SCM "Pratix N15" Flat Table Machining Center/ Load/Unload - (2012)  Ended

Ended

Load/Unload SCM CNC Machining Center - Hutto TX - See Notes on pickup location

- Winning Bid : $25,000.00 USD Sold

- 71 Bid(s)

- High Bidder: @****r

LATE MODEL SCM CNC MACHINING CENTER AUCTION - Hutto, TX ( Closed #25695810 )

PICKUP MAY BEGIN ON JANUARY 30TH, 2021 AT 10835 Bammel North Houston

$2400 LOAD FEE FROM PICKUP LOCATION - 10835 Bammel North Houston

-

Pick Up Location

PICKUP LOCATION- 10835 Bammel North Houston Road Houston, TX 77086

-

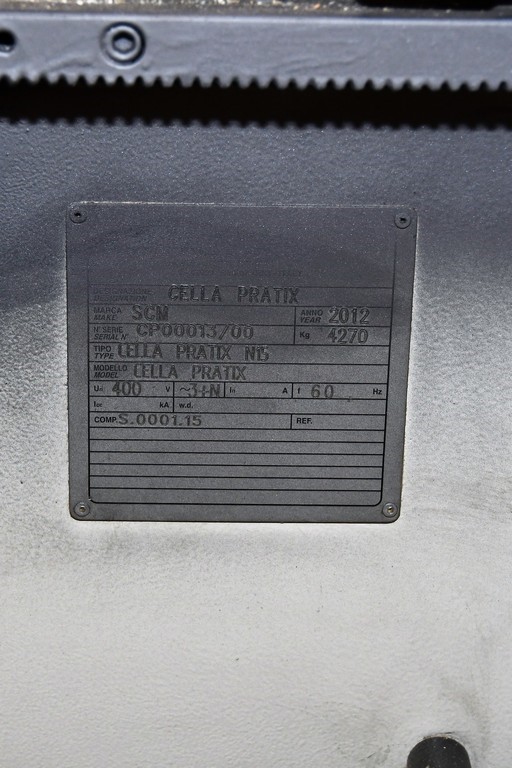

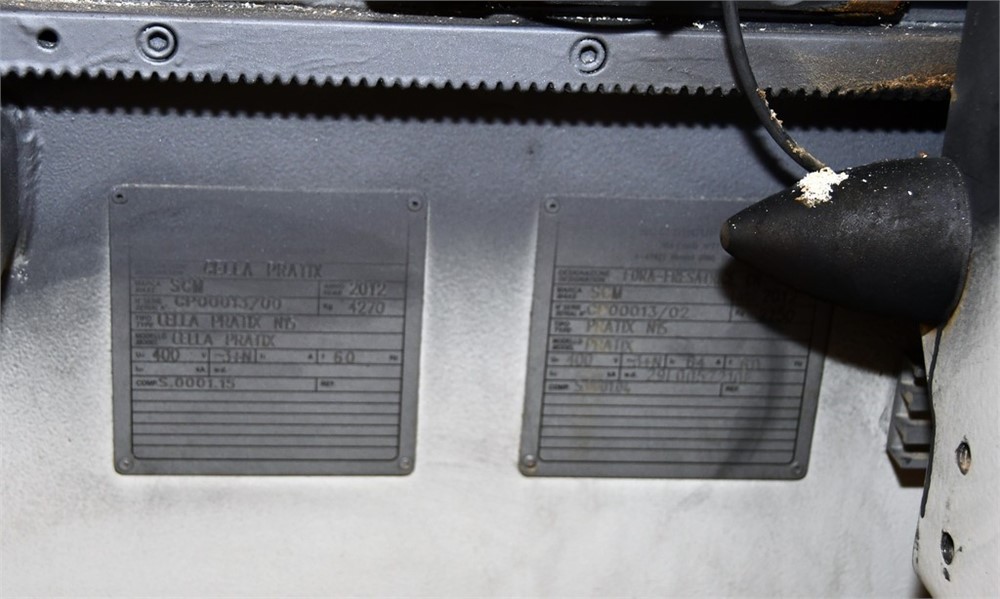

Make

SCM

-

Model

"Pratix n15" LOAD/UNLOAD CELL

-

Serial Number

CP00013700

-

Year

2012

-

Phase

3 PHASE

-

Voltage

208-230/460

-

Load Out Period

PICKUP MAY BEGIN ON JANUARY 30TH, 2021 AT 10835 Bammel North Houston Road Houston, TX 77086

-

Estimated Dimensions

For shipping purposes, A full tailer will more than likely be required.

