2017 Homag Ambition "Optimat KDN1110" Edgebander  Ended

Ended

Homag Canada - Assets No Longer Required Calgary Canada

- Winning Bid : $13,000.00 USD Sold

- 56 Bid(s)

- High Bidder: f****6

Homag Canada - Showroom Assets No Longer Required - ( Closed #22393483 )

Featuring 2017 Homag Ambition Optimat KDN1110 Edgebander, 2014 Kentwood Ms096 6 Head Moulder

-

Pick Up Location

3416-114 Ave. SE Calgary, AB T2Z 3V6

-

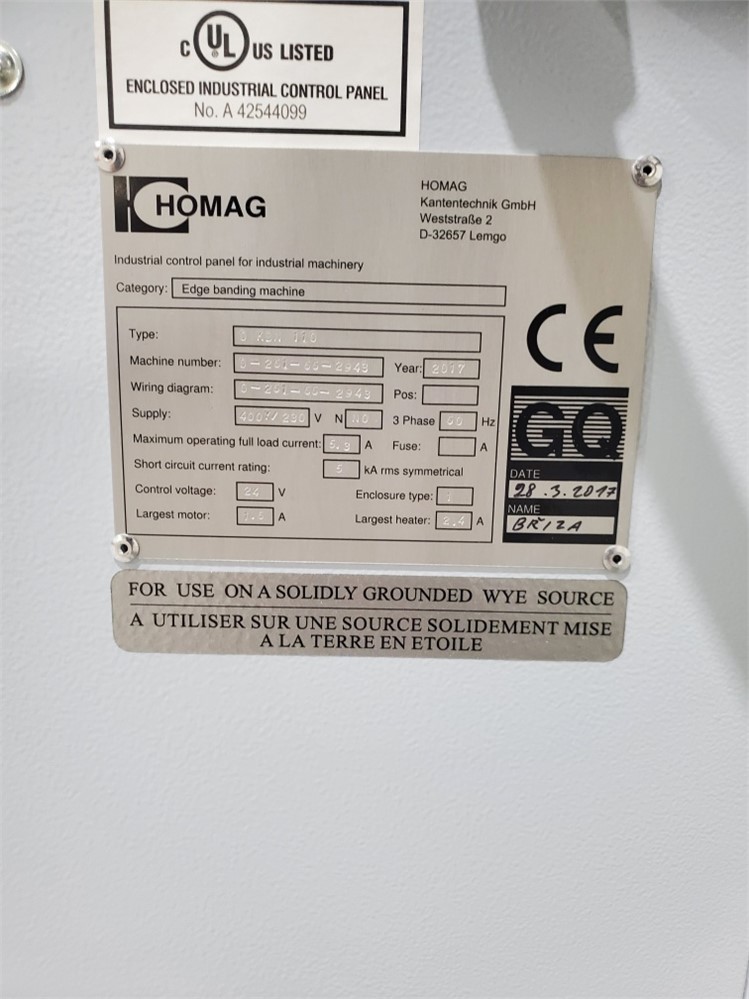

Make

Homag

-

Model

Optimat KDN1110

-

Serial Number

0-261-652943

-

Year

2017

-

Phase

3 PHASE

-

Voltage

400

-

Load Out Period

-

Estimated Dimensions

-

Estimated Weight

-

Seller Comment

Non Negotiable Load Fee 100

-

Load Fee

100

-

page views

2227

Machine currently sits on our showroom floor in Calgary showroom

Machine has only been run in our showroom for demonstration purposes

Note: The machine is currently powered 400V The machine comes with Power transformer See details below

6000 VA Power Transformer

Power transformer to connect to deviating network forms or line voltages for 50 or 60 Hz Primary connection to 200V / 208V / 230V / 440V 480V / 600V, secondary 400V +/- 10%, installed in an IP23 casing. Delivery is made as a subpackage with the machine.

The installation and fuse protection of the power transformer are the customer's responsibility, in accordance with

local ordinances.

Single-sided edge banding machine for processing straight workpiece edges and for gluing and post-processing different edging materials in longitudinal and cross through- feed.

