2015 Weeke Optimat "BHP008/Vantech480" CNC Machine  Ended

Ended

Homag Canada - Assets No Longer Required - Vancouver British Columbia- Canada

- Winning Bid : $45,000.00 USD Sold

- 54 Bid(s)

- High Bidder: m****y

Homag Canada Showroom Auction - Vancouver, BC Canada ( Closed #23036708 )

Featuring 2015 Weeke Vantech 480 CNC, 2013 Weeke ABD 050 CNC Drill and Dowel inserter

-

Pick Up Location

2900-2424 Main Mall Vancouver, BC Canada V6T1Z4

-

Make

Weeke

-

Model

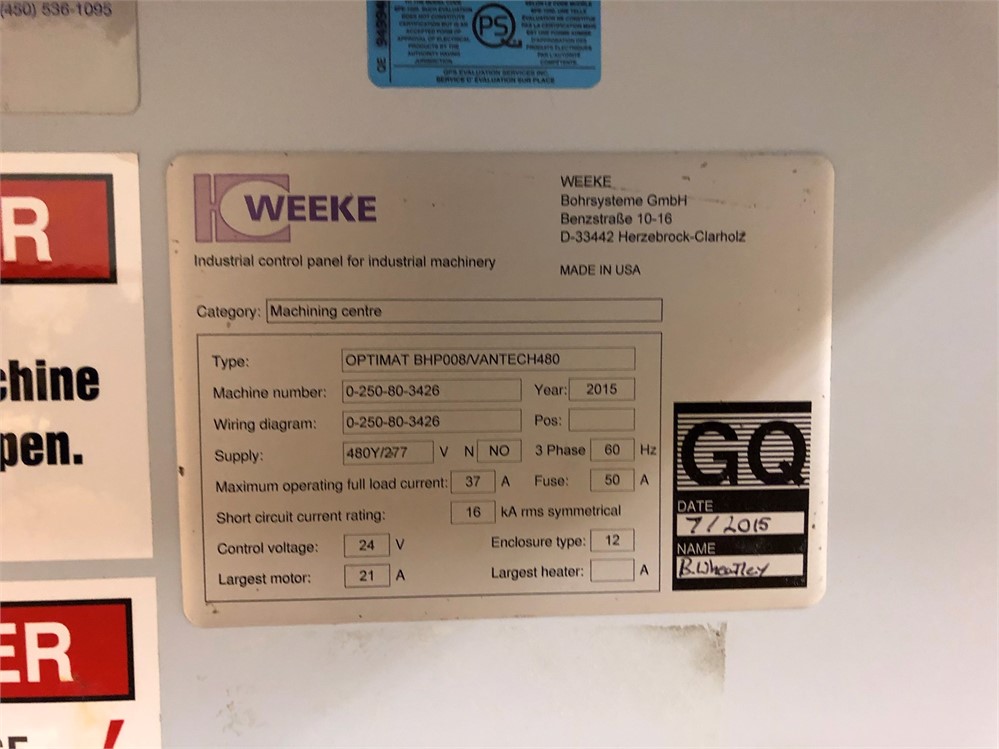

Optimat BHP008/Vantech480

-

Serial Number

0-250-80-3426

-

Year

2015

-

Phase

3 PHASE

-

Voltage

480 VOLT

-

Load Out Period

-

Estimated Dimensions

-

Estimated Weight

-

Seller Comment

Buyer Responsible for Hiring a Rigger For Removal

-

Load Fee

-

page views

5444

currently in the “HOMAG Room” at UBC (University of British Columbia). The HOMAG room is a small showroom which we have at UBC segregated from the rest of the woodworking program.

