FELDER G680 EDGEBANDER yr 2016 * PRE MILLING, 7.22 KW, 230 VOLT (SEE VIDEO)  Ended

Ended

MIKO'S WW 18 BROCKLEY Dr HAMILTON, ON CANADA L8E 3P1

- Winning Bid : $25,400.00 USD Sold

- 153 Bid(s)

- High Bidder: W****g

yr 2016 MACHINES FELDER EDGEBANDER, 10' SAW, PLANER, JOINTER in HAMILTON, CANADA ( Closed #26227281 )

MIKO'S WW IN HAMILTON, ON CANADA IS OFFERING UP FOR BID LATE MODEL FELDER MACHINERY IN EXCELLENT CONDITION AS WELL AS A BLUM HINGE BORER/INSERTER, HOLYTEK DOUBLE MITRE SAW, VIEL MOULDER/SHAPER AND A MIDWEST CS5230 COUNTERTOP SAW.

-

Pick Up Location

HAMILTON, ONTARIO CANADA

-

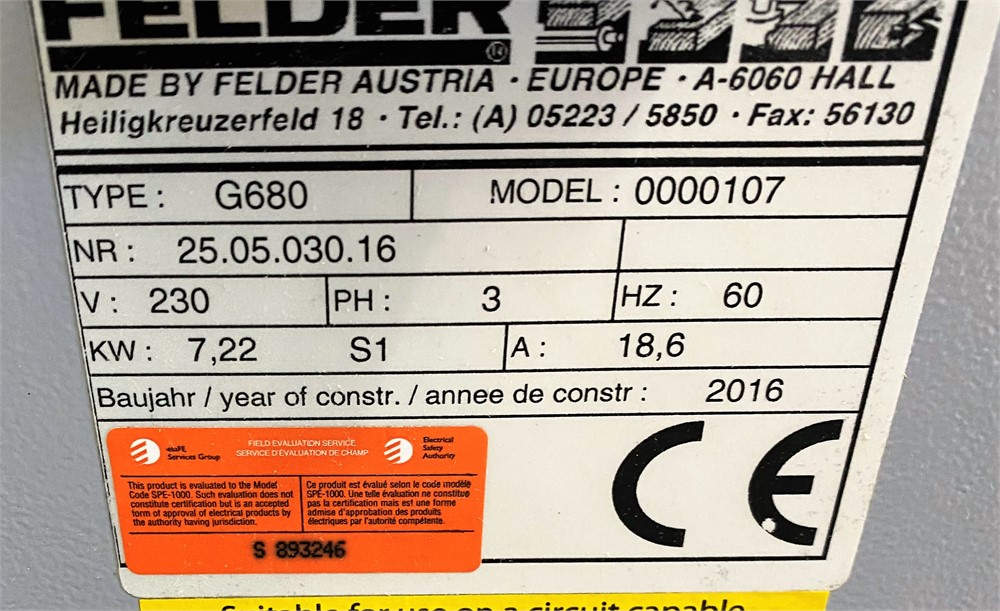

Make

FELDER

-

Model

G680

-

Serial Number

25.05.030.16

