Felder "F700Z" Tilting Spindle Moulder  Ended

Ended

Located in Golden, Co

- Winning Bid : $6,675.00 USD Sold

- 45 Bid(s)

- High Bidder: A****r

2017 Felder "F700Z" Tilting Spindle Shaper/ Moulder - Golden, Colorado ( Closed #22691542 )

Asset no longer required

-

Pick Up Location

5770 Mcintyre St Golden, Co 80403

-

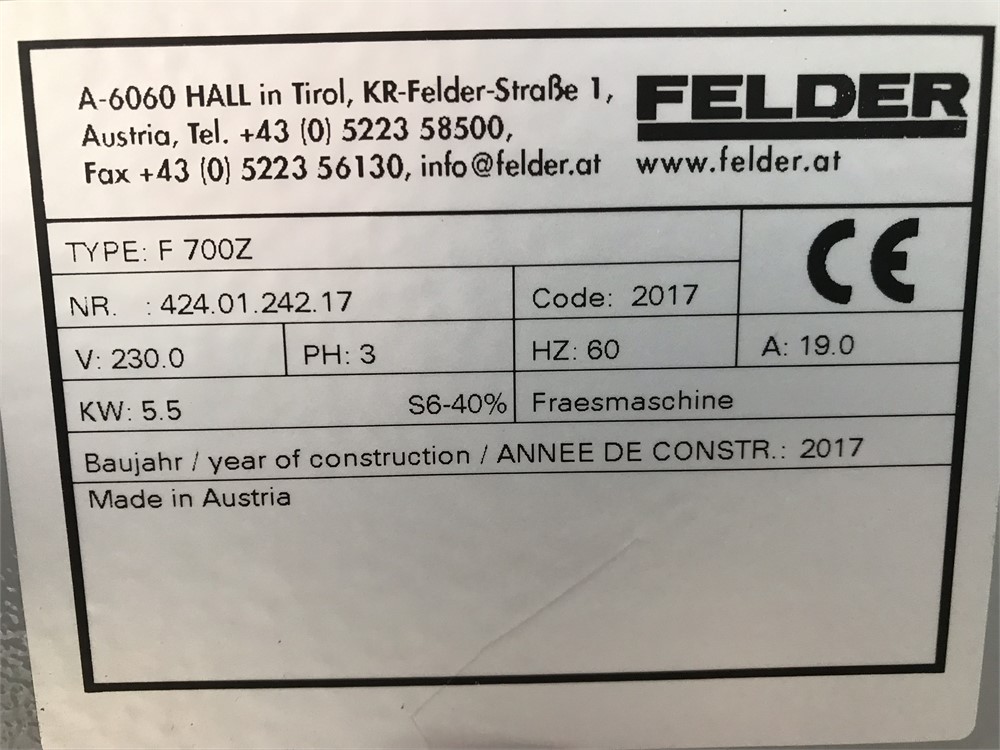

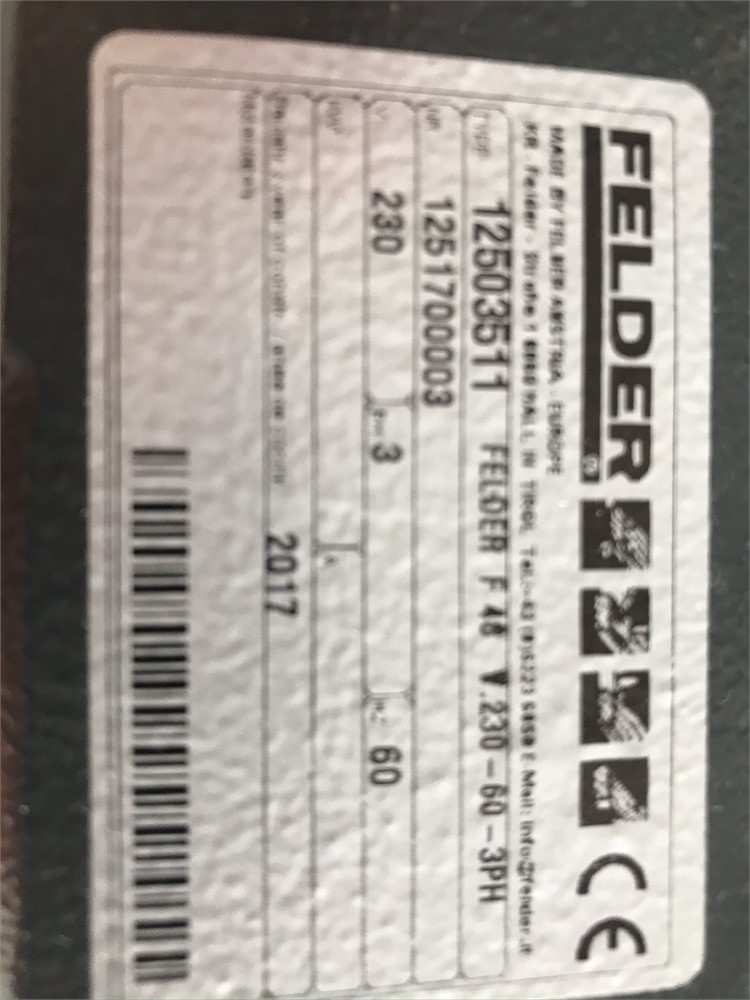

Make

Felder

-

Model

F700Z

-

Serial Number

424.01.242.17

-

Year

2017

-

Phase

3 PHASE

-

Voltage

230 VOLT

-

Load Out Period

-

Estimated Dimensions

-

Estimated Weight

-

Seller Comment

Please Contact Joe at 303-349-7923

-

Load Fee

-

page views

8191

The tilting spindle moulder from the Tyrolean machine manufacturer Felder has been a guarantee of top performance in business and industry for years. With the new models from the 700 series, Felder are not only offering a price conscious solution for all woodworking companies, but also the perfect addition to CNC supported production processes. With a solid cast iron moulding table for vibration-free stability or with the reliable 'X-Roll' sliding table for excellent slot and tenoning work – with spindle moulders from Felder you are prepared for every challenge a modern woodworker could face.

Highlights:

- Smooth and comfortable operation when slot and tenoning:

- “X-Roll” sliding table

- Maximum ease of operation with “Power-Drive”: electrical height and angle adjustment

- Felder spindle quick change system: quick changeover ensuring maximum productivity

- Maximum operating safety: Spindle tilts rearwards from 90°-45°

- Maintenance free tilting segment guide “Easy-Glide” with 6 year guarantee

- 230 mm table opening – a particular advantage when panel raising

- Reliable repeatability and precise quick settings: The Felder MULTI-adjustment system

- Dual extraction through both the spindle fence and from under the table – a clean solution

- FELDER table extensions and numerous optional configurations – individual tailor made solutions for every requirement

