(2020) Stefani "XD" Edgebander - Advanced PUR, Grooving Saw, Pre-mill & Crnr Rnd  Ended

Ended

Windsor Fixtures -Complete Plant Closure -Day 1- Lawrenceville, Ga

- Winning Bid : $191,400.00 USD Sold

- 106 Bid(s)

- High Bidder: S****c

WINDSOR FIXTURES INC COMPLETE PLANT CLOSURE - LAWRENCEVILLE, GA - DAY 1 ( Closed #26329166 )

For Rigging/Loading please contact:

Gorham Industrial, LLC - James Gorham - 803-617-8434 - [email protected] - www.gorhamindustrial.com

Preston Machinery, LLC - Tom Preston - 269-685-7591 - [email protected] - www.prestonmachineryllc.com

For Shipping Quotes, please contact: NCL Trucking, John, 615-452-7651

-

Pick Up Location

755 Raco Dr, Lawrenceville, GA 30046

-

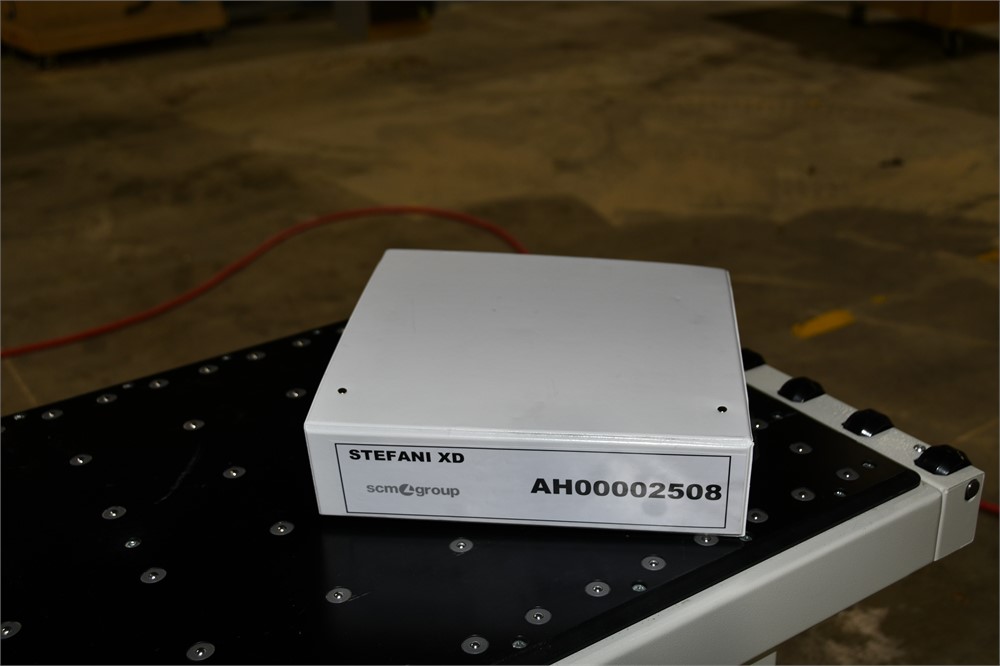

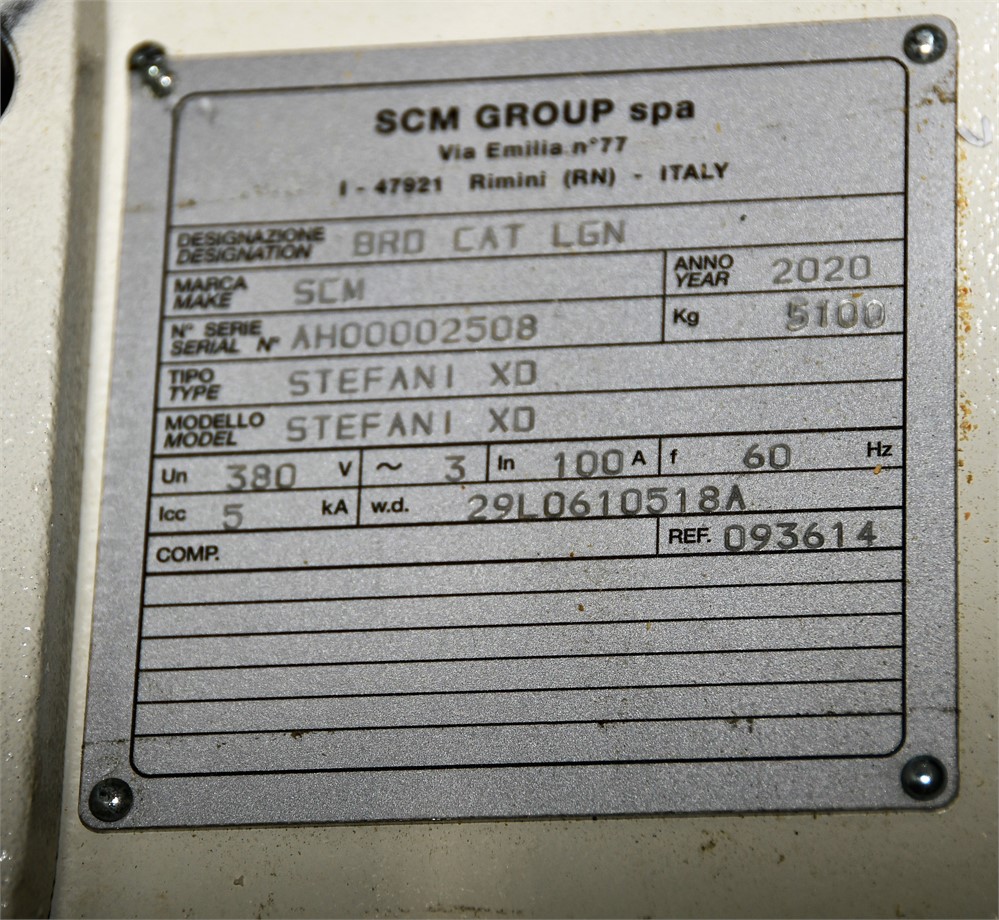

Make

Stefani

-

Model

XD

-

Serial Number

AH00002508

-

Year

2020

-

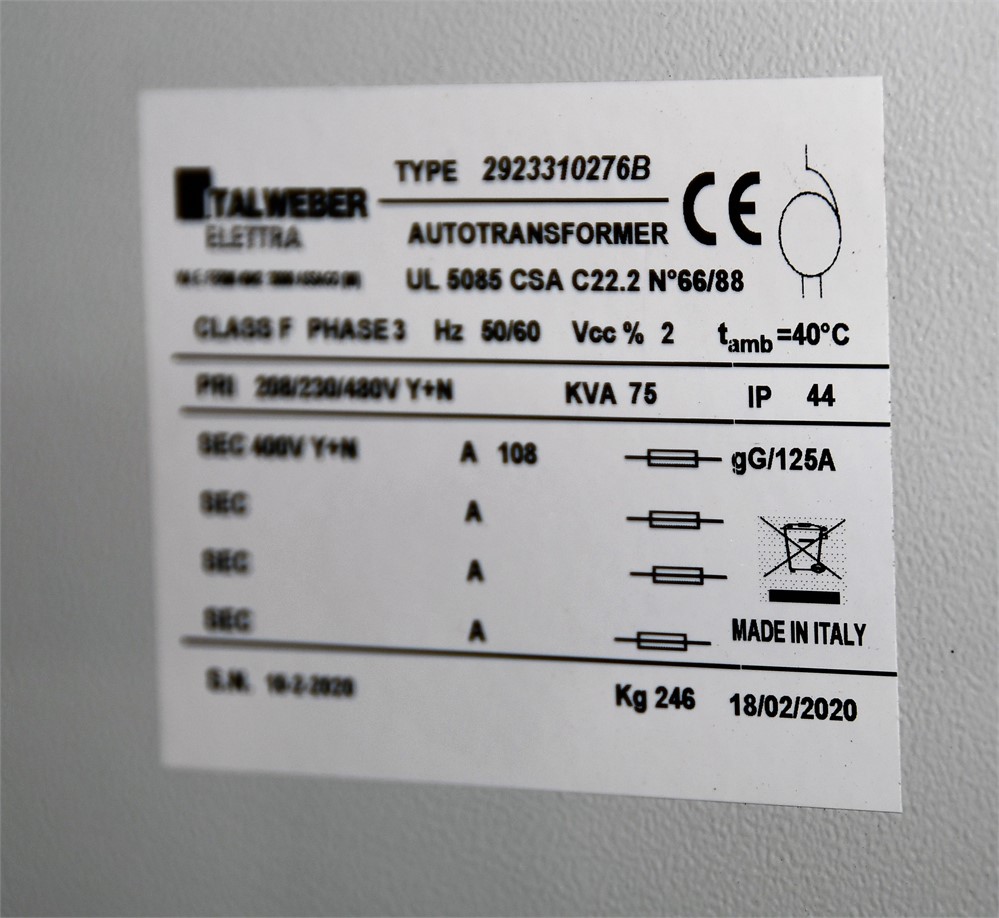

Phase

3 PHASE

-

Voltage

230/460

-

Load Out Period

April 9, 2020

-

Estimated Dimensions

30'x5'x71"

-

Estimated Weight

5,100 KG

-

Seller Comment

CONTACT ALWAYS TRUCKING for shipping quote 541-608-6532

-

Load Fee

A rigger is required for this lot. Gorham Industrial, LLC 803-617-8434 [email protected] or Preston Machinery, 269.685.7591, Tom Preston, [email protected]