-

Year

2016

-

Phase

3 PHASE

-

Voltage

230 VOLT

-

Load Out Period

MAR 03 2021

-

Estimated Dimensions

13'L X 4'W X 6'H

-

Estimated Weight

2400 LBS

-

Seller Comment

SEE SHIPPING DETAILS

-

Load Fee

475

-

page views

5792

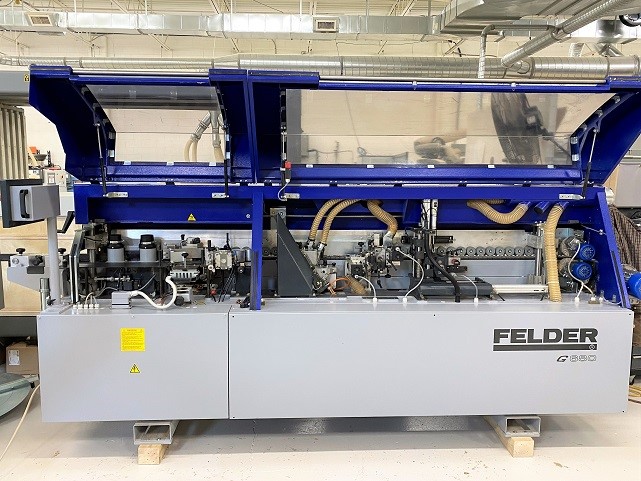

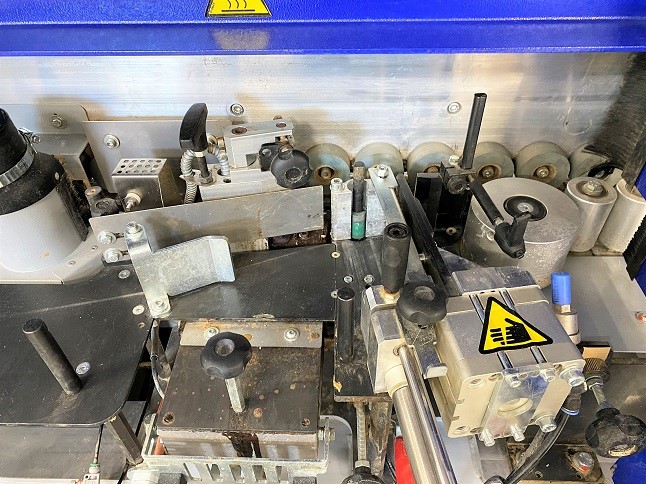

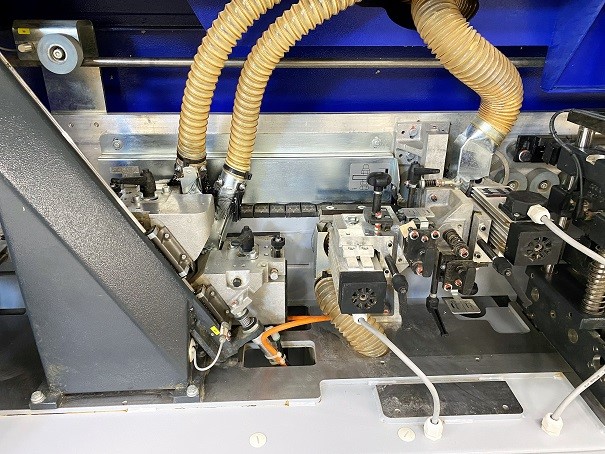

FELDER Model G680 EDGEBANDER

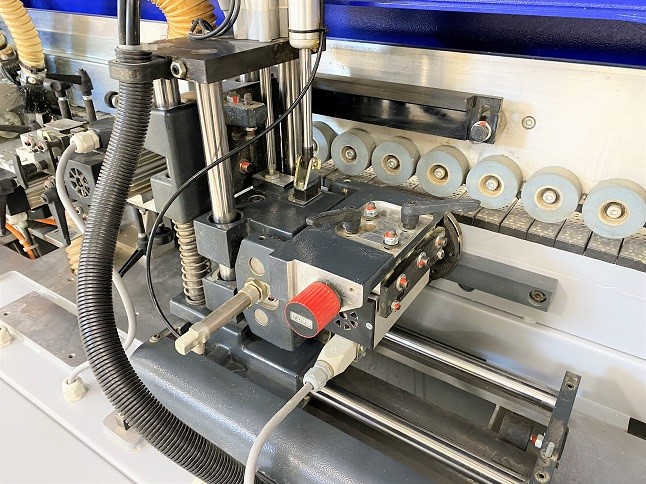

- Corner rounding unit.

- Perfect results with the flush and radius trimming unit.

- Solid pressure area with three pressure rollers.

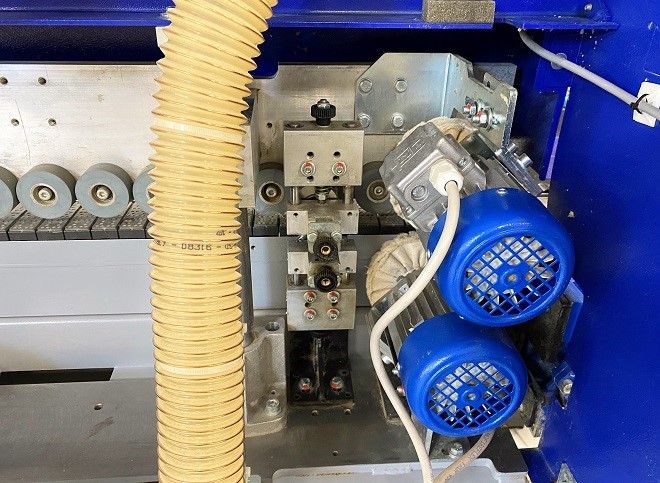

- Premilling unit with 2 diamond tipped spindles rotating in opposite directions.

