Butfering "Profi SWT-345/QHQQ" Widebelt Sander  Ended

Ended

Butfering "Profi SWT-345/QHQQ" Widebelt Sander - Longmont, CO

- Final Bid Price : $37,501.00 USD Reserve Price Not Met

- 14 Bid(s)

- High Bidder: D****3

Butfering "Profi SWT-345/QHQQ" Widebelt Sander - Longmont, CO ( Closed #29693845 )

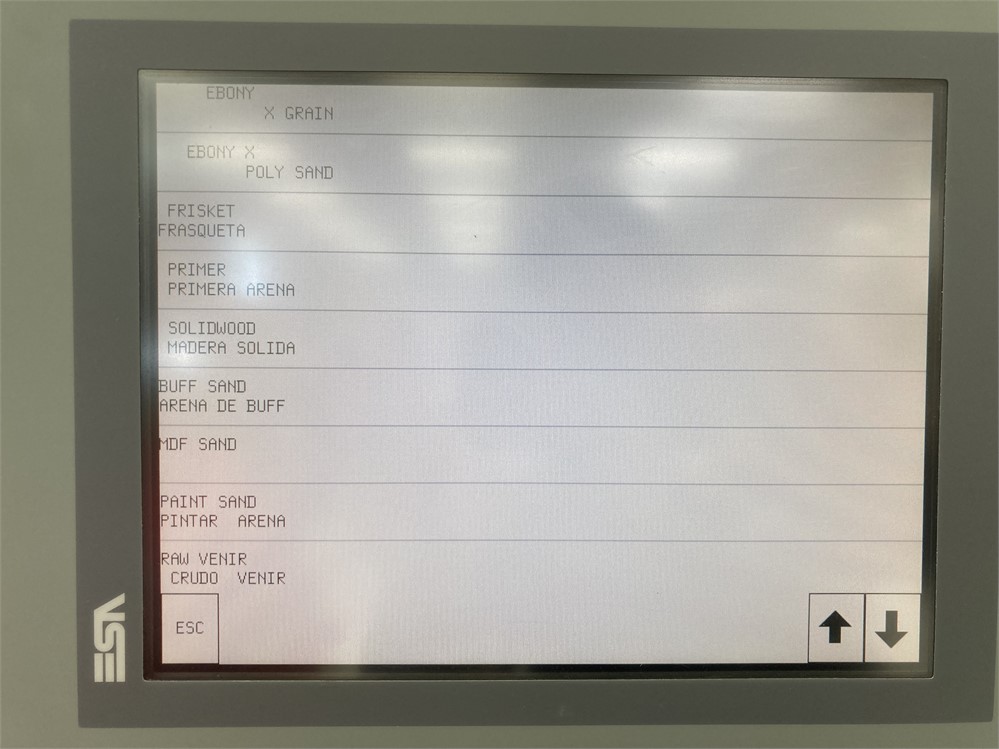

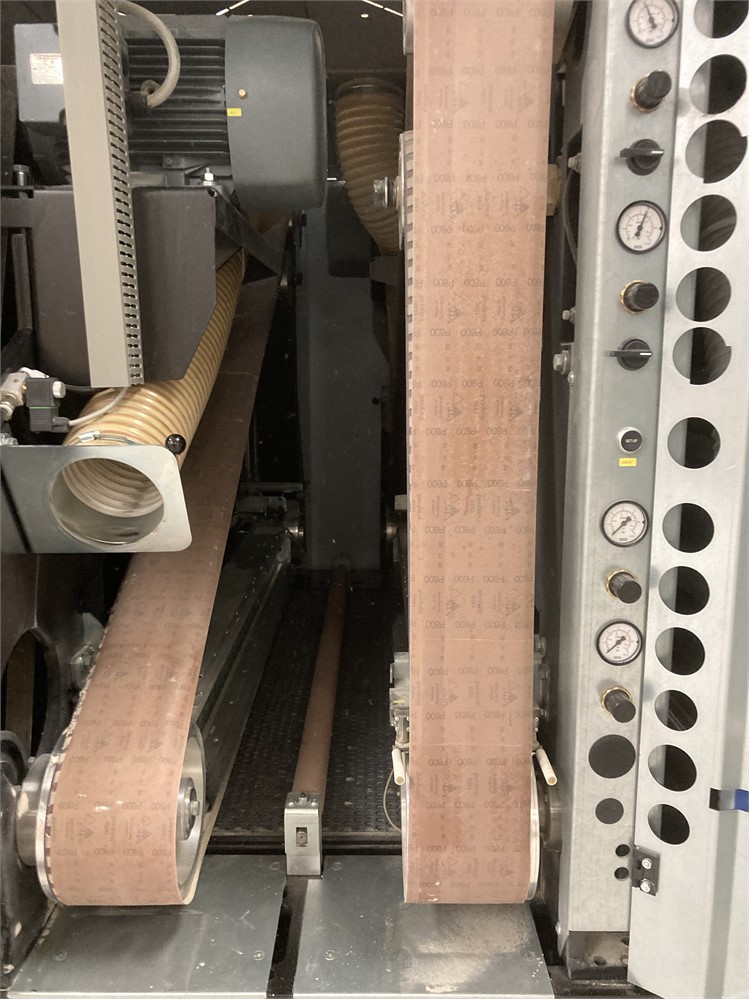

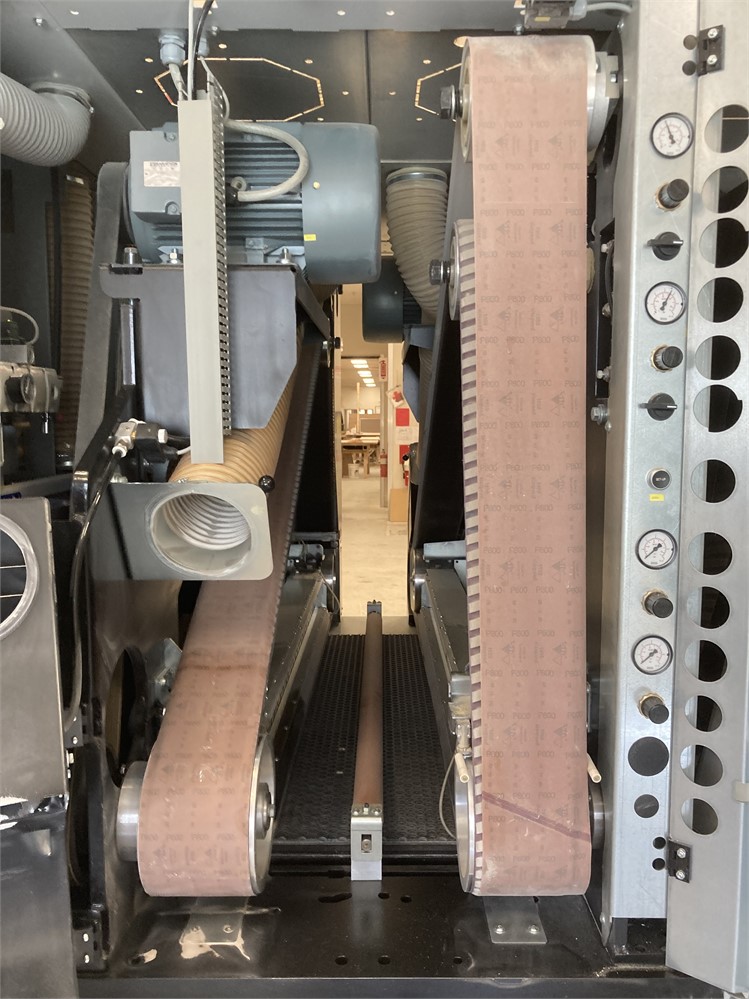

Architectural millwork firm in Denver, CO metro area is upgrading their facility and auctioning this Butfering widebelt sander. A high-end machine designed for a variety of product including veneered panels. Butfering's SWT 345 QHQQ is designed to sand lacquered and veneered work-pieces. Equipped