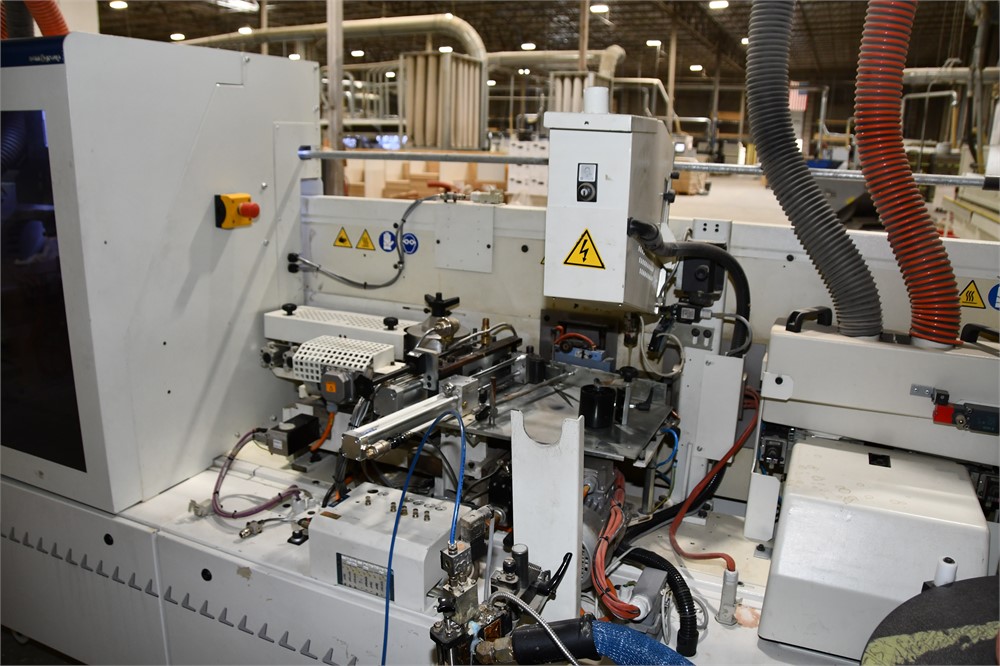

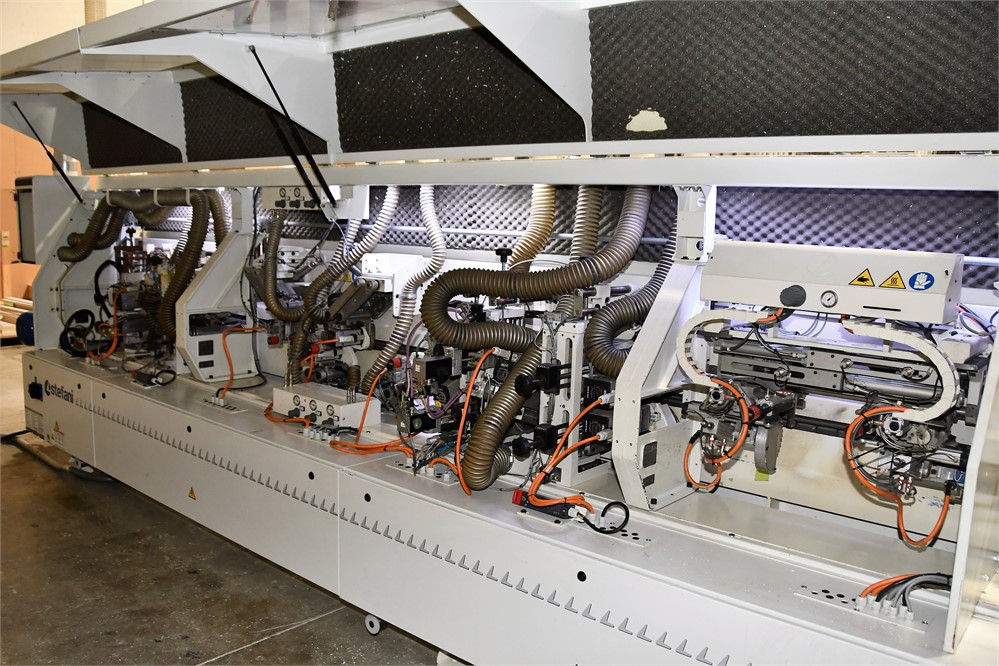

(2016) Stefani "Solution HD" Edgebander - PUR, Pre-Mill & Corner Rounding  Ended

Ended

Windsor Fixtures -Complete Plant Closure -Day 1- Lawrenceville, Ga

- Winning Bid : $25,150.00 USD Sold

- 18 Bid(s)

- High Bidder: S****c

WINDSOR FIXTURES INC COMPLETE PLANT CLOSURE - LAWRENCEVILLE, GA - DAY 1 ( Closed #26329166 )

For Rigging/Loading please contact:

Gorham Industrial, LLC - James Gorham - 803-617-8434 - [email protected] - www.gorhamindustrial.com

Preston Machinery, LLC - Tom Preston - 269-685-7591 - [email protected] - www.prestonmachineryllc.com

For Shipping Quotes, please contact: NCL Trucking, John, 615-452-7651

-

Pick Up Location

755 Raco Dr, Lawrenceville, GA 30046

-

Make

Stefani

-

Model

Solution HD

-