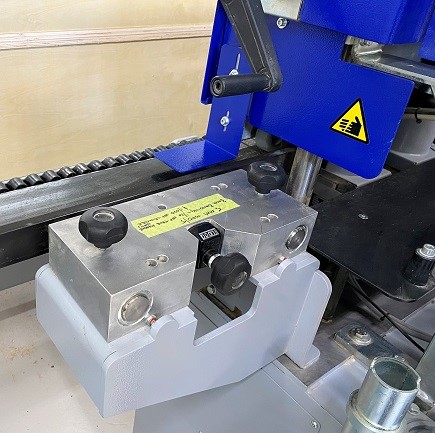

- “Quick-Set-System” for quick and precise adjustment of different edging material.

- Control panel with LCD display.

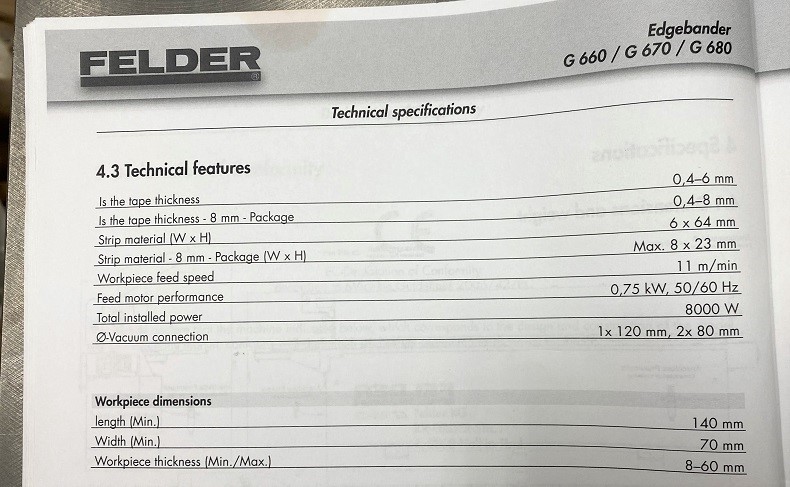

TECHNICAL DATA

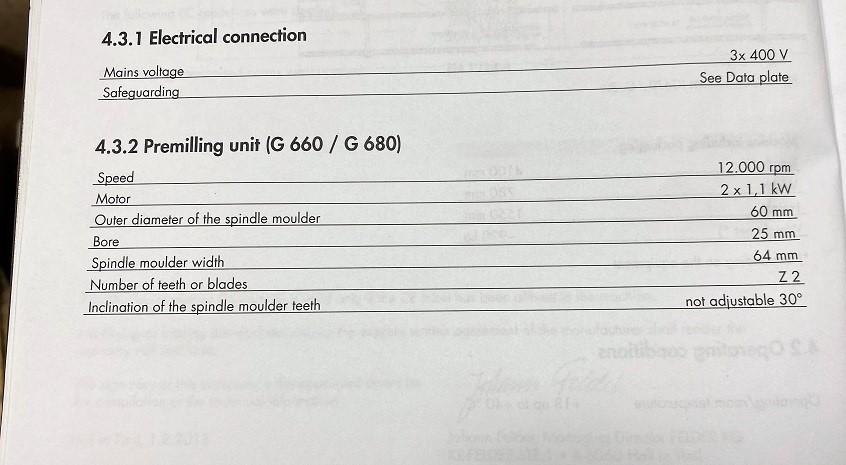

Electrical setup

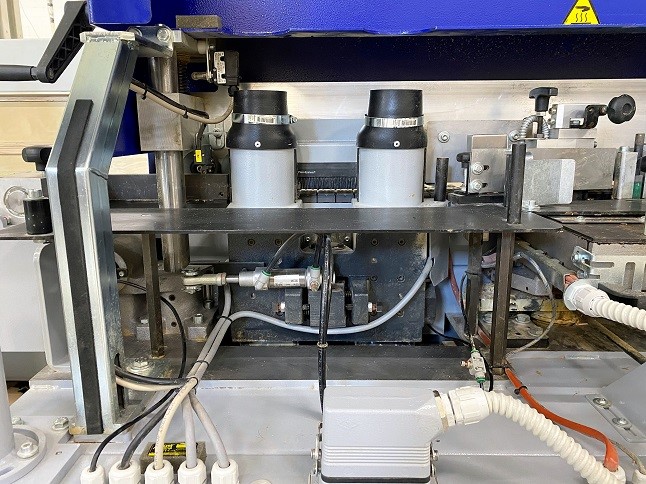

- Premilling unit

- Premilling unit centrally controlled – can be disengaged.

