Brandt "KDF 440 AT" Edgebander with Air Tec  Ended

Ended

Moon Design Mfg. - Complete Plant Closure - Vista, CA

- Winning Bid : $63,150.00 USD Sold

- 128 Bid(s)

- High Bidder: S****S

Moon Design Mfg. - Complete Plant Closure - Vista, CA ( Closed #23835954 )

After 40 years, Moon Design Mfg. in Vista, CA has ceased operations. A nationally-recognized store fixture manufactuer who worked with retailers such as Macy's and received awards from NASFM and ARE. This complete shop auction features 2017 Homag Vantage 512 CNC with "c-axis"; 2015 Brandt KDF 440 AT edgebander with "Air Tec" ; Kaeser compressor and dryer; Altendorf sliding table saw; SCMI jointer, shaper and planer; power tools, hand tools, carts, supplies, office equipment and much more! Over 300 lots available!

-

Pick Up Location

971 Park Center Dr. Vista, CA 92081

-

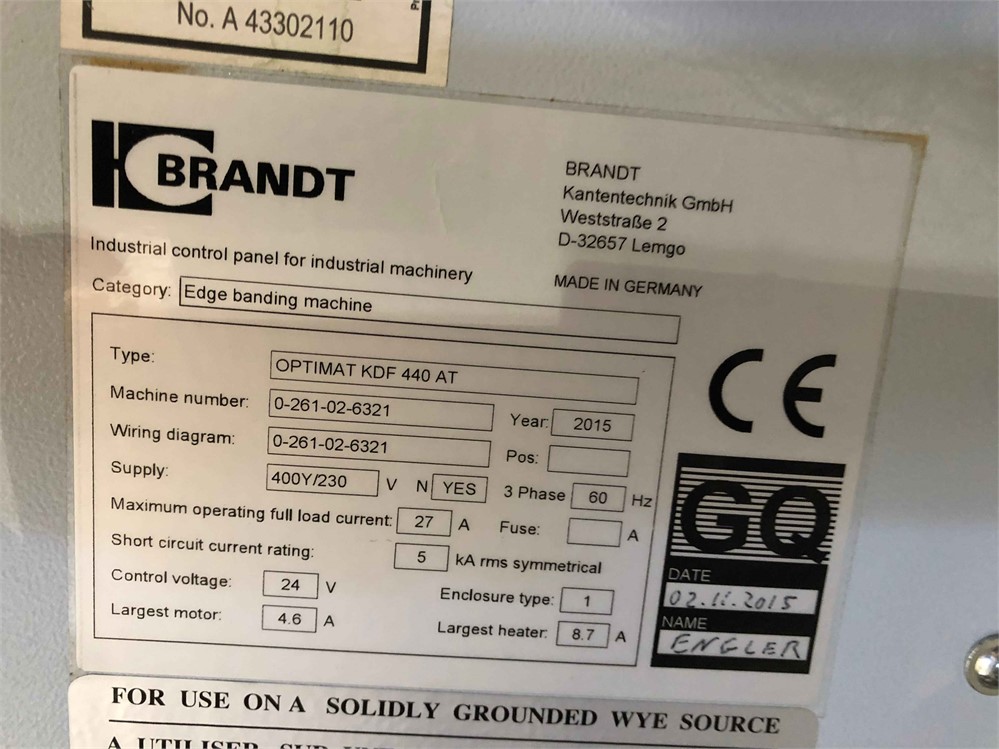

Make

Brandt

-

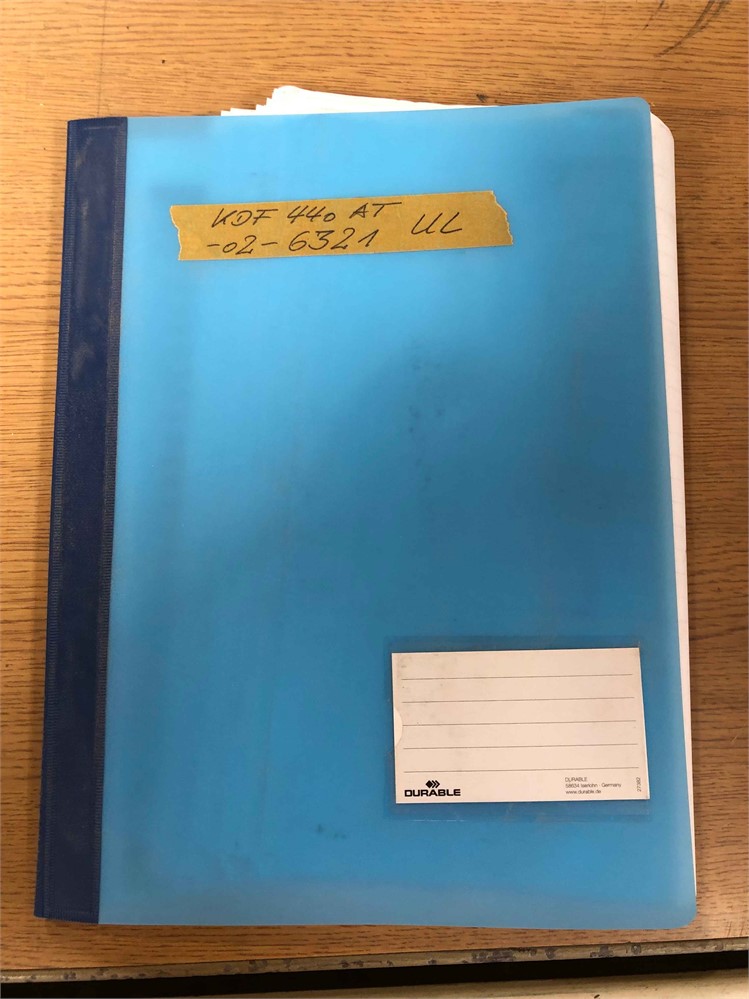

Model

KDF 440 AT

-

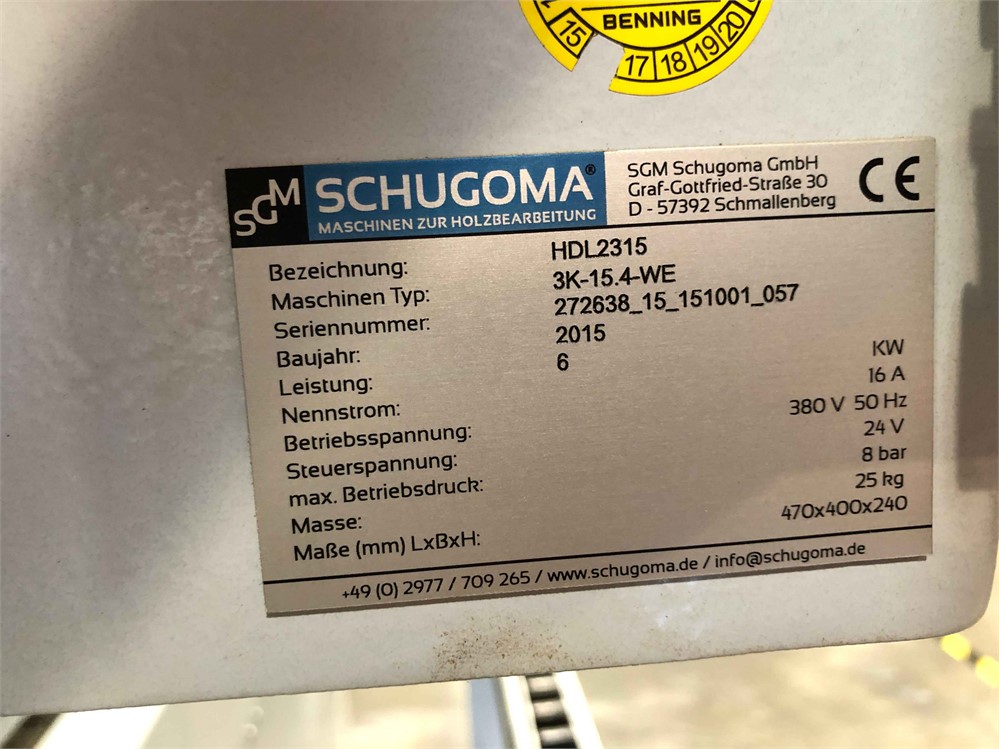

Serial Number

0-261-02-6321

-

Year

2015

-

Phase

3 PHASE

-

Voltage

400

-

Load Out Period

October 30, 2020

-

Estimated Dimensions

216" L x 60" W x 68" H (machine), 29" L x 21" W x 28" H (transformer)

-

Estimated Weight

4,500 Pounds

-

Seller Comment

Seller has forklift for loading, $250 loading fee, packaging, crating or other services at additional cost