-

page views

8728

In light of how many Edge Banders are in this auction, we want to be clear about what options each has. The specs below are a general guideline but verification of anything specific may be verified in person at the provided open houses. You may also choose to e-mail the Shop Engineer, Steve Hardy: [email protected]

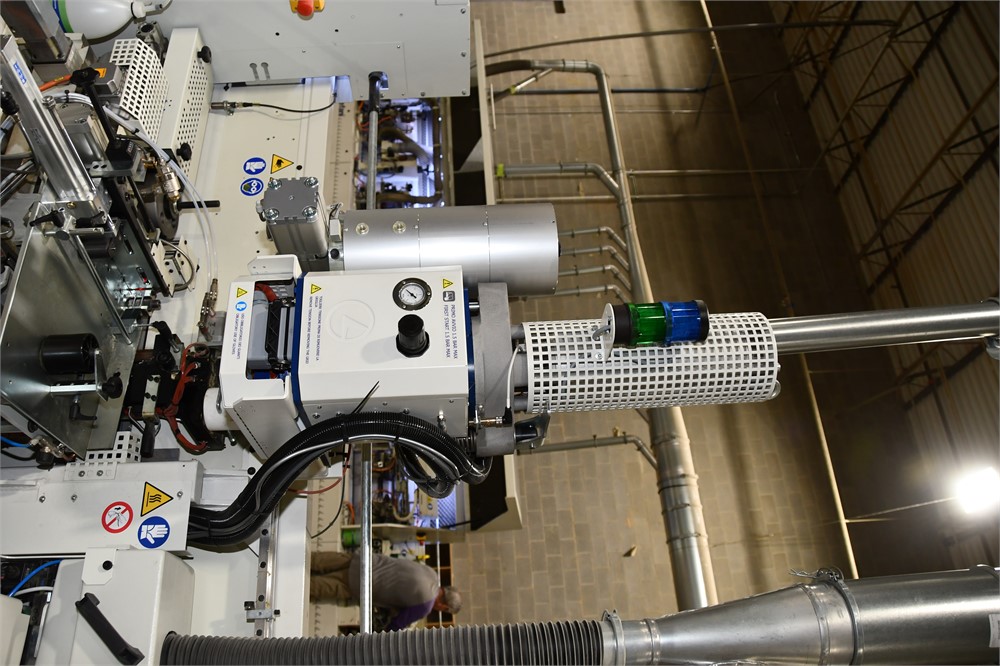

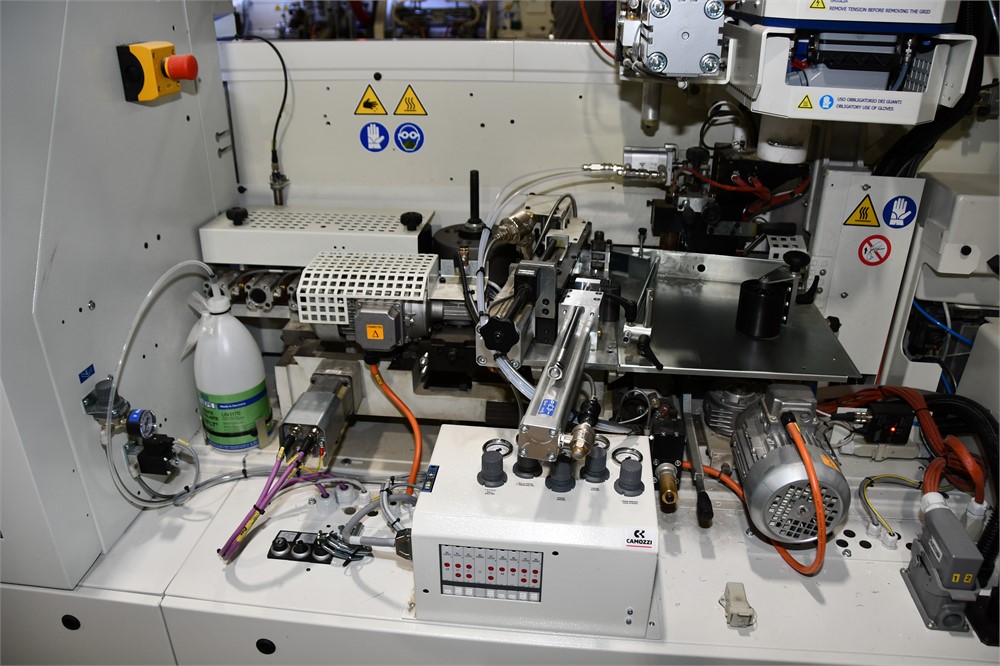

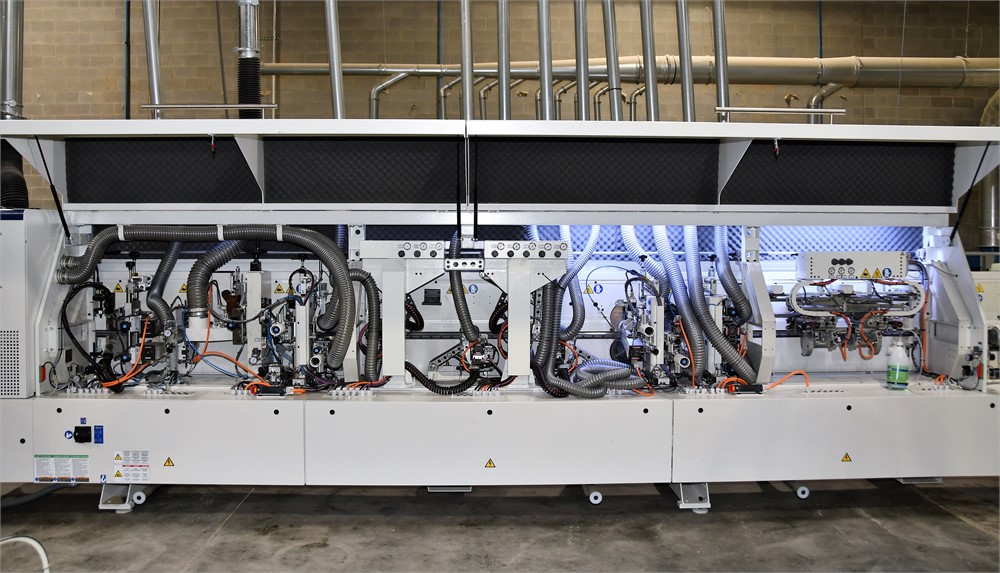

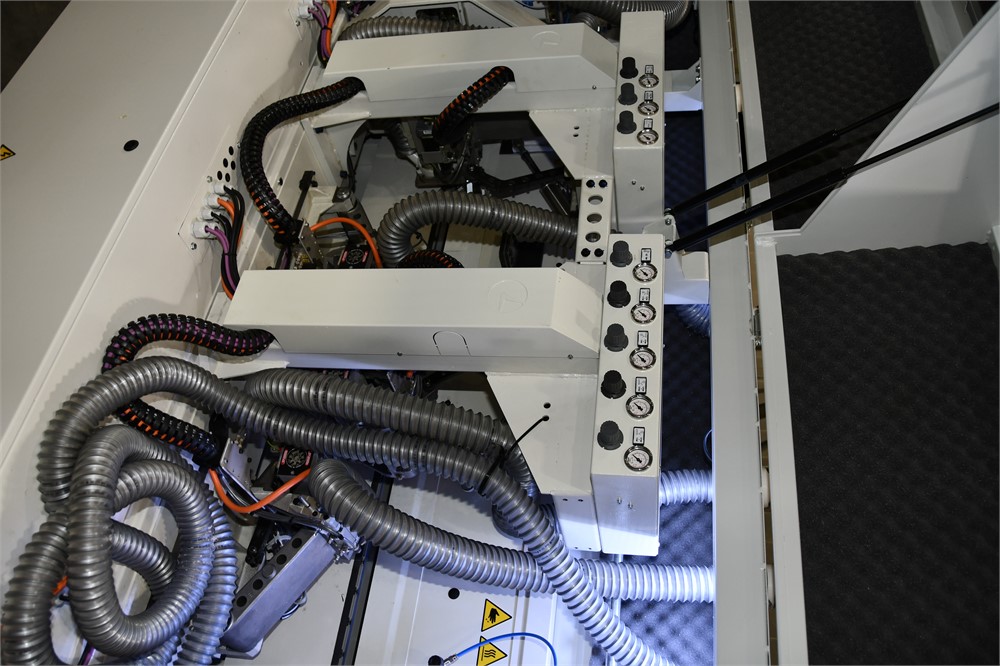