Easy Glide

- High precision double-sided trunnion support system

- High load-bearing capacity and operating life

- Play-free tilt

- Unaffected by dust

- Completely maintenance free

- No lubrication required

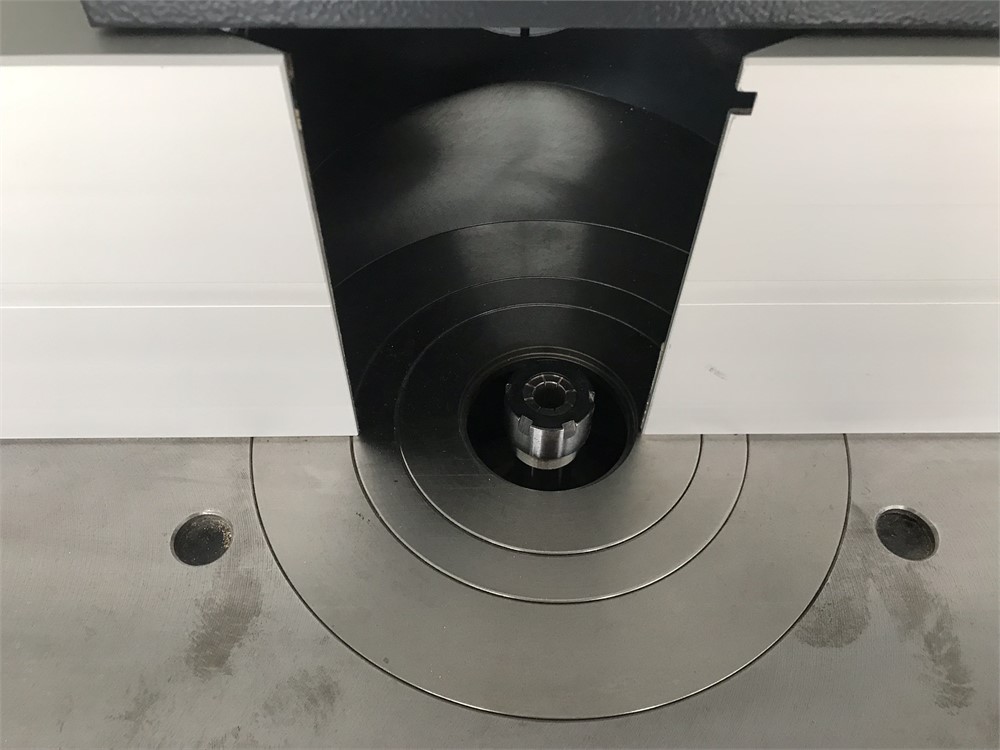

Spindle Moulder Unit

The Felder 700 Series spindle aggregate sets standards that are unparalleled.

- 115 mm useable spindle height above the table (140/160 mm)

- Quick-change system of the moulder spindle

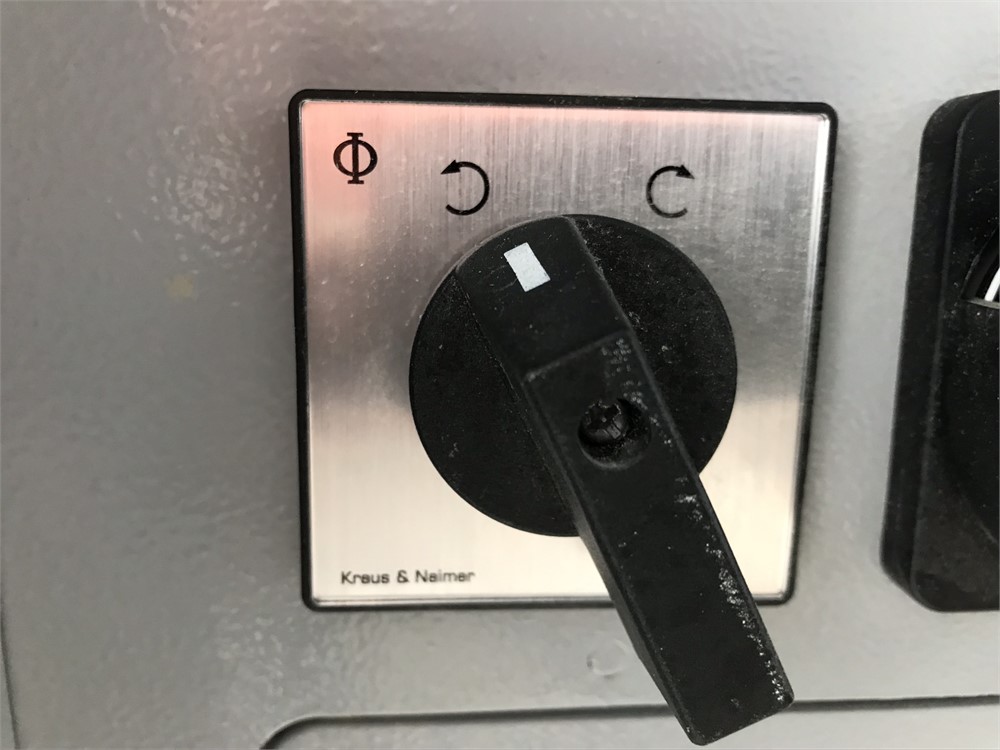

- Change the speed simply from the front of the machine

- Collet chuck spindle for router tools with a speed of 15,000 rpm

- Electrical height adjustment with digital LED display

- Electrical angle adjustment with digital LED display

- 4 operating speeds (3500, 6500, 8000, 10,000 rpm)

- Rearward tilt 0° to 45°

- Precise, double sided guide support

- Dovetail guidance system of the height adjustment

- Excellent vibration absorption from heavy cast iron unit

Power Drive Moulder SPindle

The fully electrical “Power-Drive” control offers exact adjustment and repeat accuracy. The saw blade height and the angle settings can be adjusted at the turn of a knob, the fine setting adjustments are carried out to tenth of a millimetre accuracy using a push button. Red LED digits display the current position in real time on the control panel.

