SCM SANDYA 10 RCS 110 WIDEBELT SANDER * 2 HEADS, 43" WIDE CAPACITY  Ended

Ended

130 PIPPIN RD CONCORD, ON CANADA L4K 4P4

- Winning Bid : $9,211.11 USD Sold

- 36 Bid(s)

- High Bidder: E****M

SCM PRATIX CNC, MASTERWOOD CNC, SELCO BEAM SAW * 100 LOTS in TORONTO, CANADA ( Closed #25464927 )

LOAD OUT DAYS:

MONDAY DEC 21 THRU TO WEDNESDAY DEC 23 (8:00 AM - 4:00PM)

MONDAY DEC 28 THRU TO WEDNESDAY DEC 30 (8:00 AM - 3:00 PM)

PLEASE NOTE: IT IS INCUMBENT ON THE BUYER TO BRING THE PROPER TRUCK ONSIGHT FOR LOAD OUT.

FEATURED EQUIPMENT: SCM PRATIX N15 FLAT TABLE CNC yr 2010 * MASTERWOOD PROJECT 415 FLAT TABLE CNC * HOLZMA OPTIMAT HLP11 AUTO BEAM SAW * MASTERWOOD PRIMA P&R CNC MACHINE * QUICKWOOD RO SANDER * GRIGGIO 400 SLIDING TABLE SAW * TAYLOR 79Y-M1 BOX & DRAWER CLAMP * EDGETECH CTS730 COUNTER TOP SAW * (3) MIDWEST COUNTER TOP SAWS * SILVER SWBS BANDSAW * BALLESTRINI PICO CNC TENON / MORTISE MACHINE * BACCI TTF1 MITRE DOOR MACHINE * COR-PAK BALER * KING & ROCKWELL TABLE SAWS * SPRAY BOOTH, EXPLOSION CABINETS, LUMBER RACKING, SAW BLADES, SHAPER CUTTERS...AND MUCH MORE.

-

Pick Up Location

130 PIPPIN RD CONCORD, ON CANADA L4K 4P4

-

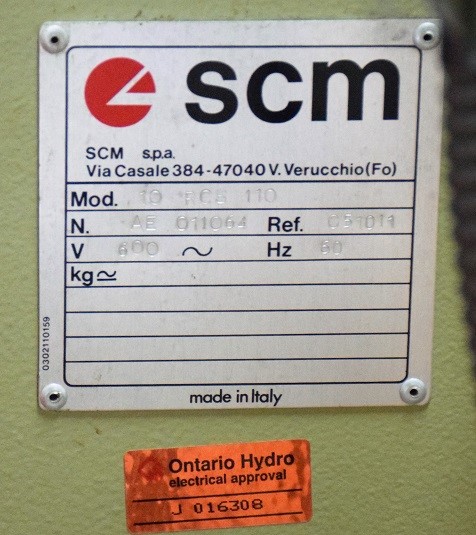

Make

SCM

-

Model

SANDYA 10RCS 110

-

Serial Number

-

Year

-

Phase

3 PHASE

-

Voltage

575 VOLT

-

Load Out Period

DEC 29 2020 (EXCEPTIONS MADE FOR USA BUYERS)

-

Estimated Dimensions

5'L x 5'W x 7'H

-

Estimated Weight

5,000 LBS

-

Seller Comment

SEE SHIPPING DETAILS

-

Load Fee

-

page views

2437

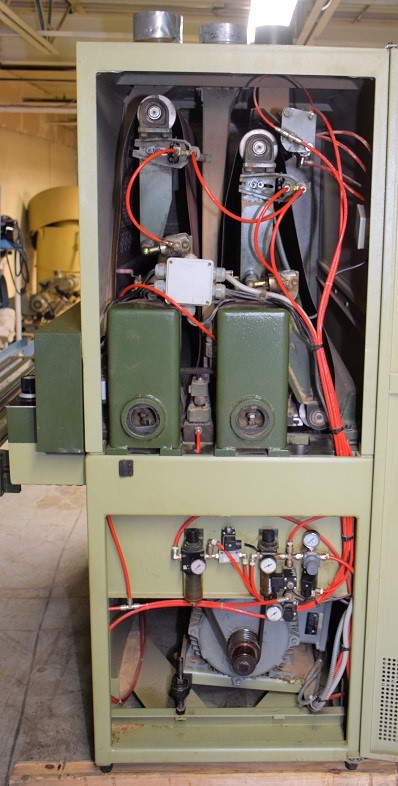

SCM Model SANDYA 10 RCS 110 WIDEBELT SANDER

STANDARD FEATURES

Control panel with dust-proof membrane buttons

Motorized adjustment of the work surface

Digital display of working thickness

Conveyor belt in natural rubber

Automatic device for tensioning and centering the conveyor belt

Floating pressure rollers covered in rubber front and back to the operating groups

Flexible steel sheet presser at the entrance to the first operator group

Two support rollers at the entrance and two at the exit of the conveyor belt

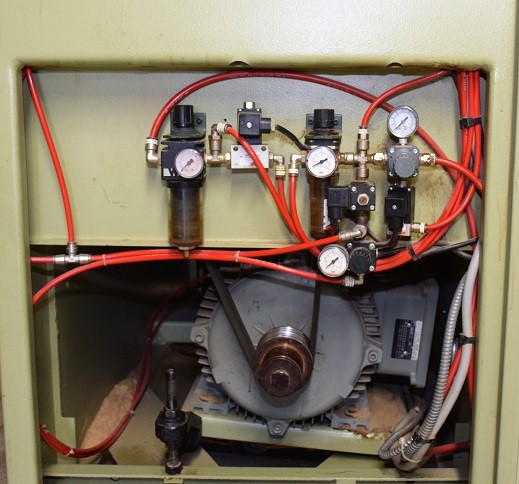

Belt oscillation with electro-pneumatic control

Dust extraction hoods with a profile designed for better performance with low consumption of air intake