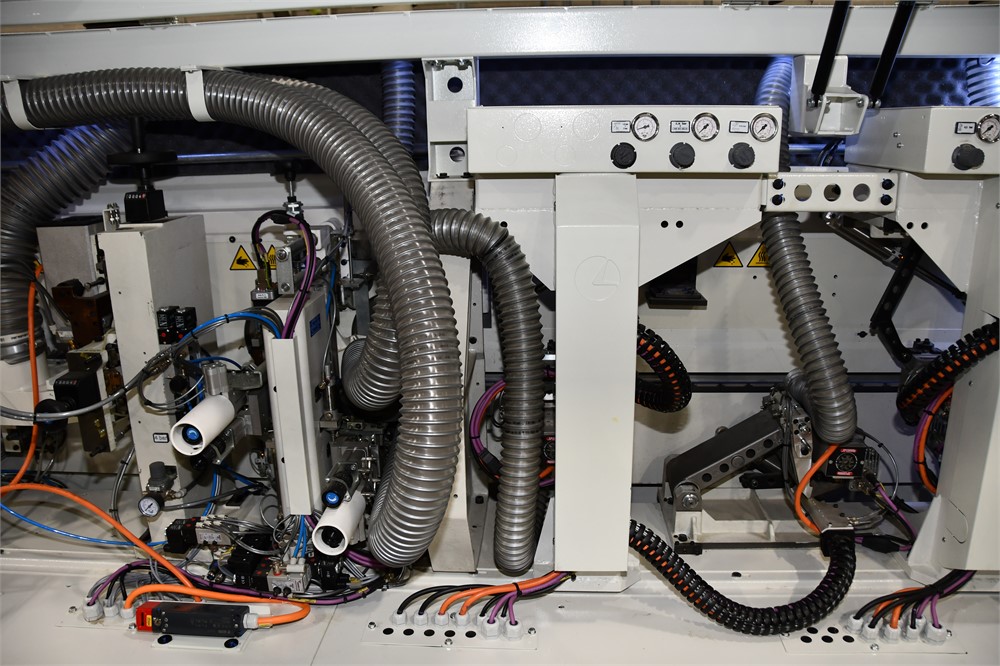

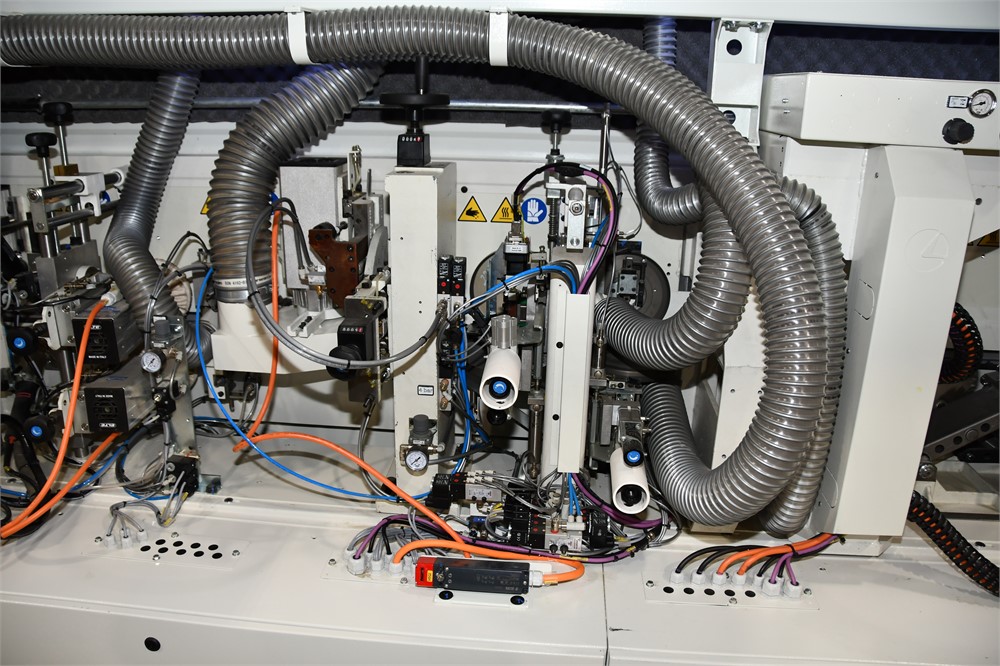

The dust extraction manifold as shown in the pictures is included. It includes the pipe that would encompass the machine and flex hoses. It does not include the remaining pipes to the dust collector.