with four (4) sanding units and MPS 25 segmented sanding pads, the SWT 345 QHQQ is a versatile production solution when veneer sanding and short grain sanding is required.

-

Pick Up Location

4076 Specialty Pl. Longmont, CO 80504

-

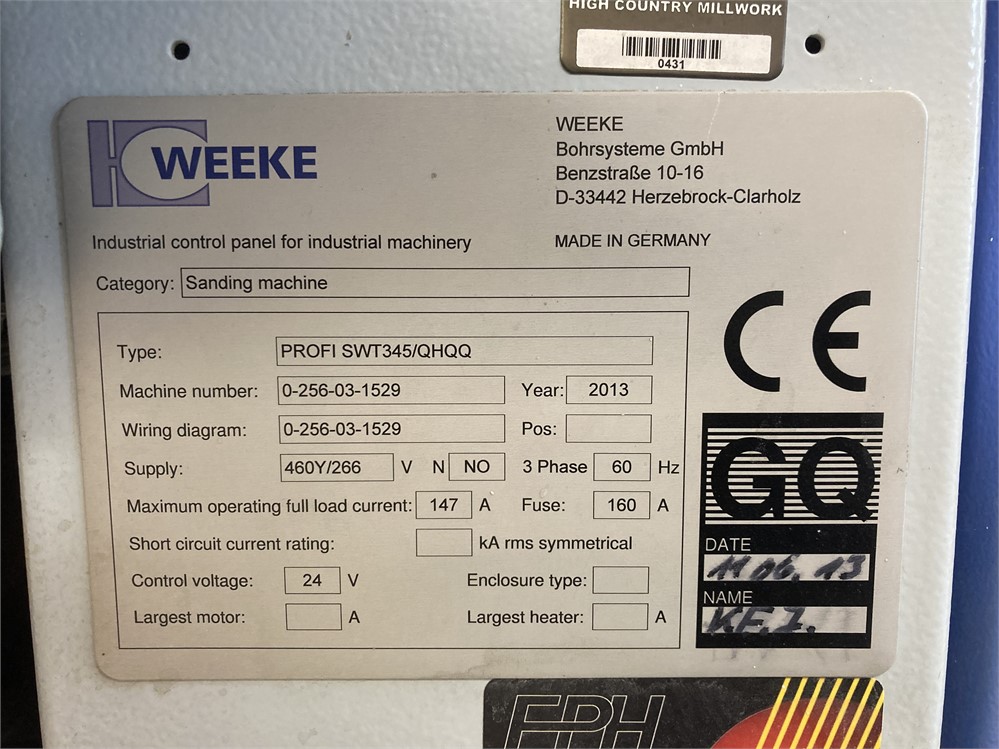

Make

Butfering

-

Model

Profi SWT-345/QHQQ

-

Serial Number

0-256-03-1529

-

Year

2013

-

Phase

3 PHASE

-

Voltage

460 VOLT

-

Load Out Period

October 20 - November 5, 2021 (by appointment)

-

Estimated Dimensions

134" L x 82" W x 90" H

-

Estimated Weight

10,000 Pounds

-

Seller Comment

This lot requires a rigger, please contact Andy Cook @ RMS Rigging, [email protected] or 720-315-9918 for quote and schedule.