Emergency hand guard in pieces entry

Front and rear emergency switch

Lockable main switch

Automatic star / delta starting on the main engines

Circuit breaker protection on each main motor

Automatic brakes for quick group shutdown

Control test on the control panel to check for emergencies, circuit breakers, operating pressure and brakes

Automatic emergency stop machine for:

- abrasive belt breakage

- abrasive belt not tensioned

- abrasive belt side exit

- opening access doors to the operating groups

- lack of compressed air

- overloading of the main engines

* motors in dust protection IP 54

TECHNICAL CHARACTERISTICS SANDYA 10 RCS 110

* useful working width 1,100 mm

* thickness min./max. machinable on a movable surface 4-170 mm

* width of abrasive belts 1,115 mm

* development of abrasive belts 2,150 mm

* power of the main engine 11 (15) kW HP)

* advance motor power 0.45 / 0.8 (0.6 / 1.1) kW (HP)

* belt advancement speed 4,5 / 9 m / min

FIRST GROUP "R" EQUIPPED WITH:

- R / 160 with a diameter of 160 mm

- 85 SH rubber coating

- manual adjustment of the working position

SECOND COMBINED GROUP "CS" EQUIPPED WITH:

- "CR / 175" roller with a diameter of 175 mm

- 45 SH rubber coating

- manual adjustment of the working position

- "TRP / E" rigid "PLUS" type flat pad made with a pneumatic locking extractable bar equipped with a felt contact element with density D = 0.68 and contact width L = 80 mm

- manual adjustment of the working position

- removable graphite canvas

MACHINE COMPOSITION

- Reading bar for sectioned pads in 19 sectors

- RA - Grooved steel calibrator roller 1st Group

- CR30 - 30 SH 2nd group rubber sanding roller

- TSE19 * Electronic sectioned pad on the 2nd group

* complete with "MESAR 470" electronic programmer

* divided into 19 sectors.

* 60 mm segmentation distance between sectors

* operation of the sectors by means of an electronic programmer which synchronizes the intervention with the speed of advancement, activates the quantities based on the geometric shape of the piece and allows the selection of a greater or lesser number to the left or to the right or from both piece sides.

* working pressure regulation

* standard equipment of type 2 contact:

1) flat semi-rigid contact insert made with a flexible steel sheet 0.6 mm thick + felt D = 0.68 and contact surface L = 60 mm.

It is suitable for sanding solid or veneered panels

2) soft semi-sandwich contact insert made with a flexible steel sheet

0.3 mm thick + rubber + felt D = 0.68 and contact surface L = 60 mm.

It is suitable for sanding veneered and / or painted panels.

* removable graphite cloth

- Pneumatic On / Off of the 1st roller

made with a pneumatic activation cylinder complete with micrometric adjustment of the roller position according to the thickness of the abrasive belt

- Pneumatic On / Off of the 2nd roller

made with a pneumatic activation cylinder complete with micrometric adjustment of the roller position according to the thickness of the abrasive belt

- Automatic intervention of the buffer

synchronized with both belt advance speeds. This device is essential in combination with the flexible or semi-rigid or elastic sectioned pad.

- Oscillating blower on the 2nd group

The device is complete with:

activation of the oscillation with electronic system

Izzato timed intervention activated directly by the workpiece

dust extraction hood

filter and pressure regulator

- 1st / 2nd group engine of 15 kW (20 Hp)

- Carpet advance with 1.5 kW motovariator (2 Hp)

LOAD FEE: $ 300.00 CDN

PALLETIZE FEE FOR LONG DISTANCE SHIPPING: N/A

US CUSTOMS BROKER

NEAR NORTH (716) 204-4020

US BUYERS SHIPPING QUOTES:

ALWAYS TRUCKING...AARON (541) 608-6532

SHIPPING WITHIN CANADA QUOTES;

MANITOULIN TRANSPORT (800) 268-9994

OVERSEAS CONTAINER QUOTES:

LISA JONES (416) 896-2688

The listed specifications & information were taken from the manufacturer’s published information, internet research, or seller’s description.

The specifications & information are assumed to be correct; however, in no way, guaranteed. Bidders are encouraged to inspect the machine, call with questions, or contact the manufacturer for more information.

Please log in to view the bid history

LoginUS CUSTOMS BROKER

NEAR NORTH (716) 204-4020

US BUYERS SHIPPING QUOTES:

ALWAYS TRUCKING...AARON (541) 608-6532

SHIPPING WITHIN CANADA QUOTES;

MANITOULIN TRANSPORT (800) 268-9994

OVERSEAS CONTAINER QUOTES:

LISA JONES (416) 896-2688

No information available

* CDN FUNDS: THIS AUCTION IS BEING HELD IN CDN FUNDS

* PAYMENT: IS REQUIRED WITHIN 48 HRS OF AUCTION ENDING. PLEASE DO NOT MAKE ANY FORM OF PAYMENT UNTIL RECEIVING YOUR INVOICE

* PAYABLE METHOD: TO EQUIPMENT AUTHORITY BY WAY OF WIRE TRANSFER, ETRANSFER OR DIRECT DEPOSIT ONLY.

* REMOVAL: AT BUYERS EXPENSE

* REMOVAL DEADLINE: DEC 29, 2020 (EXCEPTION TO US BUYERS

* INSPECTION BY APPOINTMENT CALL ROB 416-904-2475

* AUCTION END DATE: WED, DEC 16 2020 AT 1:00 PM (EDT)

* BUYER PREMIUM: 15% BUYER PREMIUM SURCHARGE WILL BE ADDED TO ALL LOTS