(2015) Holz-Her "Lumina 1380" Edgebander  Ended

Ended

Weeke CNC, Holz-Her Edgebander and Dantherm Dust Collector - Parma, OH

- Winning Bid : $57,000.00 USD Sold

- 116 Bid(s)

- High Bidder: D****a

Weeke CNC, Holz-Her Edgebander and Dantherm Dust Collector - Parma, OH ( Closed #29418593 )

Closet manufacturer in Cleveland, OH area is upgrading their shop and auctioning machinery no longer required for continuing operations. Weeke "Vantage 34 M" CNC, Holz-Her "Lumina 1380" Edgebander and Dantherm "S-750" Dust Collector.

-

Pick Up Location

5305 Commerce Pkwy. West, Parma, OH 44130

-

Make

Holz-Her

-

Model

Lumina 1380

-

Serial Number

111/1-508

-

Year

2015

-

Phase

3 PHASE

-

Voltage

Other

-

Load Out Period

September 29 - October 8, 2021 (by appointment)

-

Estimated Dimensions

220" L x 48"W x 72" H

-

Estimated Weight

5,000 Pounds

-

Seller Comment

For machinery rigging and loading, please contact Andy Zucca @ OBC Industrial, (216) 398-8800 or [email protected]. This machine has been relocated to rigger's warehouse. Buyer is responsible for loading fee of $700 within two weeks of auction close. After two weeks rigger will charge $50/week storage plus loading fee.

-

Load Fee

-

page views

3474

Holz-Her "Lumina 1380" Laser Edgebander

See video of machine in operation

The LTronic laser edgebander was developed especially for the LUMINA series and processes all edging with functional layer on the market.

60 mm (2.3") maximum panel height

160 mm (6.3") minimum panel length

60 mm (2.3") maximum panel width

0.4 - 15 mm (0.016 - 0.6") edging thickness

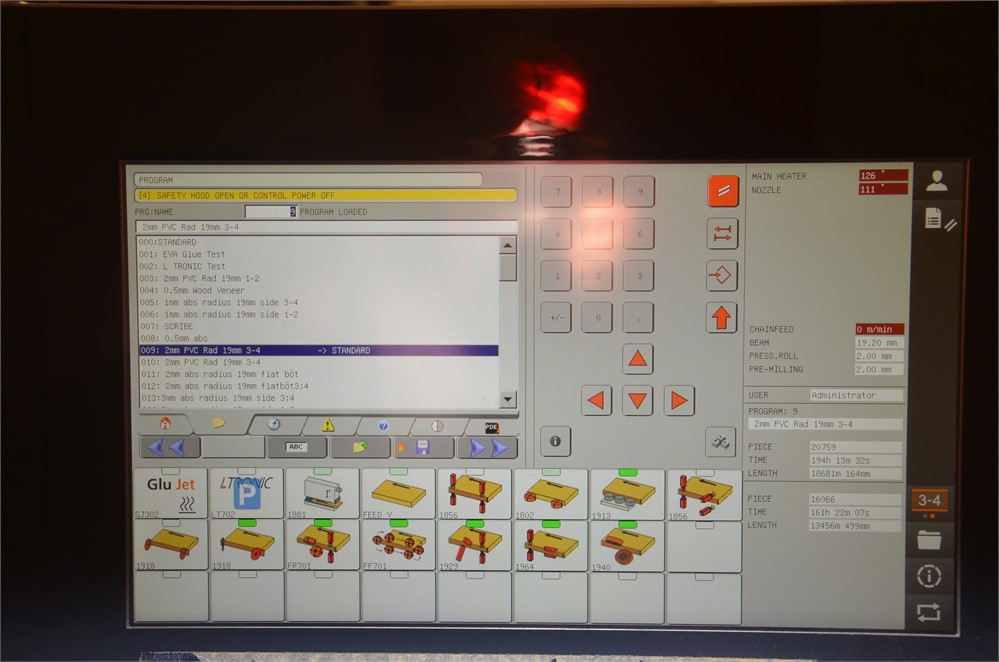

Color, touch-screen controller

18.5" display

Edging database

Motorized pressure beam height adjustment (Holz-Her 1881)