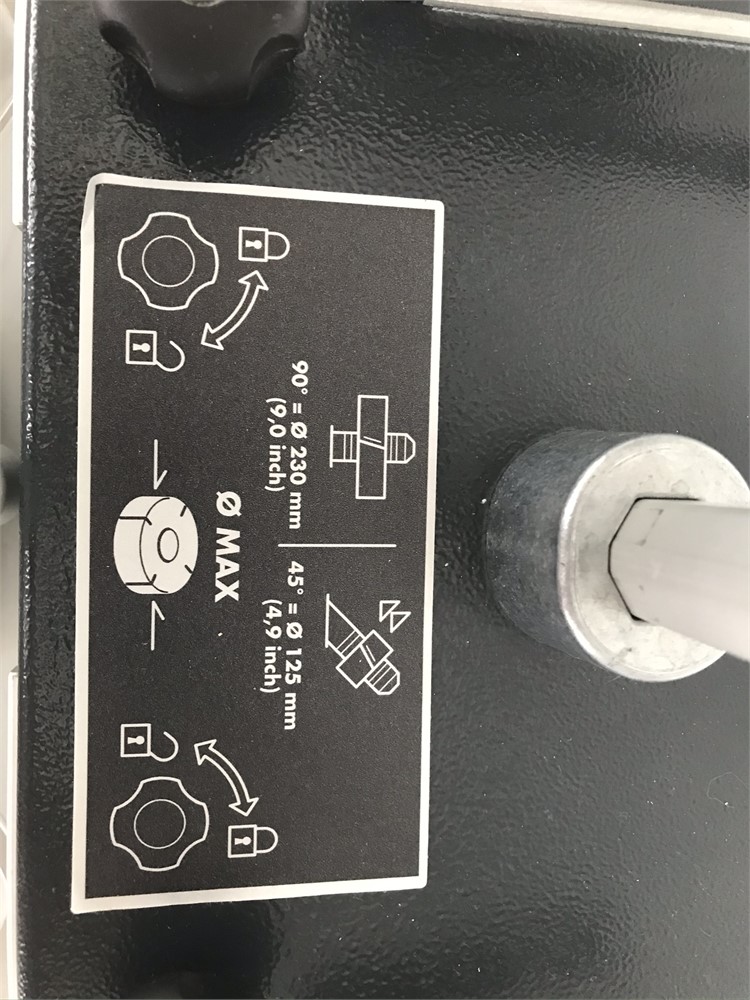

Moulder Spindle Tilting 90-45

Your Felder spindle tilts “rearward” for operational comfort and the additional following reasons:

- Safety, as there is no pinch point

- Suitable for any workpiece size

- Problem-free power feeder application

- Impeccable machined surface

- Optimal chip removal

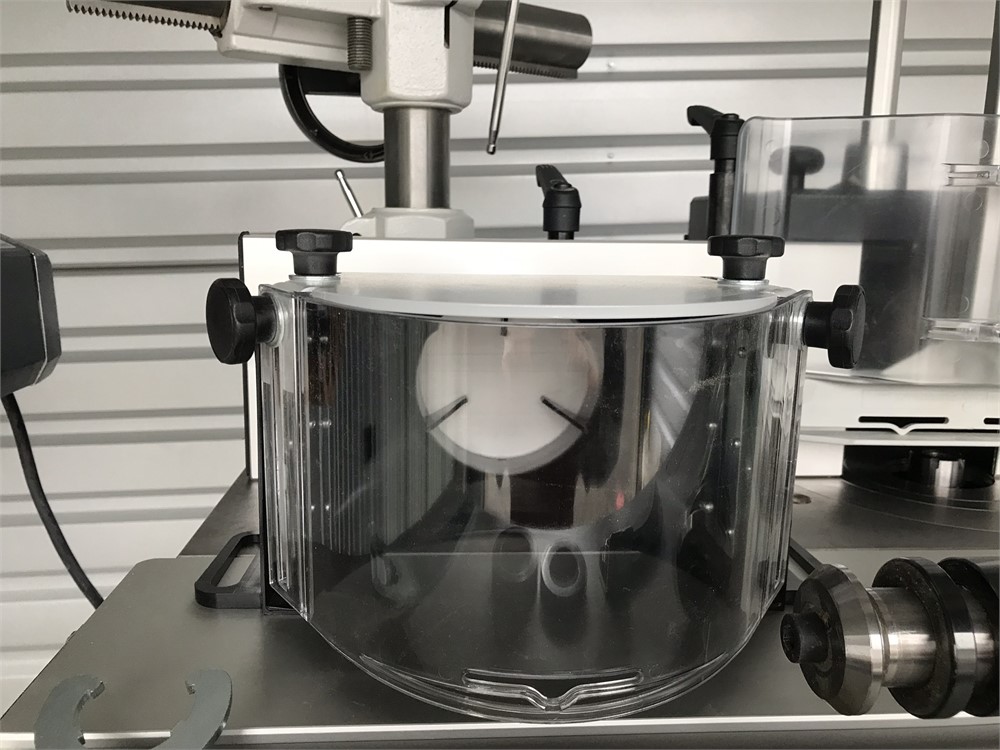

Spindle Fence

The fence allows tooling of a maximum diameter of 230 mm to be used. The fine adjustment can be set between -5 to +25 mm. The extraction of the chips is done via the integrated extraction connection.

