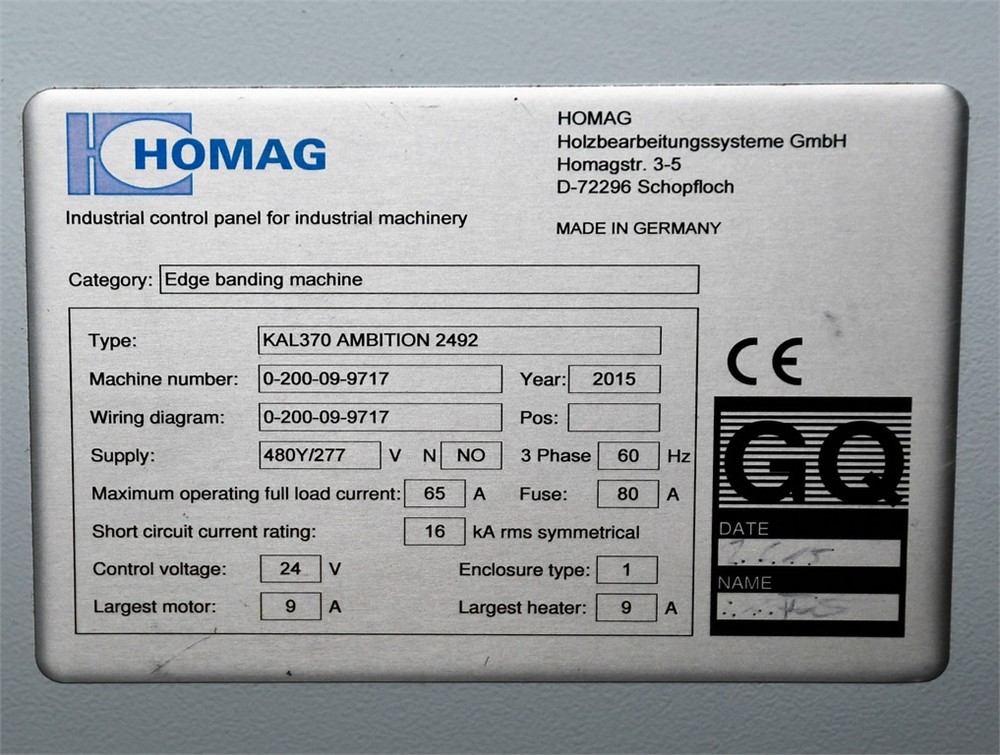

Homag "KAL 370 Ambition 2492" Edgebander - PUR (2015)  Ended

Ended

Complete Plant Liquidation in Rock Hill, SC

- Winning Bid : $115,300.00 USD Sold

- 152 Bid(s)

- High Bidder: m****r

Complete Facility of Late Model Homag Machinery - Rock Hill, SC ( Closed #30199553 )

OPEN HOUSE No appt. needed - 11/23/2021 - 10AM - 2PM. 150 Mount Gallant Road, Rock Hill, SC. Look for sign out front that says "ACL". Use shop door next to loading dock. Eric Beach 704-608-9830

Located 15 minutes from Charlotte airport. Easy Uber ride to site from CLT airport for open house or private inspections.

For rigging quotes:

Gorham Industrial - Windsor, SC - James Gorham - 803-617-8434 - [email protected]

Pedowitz Machinery Movers - Charlotte, NC - Steve Colbert - 803-679-1500 - [email protected]

Guy M. Turner Co. - Rock Hill, SC - Mac McCarley - 866-849-0031 - [email protected]

COURT ORDERED SALE OF ALL ASSETS - AUCTION CLOSES DATE EXTENDED TO NOVEMBER 30, 2021

-

Pick Up Location

150 Mount Gallant Road, Rock Hill, SC

-

Make

Homag

-

Model

"KAL 370 Ambition 2492"

-

Serial Number

0-200-09-9717

-

Year

2015

-

Phase

3 PHASE

-

Voltage

460 VOLT

-

Load Out Period

-

Estimated Dimensions

405"L x 48"W x 84"H

-

Estimated Weight

-

Seller Comment

Aaron @ All-Ways Trucking @ 541-608-6532 or John @ NCL Trucking @ 615-452-7651

-

Load Fee

A rigger is required. Buyer's Responsibility for Break-down, loading and removal.

-

page views

7536

Coiled stock min/max Edge thickness 0.4 - 3 mm (0.016. - 0.118"), Strip material min/max Edge Thickness 0.4 - 6 mm (0.16 - 0.234"),

Panel stock min/max thickness 12 - 40 mm (0.472" - 1.574"). Panel Over-Hang 30 mm (1.18").