-

Load Fee

-

page views

4324

Butfering "Profi SWT-345/QHQQ" Widebelt Sander

See video of machine in operation with wireless controller

Butfering's SWT 345 QHQQ is designed to sand lacquered and veneered work-pieces. Equipped with four (4) sanding units and MPS 25 segmented sanding pads, the SWT 345 QHQQ is a versatile production solution when veneer sanding and short grain sanding is required.

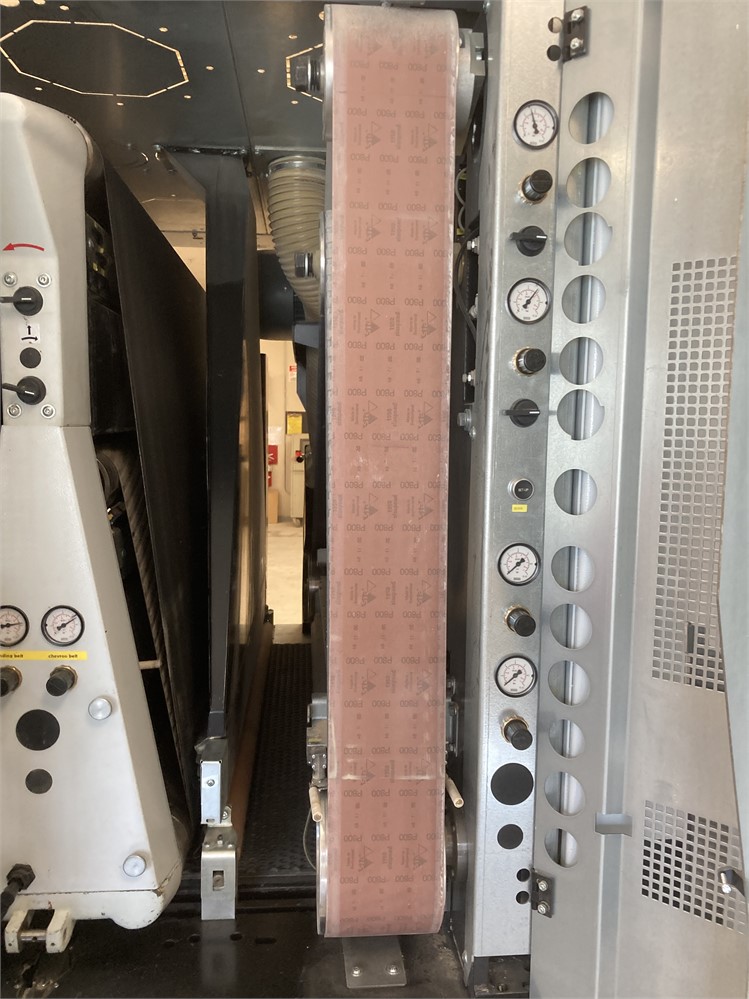

Butfering's SWT 300 series includes the following features:

- constant pass-line, 35" (900 mm)