- Adjustable cutting depth (mm): 0-2

- Tool diameter (mm): 60

- Max. processing height (mm): 60

- No. of asymmetrical diamond tipped V-cut milling units: 2+2

- Rpm: 12000

- Power (kW) of each motor: 1,1

Working dimensions

- Edge thickness min–max. (mm): 0,4-6,0(8).

- Work piece thickness min–max. (mm): 8-60

- Min. workpiece width (mm): 70

- Min. workpiece length (mm): 140

Units

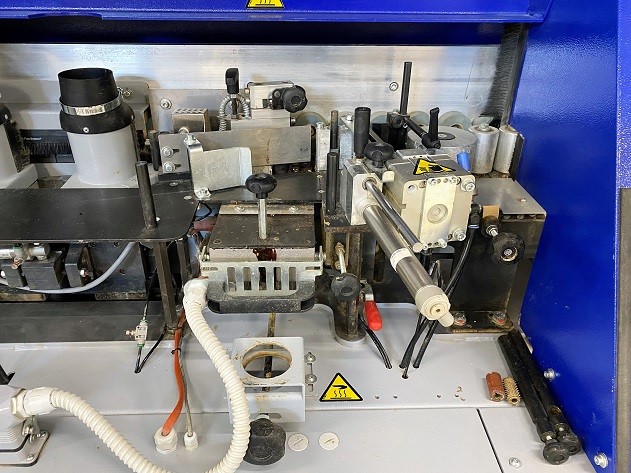

- Coiled edge band feed support plate Ø 800 mm, for PVC/ABS.

- Edge feeding is automatic for edge materials with a thickness of 0.4–6 mm, strip glue in separate feed.

- Teflon coated 2 kg capacity glue pot with quick change system, glue application via an adjustable glue roller ,~ 250lfm per 1kg granules on a 19mm plate.

- Guillotine trimming unit for the precutting of PVC/ABS edgeband material 0.4–3.0 mm thick.

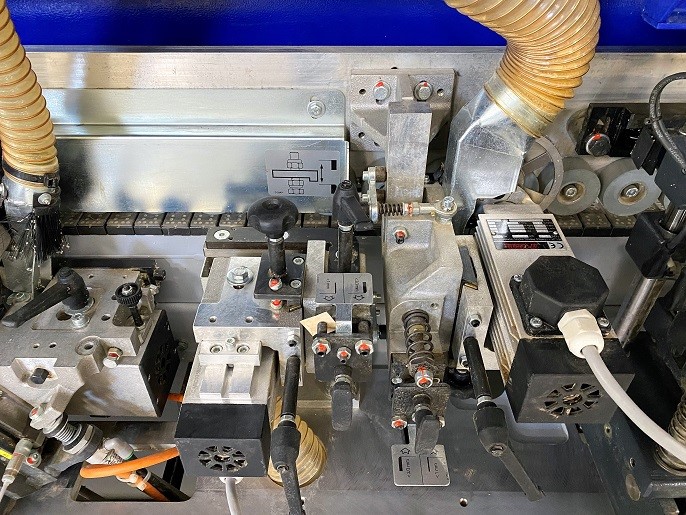

- Pressing unit is mechanically pre-stressed, 1 straight pressure roller and 2 conic additional pressure rollers, adjustment by means of an edge portion.

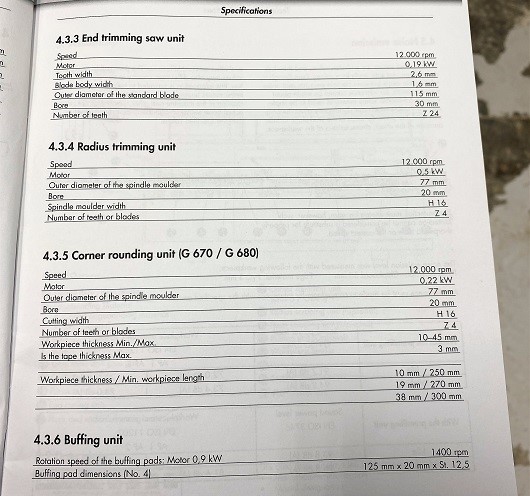

- End trimming unit with 2 independant motors, each with 0.2 kW and 12,000 rpm, both manually tiltable between 0°–10°.

- Multifunctional milling unit, 12,000 rpm, 0.50 kW, radius milling, flush milling, chamfer milling for thin edges, adjustment by means of edge section.

- Corner processing unit for soft and post-forming workpieces for processing front edges (edge thickness min.–max. 0.4–3.0 mm, max. workpiece height 45 mm, min., workpiece length 270 mm).

- Tooling for 2 mm radius.

Operation

- Operating panel with LCD display and keypad.