Servo adjustable in-feed fence.

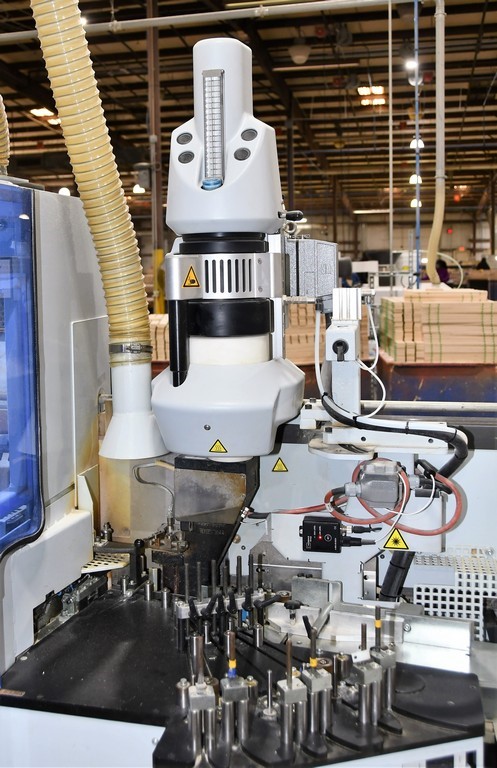

Pre-mill - two 3.0 kW (4.0 HP), 150 Hz, 9,000 RPM Motors; equipped with trimming column, (2) horizontal and cross slides with spindle adjustment, electro-pneumatic horizontal jump movement of the first motor; includes electronic frequency inverter for control of motor speed and braking, two (2) dust extraction hoods, air jet panel blow-off device & SIKO digital counters for adjustments.

Panel Pre-heater - Pre-heating the panel brings the panel to an appropriate temperature for better adhesion; this is especially beneficial in cooler temperatures. Quartz lamp for heating substrate edge before glue application improved edge quality and optimum bonding.

A multi-purpose 6-coil magazine expands capability by running coiled material, strips, and solid wood bands. An additional single coil feeder is also included for quick change over applications.

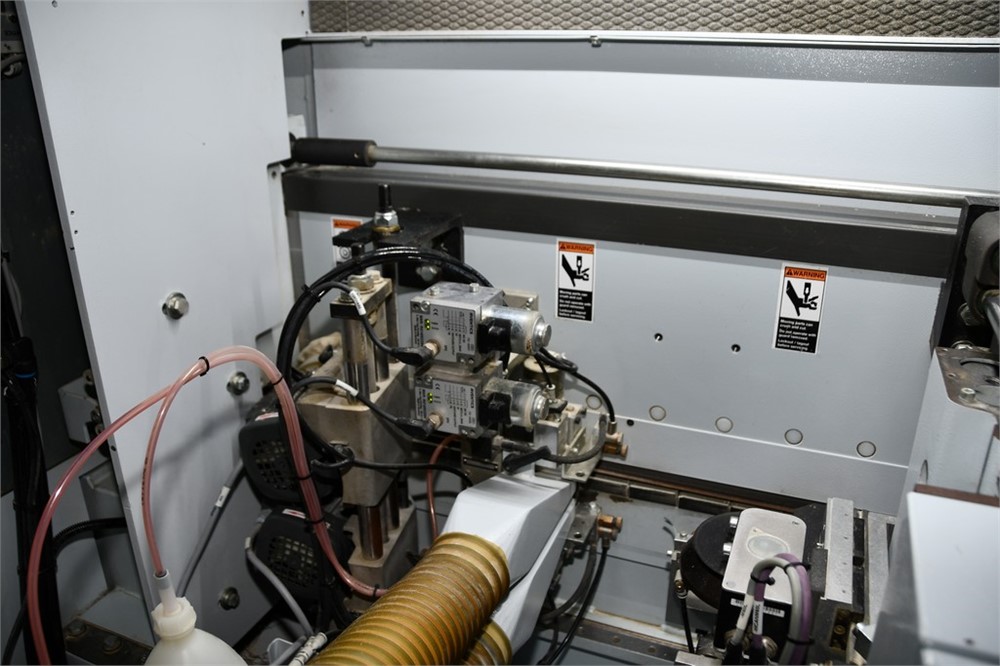

PUR Glue application.

2-Motor end trimming station: 0.8 kW (1.0 HP) x 2 - 200 Hz, 12,000 RPM Motors. to cut excess edge on the front & back of the panel; pneumatic adjusting from chamfer 30 deg. to straight cut.