- protected storage space for spare sanding inserts

- automatic "Star Delta" starting

- maintenance-free electrical main motor braking

- electronic abrasive belt oscillation

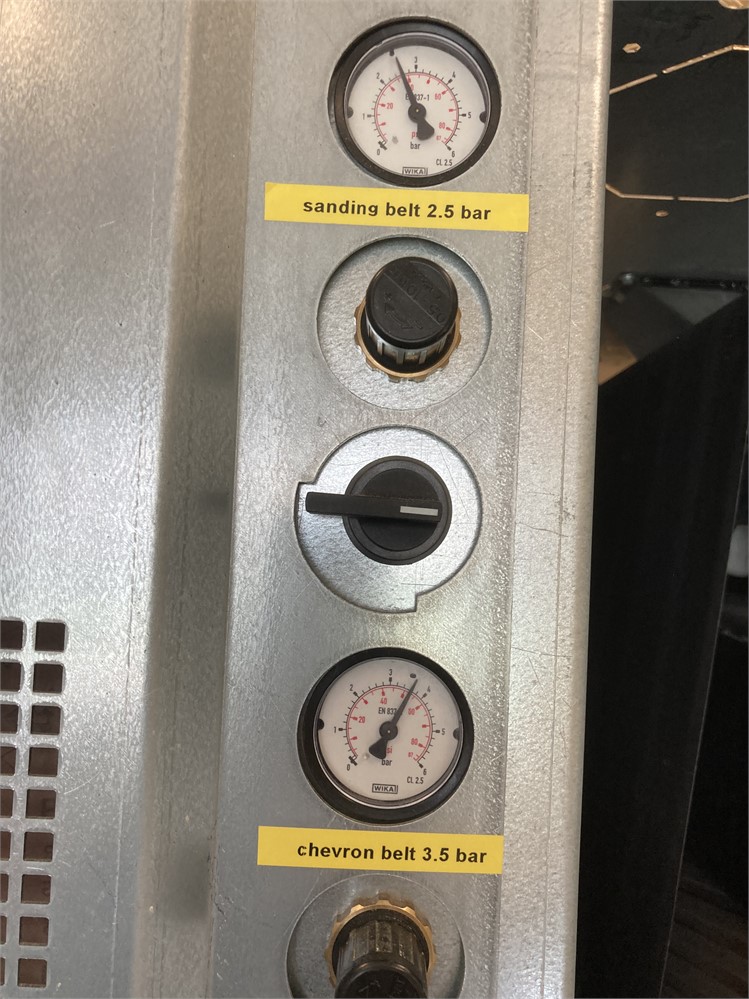

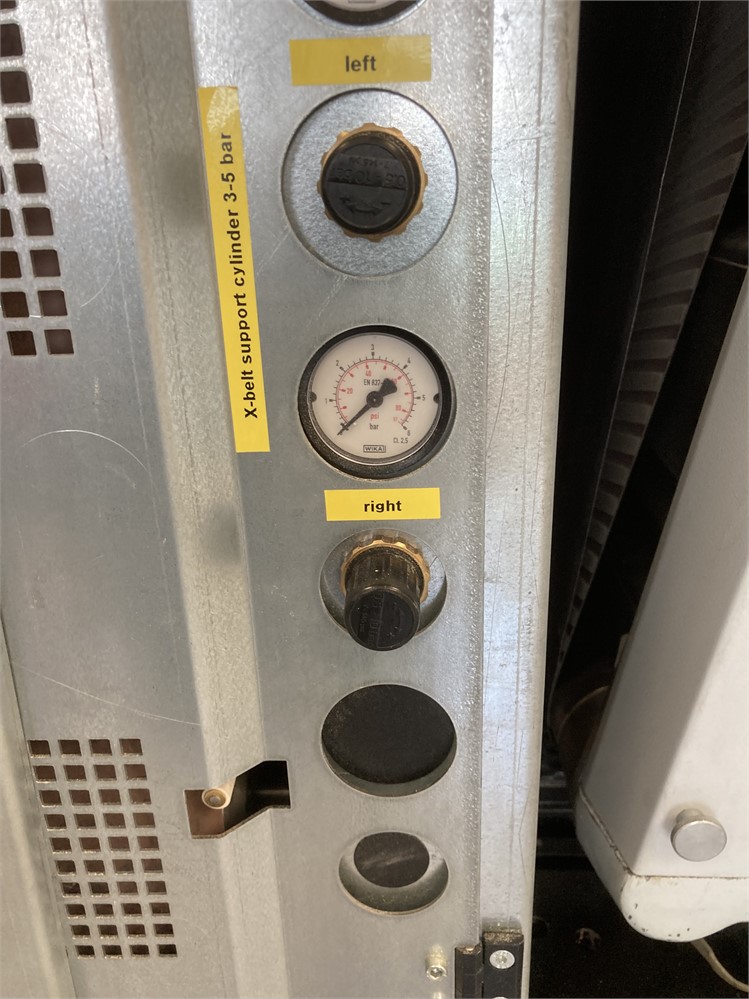

- pneumatic tensioning of abrasive belt

- abrasive belt edge compensation

- safety switch-off of machine during faulty operation

- rubberized pressure rollers

- automatic head locking

1/8" - 6" workpiece thickness

53" working width

54" x 103" abrasive belt size

Equipped with work-piece sensing with 25 mm resolution for the Magnetic Pad System

Variable frequency-controlled feed speeds of 2.5 – 13 m/min. (8 – 42 FPM)