Variable feed speed

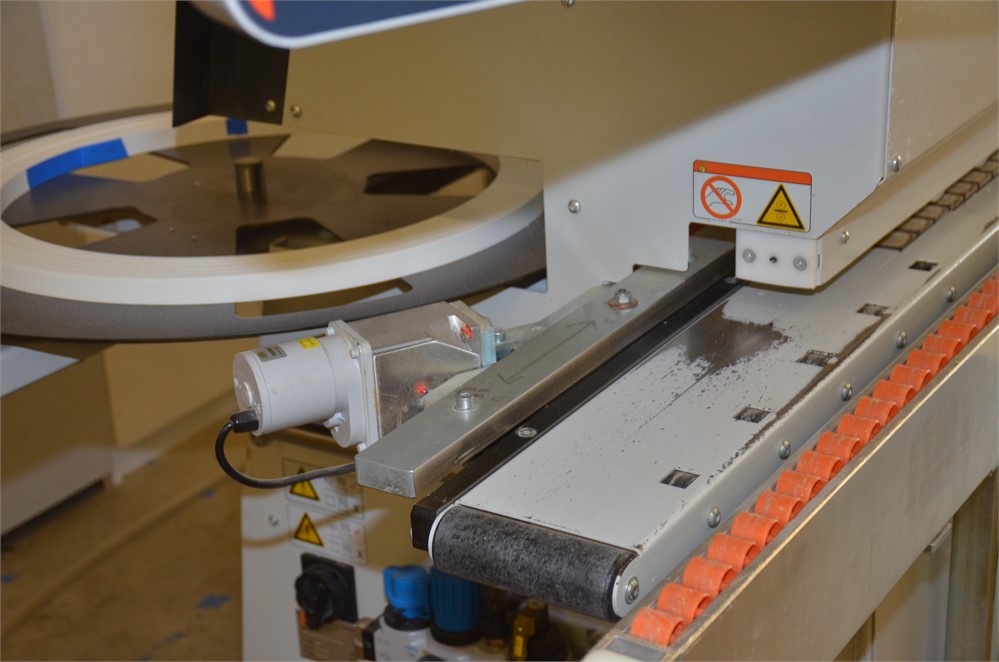

Edgebanding infeed table

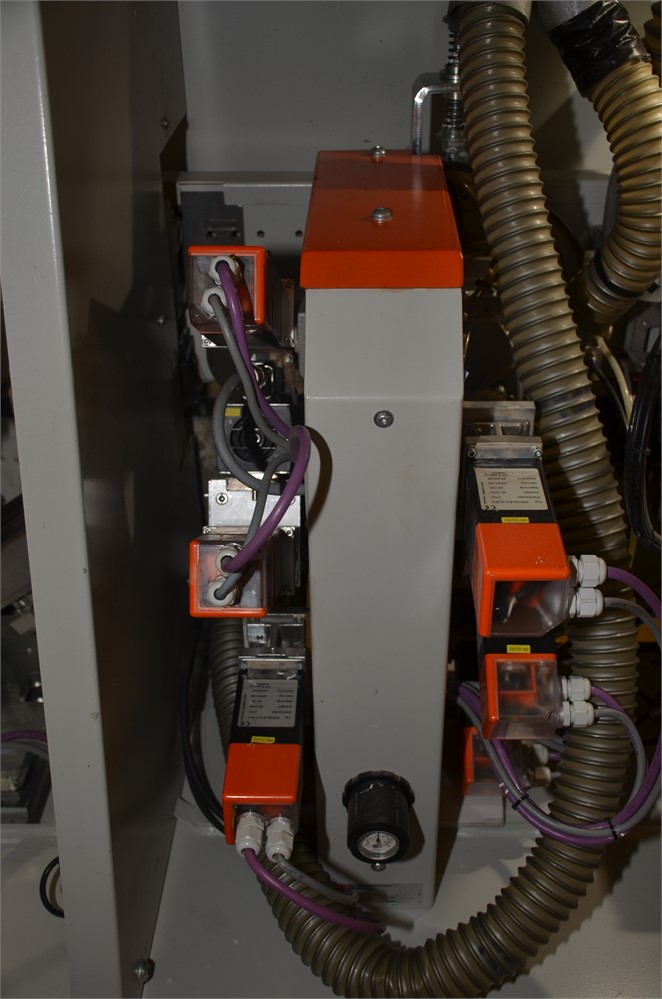

Infeed fence with NC positioning

Release agent spraying device (Holz-Her 1856)

Sprays the upper and lower side of the workpiece with adhesive along the glued edge. The lower spraying nozzle is mounted at the infeed fence of the basic machine and thus has a fixed position to the infeed plane. The upper spraying nozzle is mounted at the bridge of the basic machine and by that is adjusted automatically to the right workpiece thickness.

