(2016) Biesse "Stream A 6.0" with Winner "W4" Stacker and Return System  Ended

Ended

Biesse "Stream A 6.0" with Winner "W4" Stacker and Return System - Patterson, CA

- Winning Bid : $91,000.00 USD Sold

- 89 Bid(s)

- High Bidder: J****s

Biesse "Stream A 6.0" with Winner "W4" Stacker and Return System - Patterson, CA ( Closed #27408223 )

High end panel and component manufacturer in Northern California is upgrading its equipment and auctioning its Biesse edgebanding cell. Complete edgebanding cell with Biesse Stream A 6.0 with AirForce System; Biesse Winner W4 stacker; and return conveyor. This system retailed for almost $400,000 in 2016!

-

Pick Up Location

525 Baldwin Rd. Patterson, CA 95363

-

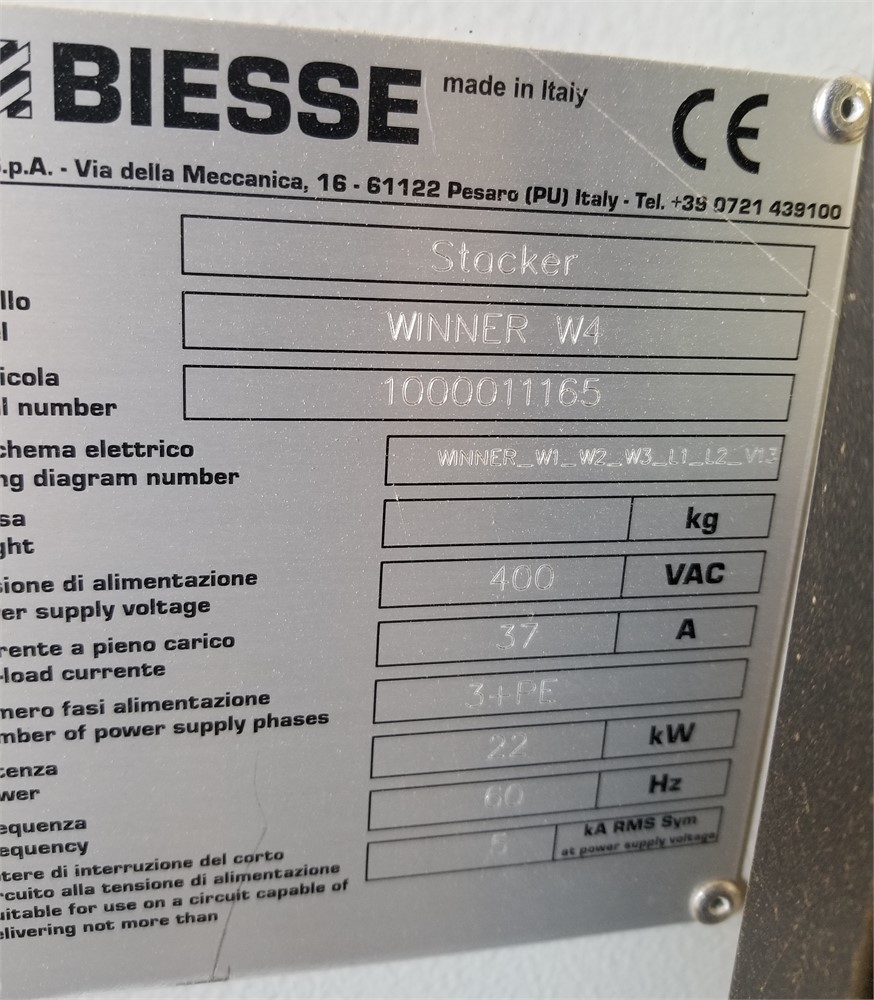

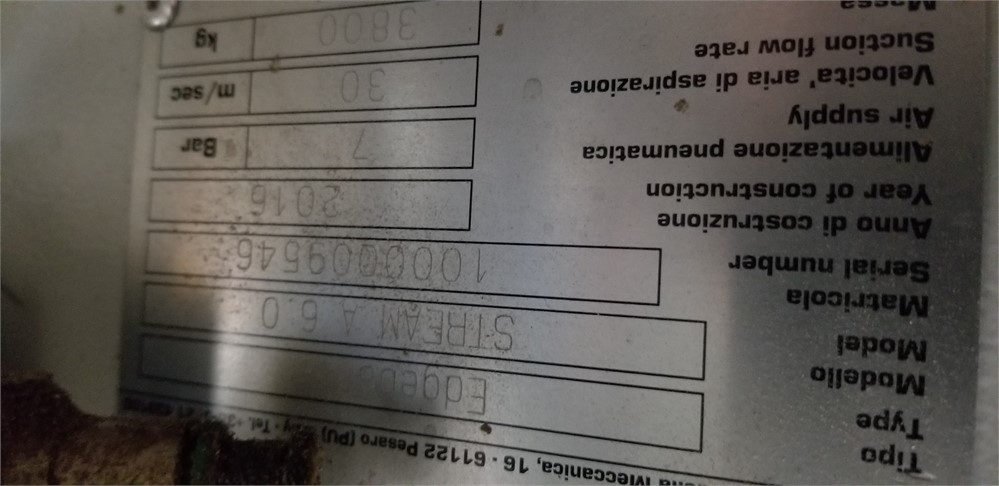

Make

Biesse

-

Model

Stream A 6.0 (edgebander), Winner W4 (stacker)

-

Serial Number

1000009546 (edgebander), 1000011165 (stacker)

-

Year

2016

-

Phase

3 PHASE

-

Voltage

400

-

Load Out Period

May 27 - June 11, 2021 (by appointment)

-

Estimated Dimensions

See photos

-

Estimated Weight

8,500 pounds (edgebander)

-

Seller Comment

Buyer is responsible for hiring a Biesse or other technician for dismantling. For rigging/loading, please contact Bruce MacLeod @ Lawson Drayage, (408) 595-5140 or [email protected].

