Casadei "Flexa 507" Edgebander - NEW Comp Code R000401  Ended

Ended

YEAR END INVENTORY CLEARANCE OF MOSTLY BRAND NEW IN BOX.

- Winning Bid : $54,151.00 USD Sold

- 145 Bid(s)

- High Bidder: J****l

BRAND NEW CASADEI YEAR END INVENTORY CLEARANCE - DULUTH GA ( Closed #25252971 )

YEAR END INVENTORY CLEARANCE OF MOSTLY BRAND NEW IN BOX AND ORIGINAL FACTORY CRATING MACHINES. MACHINES ARE CASADEI/BUSELLATO MACHINE MANUFACTURED BY SCM GROUP SPA IN ITALY. THERE ARE 12 MACHINES UP FOR AUCTION AND ALL WILL INCLUDE A 6-MONTH PARTS WARRANTY ONLY. THE LIST INCLUDES BRAND NEW CASADEI FLEXA SERIES EDGEBANDERS, CASADEI SHAPERS (BOTH TILTING AND NON-TILTING), AND MUCH MORE. IF YOU HAVE QUESTIONS, PLEASE CONTACT KIRK @ 925-250-8248 OR VIA EMAIL @ [email protected]. YOU CAN ALSO CONTACT ERIC BEACH @ 704-608-9830 OR AT [email protected] AUCTION WILL CLOSE ON THURSDAY, DECEMBER 10TH, 2020 AND PICKUP OF MACHINES WILL BE BY APPOINTMENT ONLY.

-

Pick Up Location

2475 Staellite Blvd, Duluth, GA 30096

-

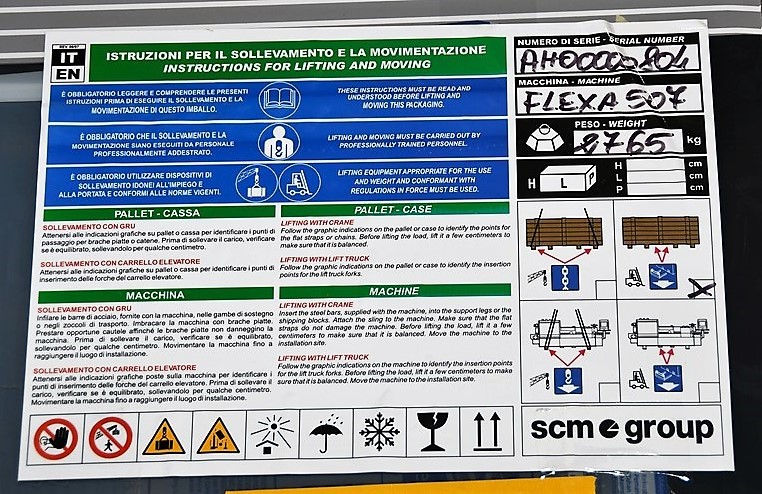

Make

Casadei

-

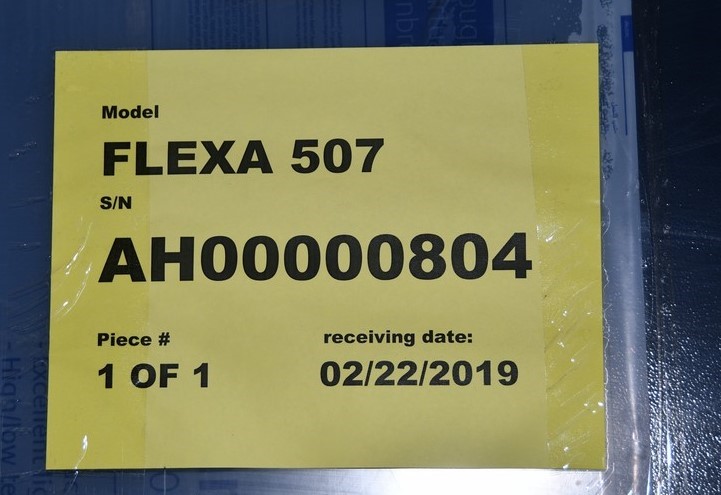

Model

Flexa 507

-

Serial Number

AH00000804

-

Year

2019

-

Phase

3 PHASE

-

Voltage

230 VOLT

-

Load Out Period

12/18/25

-

Estimated Dimensions

47" x 238" x 80"

-

Estimated Weight

6,100 Lbs

-

Seller Comment

CONTACT ALWAYS TRUCKING for shipping quote 541-608-6532

-

Load Fee

$350

-

page views

3332

FLEXA 507 RMA9

The NEW Flexa 507 Series provides users productive solutions with a modest footprint. Designed for medium to large cabinet and millwork manufactures, the Flexa507 features high production features, speeds, and units at an affordable price, while producing consistent results.