Serial Number

AH/006109

-

Year

2016

-

Phase

3 PHASE

-

Voltage

208-230/460

-

Load Out Period

April 9, 2020

-

Estimated Dimensions

30'L x 5'W x 7'H

-

Estimated Weight

4,400 KG

-

Seller Comment

CONTACT ALWAYS TRUCKING for shipping quote 541-608-6532

-

Load Fee

A rigger is required for this lot. Gorham Industrial, LLC 803-617-8434 [email protected] or Preston Machinery, 269.685.7591, Tom Preston, [email protected]

-

page views

4420

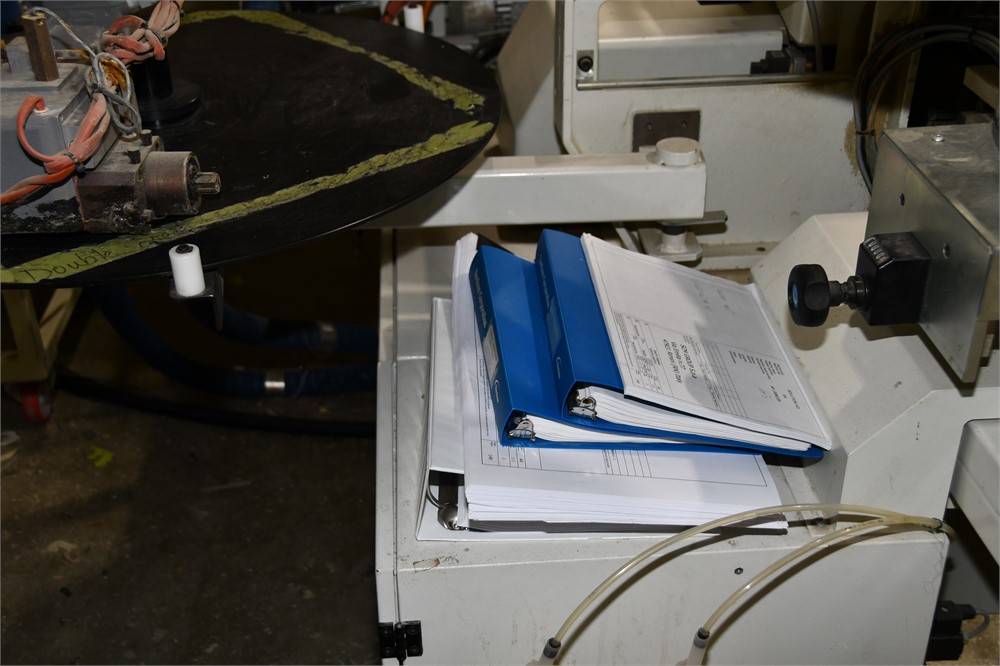

In light of how many Edge Banders are in this auction, we want to be clear about what options each has. The specs below are a general guideline but verification of anything specific may be verified in person at the provided open houses. You may also choose to e-mail the Shop Engineer, Steve Hardy: [email protected]

