2018 Superfici "Mini P" Spray Machine with Kremlin Pumps  Ended

Ended

2018 Superfici "Mini P" Spray Machine with Kremlin Pumps - Fairview, UT

- Winning Bid : $58,100.00 USD Sold

- 85 Bid(s)

- High Bidder: j****r

2018 Superfici "Mini P" Spray Machine with Kremlin Pumps - Fairview, UT ( Closed #25474078 )

High-end woodworking manufacturer in Utah is selling its 2018 Superfici spray machine. This machine is no longer required for continuing operations.

-

Pick Up Location

60 W. 300 N. Fairview, UT 84629

-

Make

Superfici

-

Model

Mini P

-

Serial Number

T308-002

-

Year

2018

-

Phase

3 PHASE

-

Voltage

480 VOLT

-

Load Out Period

December 17 - December 22 and December 28 - December 30, 2020 (9 am - 3 pm by appointment)

-

Estimated Dimensions

See photos

-

Estimated Weight

See photos

-

Seller Comment

This lot requires a rigger, see shipping section for details

-

Load Fee

-

page views

3639

2018 Superfici "Mini P" Spray Machine with Kremlin Pumps

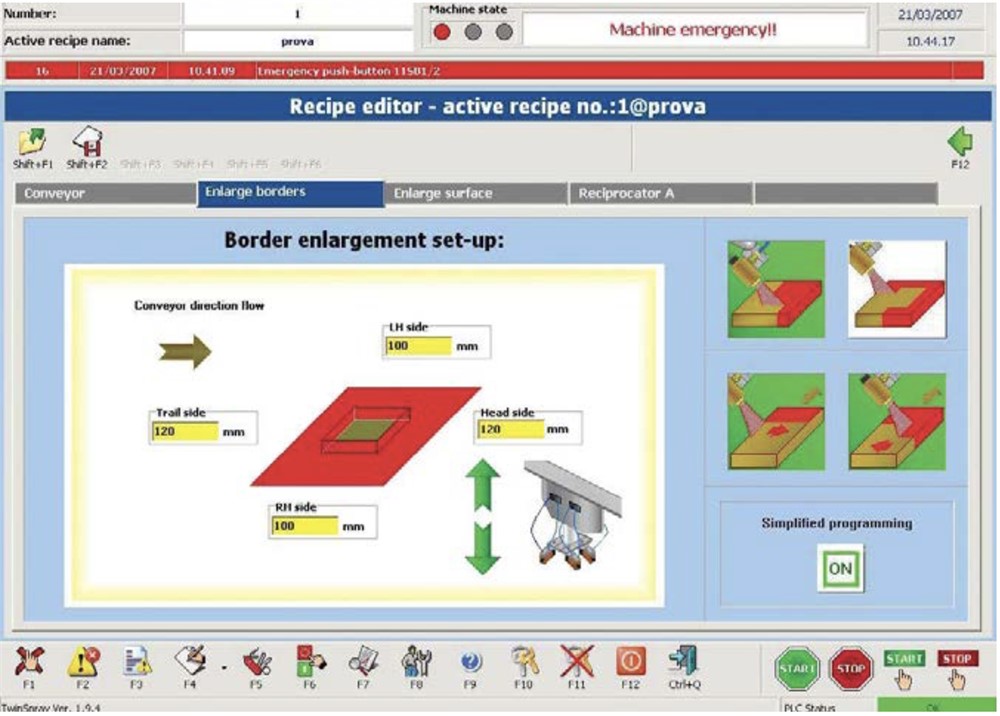

The automatic through-feed spraying machine mod. MINI achieves the advantages of automatic spraying process with a limited investment.

CONVEYING SYSTEM AND PAPER PROTECTION DEVICE

In-feed and out-feed driven roller conveyor system.

Central belt conveyor with protective paper device.

The paper function is to absorb the overspray, thus protecting the conveyor belt underneath.

The machine is equipped with a paper roll unwinding system at the in-feed and rewinding system at the out-feed. The supply includes one roll of paper.

SPRAYING ARM AND LACQUER CIRCUITS

Lacquer application system consisting of a reciprocator with single arm driven by brushless motor and sliding on a high precision linear guide.

Accurate motion guaranteed by high precision reducer.

The arm is equipped with guns holder supporting up to max four guns, with two lacquer circuits.

To achieve a higher level of flexibility, the MINI features, as standard, the QUICK CHANGE system for the guns holder.

2 atomizing manometers placed on the outside of the cabin, each to control 2 guns.

Based on the type of product as well as the grammage to be applied, it is possible to use three different types of guns (not included in the supply):

- Low pressure guns

- Airmix guns

- Airless guns

ENCLOSING CABIN

Controlled spraying environment thanks to the enclosing cabin with a highly efficient double side air suction system with dry filters. Perfectly balanced suction air flow thanks to separate exhausts for the left and right filter tanks.

Filtration by means of double stage dry filters.

The cabin is also equipped with an inspection window on the workpiece in-feed and out-feed.