Through feed

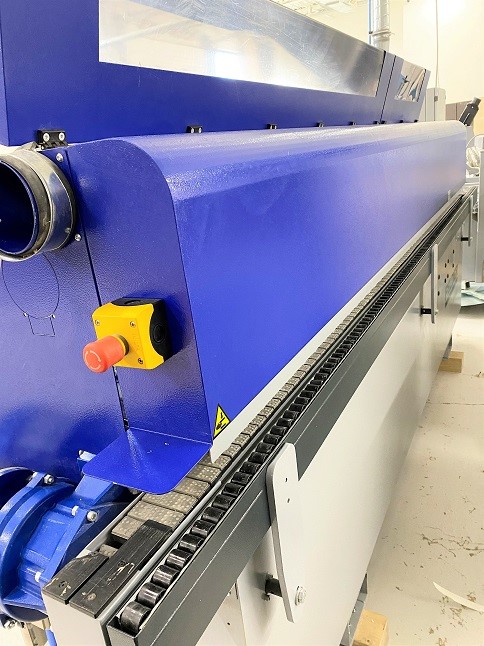

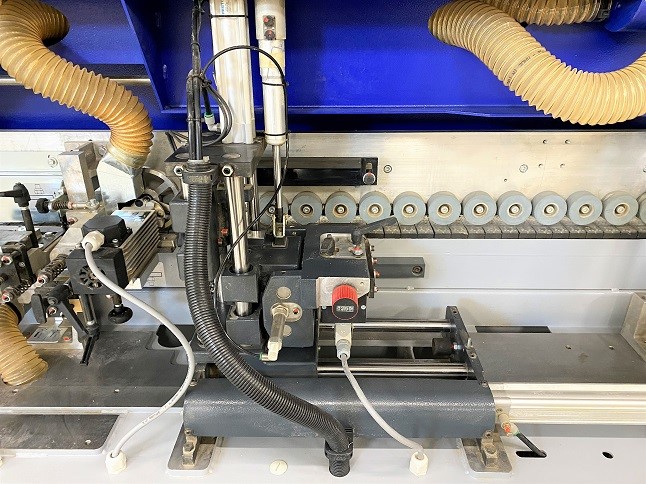

- Workpiece chain feeder.

- 11 m/min feed speed (~ 420lfm/h).

- Extensible workpiece support.

General

- Extraction connector Ø in mm: 120+ 2x80

- Weight kg (with standard configuration): 990

- Length in mm: 4550

208 VOLT, 3 PHASE

LOAD FEE....$ 475 (GROUND LEVEL ONLY)

US CUSTOMS BROKER

LOGISTIC INTL (877) 239-9669

US BUYERS SHIPPING QUOTES:

ALWAYS TRUCKING...AARON (541) 608-6532

SHIPPING WITHIN CANADA QUOTES;

MANITOULIN TRANSPORT (800) 268-9994

OVERSEAS CONTAINER QUOTES:

LISA JONES (416) 896-2688

The listed specifications & information were taken from the manufacturer’s published information, internet research, or seller’s description.

The specifications & information are assumed to be correct; however, in no way, guaranteed. Bidders are encouraged to inspect the machine, call with questions, or contact the manufacturer for more information.

Please log in to view the bid history

LoginUS CUSTOMS BROKER

LOGISTIC INTL (877) 239-9669

US BUYERS SHIPPING QUOTES:

ALWAYS TRUCKING...AARON (541) 608-6532

SHIPPING WITHIN CANADA QUOTES;

MANITOULIN TRANSPORT (800) 268-9994

OVERSEAS CONTAINER QUOTES:

LISA JONES (416) 896-2688

No information available

* CDN FUNDS: THIS AUCTION IS BEING HELD IN CDN FUNDS

* PAYMENT: IS REQUIRED WITHIN 48 HRS OF AUCTION ENDING. PLEASE DO NOT MAKE ANY FORM OF PAYMENT UNTIL RECEIVING YOUR INVOICE

* PAYABLE METHOD: TO EQUIPMENT AUTHORITY BY WAY OF WIRE TRANSFER, ETRANSFER OR DIRECT DEPOSIT ONLY.

* REMOVAL: AT BUYERS EXPENSE

* REMOVAL DEADLINE: MAR03, 2021

* INSPECTION BY APPOINTMENT CALL ROB 416-904-2475

* AUCTION END DATE: MON, FEB 22 2021 AT 2:00 PM (EDT)

* BUYER PREMIUM: 15% BUYER PREMIUM SURCHARGE WILL BE ADDED TO ALL LOTS