Telescopic work-piece feeding roller table on infeed

Vacuum table feedbelt

4.7 HP fan motor

650 CFM

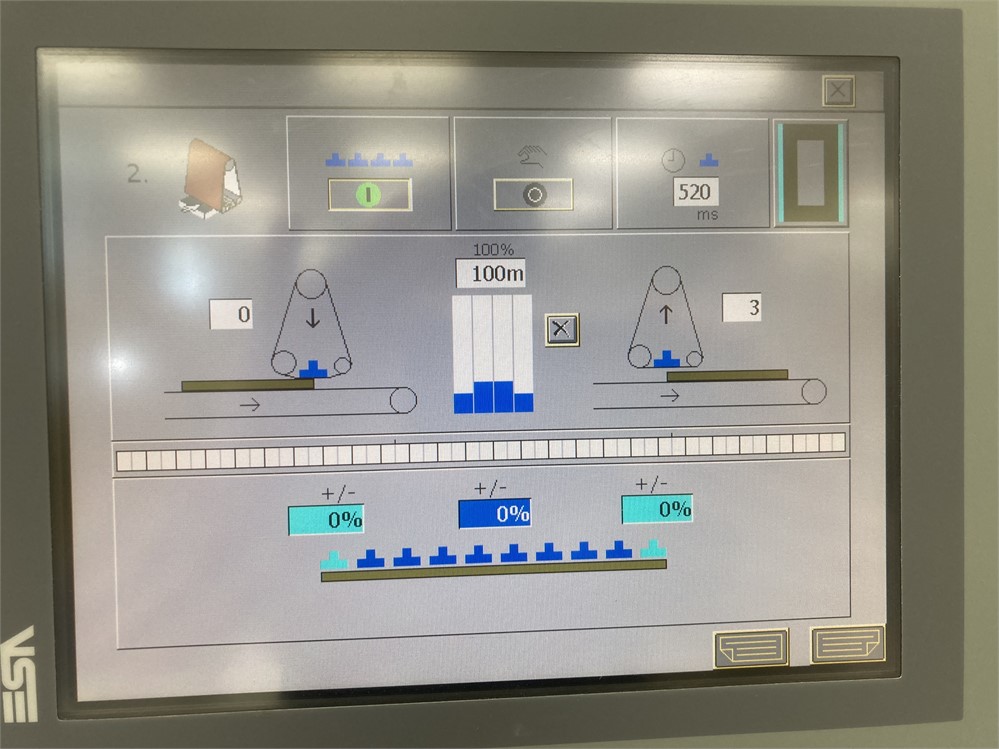

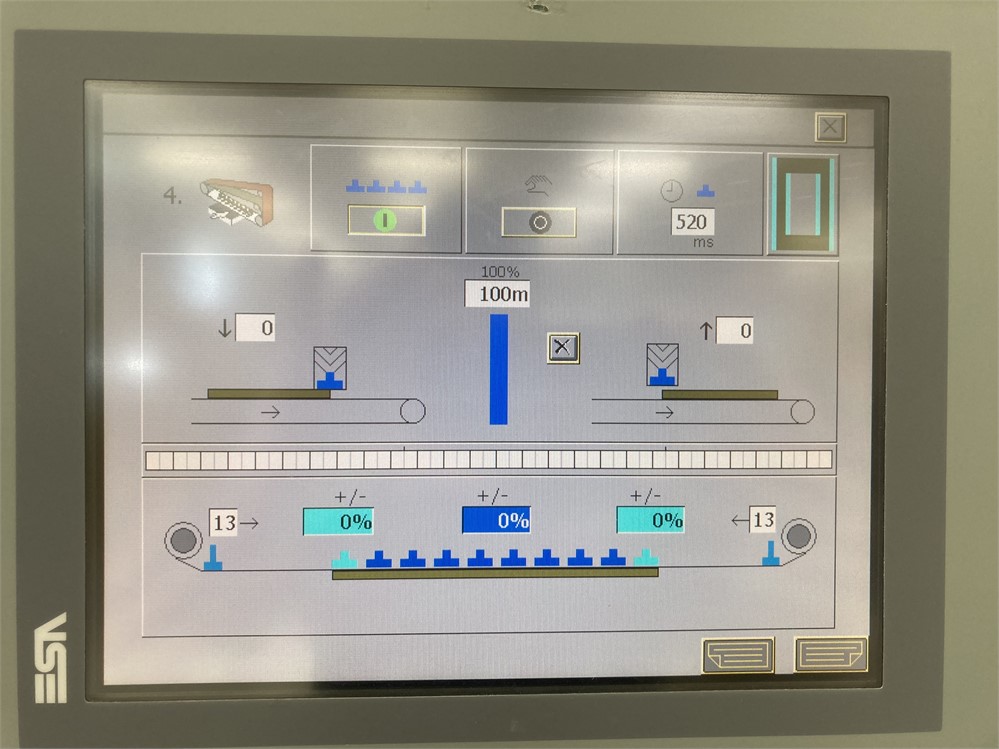

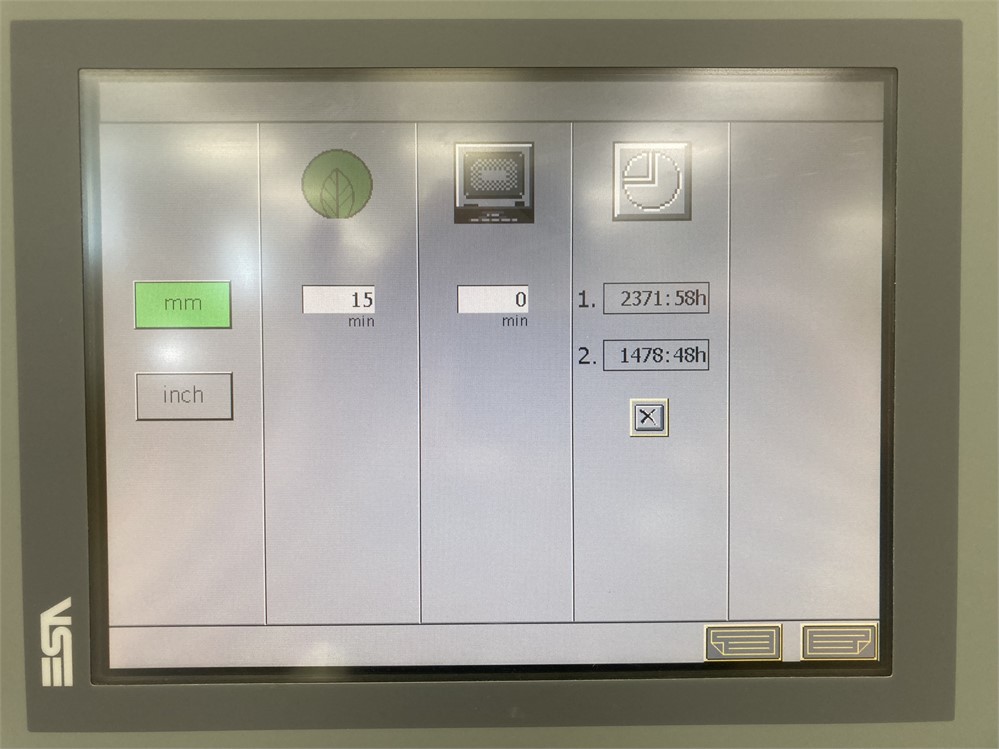

TE-14 Controller with touch screen

10.4" color screen

Millimeter or inch readout

Pre-set activation allows the operator to change the program while the machine is currently running another program. When the current part clears the machine, the new program will activate.