-

Load Fee

250

-

page views

9260

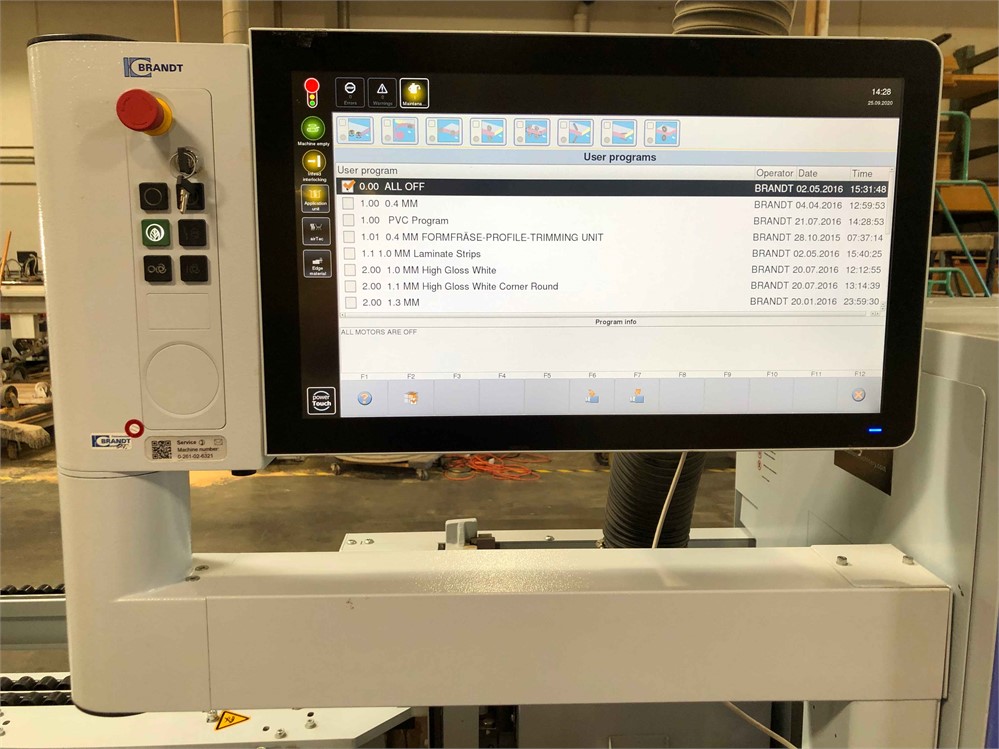

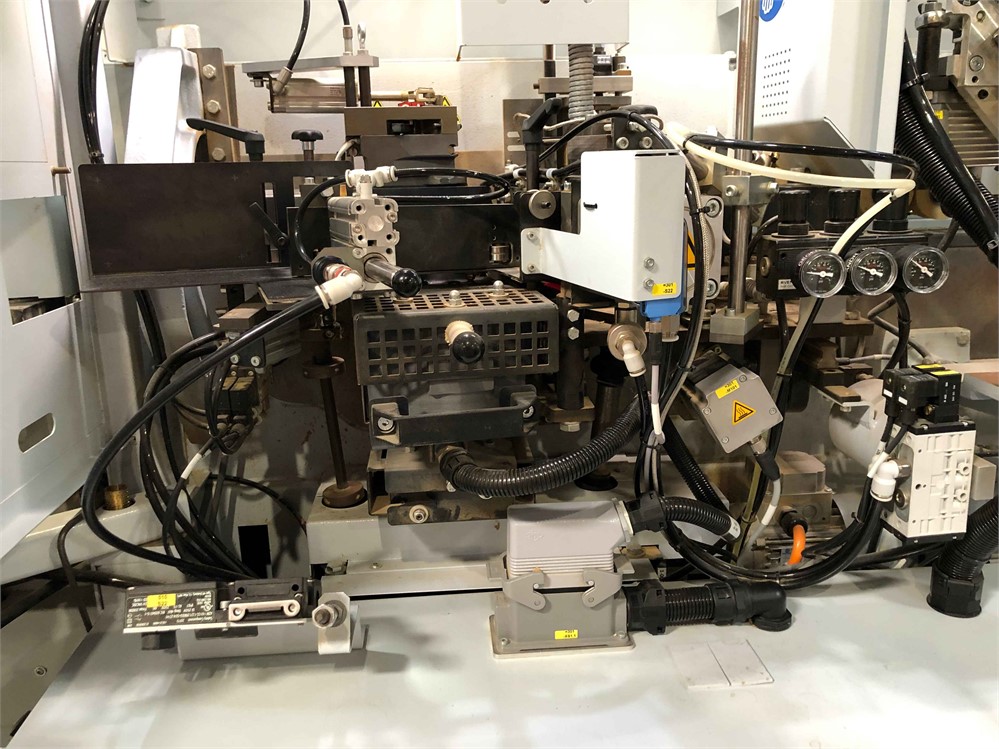

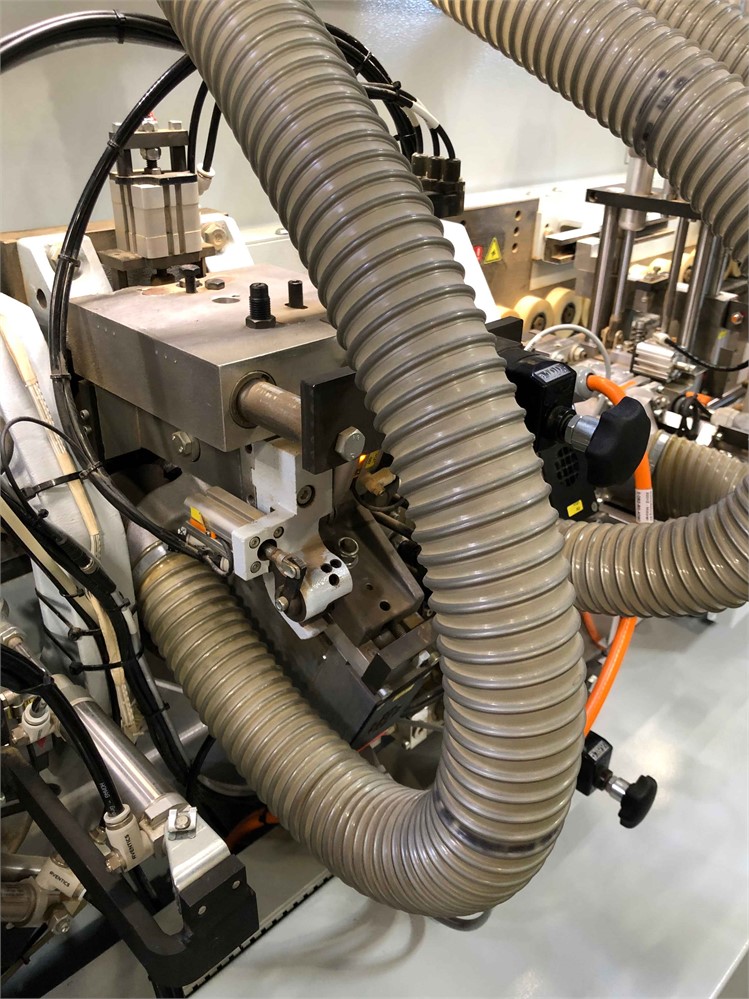

Brandt "KDF 440 AT" Edgebander with Air Tec

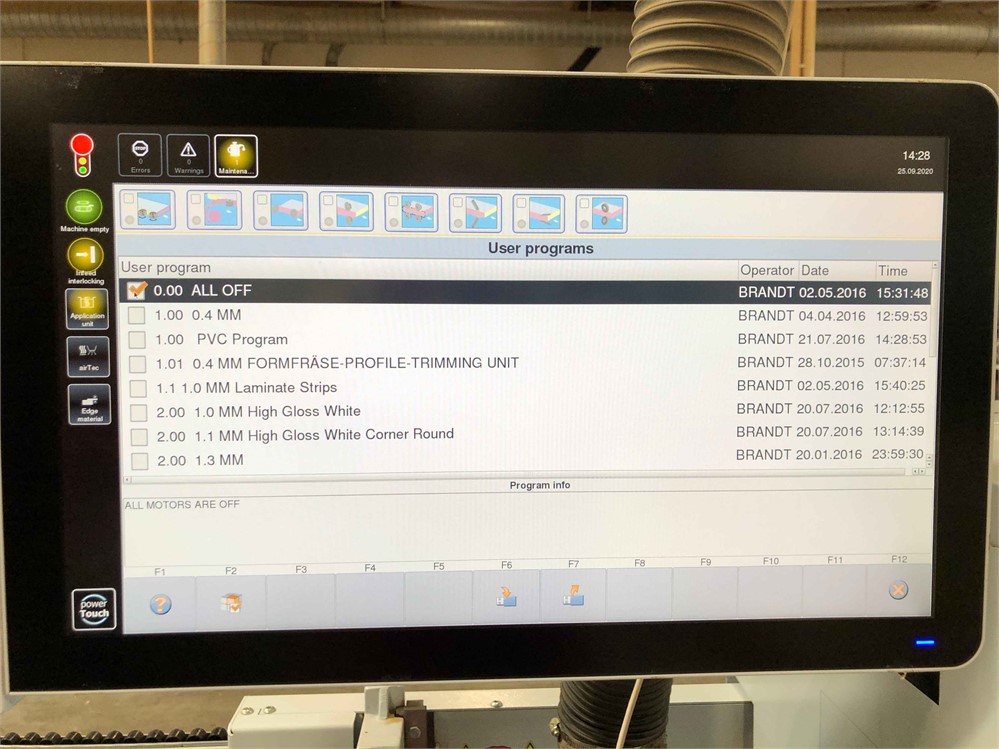

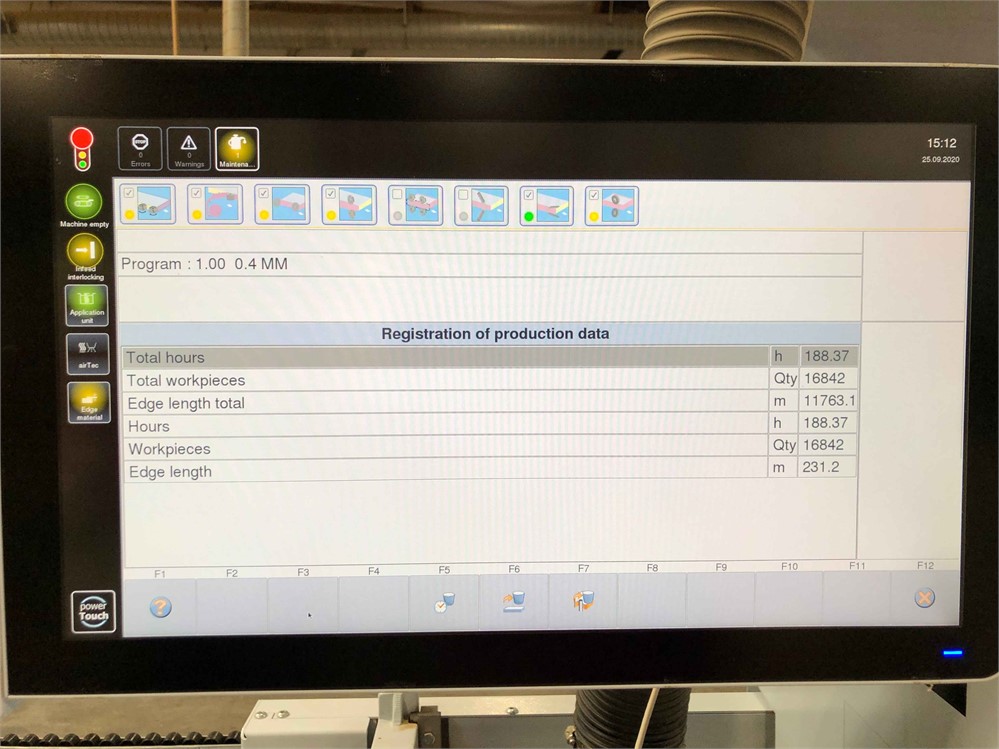

