Cosen "SH-510LDMB" Double Mitering Semi-Automatic Band Saw  Ended

Ended

Custom Store Fronts - Complete Plant Closure - Olathe, KS

- Winning Bid : $11,200.00 USD Sold

- 53 Bid(s)

- High Bidder: a****8

Custom Store Fronts complete shop closure - Olathe, KS ( Closed #24310196 )

Over 250 Lots! Custom Store Fronts in Olathe Kansas is closing it's doors. This complete shop auction includes a Biesse CNC, Black brothers cold press, Kaiser air compressor, planers, jointers, Timesavers sander, TigerStop, Razor Gauge, Scotchman angle saw, metal band saw, Weaver shapers, Nederman dust collector, JLT clamps, Table saws, large walk in spray booth...and much more.

-

Pick Up Location

1490 West Ironwood Street, Olathe, KS 66061

-

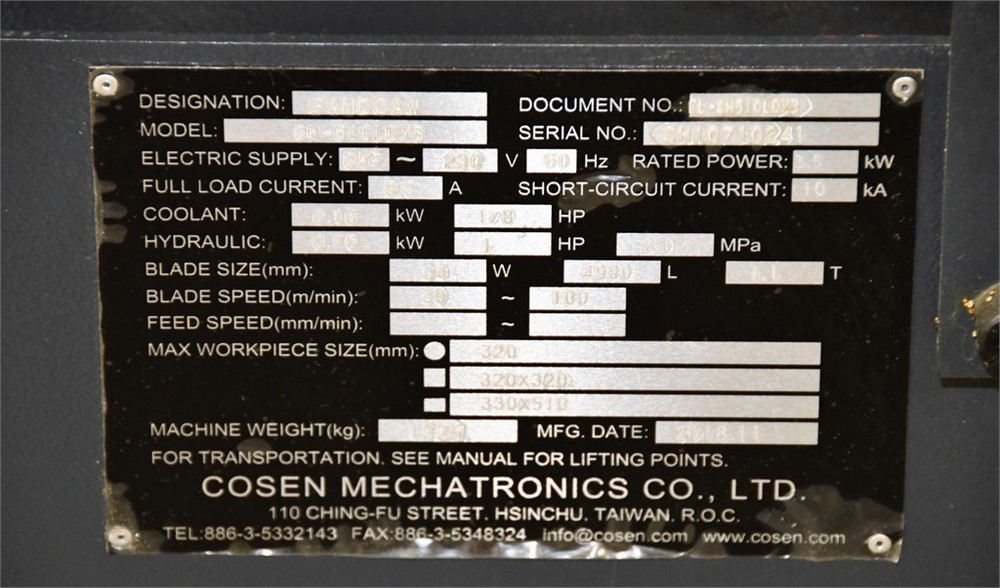

Make

Cosen

-

Model

SH-510LDMB

-

Serial Number

SH10710241

-

Year

2018

-

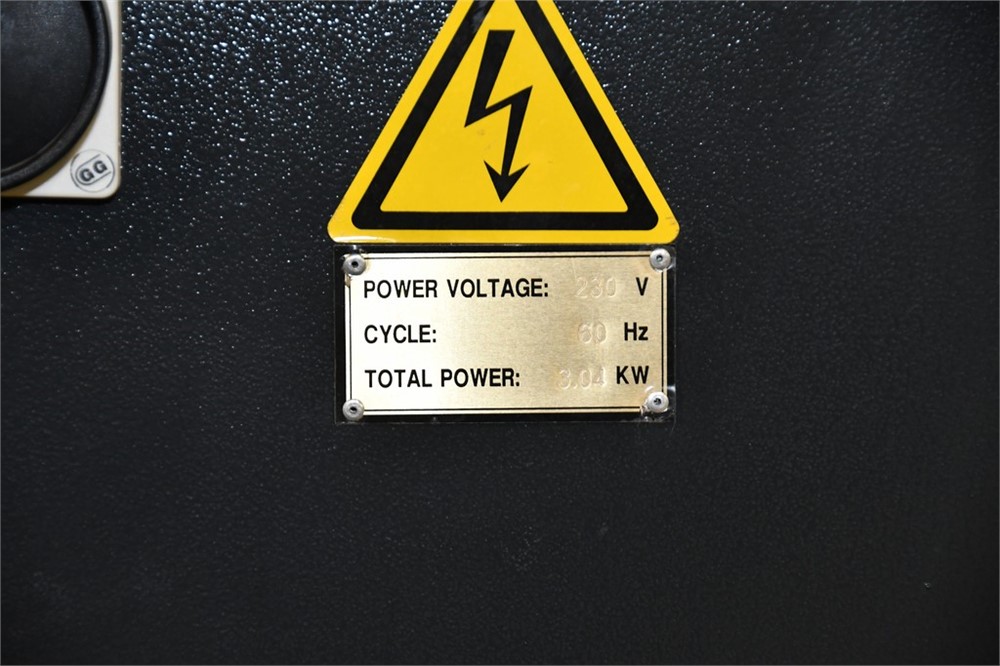

Phase

3 PHASE

-

Voltage

230 VOLT

-

Load Out Period

December 11, 2020

-

Estimated Dimensions

-

Estimated Weight

4,000 Lbs

-

Seller Comment

A non negotionable loading fee has been established - See below. This includes the rigging and loading onto a flat bed trailer. Requests for additional labor, crating or pallatization will be extra.

-

Load Fee

200

-

page views

4189

Cosen's SH-510LDMB incorporate a 3 HP blade motor, 1-1/4" wide blade, independent control panel, and heavy-duty linear rail design. These features create a very rigid, dynamically stable and productive machine. The linear guide square columns ensure smooth saw frame movement and the consistently stable cutting force required throughout the cutting cycle, thereby increasing the cutting effeciency and extending blade life. 6 degree blade cant is designed specifically for cutting structural steel such as

H-beam, I-beam, channels, etc. at the best cutting conditions. Ability to cut to 60 degrees forward and backwards are standard.

Structure:

Cosen employs a rigid, linear guide square columns design, which keeps the same penetrating angle to the material from top to bottom of cut, to enable smooth and consistent feed rate throughout the entire cutting cycle. Saw frame miters +/-60 degrees via manual saw frame swivel.

The 6 degree blade cant is designed for cutting large I-beams or other structural shapes creating more even load per blade tooth, thus increasing cutting efficiency and blade life, meanwhile eliminating blade binding in the web.

Blade Drive & Lubrication System:

- 4 Speed transmission for blade speed. Belt pulley system.

- Equipped with a 3 HP Motor, heavy duty reducer, and variable step drive assembly

- Chip brush is available for effective blade cleaning prolonging blade life & blade guides.

- Complete flood coolant system with integral recovery system

Blade Guidance:

- Automatic hydraulic blade tension with pressure gauge ensures proper tension on blade

- Guide arm is synchronized with the vise and is controlled from the operator's console & permits more efficient cutting by being able to be moved close to material, regardless of size

- Carbide blade guides are relieved to provide unsurpassed lubricating and cooling of the blade

- Addional blade guides contacting the back of the blade provides extra support for added penetrating force for faster cuts

Controls & Automation:

- Control station is located ergonomically overhead and can swivel to ideal position

- "Last Cut" or "Keep On" selector enables you to choose either to turn the machine off or return the saw head to the pre-selected cut height ready for the next cut

Material Clamping & Feeding:

- A single heavy duty full stroke machine vise provides ample hydraulic pressure onto the material

-

All information and specifications were provided from manufacturer documentation and physical inspection. While though to be accurate, not guaranteed & buyer is encouraged to inspect and verify.

The listed specifications & information were taken from the manufacturer’s published information, internet research, or seller’s description.

The specifications & information are assumed to be correct; however, in no way, guaranteed. Bidders are encouraged to inspect the machine, call with questions, or contact the manufacturer for more information.

Please log in to view the bid history

LoginPick-ups are to be scheduled by appointment only. Please contact Sabrina Burns at 209-839-7707 or [email protected] to schedule an appointment. For freight quotes please contact Aaron at All-Ways Trucking at 541-608-6532. Buyer bears all costs to remove and load this lot. Buyer must remove entire lot purchased. Anyone removing non-hand carriable lots must provide MachineryMax, Inc. with a certificate of insurance (COI) before purchased items can be removed.

Local riggers

Haggard Hauling - Aaron 816-221-7840

Olinger Rigging & hauling - Jack 816-266-7981

All buyers agree to make full payment to MachineryMax, Inc. within 48 hours of the online closing date for the auction lots purchased. All invoices over $1,500.00 are to be made by bank wire transfer or cashier’s check payable to MachineryMax, Inc. Purchases under $1,500.00 may be made using Visa MasterCard, or American Express (2% credit card processing fee will be added to the invoice). All payments are to be made in USD currency only. Bidder represents and warrants to MachineryMax, Inc. that such bidder has immediately available funds to fully pay for its successful bids within 48 hours of the online closing date. All payment questions should be directed to Sabrina Burns at 209-839-7707 or [email protected] All buyers agree that there will be a 15% Buyers premium that will be added to the final invoice.