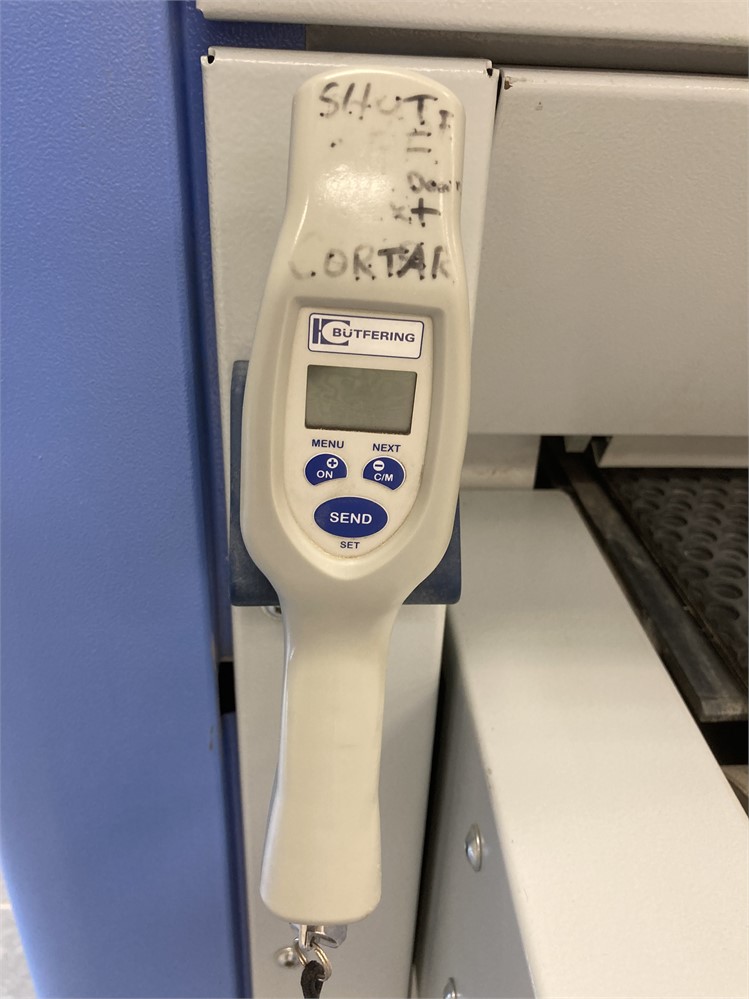

Wireless thickness caliper, 0" - 2". Transmits the work piece thickness to the machine controller automatically when the send button is pressed.