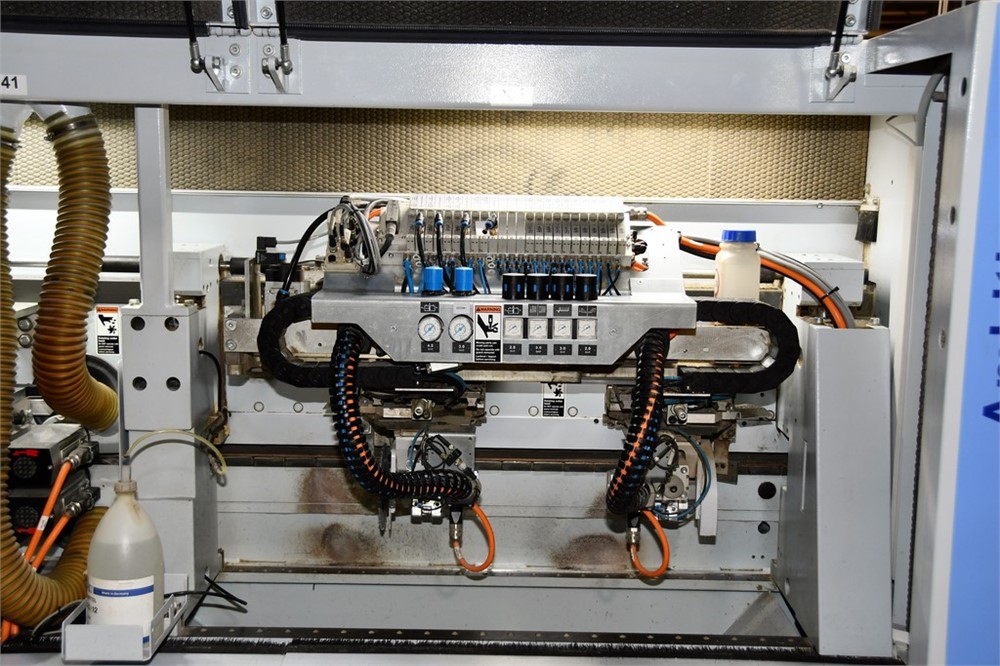

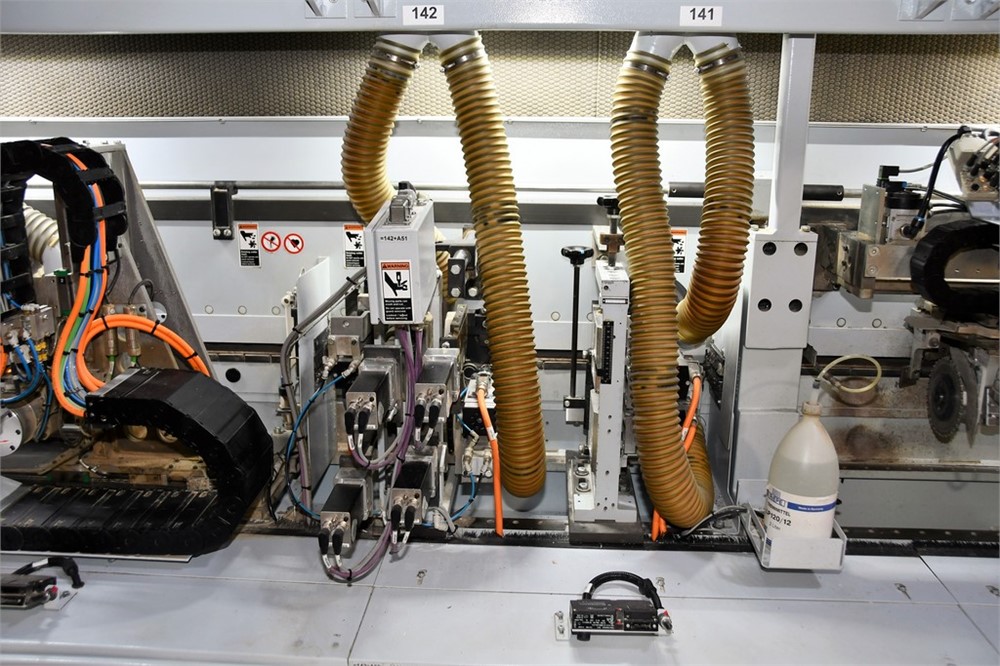

Rough - Pre-Trim Station: Top & bottom, 0.55 kW (0.74 HP) x 2 - 12,000 RPM Motors; Height adjustment with the top pressure-beam and tilting range +/- 1°.

