Cantek "MX-340-M" Edgebander  Ended

Ended

Cantek "MX-340-M" Edgebander - Lacey, WA

- Starting Bid : $500.00 USD

- 0 Bid(s)

Cantek "MX-340-M" Edgebander - Lacey, WA ( Closed #23763961 )

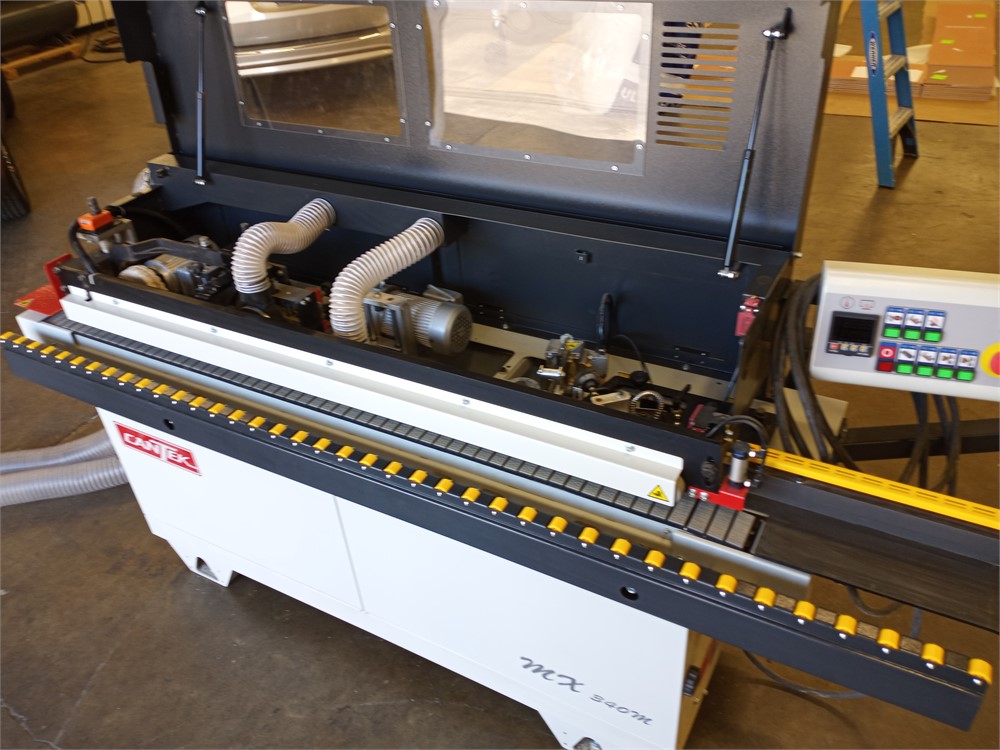

Commercial cabinet shop in Olympia, WA area is selling its edgebander. Cantek "MX-340-M" edgebander with low hours. 3 mm capable with end trim, top/bottom trim, scrape and buff. Asset no longer required for continuing operations.

