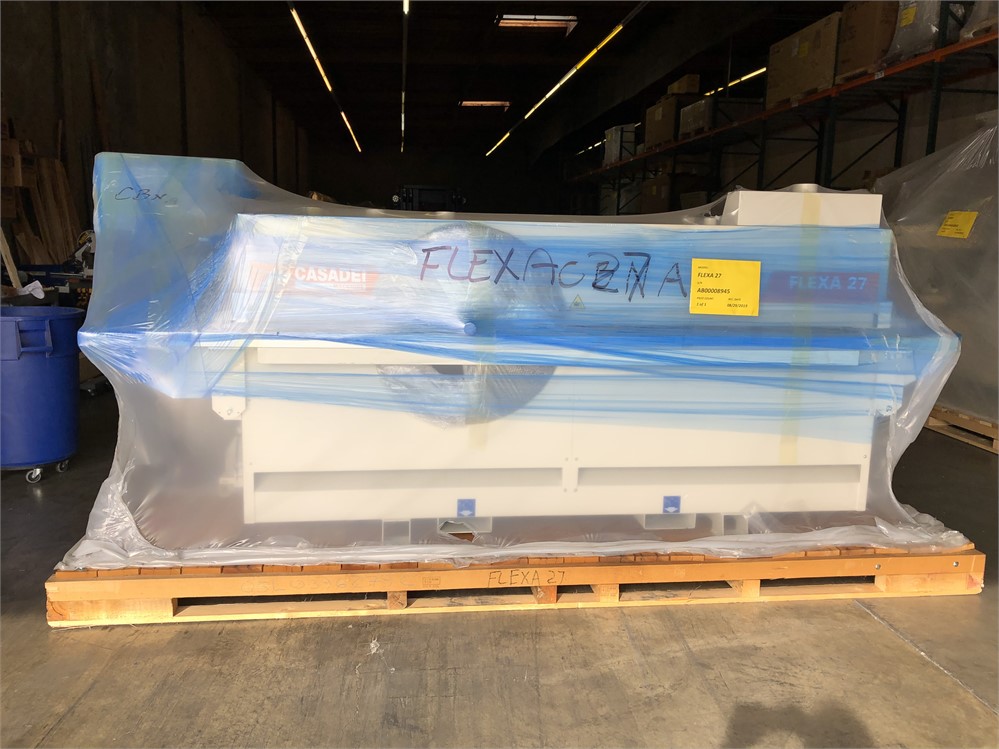

Casadei "Flexa 27" Edgebander - NEW Comp Code R011301  Ended

Ended

Brand New Machinery - Casadei/Busselato Warehouse auction - Carson, Ca

- Winning Bid : $25,650.00 USD Sold

- 41 Bid(s)

- High Bidder: E****o

Brand New Casadei Machinery Warehouse Liquidation - Carson, Ca and Tracy, Ca ( Closed #25817518 )

NEW YEAR INVENTORY CLEARANCE OF MOSTLY BRAND NEW IN BOX AND ORIGINAL FACTORY CRATED MACHINES. MACHINES ARE CASADEI/BUSELLATO MACHINE MANUFACTURED BY SCM GROUP SPA IN ITALY. IF YOU HAVE QUESTIONS, PLEASE CONTACT KIRK @ 925-250-8248 OR VIA EMAIL @ [email protected]. THE FIRST (4) LOTS ON THIS AUCTION ARE LOCATED IN CARSON CALIFORNIA AND THE FINAL (3) LOTS ARE LOCATED IN TRACY CALIFORNIA

-

Pick Up Location

Carson, Ca

-

Make

Casadei

-

Model

Flexa 27

-

Serial Number

AH00008945

-

Year

2019

-

Phase

3 PHASE

-

Voltage

230 VOLT

-

Load Out Period

-

Estimated Dimensions

40" x 144" x 67"

-

Estimated Weight

APPROXIMATELY 3500 LBS.

-

Seller Comment

-

Load Fee

-

page views

3755

**THIS IS A BRAND NEW MACHINE AND INCLUDES A 6-MONTHS PARTS WARRANTY. THE MACHINE WAS A DEMONSTRATION MODEL AT THE 2019 AWFS TRADE SHOW IN Las Vegas NV.

Flexa 27 RM7 Edgebander

The Flexa 27 Series is an affordable and flexible solution for the medium size shop with the ability of banding tape, 1-3mm pvc, laminate and wood strips. With features typically found on solutions much more expensive, the Flexa 27 Series offers a heavy duty Edgebanding solution at an entry level price.

Operating Units

Unit 1: Pre-milling unit

Unit 2: Glue applicator and pressure rollers

Unit 3: Edgebanding trimming guillotine

Unit 4: End Trim With 2 Tiltable motors 0-15 deg.