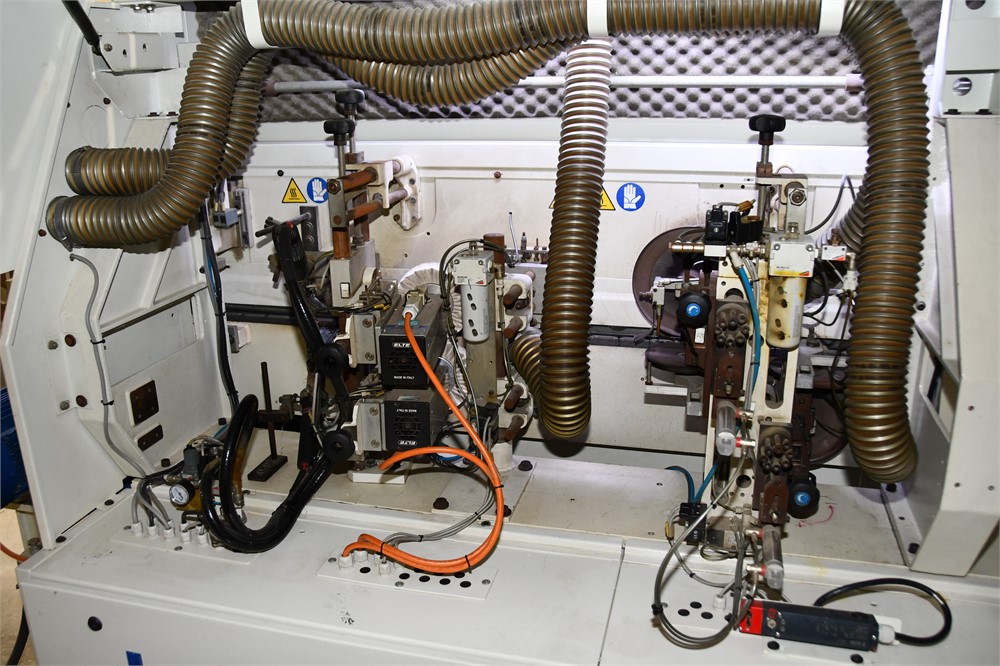

This machine does NOT HAVE:Grooving saw

The dust extraction manifold as shown in the pictures is included. It includes the pipe that would encompass the machine and flex hoses. It does not include the remaining pipes to the dust collector.

The machine base is fabricated using a heavy duty, mono-block design. This provides a solid surface for mounting all of the working units. This structure, pressure beam and working support units are all poured at SCM’s own Foundry & controlled throughout the fabrication inside the SCM Group, ensuring the most stringent specifications.

