Biesse "Rover B 7.40FT" flat table CNC Router  Ended

Ended

Items located in Topeka, KS

- Winning Bid : $7,000.00 USD Sold

- 17 Bid(s)

- High Bidder: t****0

Biesse Rover FT CNC, Beam Saw,Crane & Lift, Belfab DC in Topeka, KS ( Closed #22640012 )

Biesse Rover B7.40, Selco Beam saw, Crane and vacuum lift, Belfab interior/exterior Dust collector, Vacuum pump all located in Topeka, KS. Quick removal needed. Final removal 7-31-2020

-

Pick Up Location

6800 SE Forbes Ave, Topeka, KS 66619

-

Make

Biesse

-

Model

Rover B 7.40 FT

-

Serial Number

53304

-

Year

2004

-

Phase

3 PHASE

-

Voltage

460 VOLT

-

Load Out Period

7-31-2020 Hard date

-

Estimated Dimensions

17' x 8' x 10'

-

Estimated Weight

8000 pounds

-

Seller Comment

A non negotionable loading fee has been established - See below. This includes the rigging and loading onto a flat bed trailer. Seller will prep machine for shipment

-

Load Fee

1000

-

page views

4232

** Vacuum pump offered in lot 003 **

Working cap.: X-Axis is 145" (3,685 mm), Y-axis is 61" (1,550 mm), X-asis working field with all the tools is 145" (3,685 mm), X-axis working field with main spindle is 157" (3,996 mm), Y-axis field with all verticle spindles is 60.6" (1,539.5 mm), Y-axis working field with main spindle is 72.8" (1,850 mm), Z-axis clearance is 7" (180 mm ).

Programmable speed: X- & Y-Axis is 3,937 IPM and Z-axis is 1,181 IPM.

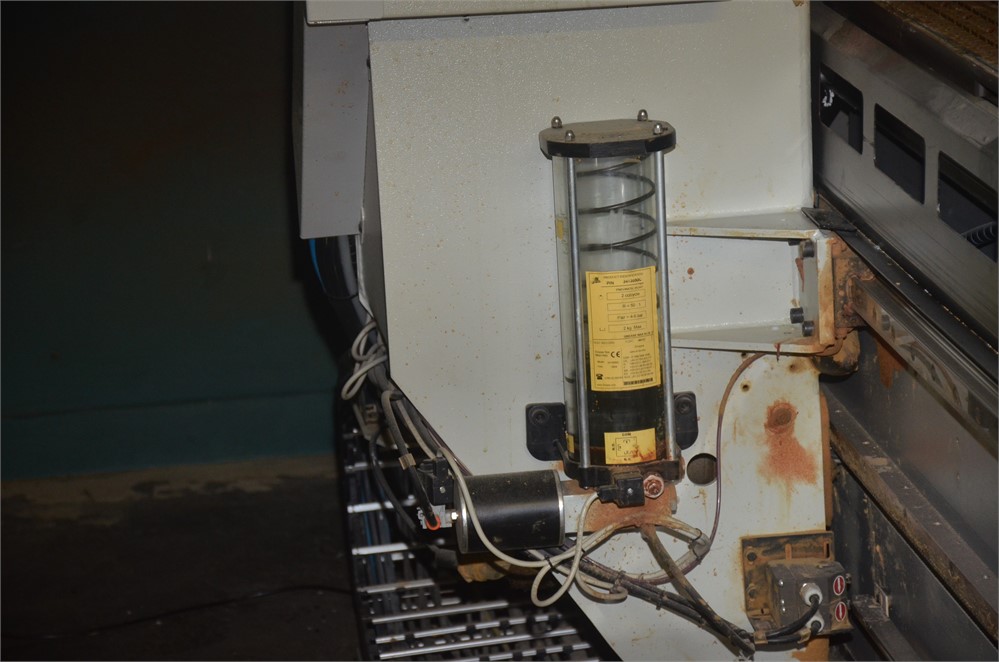

Equipped with: (12) Independent vertical boring spindles forming an L-configuration with (6) spindles on the Y-axis & (6) spindles on the X-axis; inverter controlled 2.3 HP spindle motor with 4,000 RPM.

A total of (6) horizontal spindles provide horizontal boring capabilities on all (4) edges of the panel, (4) on the X-axis (2 in ea. direction) and (2) are paralleled with the Y-axis (1 in ea. direction), X-axis grooving saw.

Options included: (1) 16.3 HP Vertically mounted HSD Electrospindle, liquid cooled and inverter driven at 1,000 - 24,000 RPM with max. torque from 12,000 - 20,000 RPM.

"Ride Along" 10-position Automatic tool changer for "on-the-fly" tool changes with HSK-63F tool holders.

Work area with: Flat table designed for "Nested Base Manufacturing" with (2) independent working areas, (12) external pop-up reference pins with (8) on the back of the table and (2) on the RH side and (2) on the LH side. The unit is prepared for (optional) "quick fit" vacuum outlets for optional clamping of small or irregularly shaped parts.

Separate control console with: "NC 1000" Controller, MS-Windows based technology, Pentium- CPU, hard drive, CR-ROM reader, mouse, USB ports, parallel port, Serial port, and network card. NC 1000 software for easy programming of boring, routing, and grooving functions.

Operating system for real-time multitask processing; programs can be transferred via diskette or downloaded by wire; built-in 1,500 W air conditioner for constant temperature & dust-free environment.

Emergency stop rope & pressure sensitive safety mats that will instantly place machine in "pause cycle" when stepped on and surrounding safety cage; sound absorbing protective head enclosure with debris curtain around bottom edge.

The listed specifications & information were taken from the manufacturer’s published information, internet research, or seller’s description.

The specifications & information are assumed to be correct; however, in no way, guaranteed. Bidders are encouraged to inspect the machine, call with questions, or contact the manufacturer for more information.

Please log in to view the bid history

LoginPick-ups are to be scheduled by appointment only. Please contact Sabrina Burns at 209-839-7707 or [email protected] to schedule an appointment. For freight quotes please contact Aaron at All-Ways Trucking at 541-608-6532. Buyer bears all costs to remove and load this lot. Buyer must remove entire lot purchased. Anyone removing non-hand carriable lots must provide MachineryMax, Inc. with a certificate of insurance (COI) before purchased items can be removed.

All buyers agree to make full payment to MachineryMax, Inc. within 48 hours of the online closing date for the auction lots purchased. All invoices over $1,500.00 are to be made by bank wire transfer or cashier’s check payable to MachineryMax, Inc. Purchases under $1,500.00 may be made using Visa MasterCard, or American Express (2% credit card processing fee will be added to the invoice). All payments are to be made in USD currency only. Bidder represents and warrants to MachineryMax, Inc. that such bidder has immediately available funds to fully pay for its successful bids within 48 hours of the online closing date. All payment questions should be directed to Sabrina Burns at 209-839-7707 or [email protected] All buyers agree that there will be a 15% Buyers premium that will be added to the final invoice.