Unit 1: Diamond pre-mill

Unit 2: Glue applicator and pressure rollers

Unit 3: Edgebanding trimming guillotine

Unit 4: (2) motor end trimmer

Unit 5: Top and bottom trimmer

Unit 6: Tilted trimming unit 20˚

Unit 7: Corner Rounding

Unit 8: Edge Scraping

Unit 9: Brushing

| TECHNICAL DATA: | ||||

| · Working height | 2.36”) | |||

| · Working height corner rounding | 12 – 45 mm | (.08 – 1.77”) | ||

| · Coil edge thickness | 0.4 – 3 mm | (0.02 – 0.11”) | ||

| · Strip edge thickness | 0.4 – 12 mm | (0.02 – 0.47”) | ||

| · Max overhang top and bottom (total top and bottom) | 5 mm (2+3) | (0.19”) | ||

| · Min panel width | 55 mm | (2.17”) | ||

| · Min panel length coil edge | 170 mm | (6.7”) | ||

| · Min panel length strip edge | 250 mm | (9.8”) | ||

| · Min distance between panels (12/18 m/min) | (550/700) mm | (21.6/27.5”) | ||

| · Feed speed (2 feed speed @ 12 & 18 m/min) | 12/ 18 mpm | (40 / 60 fpm) | ||

| · Glue Tank GP-1100 | ||||

| o Power | 3 kW | |||

| o Glue capacity | 4.8 L | |||

| · Premill Unit (diamond.) | ||||

| o Removal | .4 – 3mm | (0.02 – 0.11”) | ||

| o Motor power | 5.3Hp | |||

| o Tool height/ diam. | 64/ 100mm | (2.5” /3.9”) | ||

| o Tool cutting speed | 9,000 rpm | |||

| · End Trimming Unit IK/S | ||||

| o Motor size (each) | 0.56Hp | |||

| o Cutting speed | 12,000 rpm | |||

| · Top and Bottom trimming TS/K | ||||

| o Motor size (each) | 1Hp | |||

| o Cutting speed | 12,000 rpm | |||

| · Tilting Trimming Unit TT/1100 | ||||

| o Motor size (each) | 1Hp | |||

| o Cutting speed | 12,000 rpm | |||

| · Fixed Motor inclination | 20˚ | |||

| · Corner Round Unit ROUND A2 SUPER | ||||

| o Motor size (each) | .55Hp | |||

| o Cutting speed | 12,000 rpm | |||

| · Edge Scraping Unit SCR/1000 | ||||

| o Knives with Radius | 3mm | |||

| · Brushing Unit | ||||

| o Motor size (each) | .2Hp | |||

| o Speed | 1,400 rpm | |||

FLEXA 507 RMA9

CA3656 UL/ CSA Safety Standards

930715 230 volt

931501 Frequency 60 Hz

CA3682 Eco System Package

CA3657 Electrical execution 220/230 V 50/60 Hz

CA3658 Electrical Pre-arrangement

CA4053 Tool Kit R=3 mm instead of R=2 mm (standard)

CA2076 “Quick Size” device

CA3773 Diamond tools on pre-milling unit h=64 Z=3+3

CA5004 Edge brightening unit “F/1” for PVC/ABS edging

CA3032 Pair of knives for edging unit R=3

CA9063 Packing for machine frame L=4700

MACHINE FEATURES

Standard Features

• Control panel situated at the machine infeed which can be moved to

an ergonomic position.

• Soundproof protection cabinet with polycarbonate windows for

inspection of the units during machining, covered with acoustic

insulation and complete with internal cabinet light.

• Machine base made of bended and welded steel that ensure high

rigidity of the structure. Special openings for out-feed of not

suctioned chips.

• Panel support roller conveyor on entire machine length with

telescopic opening system and sliding wheels made of plastic with

rotating pins made of steel.

• Feeding chain track made of industrial chain with high grip rubber

coated pads. The chain track pads slide on two steel guides, one with

a circular section and one with a flat section, to guarantee feeding

straightness and resistance to lateral loads. Automatic lubrication of

the pads with optimisation of oil quantity according to processed

panels.

• Panel insertion spacer at machine infeed that allows panels to be

inserted at the correct spacing rate (time between panels). Automatic

regulation of the distance according to working speed.

• Upper pressure unit made of bended and welded steel, supported by

steel columns to assure the solid structure on which operating units are

fixed.

Two rows of panel pressure wheels made of high grip rubber sliding on

ball bearings. Guards to cover the wheels.

Electronic lifting of pressure unit according to panel thickness.

• Top operating unit fixed on pressure unit or mechanically connected

onto it, to allow its automatic adjustment according to panel thickness.

Bottom units fixed on chain track beam for a precise reference with

respect to the panel.

High frequency motors with converter (inverter)

Suction hoods of operating units placed on upper side of the

protection cabinet.

In feed and construction

- Industrial grade in feed system with high grip, interchangeable rubber pads.