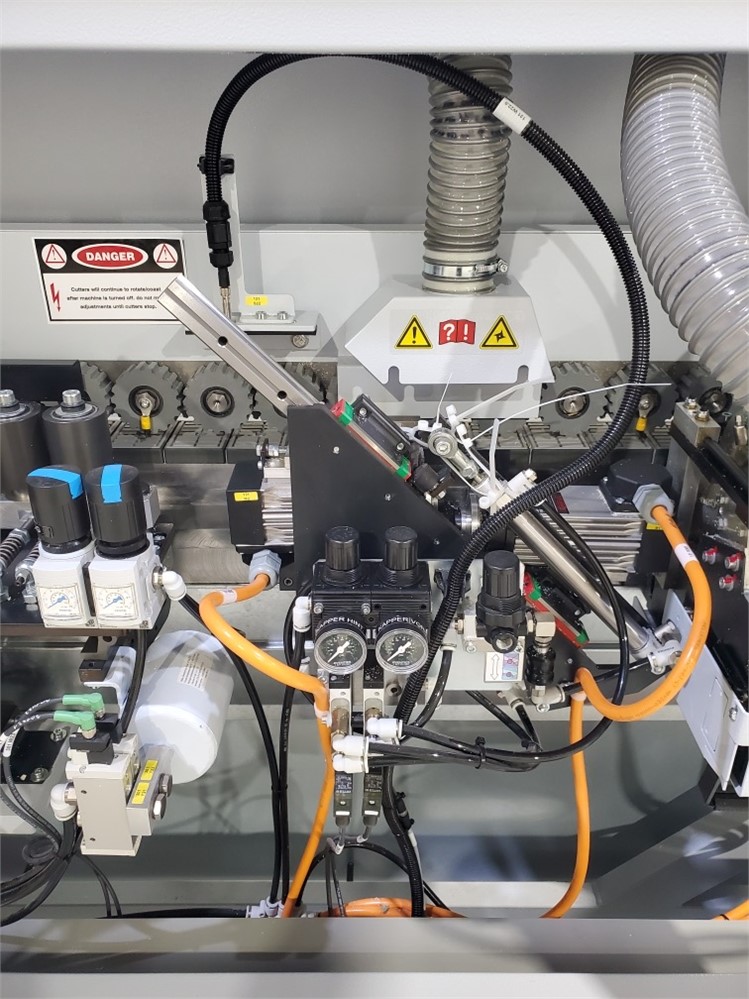

GLUING UNIT A3

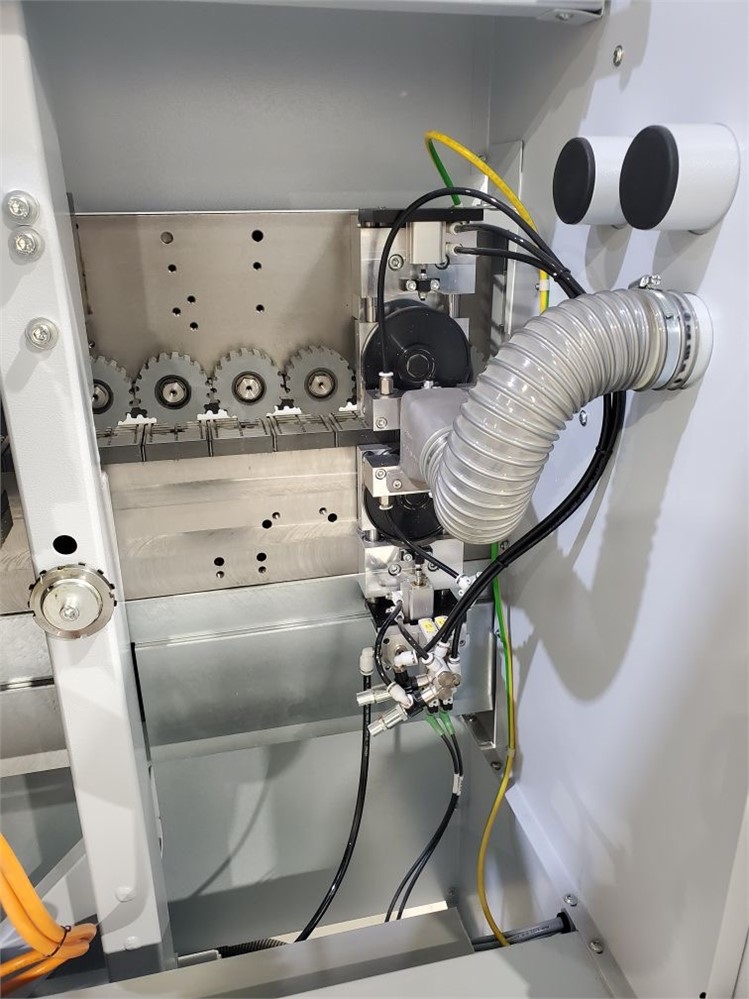

END TRIMMING UNIT STRAIGHT 2 X 0,18 KW TRIMMING UNIT 2 X 0,27 KW REVERSE ROTATION OPEN SPACE 1

OPEN SPACE 2

-

- continuous machine frame, for mounting the

processing units

-

- fixed stop side on the right

-

- lacquering grey RDS 240 80 05 -__i_n_f_e_e_d__f_e_n_c_e__

-

- top pressure:

-

- 2 single rows of staggered rollers

-

- height adjustment with digital readout for the manual set up of the top pressure beam

according to panel thickness

-

-

- workpiece transport device:

-

- transport chain with rubber coating, 80 mm wide

-

- precision running and guiding surfaces

-

- standard equipment with manual lubrication

of chain track -

- panel support with roller guide,

extendable by approx. 300 mm

-

-

- noise protection with individual extraction

ports for the post-processing units and the

chip collection box in connection with option (VKNO 5766 or VKNO 5820

- feed speed 8 m/min

- working height 950 mm

- pneumatic connection - total length min. 6bar

-Total Length 3.672mm

Technical datas refer to the standard execution.