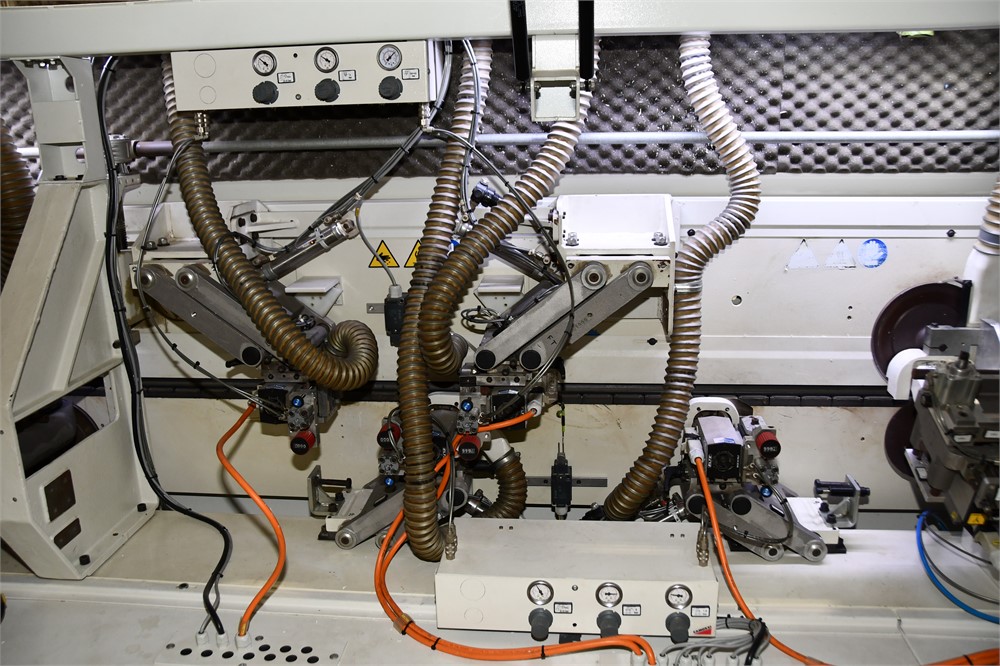

All working units are attached using the Heavy Duty “H” style supports that ensure a vibration free work environment which reduces the amount of “adjustments” that need to be made on motorized units under the hood.

The top pressure beam is made of thick steel to eliminate “flex” when maximum pressure is applied.

Top pressure beam is fitted with a twin-profile V-belt for even pressure & precise holding of even small work pieces.

The feed track consists of 70 mm wide, self-lubricating nylon sliders. The replaceable track pads are coated with wear resistant vulcanized rubber to prevent work piece movement.

The track guiding system consists of one flat guide and one round guide. The flat portion is located closest to the machine working units for maximum pressure while holding the work piece perpendicular to the working units. The round guide is located on the opposite side of working units to ensure perfect linear alignment by eliminating the possibility of “twist”. Both guides are made of hardened ground steel and are equipped with an automatic lubrication system.

The cabinet is coated with noise-reducing material and is illuminated with non-glare fixtures. The cabinet is custom configured to allow appropriate dust extraction for each working unit.

PC CONTROL SYSTEM FOR THE FAST, EASY AND PRECISE HANDLING OF THE MAIN FUNCTIONS OF THE MACHINE.

IT INCLUDES:

Creating programs Just in Time. Possibility of management by means of

production list;

Virtual preview of the processed panel with automatic selection of operating units;

Flexible and independent management of each unit and tool without machine vacuum;

Clear and concise diagnostic information for a fast resolution of problems; Working statistical data: number of worked pieces and meters, of the employed hours etc.;

Management for automatic selection and instantaneous of the magazine edge coil;

Quick selection of the main functions of the main page with PRO EDGE function;

Unit of measurement in mm;

Operator "Win-Edge" interface in the following languages: Italian, French, English, Spanish, German (opt. Portuguese and Russian).

MAIN CHARACTERISTICS:

PC Office Operating system: W XP Screen: 17" TFT

2 network card ETHERNET

6 USB ports - 2 PS/2 ports

Bar code reader management

SCM Group North America

Phone: 770-813-8818

Website: www.scmgroupna.com

STEFANI HD-78

B25282 VARIABILE FEED SPEED 12-25 M/min

The machine features variable track speed from 12-25 Meters/min. (39 – 82 feet/min) Track speed is set in the programs to suit the application.

W50605 ELECTRONIC POSITIONING OF TOP PRESSURE BEAM

Automatic motorized positioning of the top pressure beam from the control. This system also automatically adjusts all work units to accommodate the new part thickness. Beam height is set in the programs to suit the application.