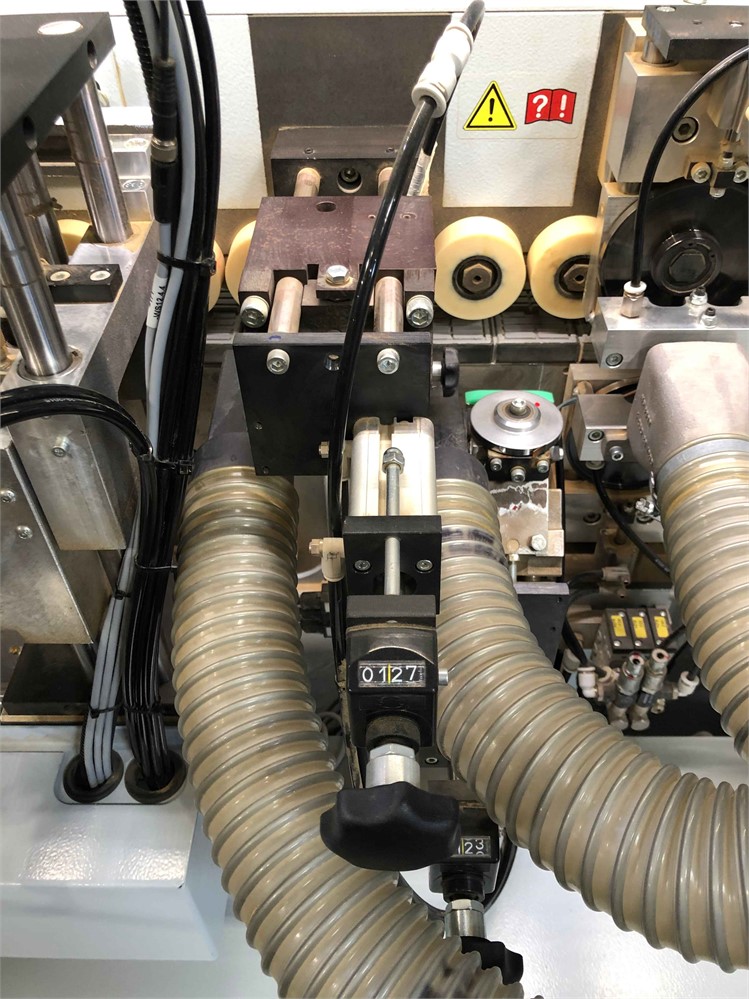

This 2015 machine has very low hours and is in showroom-condition! Seller never put the machine into full production due to changing work load. Only 188 run hours (see photo of machines monitor). Today this machine would sell new for $175,000 plus.

See video of machine in operation.