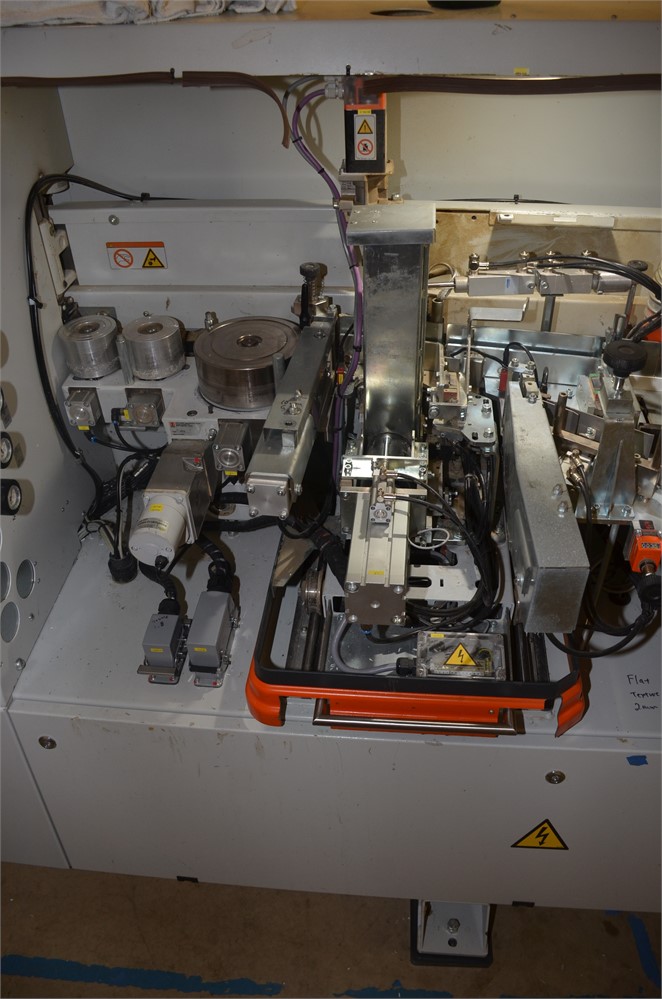

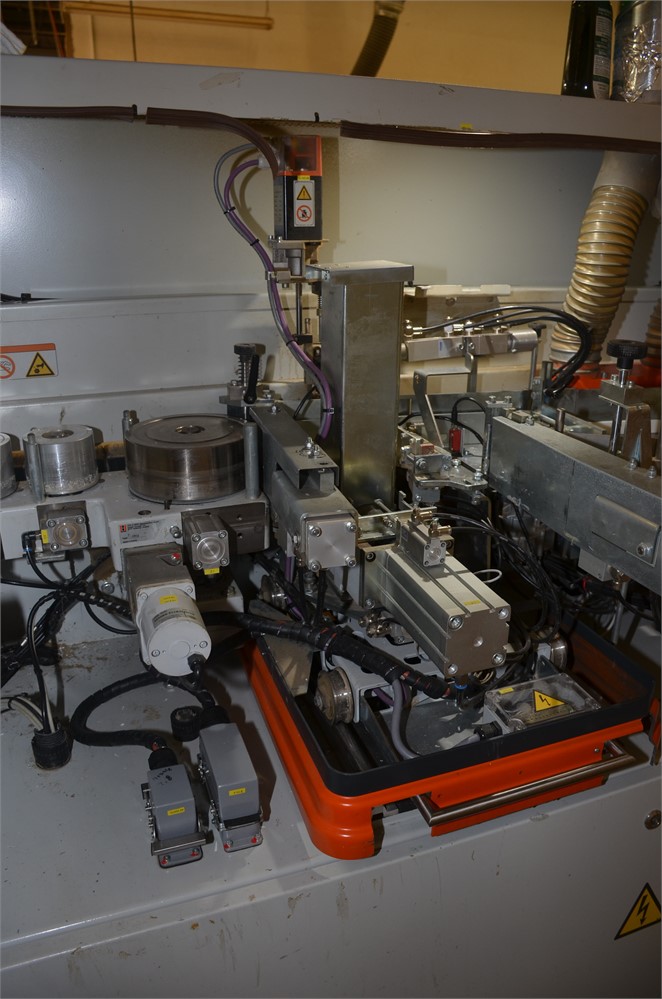

Premilling unit (Holz-Her 1802)