-

Load Fee

-

page views

10007

Package Sold New in 2016 for Approximately $380,000.00

Biesse "Stream A 6.0" with Winner "W4" Stacker and Return System

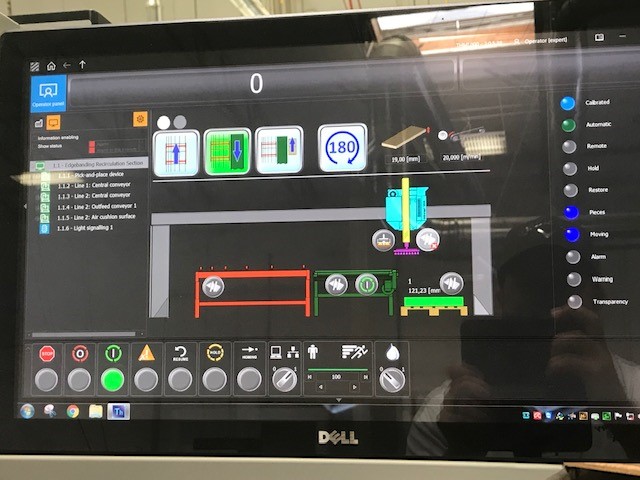

All three (3) components are integrated to operate as one system with PC control

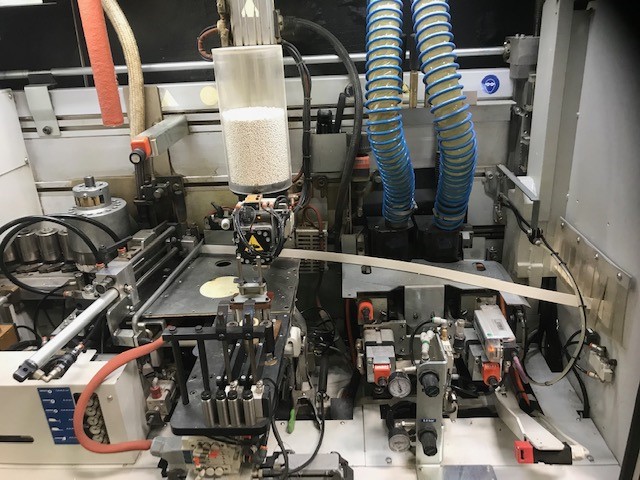

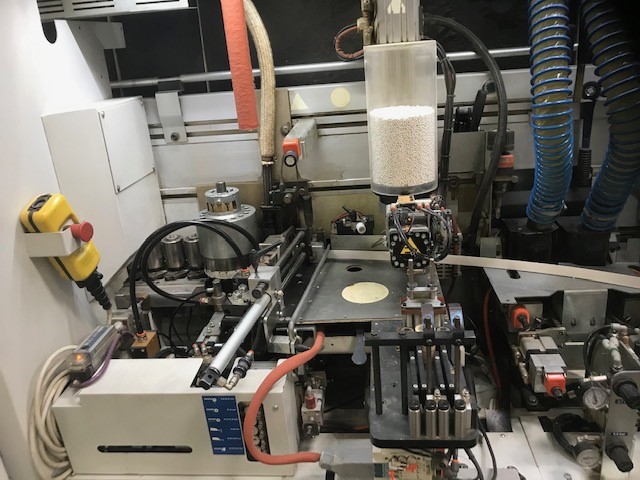

Biesse "Stream A 6.0" Edgebander

10 - 60 mm panel height

10 - 35/60 mm panel height with corner rounding (depends on profile)

14 - 64 mm edgebanding height

0.4 - 3 mm coiled banding thickness

0.4 - 22 mm strip banding thickness

25 mm panel protrusion from track

140 mm (5.5") minimum panel length

95 mm (3.7") minimum panel width (150 mm length)

70 mm (2.8") minimum panel width (250 mm length)

Bottom feed track

Variable feed speed, 12/18/20/25 MPM

Top pressure belt

Motorized positioning of top beam

Infeed fence with panel spacer

NC adjustment

Two (2) position edgebanding magazine

NC managed

Automatic edge feeding systems for coils or strips

3 mm maximum coiled banding thickness

Guillotine for cutting coiled banding

Premill unit with two (2) motors)

4.7 HP, 12000 RPM

NC adjustment on first copy shoe

Anti-adhesive unit

Infrared heating lamp

Tekno glue system with roller

Pre-melt hopper for EVA adhesive, 11 pound capacity

Two (2) quick-change glue pots, 6.6 pound capacity

External pre-heating device for extra glue pot(s)