Minimum panel length, 160 mm/6.375"

Minimum panel width, 70 mm/2.75"

Panel thickness, 8 mm/0.3" - 60 mm/2.375"

Power Touch 2 program control

Full HD multi-touch 22" display in widescreen

Homag Group operating surface

Motorized top pressure beam for panel thickness adjustment

Variable track speed up to 46 FPM

3 HP feed motor

31" diameter coil table

Built in rollers to allow for 3 mm PVC rolls

Edge strip capacity, 0.4 - 8 mm

Coil capacity, 3 mm x 45 mm (H)

Panel pre-heating

Adjustable infeed fence with servo motor control

Pneumatically-controlled hard stop on infeed to prevent premature panel feeding

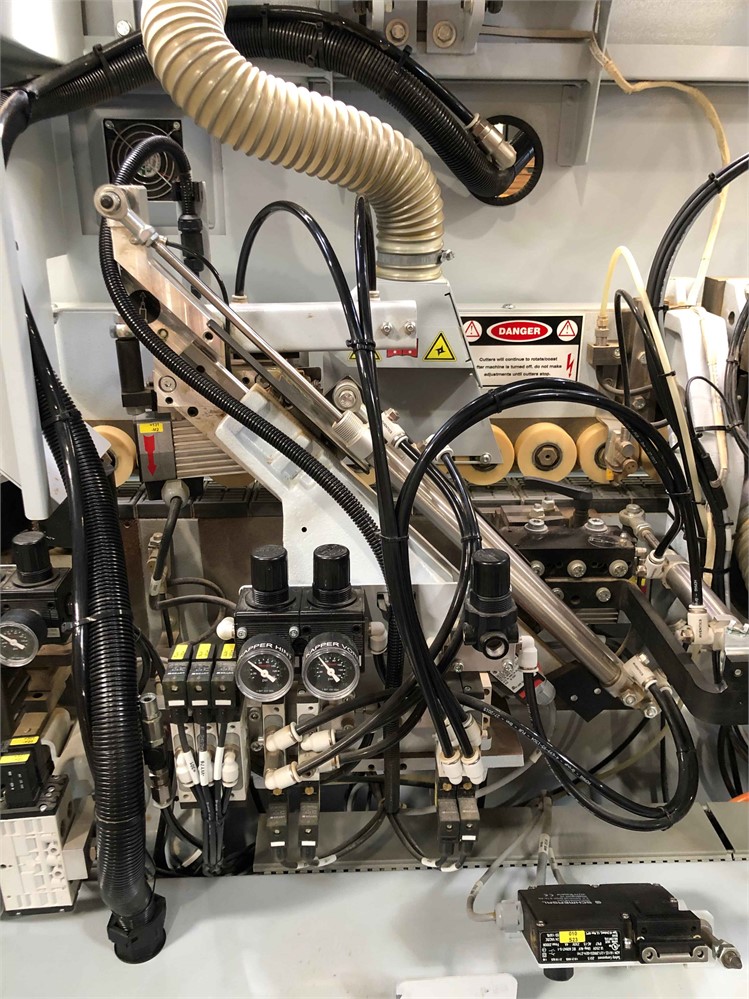

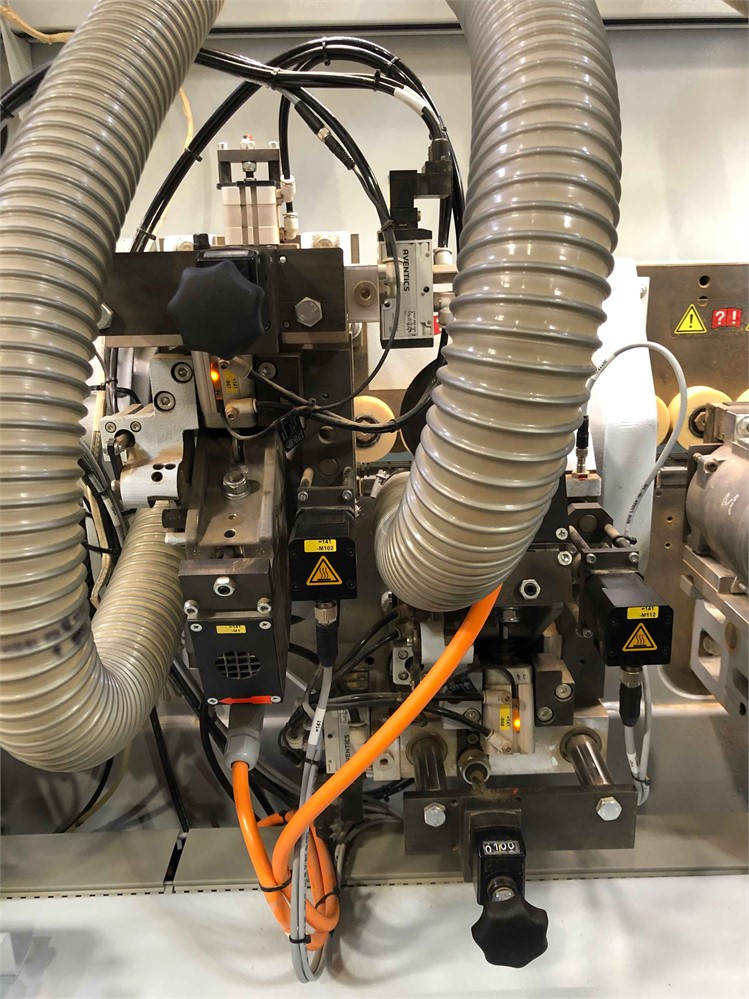

Two (2) motor premill unit

3 HP motors operating at 12,000 RPM (one CW and one CCW rotation)

Vertical spindle adjustment via digital settings

Horizontal positioning via electro-pneumatic control

Standard hot melt glue system

Quick-change tank

Reversible glue roller rotation

Glue temperature indication of glue roller via LED display

Infrared radiant glue heat zone control

Automatic temperature reduction if machine is idle for 15 minutes

Air Tec AT-15 reactivation unit for use with laser edgebanding to provide zero glueline results

