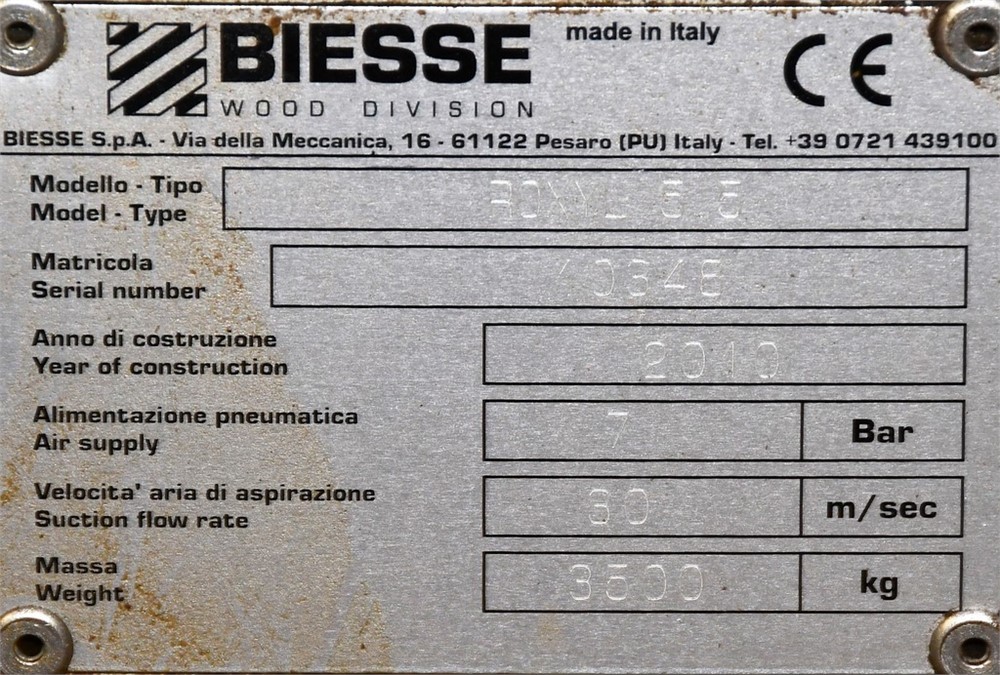

Biesse "Roxyl 5.5" Edge Bander - Pre-mill (2010)  Ended

Ended

ACME Millwork - Complete 100,000 SQ Ft Facility - San Angelo, TX

- Winning Bid : $10,950.00 USD Sold

- 21 Bid(s)

- High Bidder: t****3

Acme Millwork - Complete Plant Closure Day 1- San Angelo, TX ( Closed #28473543 )

Open House September 1 & 2 8:00AM to 3:00PM - 234 W. Ave. L, San Angelo, TX 76903

-

Pick Up Location

San Angelo, TX

-

Make

Biesse

-

Model

"Roxyl 5.5"

-

Serial Number

2010

-

Year

2010

-

Phase

3 PHASE

-

Voltage

230 VOLT

-

Load Out Period

September 17, 2021

-

Estimated Dimensions

260" x 48" x 72"

-

Estimated Weight

7,700 Lbs

-

Seller Comment

Aaron at All-Ways Trucking at 541-608-6532.

-

Load Fee

A rigger is required for this lot. Please Contact: Marco Salinas @ West Coast Movers, 323-588-3533 or [email protected]

-

page views

3062

Edge thickness for strips min./max. 0.4 - 22 mm (0.02" - 0.87"), coiled material from 0.4 - 3 mm (0.02 - 0.12"); panel thickness from 10 - 60 mm (0.39 - 2.36"), work piece width min. of 85 mm (3.34"); work piece length min. 140 mm (5.51"); feed speeds 10 - 14 - 18 - 20 MPM (33 - 46 - 59 - 65 FPM).

"Roxyl-Matic" Automated machine setup, MS/Windows XP Operating System, floppy drive, and 4 GB HD; USB port, keyboard, and mouse interface.