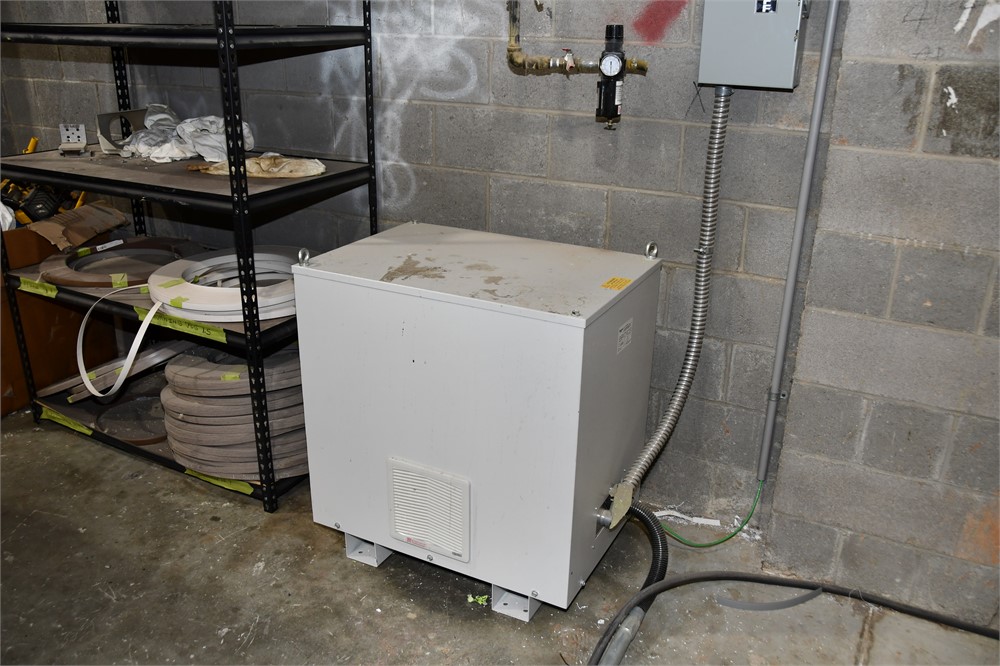

B09094 75 kVA AUTOTRANSFORMER

Multi-tap transformer to accommodate US voltages – 208-230-460

W01405 PANEL SPACING DEVICE

A95111 TWO POSITION INFEED FENCE Pneumatic two position of infeed guide.

A50164 ANTI-ADHESION UNIT AA

A95117 PRE-MILLING UNIT

This unit uses milling units rotating at 12,000 RPM to remove a pre- determined amount of material from the edge of the part.

It is equipped with:

- Two 4kw motors on THK guides for automatically advancing and retracting the counter rotating motors.

- Lateral side copy device to compensate for any improper machine feeding or warp in long boards. (Up to 1mm)

- Mechanical digital indicators

- Acoustically insulated sound enclosure

- Blowers for panel cleaning.

A71420 DIAMOND MILLING CUTTERS

Two 100mm x 64mm cutters, One cutter per head. Maximum panel thickness is 60mm.

A81553 PANEL HEATING LAMPS

This devise pre-heats the edge of the panel to improve adhesion.