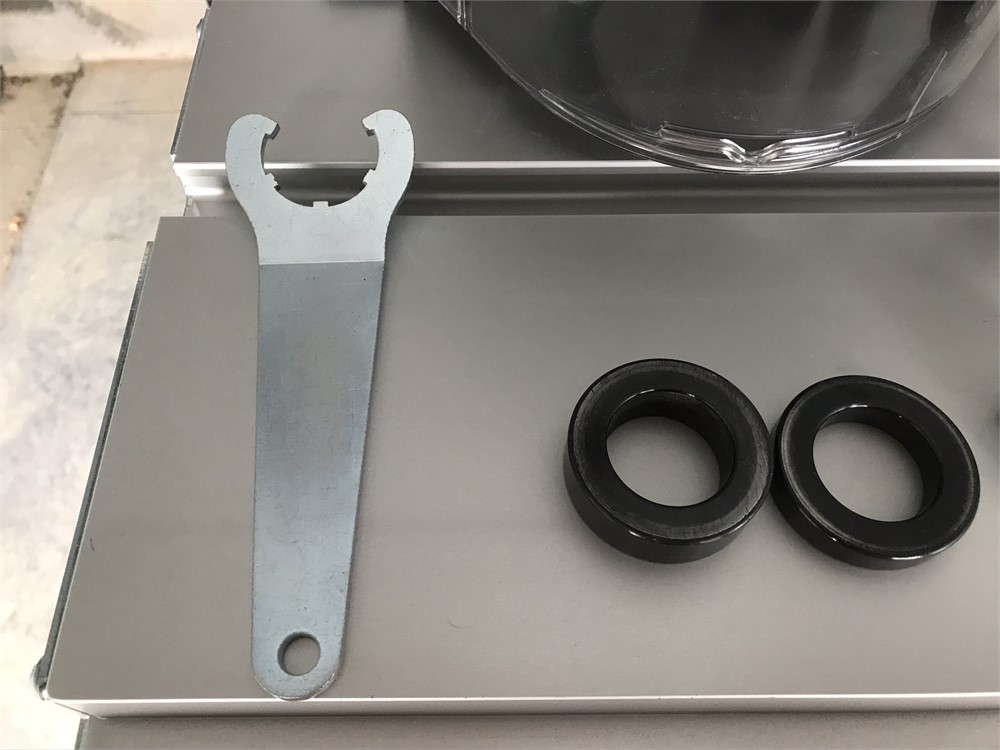

Quick Change Spindle System

Advantages of the Felder spindle quick change system:

- Quick, easy change between different types of spindles

- Ability to use 30, 32, 35, 40, 50 mm and 1¼” diameter spindles

- Use of the Felder high speed router spindle for router bits or high speed tools at 15,000 rpm.

- Automatic repeatable setting for series production work

Multi Fine Adjustment System

Additional to the parallel guiding of the spindle fence the MULTI-adjustment system also enables

- The quick adjustment to the tool diameter

- Automatic repeat setting after removal of your fence

- Parallel adjustments of the moulder fence

- Quick and accurate adjustment

- Measurement scale for depth of cut

Table Opening 230mm

The large table opening allows for maximum operator safety. For large dimension tooling, as used for tenoning and panel raising, the cutterblock can be conveniently positioned below the table.