Flat Screen (17") with color graphics interface: Programs can be easily created and recalled at will; Graphic interface makes programming easy, icon of each unit may be brought up on the screen to show the operator the status of the unit and the parameters, which can be programmed; Edgebander may be operated manually when required, without necessity to write a program.

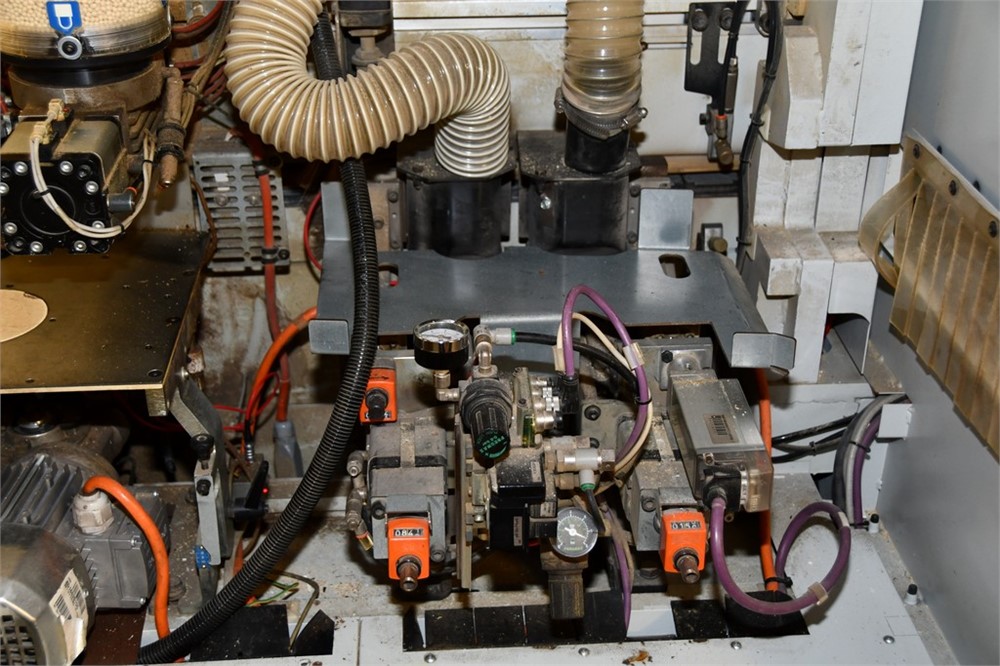

Pre-Milling Station "FL-502": (2) LH & RH Rotating NC controlled spindles with automatic center positioning.

Infrared Heating Lamp: Preheating workp iece edge to ensure best possible surface adhesion quality of edge banding material.

Edge Magazine: Automatic for processing coiled and strip edge banding material.

Pressure Section: Servo controlled programmable pressure section with (1) large driven roller and (4) idle rollers.

EVA (Hot Melt) "QM-705": Quick pre-melting granulate with glue roller applicator to cover conventional edge banding material.

AirForce "VC-710": High pressure, hot air system to reactivate special precoated edgematerial (commonly referred to as laser edge). (not verified)