Two (2) motors

One (1) CW rotation and one (1) CCW rotation

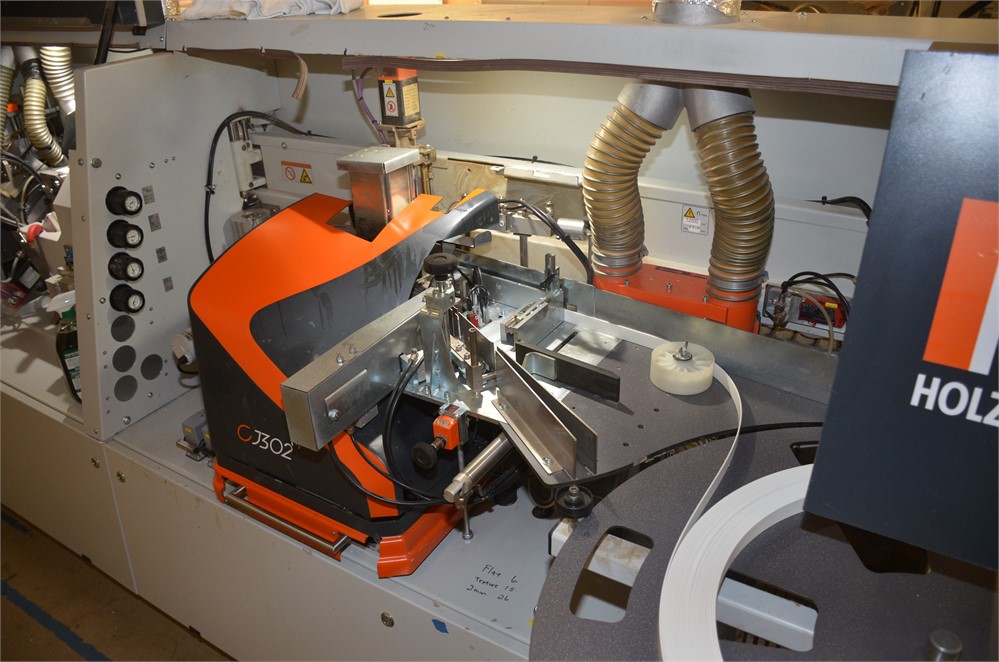

GluJet "GJ302" gluing station (Holz-Her GJ302)

The optimized "GluJet" application system on the HOLZ-HER machines ensures perfect edge appearance. With its unique hybrid technology, this unit ensures perfect interaction between glue, edging and panel material. The GluJet system ensures easy use of EVA or PUR glues in cartridge or granulate form and with its short heat-up time of only 3 minutes and low energy consumption when remelting the glue, it also helps preserve your resources.

LTronic "LT702" gluing station (Holz-Her LT702)

Switch it on and it's immediately ready for use – the new LTronic unit does not require a heat-up time or any heat-up phases during the machining process. In addition, the complete system operates absolutely silently which is a clear advantage for the user compared to other systems. Moreover, cleaning costs are minimal. The integrated protective plate on the NIR module needs to be briefly cleaned just once per week.

A highlight is the edging library completely integrated into the control. All of the very latest co-extruded and subsequently coated edging are already stored here as a factory-provided item and can be simply selected by the user via the standard touchscreen. Each laser edging needs a specific energy entry, which, by way of an example, depends on the edge thickness or the color. After the selection is made, LTronic automatically adjusts the respective energy requirement. HOLZ-HER takes perfect care of all of that with its edging library.

On mobile cart for easy installation

Pressure station (Holz-Her 1913)

One (1) driven roller

Two (2) idle rollers with pneumatic control

Second Release agent spraying device (Holz-Her 1856)

Sprays the upper and lower side of the workpiece with adhesive along the glued edge. The lower spraying nozzle is mounted at the infeed fence of the basic machine and thus has a fixed position to the infeed plane. The upper spraying nozzle is mounted at the bridge of the basic machine and by that is adjusted automatically to the right workpiece thickness.