OPTIMAT BHP008/VANTECH480 CNC-controlled processing centre in

traversing gantry construction centre

1. BASIC MACHINE

-

- Solid machine frame in rigid trasversing

gantry execution -

- Gantry movable in X-direction

-

- Cross support movable in Y- and Z-direction

-

- Paint Grey RDS 240 80 05

-

- Direct extraction at the processing unit and

separate connection for the extraction device (on site)2. GUIDING SYSTEM AND DRIVE TECHNIQUE

-

- High quality linear guiding system

-

- Toothed rack drive (synchronous drive) in

X-direction and ball bearing spindle in

Y- and Z-direction Travel range of the axes:

X = 3710 mm (146,1 Inch)

Y = 1652 mm ( 65,0 Inch) Z = 245 mm ( 9,6 Inch)

Digital drive technique in X-, Z-direction

Axis speeds:

Y- and

Vector speed:

X/Y = 96 m/min

Z = 25 m/min

Consisting of:

- maintenance free motors with

high

resolution optical encoders guarantee

high accuracy

- digital drive control units guarantee high

reliability

3. MATRIX TABLE 8'/4', 2500 X 1250 MM System MATRIX with grid grooves for clamping of templates or workpieces. Grid grooves for inlaying of a rubber sealing. Various vacuum cup types are optionally available.

Consisting of:

-

- Vacuum system for clamping of the

on the complete workpiece table

-

- The working table is divided into areas (please refer to the layout

workpieces

3 vacuum

drawing). 3 vacuum generators with a total vacuum capacity of 270/324 m3/h, 50/60 Hz (3 x

90/108 m3/h, 50/60 Hz) are directly connected with the vaccum areas via a distribution device.

One of the three vacuum generators serves as master.

To save energy the further two vaccum pumps can be switched on if required via softkeys in the operating panel.

-

- 3 pneumatically lowerable AL-workpiece stops incl. electr. surveillance of lower cylinder position

Arrangement: as per enclosed layout -

- 15 meter rubber sealing

Working table length: Working table width: Workpiece thickness:

2500 mm (8', 98,4 Inch) 1250 mm (4', 49,2 Inch) max. 100 mm (3,94 Inch)

4. CONFIGURATION BASIC MACHINE

R1-HSK63-9 KW, TC7, TOOL LENGTH CONTROL

R1-HSK63-9 KW

Automatic tool change spindle in combination with a tool change magazine.

Working

capacity: refer to separate layout Tool holder: HSK63

Tool changing: automatic

Direction

of rotation:

Speed:

right hand / left hand

1,250 - 24,000 1/min stepless programmable frequency controlled AC-motor

up to 7.5/9 kW (10/12 HP) in continuous and intermittent operation (S1/S6 - 50%)

permanent grease lubrication hybrid beariing (ceramic), little friction, higher stiffness and max. operating life

Cooling: Dust extraction:central

AIR JET

An air jet is integrated in the extraction hood. Activation via softkey in ther operating panel.

TC7

Automatic tool change magazine for 7 places.

Drive:

Max. capacity at the tool:

Spindle lubrication: Bearing:

TOOL LENGTH CONTROL

Suitable for length measuring of shaft tools. After tool change via the pick-up place a control of the length is carried out and checked with the tool data file.

5. powerControl

Modern control system which bases on Windows PC

Hardware:

-

- PLC control according to international

standard IEC 61131

-

- Operating system Windows XP (US) embedded

-

- 17 Inches TFT-flat screen

-

- USB connection at the operating panel

-

- EtherNet connection 10/100 MBIT RJ45 (without

switch)

Software:

-

- powerControl CNC-core with:

-

- path control in all axis and parallel sequences by multi-channel technology

-

- look-ahead-function for optimal speed at the transitions

-

- dynamic pre-control for top precise accuracy of the contour

-

-

- powerControl software package with graphical operating programs:

- woodWOP:for graphical, dialogue-oriented generation

of CNC-programs

-

- TOOL DATA BASE:

with graphical operator guide to manage

tool data

-

- PRODUCTION LIST SOFTWARE:

for management and creation of product lists for individual manufacturing. Hereby production sequences, target amounts and processing information can be stored

-

- MACHINE DATA RECORDING SCHULER MDE Basic: for recording of produced workpiece quantities

-

- SOFTWARE FUNCTION MOVING

Function to manufacture a right program at the left hand workpiece stop and a left program at the right hand workpiece stop -

- 3D NC-SIMULATION AND TIME CALCULATION Software for graphical simulation of a CNC- program in 3D including time calculation with a precision of +/- 10%. Optical error display and vacuum positioning control. Note: Not suited for motorically movable

consoles (AP-table)