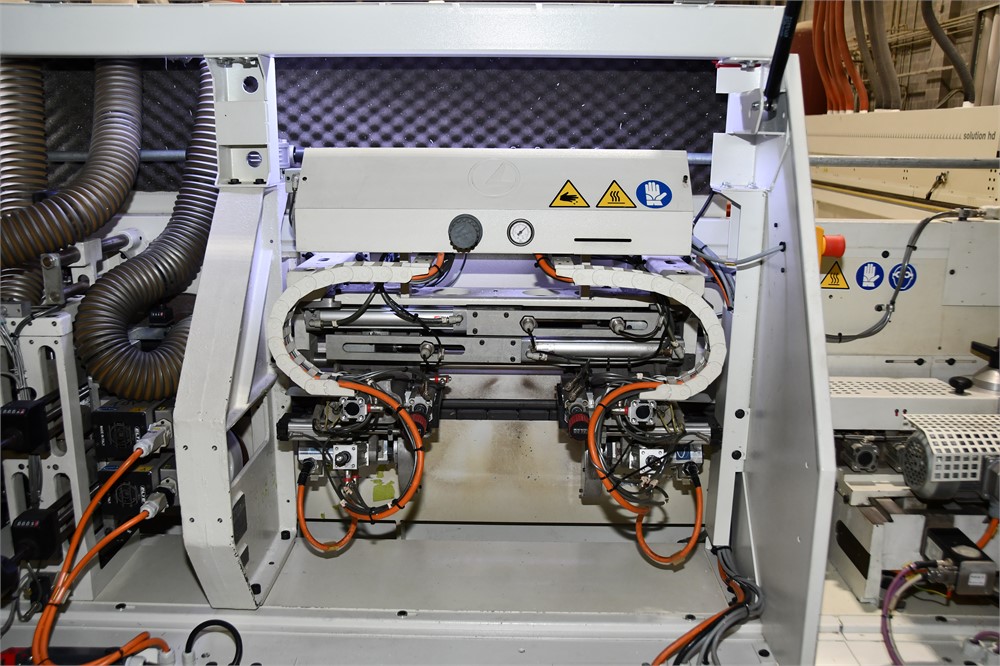

Standard GLUING UNIT VC 600

High effiecency gluing sytem for standard glue types.

- Glue pot with Teflon coating for easy cleaning

- ‘No Tool’ Glue pot removal system

- Precise control of the amount of glue on the panel edge

- Electronic control of the glue temperature

- Movement of the glue spreading roller, of the first pressure roller, and of the feed roller by motors

- Automatic temperature kick-down to avoid glue scorching

- Heavy duty guillotine for automatic tape trimming

- Automatic loading of coiled material or strips

- Pressure section with one large, motorized roller and three idle rollers with opposing tilt. All rollers have “jump” capability.

- Addition of two idle rollers for a total of six (Code A81547)

- Additional Quick Disconnect Glue Pot

The listed specifications & information were taken from the manufacturer’s published information, internet research, or seller’s description.

The specifications & information are assumed to be correct; however, in no way, guaranteed. Bidders are encouraged to inspect the machine, call with questions, or contact the manufacturer for more information.

Please log in to view the bid history

LoginPick-ups are to be scheduled by appointment only. Please contact Sabrina Burns at 209-839-7707 or [email protected] to schedule an appointment. For freight quotes please contact Aaron at All-Ways Trucking at 541-608-6532. Buyer bears all costs to remove and load this lot. Buyer must remove entire lot purchased. Anyone removing non-hand carriable lots must provide MachineryMax, Inc. with a certificate of insurance (COI) before purchased items can be removed.

For Rigging/Loading please contact:

Gorham Industrial, LLC - James Gorham - 803-617-8434 - [email protected] - www.gorhamindustrial.com

Preston Machinery, LLC - Tom Preston - 269-685-7591 - [email protected] - www.prestonmachineryllc.com

For Shipping Quotes, please contact: NCL Trucking, John, 615-452-7651

All buyers agree to make full payment to MachineryMax, Inc. within 48 hours of the online closing date for the auction lots purchased. All invoices over $1,500.00 are to be made by bank wire transfer or cashier’s check payable to MachineryMax, Inc. Purchases under $1,500.00 may be made using Visa MasterCard, or American Express (2% credit card processing fee will be added to the invoice). All payments are to be made in USD currency only. Bidder represents and warrants to MachineryMax, Inc. that such bidder has immediately available funds to fully pay for its successful bids within 48 hours of the online closing date. All payment questions should be directed to Sabrina Burns at 209-839-7707 or [email protected] All buyers agree that there will be a 15% Buyers premium that will be added to the final invoice.