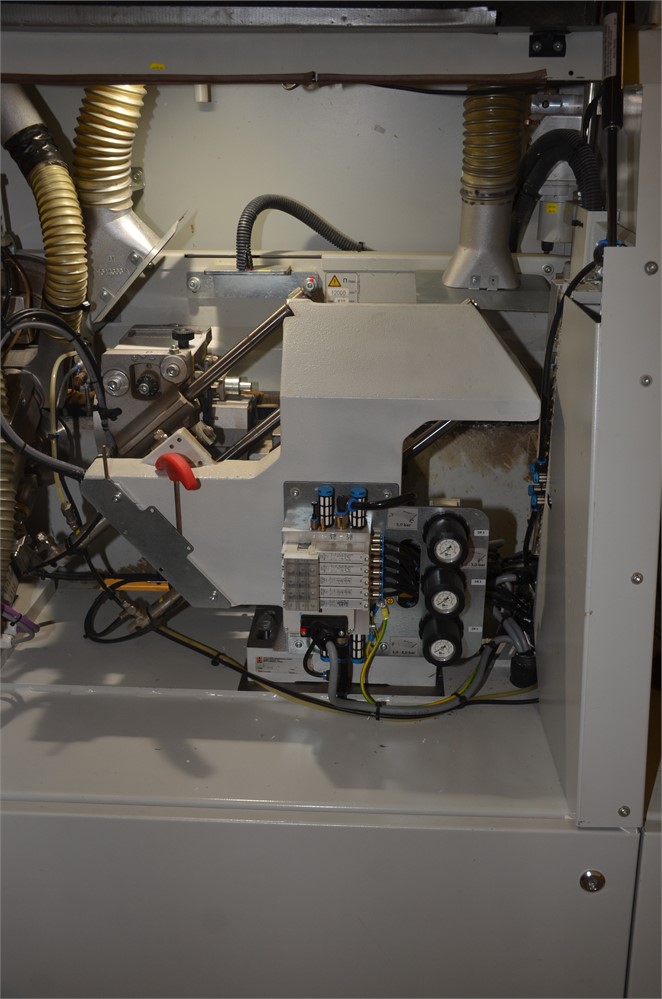

End trimming station (Holz-Her 1918)

Two (2) motors

Tiltable up to 10 degrees

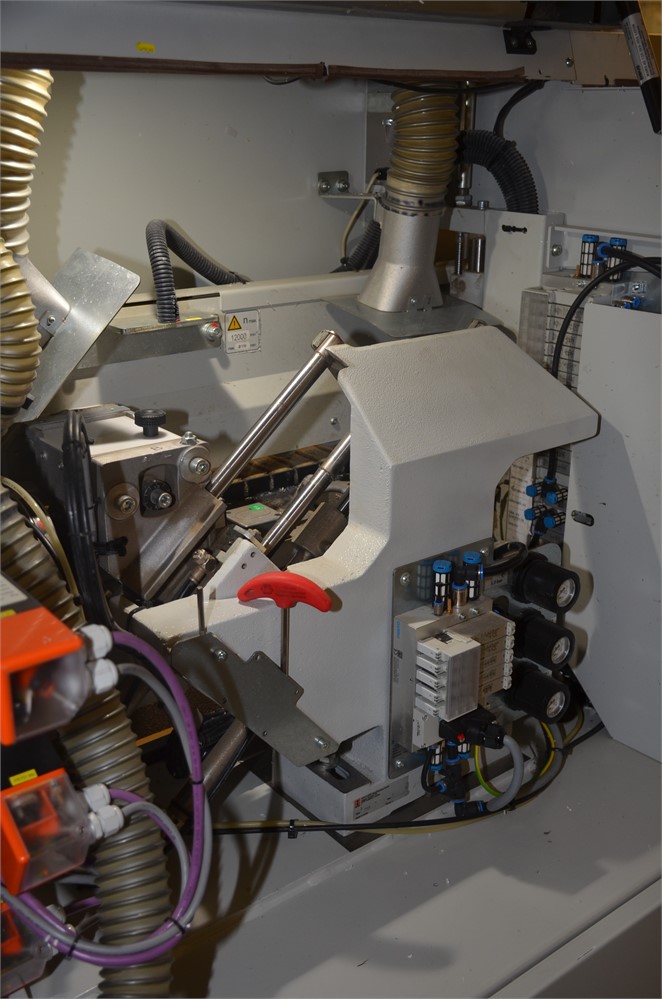

Top/bottom trimming station (Holz-Her FR701)

Two (2) motors

Six (6) NC-servo axes

Tiltable up to 15 degrees

Corner rounding station (Holz-Her FF701)

Two (2) motors

Top/bottom profile scrapping station (Holz-Her 1929)