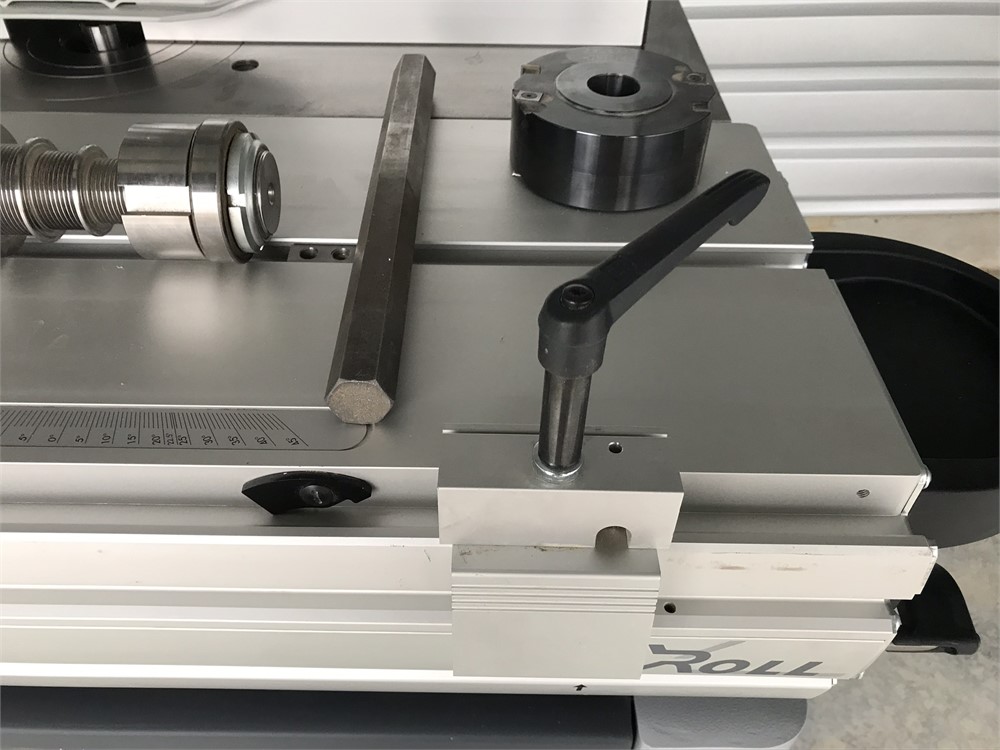

Precise Slots and Tenons

Accurate slots and tenons are much easier with the Felder “X-Roll” sliding table. This precision guiding system will accept maximum loads without compromising the smooth and accurate stroke of the sliding table. The “X”-configuration of the roller bearings optimally distributes workpiece weight to all sides. With conventional sliding tables, ball bearings are used in the guiding system. A ball bearing system creates a singular point of contact between the bearings and the flat guiding tracks. The singular point of contact will eventually wear grooves into the tracks and as a result, sideways play will develop in the sliding table. It is physically impossible for the “X-Roll” system; with roller bearing lineal contact; to wear grooves into the guiding tracks, hence the system will always remain play-free and is backed with a 10-year factory guarantee.

Pnuematic Work Piece Holder

- Easy clamping of workpieces with maximum flexibility, can be used on all panel saws and spindle moulders that have a sliding table

- Easy set up due to magnetic fittings

- Safety cylinder ensures maximum working safety

- Pressure bar function is possible with every sliding table length

- Locking height 95 mm

- Clamping force approx. 300 kg

Quick Lock

Change routing tools quickly and safely. The "Quick-Lock" clamping system allows a convenient change of cutters on the table router and reduces the risk of injury from slipping. Suitable for Ø 30 mm spindles

The listed specifications & information were taken from the manufacturer’s published information, internet research, or seller’s description.

The specifications & information are assumed to be correct; however, in no way, guaranteed. Bidders are encouraged to inspect the machine, call with questions, or contact the manufacturer for more information.

Please log in to view the bid history

LoginPick-ups are to be scheduled by appointment only. Please contact Sabrina Burns at 209-839-7707 or [email protected] to schedule an appointment. For freight quotes please contact Aaron at All-Ways Trucking at 541-608-6532. Buyer bears all costs to remove and load this lot. Buyer must remove entire lot purchased. Anyone removing non-hand carriable lots must provide MachineryMax, Inc. with a certificate of insurance (COI) before purchased items can be removed.

All buyers agree to make full payment to MachineryMax, Inc. within 48 hours of the online closing date for the auction lots purchased. All invoices over $1,500.00 are to be made by bank wire transfer or cashier’s check payable to MachineryMax, Inc. Purchases under $1,500.00 may be made using Visa, MasterCard, or American Express (2% credit card processing fee will be added to the invoice). All payments are to be made in USD currency only. Bidder represents and warrants to MachineryMax, Inc. that such bidder has immediately available funds to fully pay for its successful bids within 48 hours of the online closing date. All payment questions should be directed to Sabrina Burns at 209-839-7707 or [email protected] All buyers agree that there will be a 15% Buyers premium that will be added to the final invoice.