Adjustable temperature and pressure via program control

40 mm maximum part thickness when using Air Tec

15 m/min. (49 FPM) maximum feed speed when using Air Tec

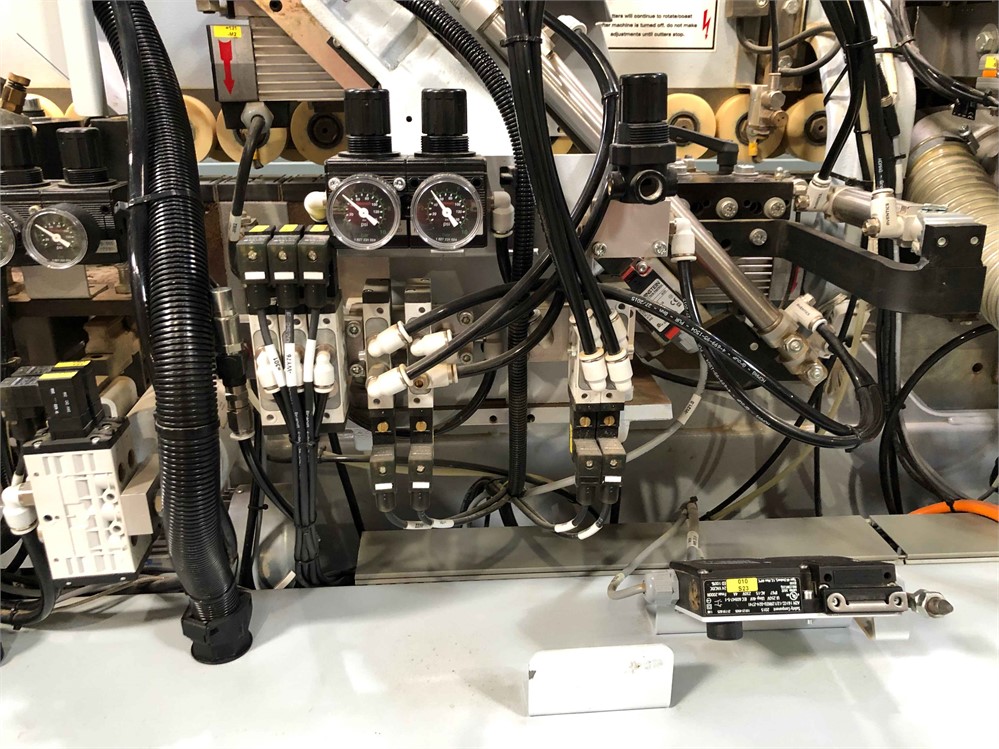

Spray mist lubrication system for delicate surfaces (such as high-gloss)