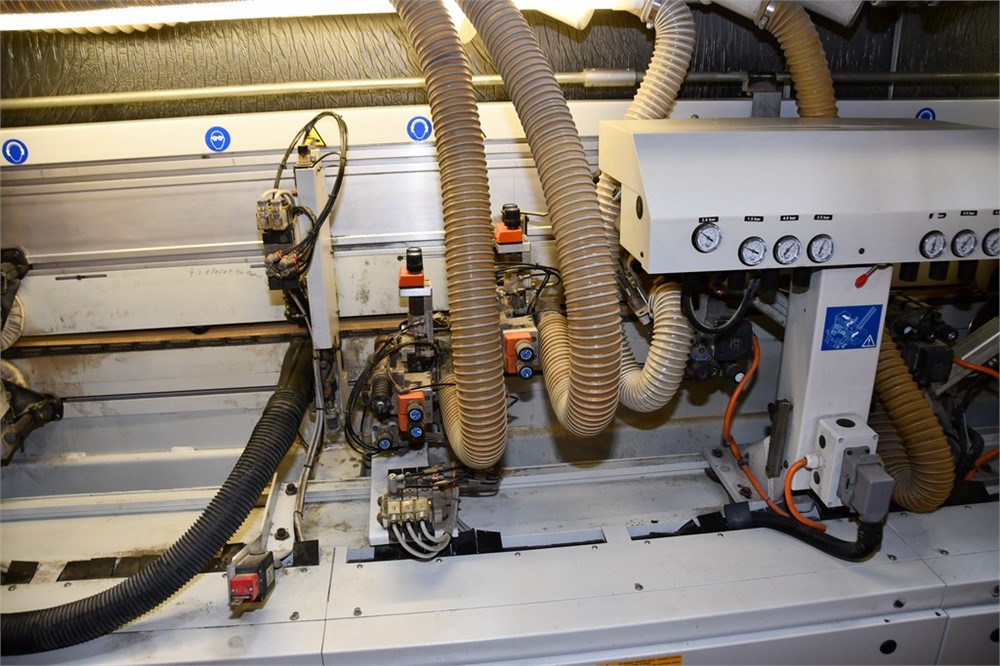

End Trimming Unit "IN-801": Front & rear trimming motors, uni-point swivel 0° - 15° bevel, programmable pneumatic change-over from flush to bevel.

Rough/Flush Trimming Unit "RS-701": Top/Bottom pre- or flush trimming motors.

Flush/Bevel/Radius Combination Trimming Unit "RF-400": Servo controlled, (2) Servo motors (one for horizontal tool position, one for tool up/down position); using combination bevel/radius/flush insert knives; pre-postioning of motors by pneumatic air cylinders.

Corner Rounding Unit "CR-202": (2) Motors for front/back corner and upper & lower edge profiling.

Profile Scraping Unit "RBK-503": Top/Bottom 2-axis NC programmable knife postioning (i.e. 2 - 3 mm radius) for PVC edges.

Glue Scraping Unit "RCC-701": Flat, top/bottom, digital positioning indicators, pneumatic controlled for in/out position.

Buffing Station "SP-501": Top & Bottom buffing motors with 150 mm ( 6") cloth buffing wheel diameter; adjusts in multiple directions.

The information provided in this lot was gathered from literature, internet & physical inspection. It is thought to be accurate; but not guaranteed. Bidders are urged to use the open house or private inspection periods to inspect and verify.

The listed specifications & information were taken from the manufacturer’s published information, internet research, or seller’s description.

The specifications & information are assumed to be correct; however, in no way, guaranteed. Bidders are encouraged to inspect the machine, call with questions, or contact the manufacturer for more information.

Please log in to view the bid history

LoginPick-ups are to be scheduled by appointment only. Please contact Sabrina Burns at 209-839-7707 or [email protected] to schedule an appointment. For freight quotes please contact Aaron at All-Ways Trucking at 541-608-6532. Buyer bears all costs to remove and load this lot. Buyer must remove entire lot purchased. Anyone removing non-hand carriable lots must provide MachineryMax, Inc. with a certificate of insurance (COI) before purchased items can be removed. For a Rigging Quote, please Contact: Marco Salinas @ West Coast Movers, 323-588-3533 or [email protected]

All buyers agree to make full payment to MachineryMax, Inc. within 48 hours of the online closing date for the auction lots purchased. All invoices over $1,500.00 are to be made by bank wire transfer or cashier’s check payable to MachineryMax, Inc. Purchases under $1,500.00 may be made using Visa, MasterCard, or American Express (2% credit card processing fee will be added to the invoice). All payments are to be made in USD currency only. Bidder represents and warrants to MachineryMax, Inc. that such bidder has immediately available funds to fully pay for its successful bids within 48 hours of the online closing date. All payment questions should be directed to Sabrina Burns at 209-839-7707 or [email protected] All buyers agree that there will be a 15% Buyers premium that will be added to the final invoice.