HEAVY-DUTY AUTOMATIC EDGE BANDER

|

|

PRODUCING IN SMART MODE THANKS TO THE ADAPTIVE 3D DESIGN OF THE PROCESSING WITH REAL TIME PREVIEW |

|

|

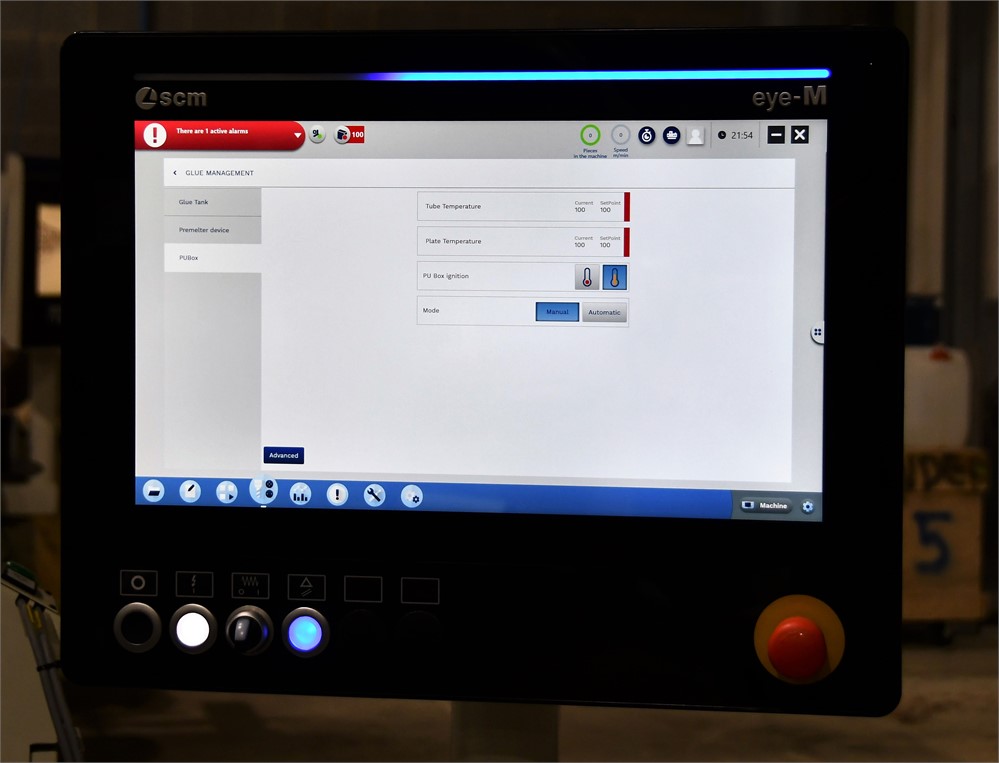

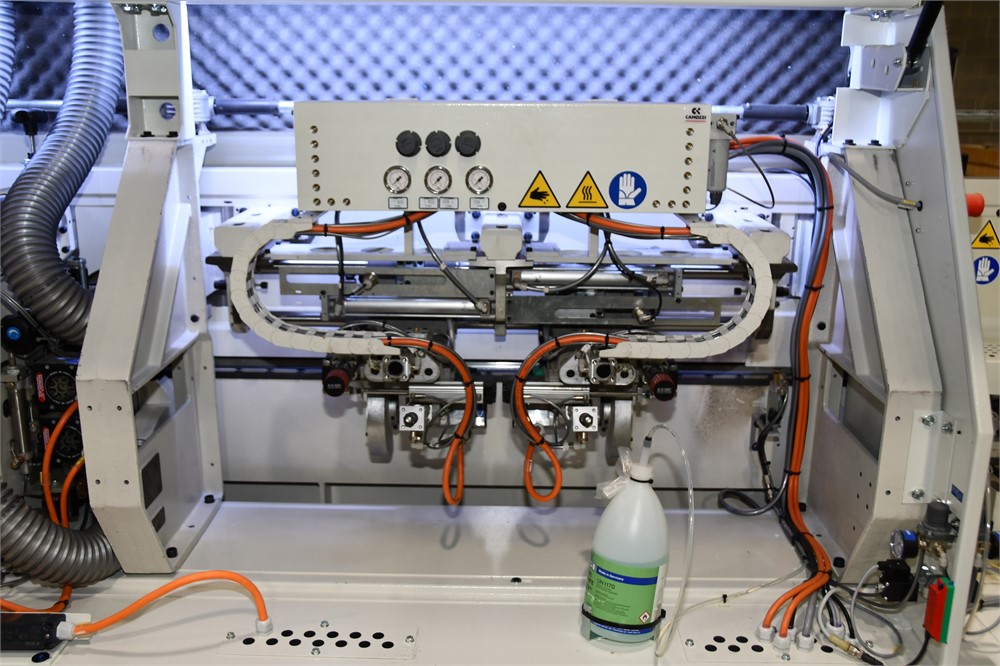

“SGP” GLUE POT: USE OF EVA AND PUR GLUES FOR A PERFECT JOINT LINE |

|

|

HIGH QUALITY MACHINING THANKS TO THE TECHNOLOGICAL SOLUTIONS OF THE “E- GENERATION” WORKING UNITS |

GENERAL FEATURES

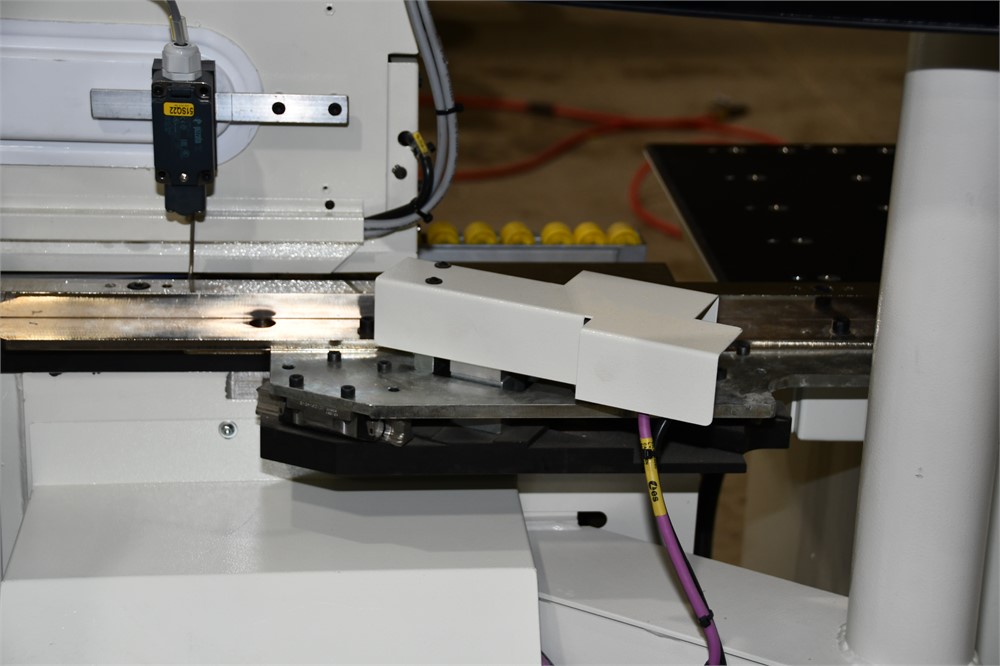

Automatic single-sided edge bander for the edge gluing with hot melt glue, for panel edge banding with material in coil or strips. Fixed working side on the left.

The machine base is made of a high rigidity single steel block giving optimum support for the working units.

The top pressure beam is made of thick steel with a twin-profile V-belt and automatic positioning according to the panel thickness by NC motor drive.

Height adjustment visualised by means of mechanical indicator and on the operator console.

Manual infeed panel system with widely dimensioned guide and enlarged support surface to make the feeding operations of even large panels easy. Adjustable infeed guide on two positions for automatic selection of the working process with or without the pre-milling unit.

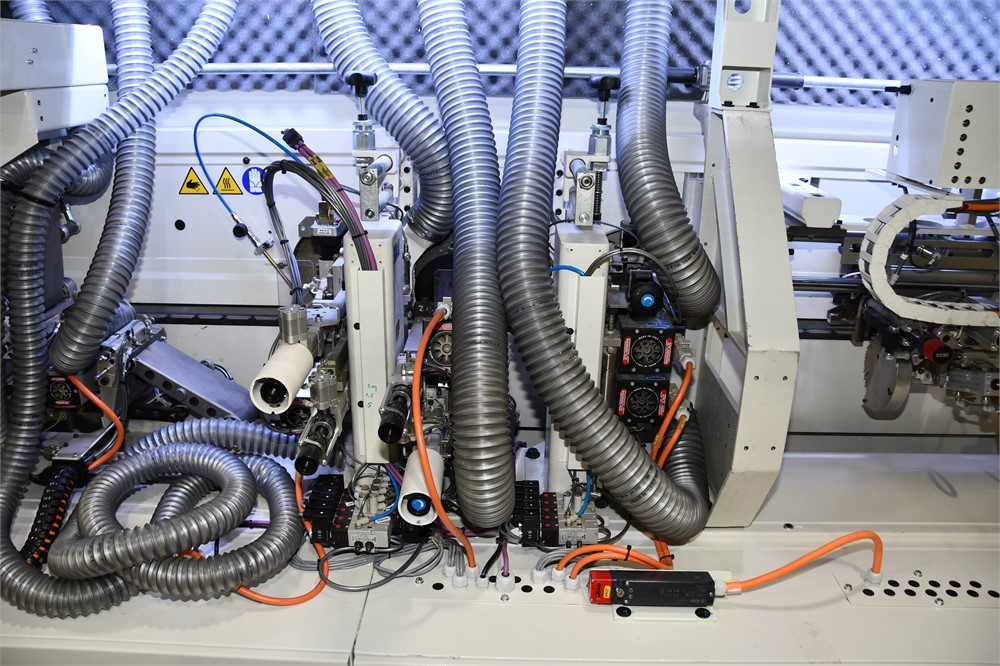

Top operating units fixed to the pressure beam or mechanically connected on to it to allow automatic positioning according to the panel thickness. Lower units fixed to the base or the horizontal beam for a precise reference with respect to the panel.

All high frequency motors are equipped with static inverter.

Inverter for each operating unit equipped with motor, in order to optimize the flexibility and the production times of the machine.

Safety cabin for all units installed after the gluing unit.

The enclosure doors have wide polycarbonate windows for the visualization of the working units during machining. Lamps for internal lighting of the cabin.

Soundproofing material, inside the cabin, for a quieter operation of the machine during machining.

Panel spacer,

installed at the machine's entry, allows the panels loading into machine with the right space between them. The loading distance automatically changes according to the selected working speed.

Exhaust outlets for the operating units are positioned on the top side of the safety cabin.

Electrical cabinet is in conformity with the current safety regulations.

Electrical components positioned inside the metal case, fixed to the machine base with door that allow an easy access in case of any maintenance operations.