Anti-static spray mist unit

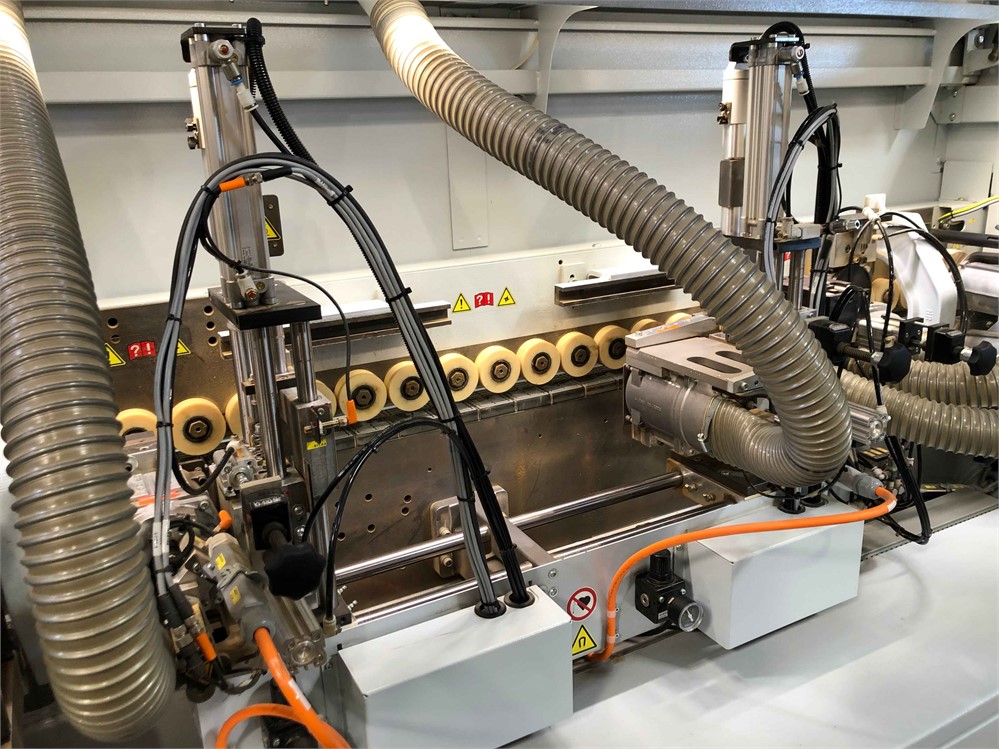

Pressure zone

Motorized positioning

One (1) driven roller

Two (2) idle rollers

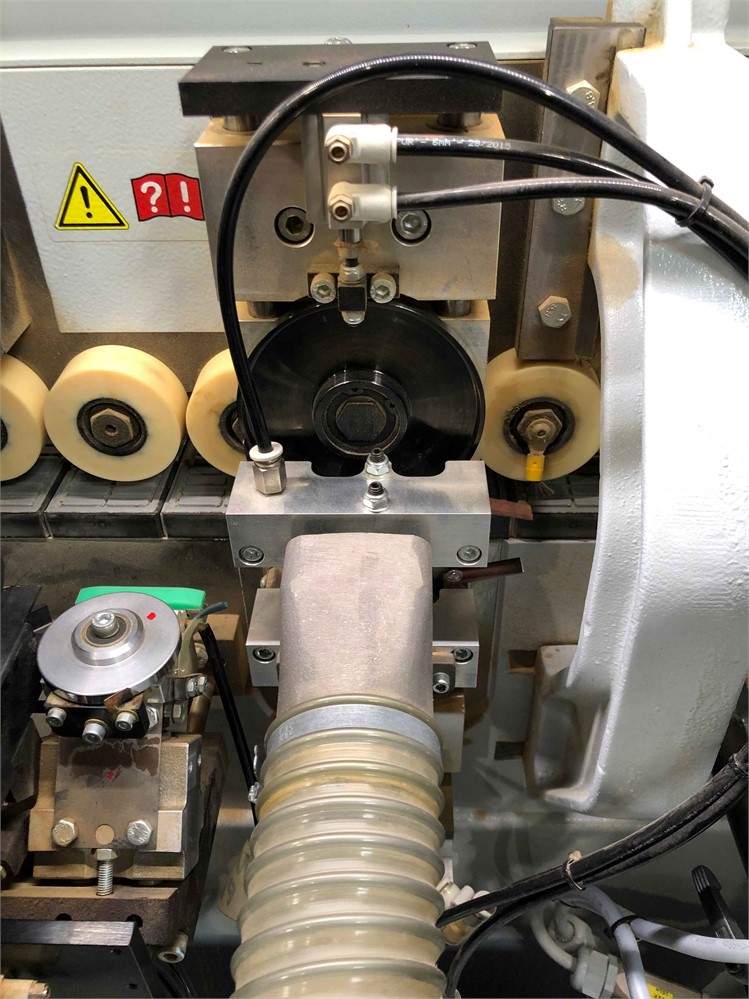

Two (2) motor end trimming unit

0.5 HP motors, 12000 RPM

Chamfer up to 15 degrees

Program controlled indexing from straight to bevel end trimming

Motor brake

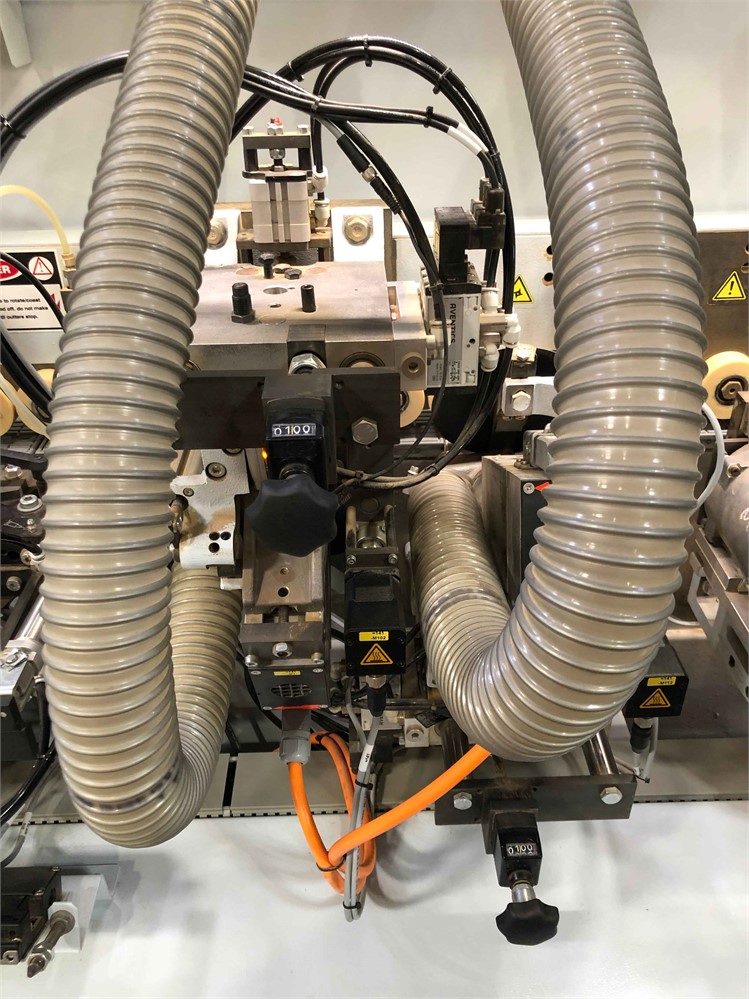

Multi-stage, top/bottom fine trimming unit

0.75 HP motors, 12000 RPM

Three (3) positions: profile 1, profile 2, flush

Auto-tilt and servo controlled horizontal tracing rollers

Servo motor controlled positioning to edge thickness

Motor brake

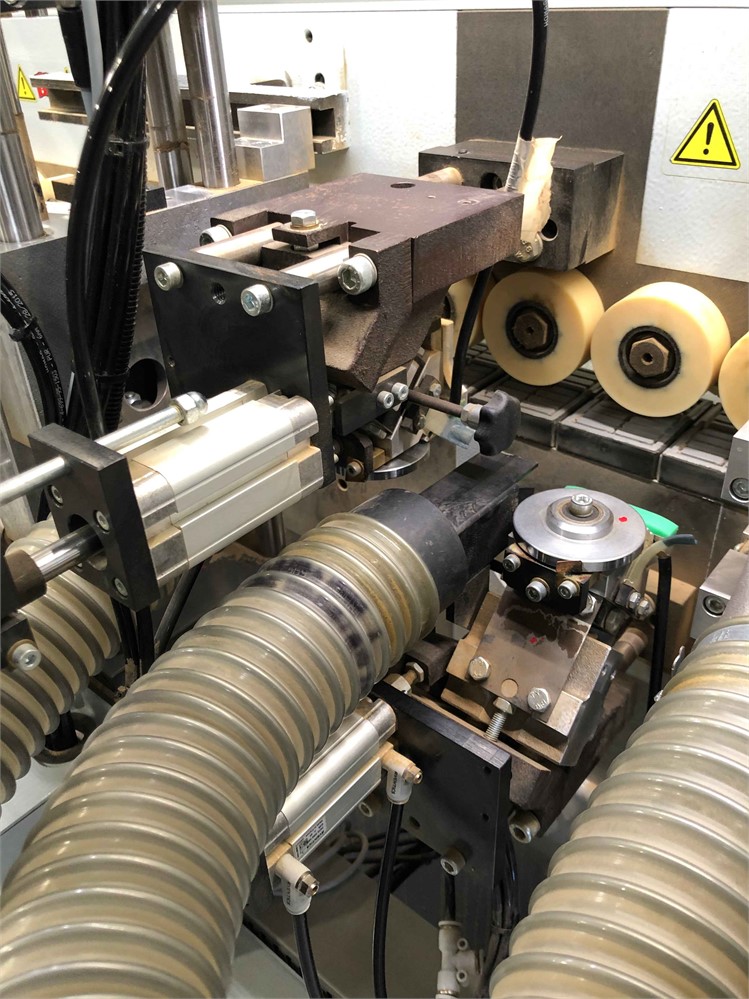

Two (2) motor multi function contour trimming unit

Corner rounding and/or continuous trimming of top/bottom edge

0.5 HP motors, 12000 RPM

Magnetic linear drive system with soft touch feature

Motor brake

12 - 60 mm panel thickness

3 mm maximum edge thickness

Quick-change scraping unit

Program-controlled pneumatic indexing

Vertical and horizontal tracing wheels

External collection box

Finish scraping unit