Unit 5: Top and Bottom Trimming via 2 motors

Unit 6: Profile/ Radius Scrape

Unit 7: Glue Scraping

Unit 8: Brushing

|

TECHNICAL DATA: |

Flexa 27 RM7 |

||

|

· Panel height |

8-60 mm |

0.3 - 2.36” |

|

|

· Coil edge thickness |

3mm |

.12” |

|

|

· Strip edge thickness |

.3 - 6mm |

.015 - .24” |

|

|

· Max overhang top and bottom (total top and bottom) |

4 (2+2) mm |

0.16” |

|

|

· Min panel width (with min length of 210mm or 8 ¼ “) |

90mm |

3.54” |

|

|

· Min panel length (with min width of 100mm or 3 15/16 “) |

140mm |

5.5” |

|

|

· Feed speed |

10 m/ min |

33 f/min |

|

|

· Glue Tank GP-200 |

|

|

|

|

o Power |

|

2.4 kW |

|

|

o Glue capacity |

1.5 kg |

3.3 lbs |

|

|

· End Trimming Unit IK/200 (each) |

|

|

|

|

o Motor size |

|

.3 HP |

|

|

o Cutting speed |

|

12,000 RPM |

|

|

o Blade tilt |

|

0-15 deg. |

|

|

· Top and Bottom Trimming TT/K |

|

|

|

|

o Motor size (each) |

|

.4 HP |

|

|

o Cutting speed |

|

12,000 RPM |

|

|

CA1781 |

STANDARD EQUIPMENT |

|

· Thick, welded Steel Frame · Steel pressure beam with 2 rows rubber rollers · Feed chain with industrial high grip rubber o Chain on hardened steel guides o Guides consist of one circular and one flat · Manual adjustment of the pressure beam w/ readout o Automatic pos. of the working units w/ reference to panel · Mechanical digital indicators for panel thickness · High Frequency Motors w/ Inverter · Centralized dust extraction · Adjustable panel support rollers · Sound enclosure · Lockable switch cabinet · Equipped with o Glue pot and edge processing magazine o 2-Motor end trimming Unit. 0-15 deg o 2- Motor Top and bottom trimming unit o Edge scraping unit for 3mm o Brushing unit |

|

|

INCLUDED FEATURES |

|

|

CA4785 |

Execution complying to US regulations (UL/CSA) Safety Standards |

|

CA2074 |

Anti-adhesive Unit “RA” |

|

CA4532 |

Spare glue tank 1.5kg for GP200 unit |

|

CA4053 |

Tool kit 3mm on all units |

|

CA4059 |

Pair of additional cutters “Combi” for the trimming unit R = 3mm |

|

CA3032 |

Pair of knives for edge scraping unit R = 3mm |

|

CA4526 CA5555 CA4088 |

Kit for processing 6 x 60mm Glue Scraping Unit “GS/K1” Brushing/ Buffing Unit “BFK” |

|

|

|

ELECTRICAL DATA:

E-Stop on main control panel

230 V – 3 Ph – 60 Hz. 37 Amps

MACHINE FEATURES

In feed and construction

· Industrial grade in feed system with high grip, interchangeable rubber pads.

· Guided by a chain for accurate feeding and long lasting perfection

· Thick, Steel top pressure beam complete with two rows of rubber coated wheels.

· Robust panel support which can be extended according to the size of the parts

MEGA 120 Controller

· Ergonomic positioning

· 4”Graphic Display w/ multi language selection

· Glue temp. control w/ temp

· Unit operation and feed track start/ stop

· Digital readouts

· Parameter/ setting control

· On board diagnostics

· Partial and absolute statistical info: # of pieces worked, edge used and feeding information

Pre-milling unit

● Two cutter heads with automatic timing

● Independent high frequency motors with

● Stock removal determined by infeed fence with digital display

● Timed blower to clean the machined surface

● Diamond tools

2.4 hp each. Tools D=100mm H=49mm

Max stock removal is H=45mm / 55mm ²

GP-200

· Three Pressure rollers (1 large driven, 2 idle with opposed conicity)

· Teflon coated glue pot

· Automatic glue temperature regulator to reduce glue temperature if machine is not in use to reduce glue heat time

· Automatic recovery of glue

· Automatic loader for strips

2.4 kW. 3.3 HP Power. 1.5 Kg Capacity

End Trimming Unit IK/200

· 2 Independent high frequency motors w/ blades

· Pneumatic tilting of the saw blade 0 – 15 deg. from control panel

· Units slide on THK guideways

· Mounted to the base for vibration free machining

12,000 RPM and .3 hp each

Trimming Unit “TT/K”

· 2 Independent high frequency motors

· Vertical revolving copy devices and front copy pads for accurate positioning

· Dust extraction hood

· 3mm tooling standard

12,000 RPM and .4 hp each

Edge Scraping Unit “SCR/K”

· For finishing 1mm – 3mm PVC/ ABS edging

· Front and vertical copy devices for accurate positioning of the knives

· Complete with digital mechanical readouts for accurate positioning and adjustment

· Dust extraction

· Supplied with 3mm tooling

Glue Scraping Unit GS/K1

- Eliminates excess glue between panel and edge

- Eliminates small edging overhang (0.1 – 1mm)

- 2 Pairs of vertical rotating copiers

- Air blowers on both cleaning knives

Self-adjusting throwaway knives

The listed specifications & information were taken from the manufacturer’s published information, internet research, or seller’s description.

The specifications & information are assumed to be correct; however, in no way, guaranteed. Bidders are encouraged to inspect the machine, call with questions, or contact the manufacturer for more information.

Please log in to view the bid history

Login

ALL ITEMS WILL HAVE LOADING FEES AND WILL BE ADDED TO EACH LISTING. MOST MACHINES ARE FULLY CRATED AND CAN BE SHIPPED VIA COMMON CARRIER OR FLAT BED TRUCK/TRAILER.

LOADOUT WILL BE BY APPT. ONLY WITH A FULLY PAID INVOICE AND RECEIPT.

All buyers agree to make full payment to MachineryMax, Inc. within 48 hours of the online closing date for the auction lots purchased. All invoices over $1,500.00 are to be made by bank wire transfer or cashier’s check payable to MachineryMax, Inc. Purchases under $1,500.00 may be made using Visa, MasterCard, or American Express (2% credit card processing fee will be added to the invoice). All payments are to be made in USD currency only. Bidder represents and warrants to MachineryMax, Inc. that such bidder has immediately available funds to fully pay for its successful bids within 48 hours of the online closing date. All payment questions should be directed to Sabrina Burns at 209-839-7707 or [email protected] All buyers agree that there will be a 15% Buyers premium that will be added to the final invoice.