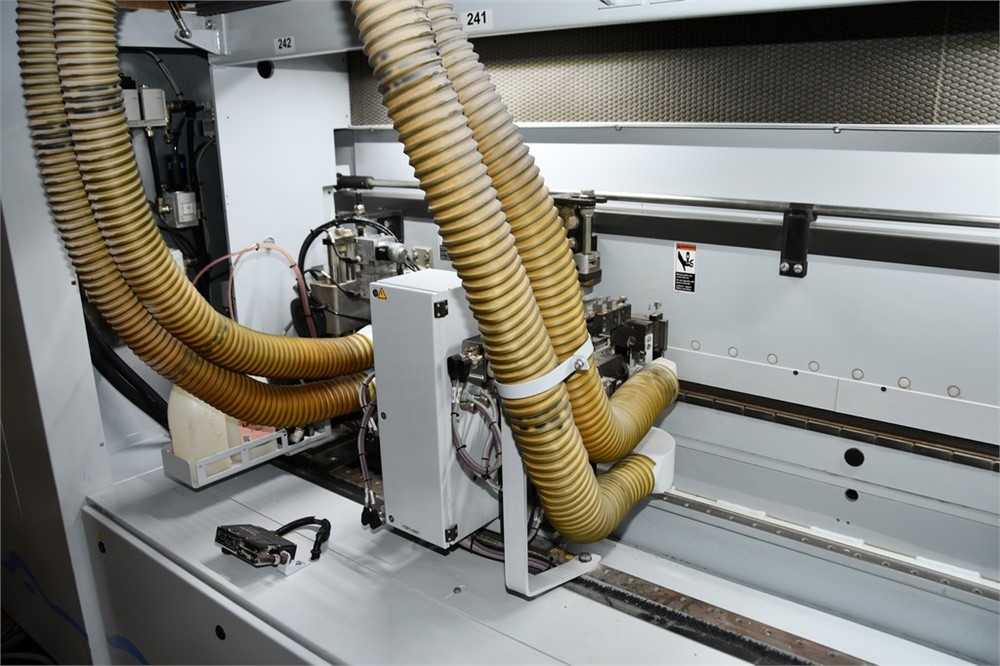

Fine - Profile Trim Sation: Top & bottom - Servo adjustment.

Corner Rounding - Multi function 0.4 kW (0.54 HP) x 2)- 12,000 RPM Motor to fine trim the edge overhangs at the work-piece upper & lower edge, as well as trimming around the front & rear vertical edge; Servo controlled, Max. feed speed 20 MPM (65.6 FPM).

Profile/Bevel Scraping Unit: Top & bottom for thick PVC/ABS, pneumatically activated.

Flat Glue Scraper Unit: Top & bottom, pneumatically activated to remove potential glue squeeze-out.

Buffing Unit: Top & bottom edge buffing/polishing.

Return Conveyor sold separate. See lot #006.

The information provided in this lot was gathered from literature, internet & physical inspection. It is thought to be accurate; but not guaranteed. Bidders are urged to use the open house or private inspection periods to inspect and verify.

The listed specifications & information were taken from the manufacturer’s published information, internet research, or seller’s description.

The specifications & information are assumed to be correct; however, in no way, guaranteed. Bidders are encouraged to inspect the machine, call with questions, or contact the manufacturer for more information.

Please log in to view the bid history

LoginPick-ups are to be scheduled by appointment only. Please contact Sabrina Burns at 209-839-7707 or [email protected] to schedule an appointment. For freight quotes please contact Aaron at All-Ways Trucking at 541-608-6532. Buyer bears all costs to remove and load this lot. Buyer must remove entire lot purchased. Anyone removing non-hand carriable lots must provide MachineryMax, Inc. with a certificate of insurance (COI) before purchased items can be removed.

All buyers agree to make full payment to MachineryMax, Inc. within 48 hours of the online closing date for the auction lots purchased. All invoices over $1,500.00 are to be made by bank wire transfer or cashier’s check payable to MachineryMax, Inc. Purchases under $1,500.00 may be made using Visa, MasterCard, or American Express (2% credit card processing fee will be added to the invoice). All payments are to be made in USD currency only. Bidder represents and warrants to MachineryMax, Inc. that such bidder has immediately available funds to fully pay for its successful bids within 48 hours of the online closing date. All payment questions should be directed to Sabrina Burns at 209-839-7707 or [email protected] All buyers agree that there will be a 15% Buyers premium that will be added to the final invoice.