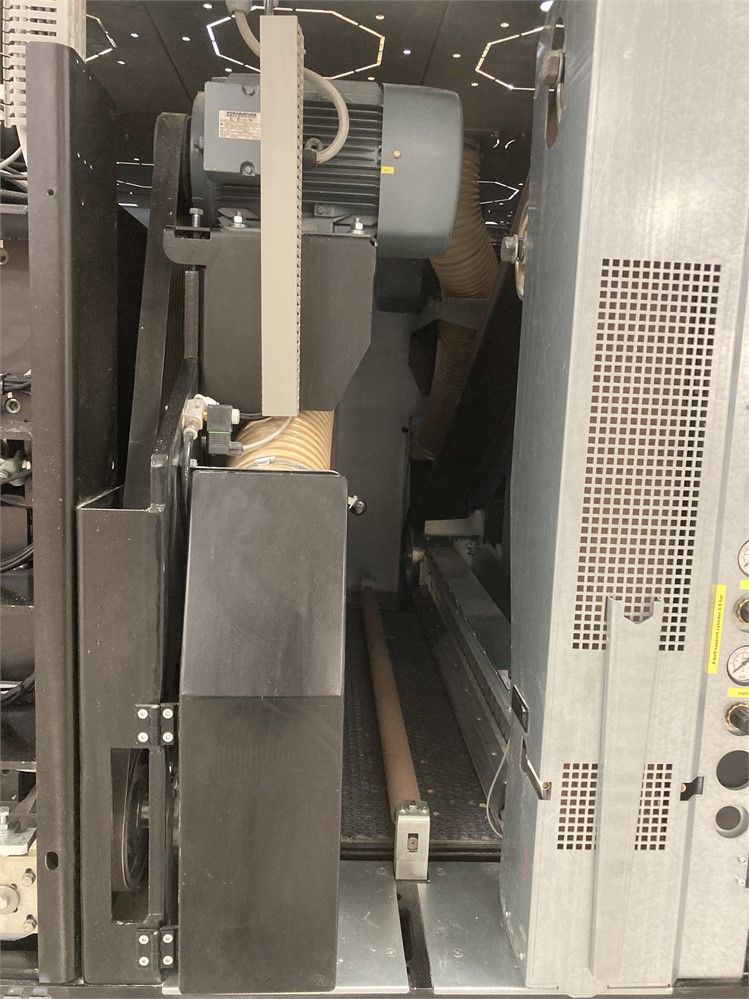

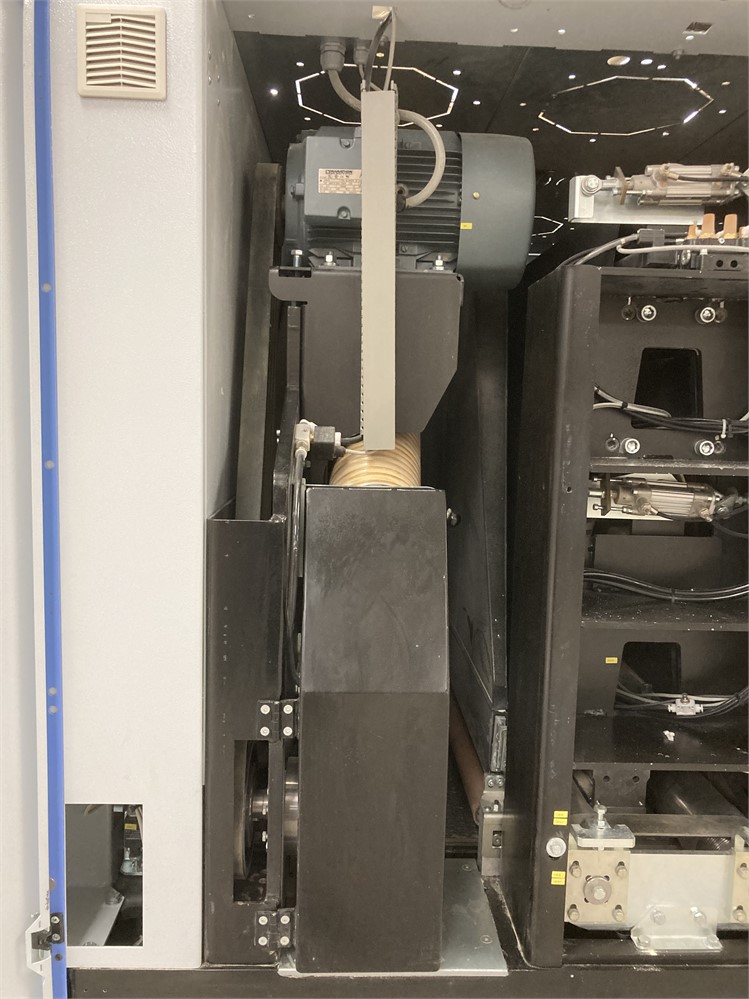

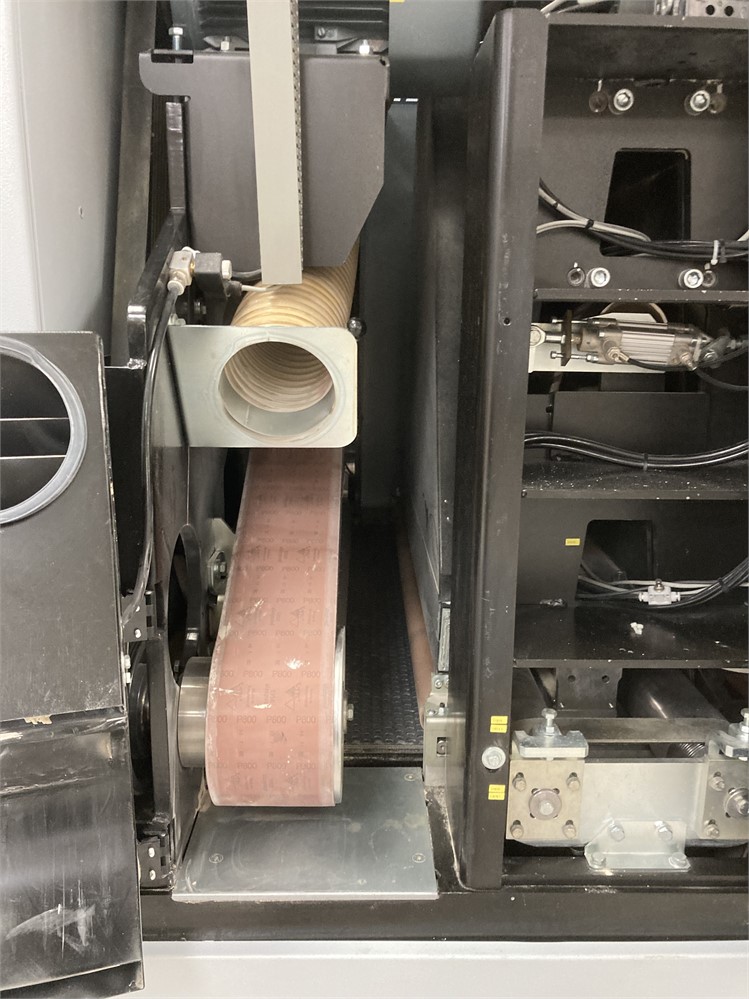

Unit 1

Q-Head – Cross sanding unit

This cross sanding head runs perpendicular to the belt feed. It is ideal for white wood sanding of laid up veneer panels as it levels out the veneer joints and aids in reducing wood fiber length. The cross belt is also used for sealer / lacquer sanding as well as sanding high gloss materials. 5360 x 150 mm (233" x 6") abrasive belt length.

18 HP motor

6.6 - 52.5 F/Sec. sanding speed

MPS-25 Magnetic controlled segmented pad with electro-magnetically controlled pressure.

Unit 2

H-Head – Longitudinal sanding with Inner Chevron Belt

Longitudinal sanding head with a segmented pressure pad and Inner Chevron Belt

30 HP motor

6.6 - 52.5 F/Sec. sanding speed

MPS-25 Magnetic controlled segmented pad with electro-magnetically controlled pressure.