Options can cause changes to the connected load for power, dust extraction and air consumption.

2_.Workpiece Edge Parameters

- workpiece width min:

- in case of workpiece

thickness 8-22mm ¦ 70 mm*

- in case of workpiece Thickness 23-40mm :120mm

WorkPiece Overhang 38mm

Workpiece thickness 8-40mm

edge height max = Panel Thickness +5mm

Edge Material Coil 0,4 -3 mm

Edge mat. cross section max PVC 135mm veneer 100mm

coil diameter Max 830 mm

edge material strips 0,4 -3mm

UNIT EQUIPMENT

Gluing Unit

-

STANDARD APPLICATION UNIT

-

- quick change application unit

-

- processing of PU adhesives is possible with

standard application unit changeable PU glue (VKNO 2068) in compliance with the processing prescriptions

-

- glue reservoir underneath the glue roller

-

- glue application to the workpiece by means

of a glue roller no adjustment of the glue roller is required

-

when changing the workpiece thickness

-

- glue roller rotation with the workpiece feed

direction

-

- glue temperature control by means of

electronic thermostat

-

- automatic reduction of glue temperature upon

interruption of the working process

-

Magazine

-

automatic edge magazine for coiled material

and fixed lengths, incl. roller plate

-

- equipped with heavy duty guillotine for

cutting

Pressure Zone

-

pressure zone with driven main pressure

roller and 2 idle post pressure rollers

-

- equipped with a digital readout for manual

adjustment of the pressure zone to edge thickness

End Trim. Unit straight 2x0,18kw

-

for end trimming of the front and rear edge

material overhang with drawing cut

2 motors, equipped with one saw blade each,

-

- 2 motors 0,18 kW ea., 200 Hz, 12.000 rpm

-

- 2 saw blades diam. 100 x 32 x 2,6 mm, T = 30

-

- feed speed: 8 m/min

Trimming Unit 2x0,27 KW reverse Rotation

-

for trimming the top and bottom edge material

overhang, vertically and horizontally sensing.

Height adjustment of the upper motor with the top pressure beam -

- Unit manually adjustable between 3 different working positions: Flush trimming straight Trimming with overhang Radius-/Chamfer trimming

-

- all spindles equipped with digital readouts

for fast adjustment

2 motors 0,27 kW ea., 200 Hz, 12.000 rpm equipped with DFC combination cutters for flush, chamfer and radius trimming

edge thickness max. 3 mm

Open Space1

Open Space 2

Brandt Control System EasyTouch

With a touch display in widescreen format for simple and comfortable operation and programming of the machine.

Technical details:

-

- control panel at machine infeed

-

- clear 7" touch display for easy navigation

and an intuitive oparation of the machine

-

- visual readout of the essential set values

and actual machine values

-

- integrated line control for controlling

the working functions

-

- simple choice and adjustment of line

points

-

- intelligent display of readyness of

production by light function

-

- online change between various languages

-

- machine data capturing for the

representation of important operating figures (e.g. number of pieces, production time, edge material quantity)

-

- clear text information about the status

-

- storage of up to 20 processing programs

Special Voltage USA/CAN

-

For 60 Hz electricity networks

-

- Switch cabinet executed according to CSA / UL

specifications

-

- It's compulsory to apply an isolating

transformer from the option list of the

corresponding machine

-

- In case of Profiline machines the

corresponding isolating transformer will be determined by the Brandt sales manager.

Glue Joint Scraping Unit

-

for removal of adhesive residues in the area

of the glue joint

-

- sensing from top and bottom. Height

adjustment with the top pressure beam

-

- equipped with 2 reversible cutter knives.

-

- incl. dust extraction

The listed specifications & information were taken from the manufacturer’s published information, internet research, or seller’s description.

The specifications & information are assumed to be correct; however, in no way, guaranteed. Bidders are encouraged to inspect the machine, call with questions, or contact the manufacturer for more information.

Please log in to view the bid history

LoginPick-ups are to be scheduled by appointment only. Please contact Sabrina Burns at 209-839-7707 or [email protected] to schedule an appointment. For freight quotes please contact Aaron at All-Ways Trucking at 541-608-6532. Buyer bears all costs to remove and load this lot. Buyer must remove entire lot purchased. Anyone removing non-hand carriable lots must provide MachineryMax, Inc. with a certificate of insurance (COI) before purchased items can be removed.

All buyers agree to make full payment to MachineryMax, Inc. within 48 hours of the online closing date for the auction lots purchased. All invoices over $1,500.00 are to be made by bank wire transfer or cashier’s check payable to MachineryMax, Inc. Purchases under $1,500.00 may be made using Visa MasterCard, or American Express (2% credit card processing fee will be added to the invoice). All payments are to be made in USD currency only. Bidder represents and warrants to MachineryMax, Inc. that such bidder has immediately available funds to fully pay for its successful bids within 48 hours of the online closing date. All payment questions should be directed to Sabrina Burns at 209-839-7707 or [email protected] All buyers agree that there will be a 15% Buyers premium that will be added to the final invoice.