-

- SOFTWARE FUNCTION OPTIMIZATION OF SPACE

OCCUPATION:

Extension of the location for machines with MCC by the possibility to connect work- pieces over the whole table or for the respective working field. This includes an additional optimization of the processings in order to save tool changes (in case the processing sequence of the individual programs allow it)Software package for external PC:

-

- woodWOP:

for graphical, dialogue-oriented generation

of CNC-programs

-

- woodWOP DXF Basic:

exchange from 2D-CAD-programs to woodWOP - import of 2D-DXF-files

- conversion is effected acc. to fixedprofiles (rules)

-

- display of geometry, layer and drawing elements

-

- generation of the woodWOP-program

-

- woodAssembler:

to visualize woodWOP-programs (MPR) in 3D. This software enables the construction of individual workpieces to finished objects.

-

- woodNest Basic

Software for the Nesting of woodWOP-program-

- manual positioning and turning of work-

pieces by drag and drop -

- visualization of spacing between

workpieces

-

-

- woodWOP MOSAIC

Software for woodWOP-data administration with graphical preview 'thumbnails'

-

- with this software woodWOP-data files

and complete directories can be managedfrom the graphical point of view -

- Programs can be administered by drag

and drop

-

-

- woodType

Software to generate routing contours for caracters and texts in all available Windows-True-Type-fonts

Can only be operated with Windows NT4, W2K resp. XP or VistaCopy protection of all software licences via the HOMAG Group licence server. The product must be activated following the installation. Activation via www.eparts.de

6. SECURTIY AND SAFETY UNITS See technical data sheet

7. DOCUMENTATION AND TECHNICAL DATA Technical connection values for pneumatics, dust extraction and electrics as per enclosed technical data sheet. Documentation on CD including spare parts catalogue and wiring diagram.

8. ELETRICAL CONNECTION

Voltage: 480V, 50/60 Hz, 3 phases

DRILLING AGGREGAT V7

Vertical drilling block with 7 spindles. Special feature: Spindle clamping to achieve

Page : 7

G.0004

Number : 0242 1 off

EXTENSION OF THE STOP SYSTEM, FRONT RIGHT HAND SIDE

- 4 pneumatically lowerable AL-workpiece stops fix mounted at the working table (front right hand side) incl. electr. surveillance of lower cylinder position

Note: Not in combination with pneumatically lowerable stop fence.

Working: capacity: Stroke Z-direction: Drillin depth: Direction of rotation: Drehzahl: Drive:

the drilling depth safely. refer to separate layout

60 mm

max. 38 mm

right hand/left hand 2800/3450 1/min (50/60 Hz) 1.5 kW

d = 10 mm

Shaft diameter: Total length of drill: Drilling diameter: Distance between spindles: 32 mm Type of spindle:individually selectable Arrangement: as per enclosed layout

The listed specifications & information were taken from the manufacturer’s published information, internet research, or seller’s description.

The specifications & information are assumed to be correct; however, in no way, guaranteed. Bidders are encouraged to inspect the machine, call with questions, or contact the manufacturer for more information.

Please log in to view the bid history

LoginPick-ups are to be scheduled by appointment only. Please contact Sabrina Burns at 209-839-7707 or [email protected] to schedule an appointment. For freight quotes please contact Aaron at All-Ways Trucking at 541-608-6532. Buyer bears all costs to remove and load this lot. Buyer must remove entire lot purchased. Anyone removing non-hand carriable lots must provide MachineryMax, Inc. with a certificate of insurance (COI) before purchased items can be removed.

All buyers agree to make full payment to MachineryMax, Inc. within 48 hours of the online closing date for the auction lots purchased. All invoices over $1,500.00 are to be made by bank wire transfer or cashier’s check payable to MachineryMax, Inc. Purchases under $1,500.00 may be made using Visa, MasterCard, or American Express (2% credit card processing fee will be added to the invoice). All payments are to be made in USD currency only. Bidder represents and warrants to MachineryMax, Inc. that such bidder has immediately available funds to fully pay for its successful bids within 48 hours of the online closing date. All payment questions should be directed to Sabrina Burns at 209-839-7707 or [email protected] All buyers agree that there will be a 15% Buyers premium that will be added to the final invoice.