Air jet blower with five (5) settings

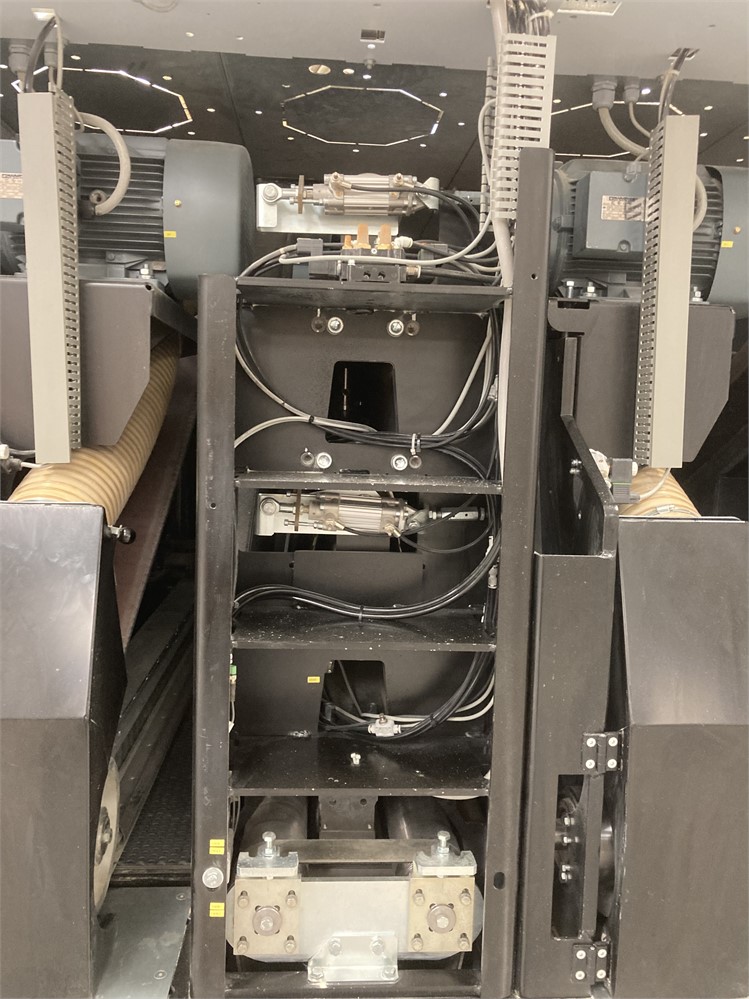

Unit 3

Q-Head – Cross sanding unit

This cross sanding head runs perpendicular to the belt feed. It is ideal for white wood sanding of laid up veneer panels as it levels out the veneer joints and aids in reducing wood fiber length. The cross belt is also used for sealer / lacquer sanding as well as sanding high gloss materials.

6" x 233" abrasive belt size

18 HP motor

6.6 - 52.5 F/Sec. sanding speed

MPS-25 Magnetic controlled segmented pad with electro-magnetically controlled pressure.

Unit 4

Q-Head – Cross sanding unit

This cross sanding head runs perpendicular to the belt feed. It is ideal for white wood sanding of laid up veneer panels as it levels out the veneer joints and aids in reducing wood fiber length. The cross belt is also used for sealer / lacquer sanding as well as sanding high gloss materials.

6" x 233" abrasive belt size

18 HP motor

6.6 - 52.5 F/Sec. sanding speed

MPS-25 Magnetic controlled segmented pad with electro-magnetically controlled pressure.

Rotary Air Jet Work Piece Cleaning with De-ionization

Butfering's Integrated Cleaning Plant includes a de-ionization bar to reduce static charge for better work-piece cleaning. The cleaning plant also includes a work-piece cleaning device with rotating air jets.

Roller Out Feed Table

A roller table at the out feed assists in transporting work-pieces from the machine and features an extension of 300 mm (11.8").

Outfeed conveyor NOT included

Listed specifications were taken from manufacturer's published information and is assumed to be correct but not guaranteed. Bidder is encouraged to inspect the machine, call with questions or contact the manufacturer for more information.

The listed specifications & information were taken from the manufacturer’s published information, internet research, or seller’s description.

The specifications & information are assumed to be correct; however, in no way, guaranteed. Bidders are encouraged to inspect the machine, call with questions, or contact the manufacturer for more information.

Please log in to view the bid history

LoginPick-ups are to be scheduled by appointment only. Please contact Sabrina Burns at 209-839-7707 or [email protected] to schedule an appointment. For freight quotes please contact Aaron at All-Ways Trucking at 541-608-6532. Buyer bears all costs to remove and load this lot. Buyer must remove entire lot purchased. Anyone removing non-hand carriable lots must provide MachineryMax, Inc. with a certificate of insurance (COI) before purchased items can be removed.

All buyers agree to make full payment to MachineryMax, Inc. within 48 hours of the online closing date for the auction lots purchased. All invoices over $1,500.00 are to be made by bank wire transfer or cashier’s check payable to MachineryMax, Inc. Purchases under $1,500.00 may be made using Visa, MasterCard, or American Express (2% credit card processing fee will be added to the invoice). All payments are to be made in USD currency only. Bidder represents and warrants to MachineryMax, Inc. that such bidder has immediately available funds to fully pay for its successful bids within 48 hours of the online closing date. All payment questions should be directed to Sabrina Burns at 209-839-7707 or [email protected] All buyers agree that there will be a 15% Buyers premium that will be added to the final invoice.