-

Pick Up Location

1225 Ruddell Rd. SE, Suite E Lacey, WA 98503

-

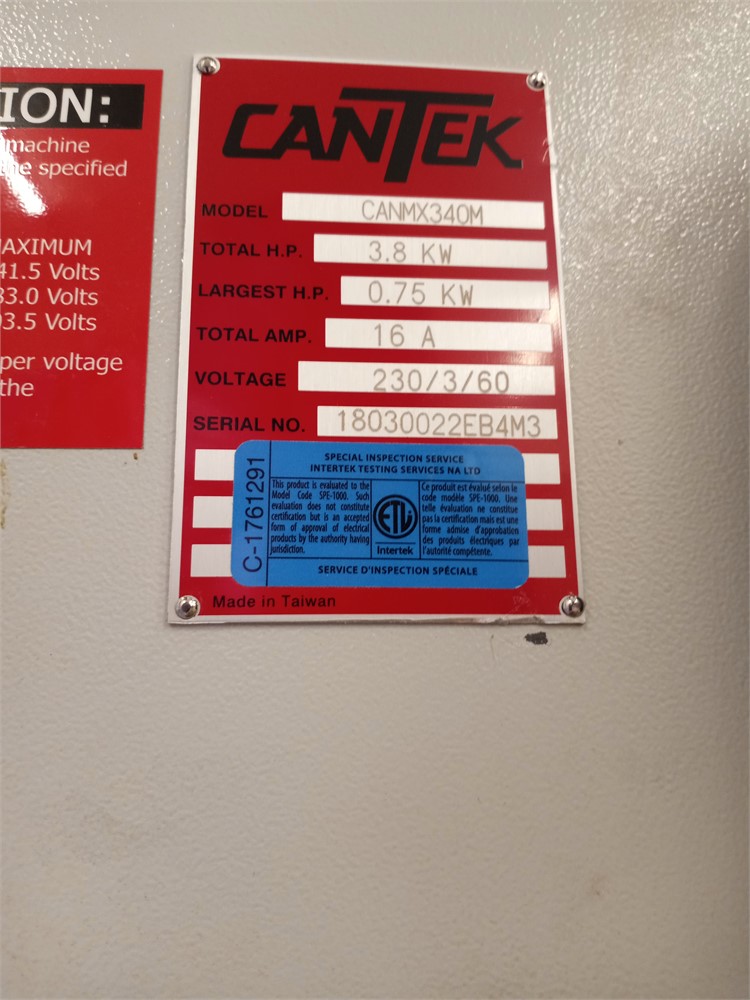

Make

Cantek

-

Model

MX-340-M

-

Serial Number

18030022EB4M3

-

Year

-

Phase

3 PHASE

-

Voltage

230 VOLT

-

Load Out Period

TBD

-

Estimated Dimensions

89” L x 29" W x 66" H

-

Estimated Weight

1,228 Pounds

-

Seller Comment

Seller has forklift for loading, $100 loading fee, packaging, crating or other services at additional cost

-

Load Fee

100

-

page views

5048

Cantek "MX-340-M" Edgebander

The MX340 from Cantek is designed to be a compact, and durable edgebander offered at an affordable price. This machine is equipped with end trimming, flush trimming, PVC scraping, and buffing. User friendly controls and adjustments allow for efficient changeovers of edge tape thicknesses between 0.4 mm and 3 mm.

Features

• PLC control system with LED display and keypad • Work-piece is fed by chain • Edge coil support plate: Ø 800 mm/31", for PVC/ABS • Edge feeding is automatic edge feeding with a thickness capacity of 0.4 – 3 mm; strip material can be handfed • Coiled edge bands up to 3 mm in thickness in hard-PVC/ABS are cut with guillotine shears. • Teflon-coated hot-melt glue pot • Spring loaded pressure unit with two (2) pressure rollers • High frequency 12,000 RPM end trimming unit, with Ø100 mm/4" TC-saw blades • High frequency 12,000 RPM top and bottom trimmers with insert knife cutters for radius trimming & bevel trimming • Radius scraper with 2mm radius • 3,000 RPM top and bottom buffing units • Heavy duty pressure beam with extendable work-piece support • Heated infeed fence for pre-heating the panel for optimum glue penetration

SPECIFICATIONS

Feeding speed 29.5 FPM 9 m/min. Panel thickness 0.315~1.77” 8~45 mm. Edge thickness 0.0158”~0.118” 0.4 ~ 3 mm. Min. panel width 4”/100 mm. Min. panel length 6.69”/170 mm. Working table height 33.5”/850 mm. Dust collection outlet dia. 5”/127 mm. Total connected power 7.4 HP/ 5.5 KW. Machine dimensions (LxWXH) 116” x 44” x 55” 2950 x 1120 x 1390mm. Machine weight 1144 lbs/520 KG. Shipping dimensions (LxWxH) 89” x 28 ½” x 65 ¾” 2260 x 720 x 1670mm. Shipping weight 1228 lbs./ 558 KG. Voltage 230/3/60 230/3/60. Electrical requirement 30 amps (Voltage must be +/- 5%)

MOTOR SPECIFICATIONS

Feeding motor 1 HP/0.75 kW. Glue spindle motor ¼ HP/0.18 kW. Front/rear trimming motor 0.3 HP/ 0.22 kW. Upper trimming motor ½ HP/ 0.37 kW. Lower trimming motor ½ HP/ 0.37 kW. Upper buffing motor 0.16 HP/0.12 kW. Lower buffing motor 0.16 HP/ 0.12 kW. Pre-heating ½ HP/ 0.4 kW. Glue pot 1 ¾ HP/1.315 kW.