With external collection box

Top/bottom flat scraping station (Holz-Her 1964)

Top/bottom buffing station (Holz-Her 1940)

With lubrication/misting

Outboard roller support

Lighted sound enclosure

Custom dust manifold

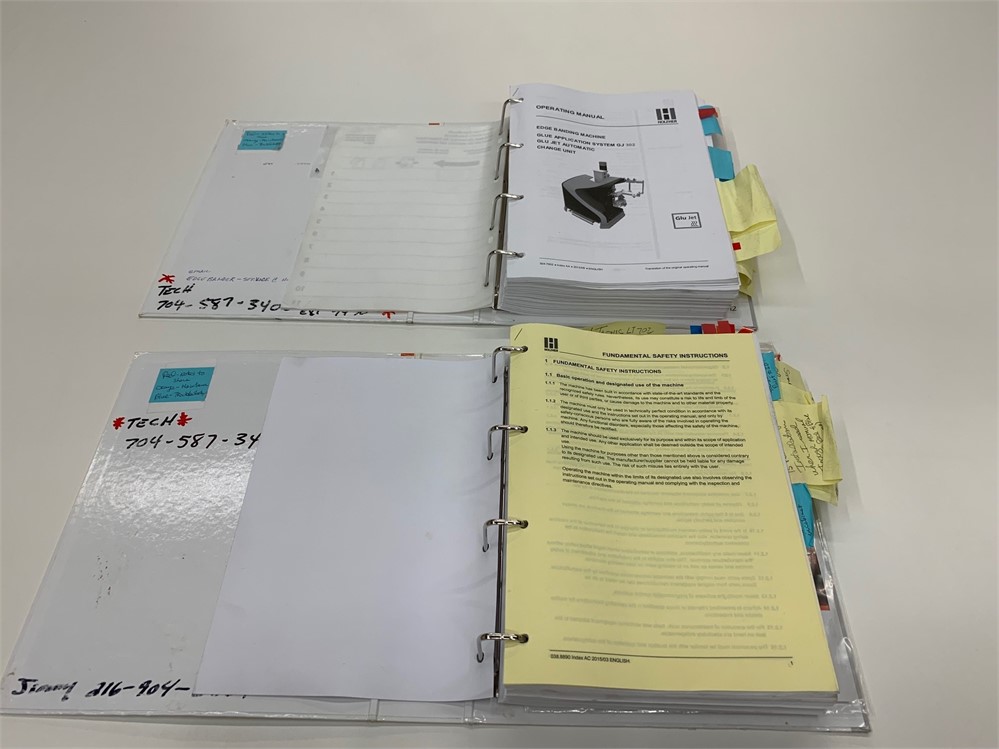

Manuals

See specific notes and pricing for rigging in the shipping section

Listed specifications were taken from manufacturer's published information and is assumed to be correct but not guaranteed. Bidder is encouraged to inspect the machine, call with questions or contact the manufacturer for more information.

The listed specifications & information were taken from the manufacturer’s published information, internet research, or seller’s description.

The specifications & information are assumed to be correct; however, in no way, guaranteed. Bidders are encouraged to inspect the machine, call with questions, or contact the manufacturer for more information.

Please log in to view the bid history

LoginPick-ups are to be scheduled by appointment only. Please contact Sabrina Burns at 209-839-7707 or [email protected] to schedule an appointment. For freight quotes please contact Aaron at All-Ways Trucking at 541-608-6532. Buyer bears all costs to remove and load this lot. Buyer must remove entire lot purchased. Anyone removing non-hand carriable lots must provide MachineryMax, Inc. with a certificate of insurance (COI) before purchased items can be removed. For machinery rigging and loading, please contact Andy Zucca @ OBC Industrial, (216) 398-8800 or [email protected].

All buyers agree to make full payment to MachineryMax, Inc. within 48 hours of the online closing date for the auction lots purchased. All invoices over $1,500.00 are to be made by bank wire transfer or cashier’s check payable to MachineryMax, Inc. Purchases under $1,500.00 may be made using Visa, MasterCard, or American Express (2% credit card processing fee will be added to the invoice). All payments are to be made in USD currency only. Bidder represents and warrants to MachineryMax, Inc. that such bidder has immediately available funds to fully pay for its successful bids within 48 hours of the online closing date. All payment questions should be directed to Sabrina Burns at 209-839-7707 or [email protected] All buyers agree that there will be a 15% Buyers premium that will be added to the final invoice.