400 V EU 50 Hz standard power supply (with neutral).

Feed track made of 80 mm wide nylon pads, coated with wear proof vulcanised rubber with a high coefficient of friction to grant an optimal panel holding and a high machining precision.

Sliding of pads on two guideways (in hardened and ground steel), one round and one flat, to ensure straightness of movement and resistance to side loads.

Automatic pads lubrication.

The oil quantity is optimized by the machine control according to the machined panels.

Panel support rollers positioned parallel to the track. It can be extended on the entire length of the machine. It is made of telescopic opening system with 650 mm extension (for panel with 1200 mm maximum width).

SAFETY REGULATIONS

The machine is in conformity with the following directives:

- Directive 2006/42/CE ("machine")

- Directive 2014/30/UE ("electromagnetic compatibility")

Machine complete with set-up for I/O line consents in order to ensure interfacing with any upstream and/or downstream machines.

The use of the aforementioned consents in the context of line installation annuls the effectiveness of the EC declaration, issued under Attachment IIA of Directive 2006/42/EC, provided with the machine, and requires recertification at the Customer's expense and responsibility of the resulting set of equipment of which he will become "manufacturer" under the provisions of Directive 2006/42/EC.

When inserted in a line, the machine must not be commissioned until the line it is inserted into is declared in accordance to the Directive 2006/42/EC.

Enclosed user manual

Standard paint finish: Grey RAL 9002

Production code: STEFANI XD

|

R0.02.98 |

stefani xd - "W+" composition (78) |

N. 1 |

|

The standard machine composition includes free spaces for the installation of optional working units as follows:

(1) = Milling or Sanding unit

(½) = Glue scraping unit

(1F) = Edge brightening unit

Machine length: 8750 mm (78)

|

TECHNICAL DATA |

||

|

Variable track feed speed |

m/min |

10 - 25 |

|

Max. variable track feed speed with solid wood |

m/min |

12 |

|

Panel thickness |

mm |

8 – 60 |

|

Thickness of coiled edge: with 8 mm panel thickness with 10 mm panel thickness with panel thickness from 12 to 60 mm |

mm mm mm |

0,3-1 0,3-2 0,3-3 |

|

Thickness of edge in strips * (with option: kit for solid wood up to 22 mm) |

mm |

0.3 - 12 (opt. 22)* |

|

Min. panel distance at 25 m/min speed (depending on the working units fitted) |

mm |

350 |

|

Minimum panel length with edge in coils or strips (100mm minimum width at 12 m/min speed) (depending on the working unit fitted) *(130 mm with kit for narrow pieces) |

mm

|

145 (130)*

|

|

Minimum panel length with solid wood edge (100mm min. width) - with counter shoulder - without counter shoulder |

mm mm |

200 380 |

|

Minimum panel width (250 mm minimum length) |

mm |

95 |

|

Work-table height |

mm |

960-970 |

For the lines consisting of machines and automatic handling devices, the data of the minimum and maximum panel dimensions to be machined into the line have to be considered the higher ones among the data of each single machine/automatic handling devices included in the line.

The performance indicated in the offer can vary according to the type of machining

(especially according to the speed, processed materials and material removal to be carried out).

The listed specifications & information were taken from the manufacturer’s published information, internet research, or seller’s description.

The specifications & information are assumed to be correct; however, in no way, guaranteed. Bidders are encouraged to inspect the machine, call with questions, or contact the manufacturer for more information.

Please log in to view the bid history

LoginPick-ups are to be scheduled by appointment only. Please contact Sabrina Burns at 209-839-7707 or [email protected] to schedule an appointment. For freight quotes please contact Aaron at All-Ways Trucking at 541-608-6532. Buyer bears all costs to remove and load this lot. Buyer must remove entire lot purchased. Anyone removing non-hand carriable lots must provide MachineryMax, Inc. with a certificate of insurance (COI) before purchased items can be removed.

For Rigging/Loading please contact:

Gorham Industrial, LLC - James Gorham - 803-617-8434 - [email protected] - www.gorhamindustrial.com

Preston Machinery, LLC - Tom Preston - 269-685-7591 - [email protected] - www.prestonmachineryllc.com

For Shipping Quotes, please contact: NCL Trucking, John, 615-452-7651

All buyers agree to make full payment to MachineryMax, Inc. within 48 hours of the online closing date for the auction lots purchased. All invoices over $1,500.00 are to be made by bank wire transfer or cashier’s check payable to MachineryMax, Inc. Purchases under $1,500.00 may be made using Visa MasterCard, or American Express (2% credit card processing fee will be added to the invoice). All payments are to be made in USD currency only. Bidder represents and warrants to MachineryMax, Inc. that such bidder has immediately available funds to fully pay for its successful bids within 48 hours of the online closing date. All payment questions should be directed to Sabrina Burns at 209-839-7707 or [email protected] All buyers agree that there will be a 15% Buyers premium that will be added to the final invoice.