Operating panel with LED keypad • Glue temperature settings • Units can be selected and disengaged individually • Heated fence

Edge feeding for coiled materials • Edge feeding is automatic for roller materials with a thickness of 0.4–3 mm

Heavy-duty chain feeder • The steady work-piece feeding mechanism is comprised of a chain and set of drive rollers, which will not scratch the work-piece surface.

Glue Pot • The 2.6 pound/1.2 KG Teflon-coated glue pot is designed for EVA hot-melt glue. The glue is applied by a roller and the glue amount is adjustable

Pressure Roller • The pressure roller unit consists of one large roller, followed by a smaller one. The purpose of the unit is to improve the glue bond between the edge and the material. The unit is mechanically spring-loaded and due to the “Quick” setup system, can be adjusted exactly to the required edge thickness. The adjustable spring system allows for a perfect bond between the panel and edge every time.

Guillotine Shears • Coiled material up to 3 mm in thickness can be trimmed by the guillotine shears.

End Trimming Unit • Mounted on high-precision linear bearings, which ensure perfect cutting results for years to come. The high frequency 12,000 RPM motor meets any challenge, regardless of edge type and thickness.

Flush and Radius Trimming Unit • The biggest advantage of the new multi-functional combination unit is the amount of space it saves in the machine. The adjustment of the settings from flush to beveled finish for thin edges, as well as radius trimming for thicker edges, is quick and easy. TC 2 mm radius tooling.

Scraping Unit – Radius Scraping Unit • The scraping unit fine-tunes the edge radius while removing knife marks left on during the milling process on 2mm & 3mm edging.

Buffing Unit • The buffing unit leaves a super finish on ABS and PVC edging, and removes any discoloration on the edges, which is especially noticeable when working with dark edge material.

Panel Thickness Setting • Panel thickness adjustment is quick and accurate & is achieved by a handwheel with digital readout.

Feeding Motor • The feeding motor is located on the outside of the machine, which allows it to stay cool. It is equipped with an oversized, heavy-duty gearbox, which will guarantee years of flawless operation.

Dust Port • 5” dust port

The listed specifications & information were taken from the manufacturer’s published information, internet research, or seller’s description.

The specifications & information are assumed to be correct; however, in no way, guaranteed. Bidders are encouraged to inspect the machine, call with questions, or contact the manufacturer for more information.

Please log in to view the bid history

LoginPick-ups are to be scheduled by appointment only. Please contact Sabrina Burns at 209-839-7707 or [email protected] to schedule an appointment. For freight quotes please contact Aaron at All-Ways Trucking at 541-608-6532. Buyer bears all costs to remove and load this lot. Buyer must remove entire lot purchased. Anyone removing non-hand carriable lots must provide MachineryMax, Inc. with a certificate of insurance (COI) before purchased items can be removed.

All buyers agree to make full payment to MachineryMax, Inc. within 48 hours of the online closing date for the auction lots purchased. All invoices over $1,500.00 are to be made by bank wire transfer or cashier’s check payable to MachineryMax, Inc. Purchases under $1,500.00 may be made using Visa, MasterCard, or American Express (2% credit card processing fee will be added to the invoice). All payments are to be made in USD currency only. Bidder represents and warrants to MachineryMax, Inc. that such bidder has immediately available funds to fully pay for its successful bids within 48 hours of the online closing date. All payment questions should be directed to Sabrina Burns at 209-839-7707 or [email protected] All buyers agree that there will be a 15% Buyers premium that will be added to the final invoice.