Bi-directional glue roller

Dual thermostat

Automatic temperature reduction when machine is idle

Compatible with EVA or Polyurethane adhesives

AirForce system

Hot compressed air for application of laser edges

12 - 60 mm panel height

1 mm minimum edge thickness with 1.2 mm functional layer

Pressure unit

One (1) driven roller

Five (5) idle rollers, 60 mm/2.4" diameter

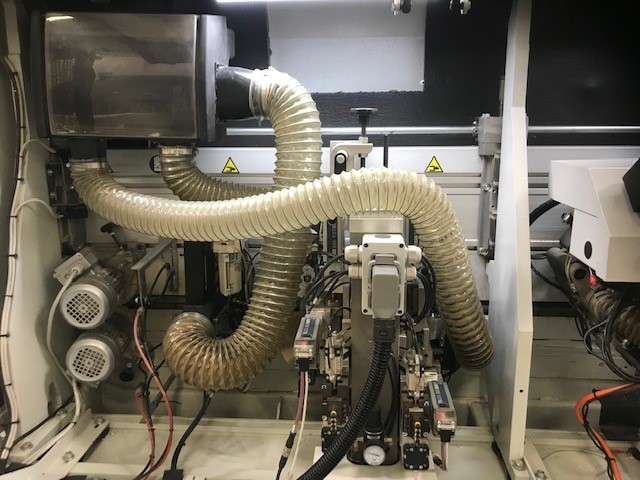

Two (2) motor end trim unit

0.8 HP, 12000 RPM

0 - 25 degree vertical incline, automatic rotation

Three (3) pneumatic positions

Top/bottom rough trim unit

12,000 RPM

Can be tilted up to 1 degree

Two (2) position pneumatic exclusion

Four (4) NC axes driven by brushless motors and ball screws

Top/bottom fine trim unit

12,000 RPM

0 - 45 degree tilt

Pneumatic exclusion

Pro Nest

Lubrication unit to enhance corner rounding finished appearance

Two (2) motor corner round unit

12,000 RPM

NC adjustment

Pneumatic exclusion

Top/bottom profile scrape unit with external collection box

NC adjustment

Pneumatic exclusion

Pro Nest

Top/bottom flat scrape unit

Pneumatic exclusion

Air blowers

Top/bottom buff unit

0.5 HP, 2800 RPM

Tiltable

Misting unit

Hot air blower

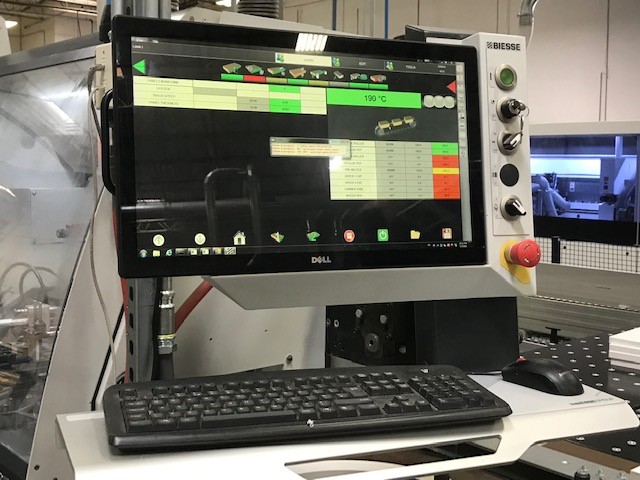

PC control (Dell)

Smart-Touch 21.5 numerical control

Windows operating system

Sintra HD software

21.5" color monitor

Standard keyboard and mouse

Integrated hard drive, USB port

Lighted sound enclosure

Outboard roller support

Automatic lubrication system

External electrical transformer

Biesse "Winner W4" Stacker

2,500 mm/98" maximum panel length

250 mm/9.8" minimum panel length

1,000 mm/39.3" maximum panel width

100 mm/3.9" minimum panel width

60 mm/2.4" maximum panel thickness

10 mm/0.4" minimum panel thickenss

154 pound maximum weight

10 cycles/min. for panel returning

8 cycles/min. for panel stacking

800 mm/31.5" maximum stack height (on pallet on floor)

Overhead pneumatic stacker

Bridge support

Aluminum plate with suction cups

Transfer table with left reference

Beckhoff PLC

Safety fencing and photo barrier

External electrical transformer

Return conveyor

Belt return conveyor

Two (2) sections

Air floatation tables

Safety fencing

Dust collection pipe and flex hose NOT included

The listed specifications & information were taken from the manufacturer’s published information, internet research, or seller’s description.

The specifications & information are assumed to be correct; however, in no way, guaranteed. Bidders are encouraged to inspect the machine, call with questions, or contact the manufacturer for more information.

Please log in to view the bid history

LoginPick-ups are to be scheduled by appointment only. Please contact Sabrina Burns at 209-839-7707 or [email protected] to schedule an appointment. For freight quotes please contact Aaron at All-Ways Trucking at 541-608-6532. Buyer bears all costs to remove and load this lot. Buyer must remove entire lot purchased. Anyone removing non-hand carriable lots must provide MachineryMax, Inc. with a certificate of insurance (COI) before purchased items can be removed.

All buyers agree to make full payment to MachineryMax, Inc. within 48 hours of the online closing date for the auction lots purchased. All invoices over $1,500.00 are to be made by bank wire transfer or cashier’s check payable to MachineryMax, Inc. Purchases under $1,500.00 may be made using Visa, MasterCard, or American Express (2% credit card processing fee will be added to the invoice). All payments are to be made in USD currency only. Bidder represents and warrants to MachineryMax, Inc. that such bidder has immediately available funds to fully pay for its successful bids within 48 hours of the online closing date. All payment questions should be directed to Sabrina Burns at 209-839-7707 or [email protected] All buyers agree that there will be a 15% Buyers premium that will be added to the final invoice.