Top/bottom buffing unit

0.25 HP motors, 2800 RPM

20 mm x 150 mm cloth discs

Inclinable

Outboard roller support

Lighted sound enclosure

Two (2) doors

Safety interlock

Automatic feed track lubrication system

External electrical transformer

Extra scraping units

Manuals and tools

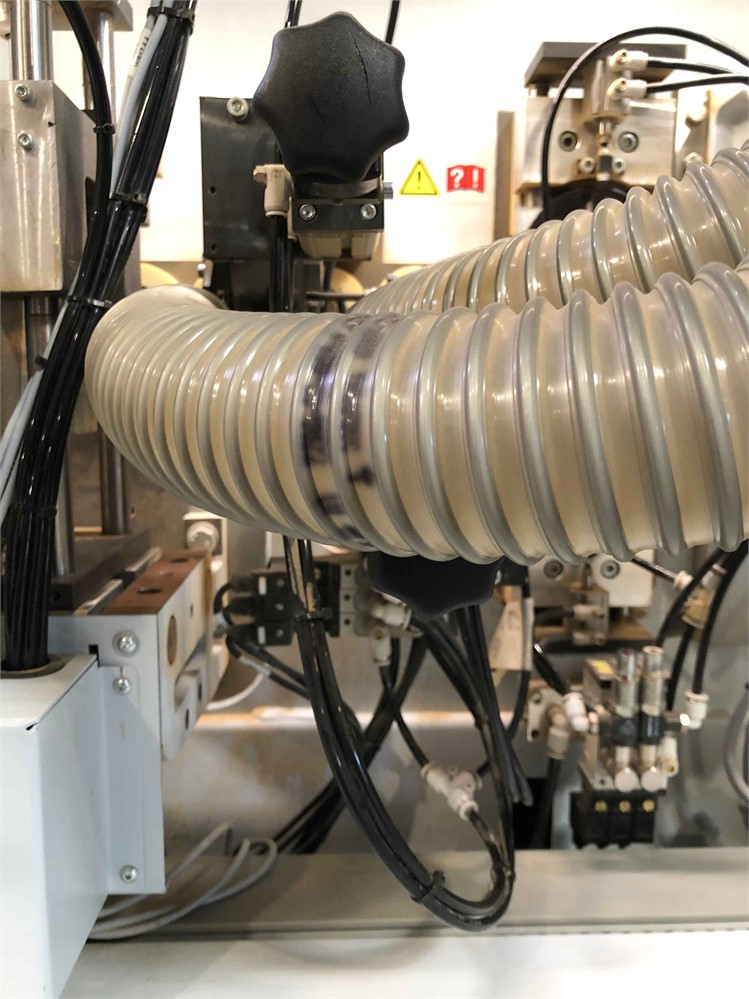

Dust pipe and flex hose NOT included, offered in lot 235

Edgebanding and supplies offered in lots 068 and 069

The listed specifications & information were taken from the manufacturer’s published information, internet research, or seller’s description.

The specifications & information are assumed to be correct; however, in no way, guaranteed. Bidders are encouraged to inspect the machine, call with questions, or contact the manufacturer for more information.

Please log in to view the bid history

LoginPick-ups are to be scheduled by appointment only. Please contact Sabrina Burns at 209-839-7707 or [email protected] to schedule an appointment. For freight quotes please contact Aaron at All-Ways Trucking at 541-608-6532. Buyer bears all costs to remove and load this lot. Buyer must remove entire lot purchased. Anyone removing non-hand carriable lots must provide MachineryMax, Inc. with a certificate of insurance (COI) before purchased items can be removed. For machinery moving/rigging please contact Carl Lewis at Carl's Machinery Moving, 8585-541-0729 or [email protected].

All buyers agree to make full payment to MachineryMax, Inc. within 48 hours of the online closing date for the auction lots purchased. All invoices over $1,500.00 are to be made by bank wire transfer or cashier’s check payable to MachineryMax, Inc. Purchases under $1,500.00 may be made using Visa, MasterCard, or American Express (2% credit card processing fee will be added to the invoice). All payments are to be made in USD currency only. Bidder represents and warrants to MachineryMax, Inc. that such bidder has immediately available funds to fully pay for its successful bids within 48 hours of the online closing date. All payment questions should be directed to Sabrina Burns at 209-839-7707 or [email protected] All buyers agree that there will be a 15% Buyers premium that will be added to the final invoice.