- Guided by a chain for accurate feeding and long lasting perfection

- Thick, Steel top pressure beam complete with two rows of rubber coated wheels

- Robust panel support which can be extended according to the size of the parts

MEGA 300 TS Controller

- 12” color touch screen

- Sequential motor start

- Ergonomic positioning

- Control of glue temp 0º - 45º C

- Programmable up to 100 programs/ set-ups w/ rapid recall for 6 common programs

- Pneumatic controls of the units when applicable

- Graphic representation of all operating unit and on/ off status

- Guided technical diagnostics

- Partial and absolute data: number of panels, edgings used, machines use

- Programmable maintenance alarms

Premilling unit TR/E with “Quick Size” Device

- Diamond pre-mill unit

- Electronic pos. of infeed guide

- Digital readouts for manual copier position

- Automatic timed intervention

- 90 mm² max. removable section

9,000 RPM and 5.3Hp each

Gluing Unit GP-1100

- Four Pressure rollers (1 powered, 2 & 3rd tapered, 4 flat)

- Teflon coated glue pot w/ <10 min. heat time

- Automatic glue temperature regulator to reduce glue temperature if machine is not in use

- Automatic recovery of glue

- Automatic loader for strips

4 Hp w/ 3.3 lb capacity

End Trimming Unit IK/S

- 2 Independent high frequency motors

- Pneumatic tilting of the saw blade 0 – 15 deg from control panel

- Units slide on deticated THK guideways

- Mounted to the base for vibration free machining

- Soft/ post –formed panels can also be trimmed

- Horizontal movement of the unit

12,000 RPM and .55 HP each

Top & Bottom Trimming Unit “TS/K”

- Two independent high frequency motors

- Pneumatic pos. from PLC

- Vertical revolving copy devices and horizontal copy pads for accurate positioning

- Digital readouts for positioning

- Dust extraction hood

12,000 RPM and 1 HP each

Tilting Trimming Unit TT/1100

- Two independent high frequency motors

- Vertical rotating copying device for perfect adjustment

- Pneumatic positioning from the unit for

- Bevel trimming for thin edges (.1 - .6mm)

- Edge trimming with 2radius (1 & 2 mm)

- Trimming of solid edges with max. thickness 12mm

- Different trimming such as radius top straight bottom

Corner Rounding Unit Round A/2 Super

- 2 High frequency motors

- Front and vertical copying devices with chrome plated contact surfaces

- Pneumatic exclusion & Position from PLC

- 2 position pneumatic control from control panel

- Unit can be locked into place to double as a second set of top and bottom trimmer or a fine station

Technical specifications:

12,000 RPM and .89 HP each

Edge Scraping Unit SCR/1000

For finishing edges with radius in PVC/ABS:

- Rigid structure allows for a perfect finish without any vibration

- Front and vertical revolving feelers accurately position knives with respect to cutting point, guaranteeing extreme machine precision.

- Pneumatic exclusion (on/off) from PLC controller

“BFN" Brushing Unit

For cleaning and polishing the top and bottom edge.

- 2 independent motors, each .3 HP

- 1,400 rpm rotating speed

Edge brightening unit “F/1”

For heating PVC/ ABS edging to reactivate the original color

- Adjustable power up to 3500 W

- PLC Controlled

MACHINE ALSO SUPPLIED WITH:

1 ea. USE AND MAINTENANCE MANUAL IN ENGLISH

1 ea. ELECTRICAL SCHEMATIC IN ENGLISH

The listed specifications & information were taken from the manufacturer’s published information, internet research, or seller’s description.

The specifications & information are assumed to be correct; however, in no way, guaranteed. Bidders are encouraged to inspect the machine, call with questions, or contact the manufacturer for more information.

Please log in to view the bid history

LoginALL ITEMS WILL HAVE LOADING FEES AND WILL BE ADDED TO EACH LISTING. MOST MACHINES ARE FULLY CRATED AND CAN BE SHIPPED VIA COMMON CARRIER OR FLAT BED TRUCK/TRAILER.

LOADOUT WILL BE BY APPT. ONLY WITH A FULLY PAID INVOICE AND RECEIPT.

All buyers agree to make full payment to MachineryMax, Inc. within 48 hours of the online closing date for the auction lots purchased. All invoices over $1,500.00 are to be made by bank wire transfer or cashier’s check payable to MachineryMax, Inc. Purchases under $1,500.00 may be made using Visa, MasterCard, or American Express (2% credit card processing fee will be added to the invoice). All payments are to be made in USD currency only. Bidder represents and warrants to MachineryMax, Inc. that such bidder has immediately available funds to fully pay for its successful bids within 48 hours of the online closing date. All payment questions should be directed to Sabrina Burns at 209-839-7707 or [email protected] All buyers agree that there will be a 15% Buyers premium that will be added to the final invoice.