The machine structure integrates all necessary items: control cabinet, exhaust fans, pump support.

This feature makes the MINI plug & spray a space saving equipment.

PLC CONTROLLED

The automatic detection of the required working width along with the PLC control allow the reduction of lacquer consumption and achieves consistency in the quality results.

- "B&R" PLC control with 5,7” colour touch screen mounted on board of the machine, to set and control the automatic spray guns opening and closing in agreement with the conveying speed and with the recognised necessary working width.

- Easy to use control software OPTISPRAY

TECHNICAL FEATURES:

Working width 1300 mm

Paper roll width 1600 mm

Max. paper roll diam. 300 mm

Max. work-piece thickness 120 mm Working table height 900 +/- 20 mm Feed speed 1-3 m/min

Compressed air consumption approx. 1800 Nl/min. (with 4 airmix guns)

Exhaust air volume 8000 m3/H

Installed power 9 Kw

Colour grey RAL 9002

Operating side right hand (left by request) Infeed roller conveyor length 667 mm Outfeed roller conveyor length 697 mm. Cabin height 2070 mm

Cabin width 3670 mm

Cabin length 2150 mm

Total machine length 3510 mm

Machine executed according to the European norms, suitable to be used with solvent-based lacquers. The correct use of the machine allows to keep the area with risk of explosion (Zone2) inside the machine.

Machine to be positioned in a safe environment (not classified as an area with risk of explosion).

Control cabinets have no explosion-proof devices and have to be placed in a safe environment.

STD USA = 480 V /60 HZ - NORME UL

Execution according to USA UL standards and voltage 480V/60Hz.

SET OF QUICK CHANGE CONNECTORS FOR LACQUER CIRCUITS

Set of quick change connectors for lacquer circuits.

Additional holding plate for 4 airmix/airless guns equipped with quick connection device.

SET OF QUICK CHANGE CONNECTORS FOR LACQUER CIRCUITS ON ADDITIONAL HOLDING PLATE (HP)

Set of quick change connectors for lacquer circuits on additional holding plate, for Airmix/Airless guns.

4 AA GUNS + 1 HIGH PRESSURE PUMP + FLUID REGULATOR

Suitable for common traditional coatings and stains, consisting of:

- 4 air-assisted airless or airless guns complete, with 1 set nozzles (Kremlin ATX)

- 1 set spare nozzles in a different size - connection piping for 1 circuit - 1 high pressure pump, able to feed up simultaneously 4 spray guns, with air regulator, fluid filter, fluid pressure gage, and 5 gallon suction tube (Kremlin 20-50T)

- fluid pressure regulator with gage

- hoses, fittings, etc. for fluid, including L ported manual valve

- shipping, installation, and training

4 AA GUNS + 1 HIGH PRESSURE PUMP + FLUID REGULATOR + RECIRCULATION

Suitable for common traditional coatings and stains, consisting of:

- 4 air-assisted airless or airless guns complete, with 1 set nozzles (Kremlin ATX)

- 1 set spare nozzles in a different size - connection piping for 1 circuit - 1 high pressure pump, able to feed up simultaneously 4 spray guns, with air regulator, fluid filter, fluid pressure gage, and 5 gallon suction tube (Kremlin 20-50T)

- fluid pressure regulator with gage

- recirculation valve (Kremlin) or back pressure regulator (Graco) - hoses, fittings, etc. for fluid, including L ported manual valve

- shipping, installation, and training

Machine has been un-installed and palletized. Ready for loading.

The listed specifications & information were taken from the manufacturer’s published information, internet research, or seller’s description.

The specifications & information are assumed to be correct; however, in no way, guaranteed. Bidders are encouraged to inspect the machine, call with questions, or contact the manufacturer for more information.

Please log in to view the bid history

LoginPick-ups are to be scheduled by appointment only. Please contact Sabrina Burns at 209-839-7707 or [email protected] to schedule an appointment. For freight quotes please contact Aaron at All-Ways Trucking at 541-608-6532. Buyer bears all costs to remove and load this lot. Buyer must remove entire lot purchased. Anyone removing non-hand carriable lots must provide MachineryMax, Inc. with a certificate of insurance (COI) before purchased items can be removed. For rigging/machinery moving, please contact Luke Nielson at Atlas Rigging, [email protected]. At this time we are verifying size and weight and once verified will post a quote.

All buyers agree to make full payment to MachineryMax, Inc. within 48 hours of the online closing date for the auction lots purchased. All invoices over $1,500.00 are to be made by bank wire transfer or cashier’s check payable to MachineryMax, Inc. Purchases under $1,500.00 may be made using Visa, MasterCard, or American Express (2% credit card processing fee will be added to the invoice). All payments are to be made in USD currency only. Bidder represents and warrants to MachineryMax, Inc. that such bidder has immediately available funds to fully pay for its successful bids within 48 hours of the online closing date. All payment questions should be directed to Sabrina Burns at 209-839-7707 or [email protected] All buyers agree that there will be a 15% Buyers premium that will be added to the final invoice.