SCM GROUP "STARTECH 27" MULTI SPINDLE DRILL, YEAR 2017  Ended

Ended

STARTECH 27 DRILL AND SCMI SANDYA 10 AUCTION - Costa Mesa CA

- Winning Bid : $6,101.00 USD Sold

- 57 Bid(s)

- High Bidder: S****S

2017 SCM GROUP STARTECH 27 AND SCM SANDYA 10S SANDER - Costa Mesa CA ( Closed #28221545 )

2017 SCM GROUP MODEL #STARTECH 27 MULTI SPINDLE BORING MACHINE AND 2003 SCMI SANDYA 10S 2 HEAD 52" WIDE BELT SANDER UP FOR AUCTION TO THE HIGHEST BIDDER. FOR QUESTIONS PLEASE CONTACT KIRK AT 925-250-8248 OR VIA EMAIL AT [email protected]

-

Pick Up Location

1139 Baker St, Costa Mesa, CA 92626, USA

-

Make

SCM GROUP

-

Model

STARTECH 27

-

Serial Number

KK138030

-

Year

2017

-

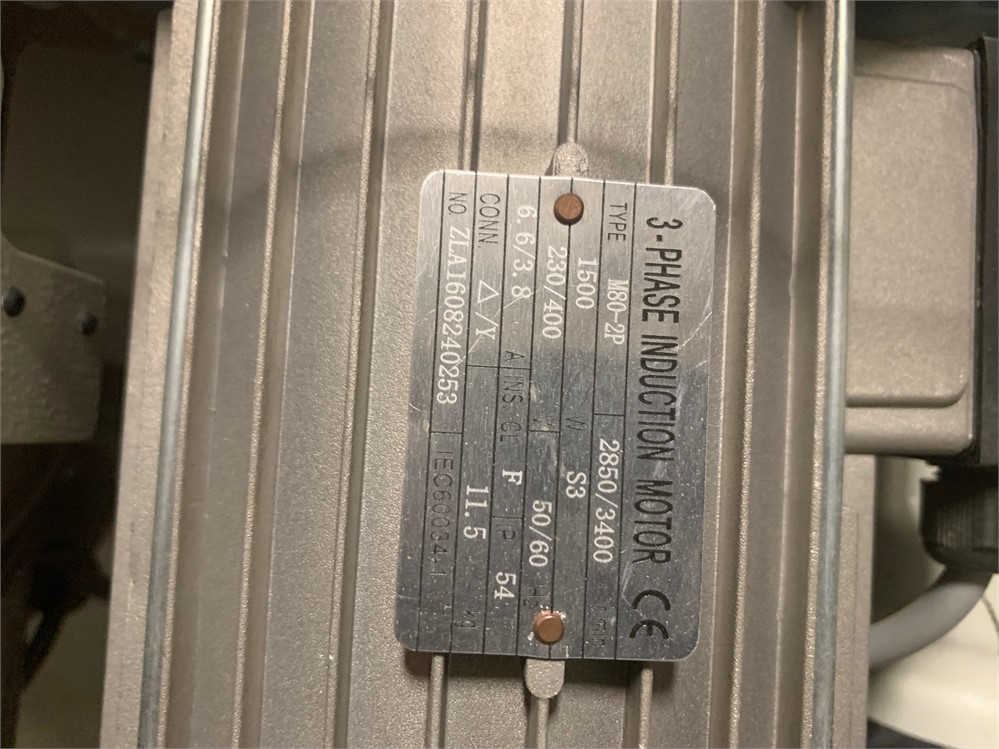

Phase

3 PHASE

-

Voltage

230 VOLT

-

Load Out Period

AUGUST 9TH, 2021

-

Estimated Dimensions

-

Estimated Weight

-

Seller Comment

-

Load Fee

$200 LOADING FEE

-

page views

5069

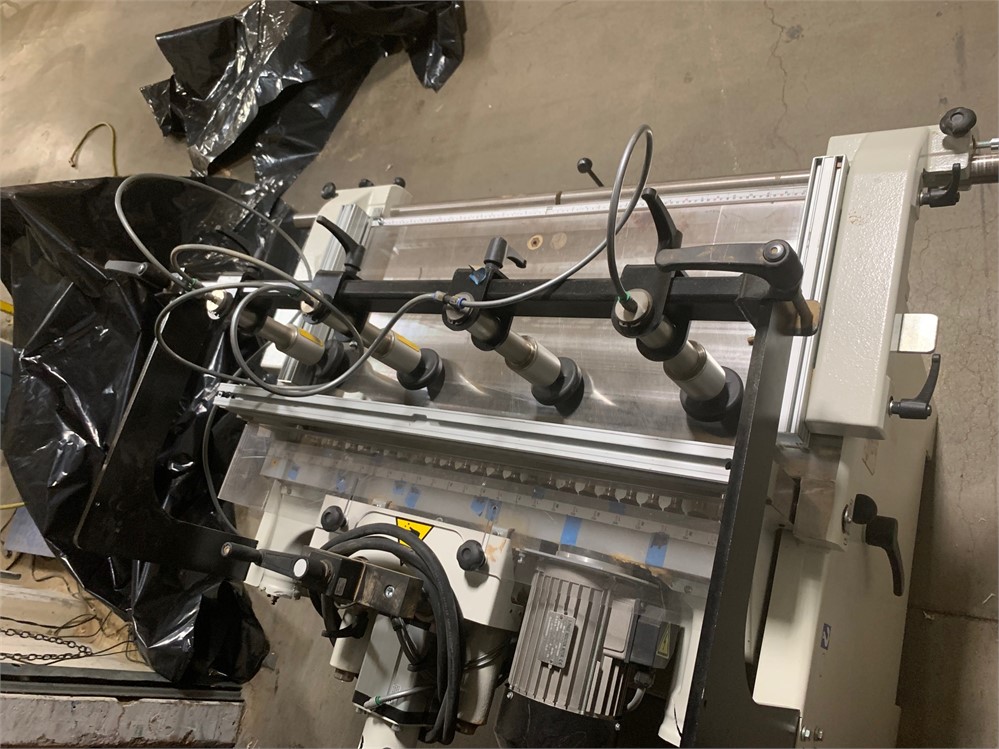

Multi-spindle Boring Machine

The Startech 27 is a heavy duty, Single head multiboring machine that is capable of performing horizontal, vertical and 45°

boring operations for wood and similar materials.

Base and working table

The base and worktable are made of both bended and welded steel plates to

create a large workpiece support surface for large jobs. Right/left extensions with

retractable stops L=3000mm are now standard! The extensions can be installed

on the guides already mounted on the machine and are positioned at 90° with

reference to the boring line; They are complete with no. 4 retractable stops

(which may also be used as rear guides) and two upper pressure cylinders for

the workpieces hold-down. The compass device allows the quick positioning of

the guide located opposite the one in use without the necessity of metric reads.

Gantry structure

The gantry uses an ultra-thick steel structure, with depth adjustment, to easily support the load bearing stress. Pneumatic

cylinders for the workpieces lock when machining pieces.

Standard Operating unit

Boring head with quick attachment spindles (32mm center-to-center distance) with an aluminium structure and gears.

The boring head movement is created through a pneumatic piston (standard).

Horizontal/vertical autom. positioning of boring unit

Adjustment, activated by pneumatic circuit, which allows the automatic boring head rotation from the control board

All spindles are preset for quick change adaptors

18 drilling bit-holder quick connect bushes 10 mm dia (9-standard and 9 additional ordered as an accesory)

Suction for shavings have an independent outlet on the boring head and air conveyor on the base

Workpiece and operating unit movement