-

Estimated Weight

4,270 Kg CNC weight plus infeed/outfeed. Estimated 12,000 Lbs total

-

Seller Comment

$2400 LOAD FEE FROM PICKUP LOCATION - 10835 Bammel North Houston Road Houston, TX 77086

-

Load Fee

$2,400

-

page views

8471

THE NEW PICKUP LOCATION OF MACHINE WILL BE THE FOLLOWING:

-

10835 Bammel North Houston Road Houston, TX 77086

-

THE MACHINE WILL HAVE A DELAYED LOADOUT AND PICKUP FROM THE ABOVE ADDRESS WILL TAKE PLACE STARTING ON JANUARY 30TH, 2021. THIS ITEM WILL BE LOCATED AT RIGGERS FACILITY AND CAN BE LOADED ONTO FLAT BED TRUCK OR TRAILER.

Single 5' x 12' traveling "Bridge Gantry" and stationary aluminum vacuum table with a "MATRIX" square grid pattern for fixturing parts.

Grid pattern allows use of vacuum pods or closed cell rope gasketing material and use of spoilboards for "nested base machining".

(4) Part location pop-up pins mounted on the table perimeter, (3) pins are in the rear & (1) on the RH side; (8) individual vacuum areas controlled by electronic switching.

X-Axis is 144.9" (3,660 mm); Y-axis is 61" (1,550 mm); Z-axis stroke is 9.4" (240 mm); max. clearance with the automatic unloading device is 5.1" (130 mm); max. material thickness is 4.9" (125 mm).

X- & Y-Axis at 229 FPM (70 MPM), Z-axis at 82 FPM (26 MPM); closed loop AC Servo drive system with high precision "Rack & Pinion" system in X-axis & precision ground ball screws in Y- & Z-axis; all axes ride on extra large precision profile linear guideways.

3 HP (2.2 kW) - 4,000 RPM motor; (12) independent vertical spindles on 32 mm centers, (7) spindles in X-axis & (5) spindles in Y-axis.

(1) 16.5 HP (12.3 kW) Electro spindle with HSK F63 adaptor; variable spindle speeds from 1,500 - 24,000 RPM.

(1) 20-Position tool rack mounted at the rear of the machine base, max. tool dia is 4.7" (120 mm).

(2) 300 cbm/Hr Vacuum Pump; automatic lube system; 208/230/460 auto-transformer; safety enclosure around the spindle carriage; photo-cell safety sensors & perimiter fencing; documents & manuals.

(2) 300 cbm/Hr Vacuum Pump; automatic lube system; 208/230/460 auto-transformer; safety enclosure around the spindle carriage; photo-cell safety sensors & perimiter fencing; documents & manuals.

Automatic lifting table for "Pratix N 15" Panel stack specifications: Max. panel stack height is 24", max. panel stack weight is 4,000 kG (8,800 Lbs), max. panel stack misalignment for X-axis is 30 mm (1.18") & Y-axis is 5 mm (0.19").

Workpiece Loading Unit with Scution Cups for "Pratix N15": Vacuum device mounted on the machine upright with suction cups able to grip the upper panel of the stack on the machine right side and move it up to the machine table support stops.

Workpiece outfeed pusher on the left side for "Pratix N15" (Right to Left): Device mounted on the machine upright that moves the workpieces towards the unloading area on the machine left side. - This device cleans the spoil board while it unloads the components.

Outfeed Conveyor Belt on Left Side for "Pratix N15": Powered belt capable of moving components from the machine table to the unloading position. This position is equipped with a photo-cell automatic detecting system for the belt start/stop & push-button for belt manual positioning.

All specs were taken from literature online. While thought to be accurate, buyer is encouraged to inspect for themselves. Please call for a private inspection.

The listed specifications & information were taken from the manufacturer’s published information, internet research, or seller’s description.

The specifications & information are assumed to be correct; however, in no way, guaranteed. Bidders are encouraged to inspect the machine, call with questions, or contact the manufacturer for more information.

Please log in to view the bid history

LoginPick-ups are to be scheduled by appointment only. Please contact Sabrina Burns at 209-839-7707 or [email protected] to schedule an appointment. For freight quotes please contact Aaron at All-Ways Trucking at 541-608-6532. Buyer bears all costs to remove and load this lot. Buyer must remove entire lot purchased. Anyone removing non-hand carriable lots must provide MachineryMax, Inc. with a certificate of insurance (COI) before purchased items can be removed.

All buyers agree to make full payment to MachineryMax, Inc. within 48 hours of the online closing date for the auction lots purchased. All invoices over $1,500.00 are to be made by bank wire transfer or cashier’s check payable to MachineryMax, Inc. Purchases under $1,500.00 may be made using Visa, MasterCard, or American Express (2% credit card processing fee will be added to the invoice). All payments are to be made in USD currency only. Bidder represents and warrants to MachineryMax, Inc. that such bidder has immediately available funds to fully pay for its successful bids within 48 hours of the online closing date. All payment questions should be directed to Sabrina Burns at 209-839-7707 or [email protected] All buyers agree that there will be a 15% Buyers premium that will be added to the final invoice.