Automatic head movement for the horizontal and vertical boring unit positioning,

with locking at 45°rear stops, lateral stops and extensions for long workpieces are

engineered to ensure the best working precision on the piece.

Major Features

- Line and Construction boring with 45° positive stop

- Two Pneumatic clamps

- Preset with a total of 18 quick change 10mm adaptors

- Right Left Extension fence with retractable stops (3000mm)

- Fence for horizontal boring at 45°

- One Supplementary top pressure cylinder

- Device for working narrow workpieces

- Calibration Jig

Specifications

HEAD GROUP

- Number of spindles 27

- Center-to-center distance between spindles 32mm

- Spindles speed 3000 rpms

- Motor power of spindles 1.5 (2) kW (Hp)

- Number of revolving turret positions 6

- Max stroke of boring unit 63mm

- Stroke of hydraulic brake 50mm

TOOL

- Maximum tool length 80mm

- Max tool diameter 40mm

PANEL

- Max. horizontal boring height mm 50

- Max. width under the “gantry structure” mm 1.025

- Max. distance of vertical borings from panel edge mm 110/320

- Min. panel thickness mm 10

- Max. panel thickness mm 60

INSTALLATION

- Compressed air pressure bar 6

- Compressed air consumption Nl/cycle 3,6

- Exhaust outlets diameter mm 120+60+60

- Exhaust air speed m/sec 30

- Exhaust air consumption m3/hr 1220+300+300

- Working table dimension mm 1.096 x 407

- Worktable height from floor mm/inches 900/35.5”

- Weight 370/815 Kg/Lbs

The listed specifications & information were taken from the manufacturer’s published information, internet research, or seller’s description.

The specifications & information are assumed to be correct; however, in no way, guaranteed. Bidders are encouraged to inspect the machine, call with questions, or contact the manufacturer for more information.

Please log in to view the bid history

LoginA $200.00 LOADING FEE WILL BE CHARGED FOR LOADING ONTO FLAT BED TRUCK OR TRAILER ONLY.

All buyers agree to make full payment to MachineryMax, Inc. within 48 hours of the online closing date for the auction lots purchased. All invoices over $1,500.00 are to be made by bank wire transfer or cashier’s check payable to MachineryMax, Inc. Purchases under $1,500.00 may be made using Visa, MasterCard, or American Express (2% credit card processing fee will be added to the invoice). All payments are to be made in USD currency only. Bidder represents and warrants to MachineryMax, Inc. that such bidder has immediately available funds to fully pay for its successful bids within 48 hours of the online closing date. All payment questions should be directed to Sabrina Burns at 209-839-7707 or [email protected] All buyers agree that there will be a 15% Buyers premium that will be added to the final invoice.