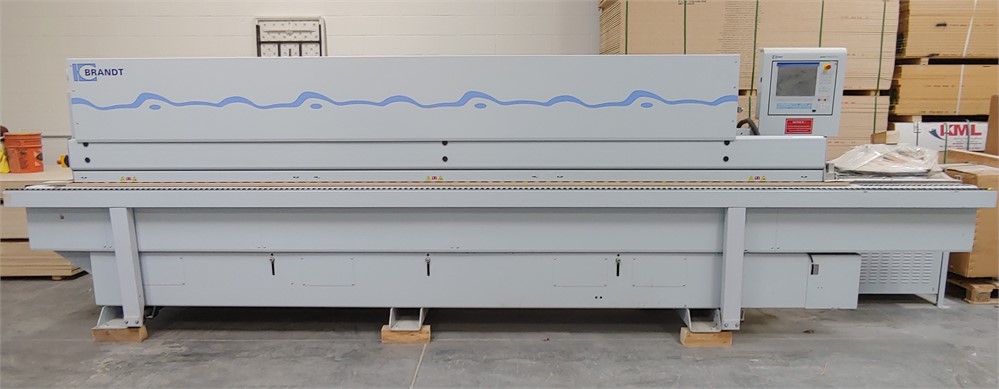

Brandt "KDF 650" edgebander with pre mill and corner rounding.  Ended

Ended

Items located in Idaho Falls, ID

- Winning Bid : $18,000.00 USD Sold

- 79 Bid(s)

- High Bidder: j****5

Brandt "KDF 650" edgebander and return conveyor in Idaho Falls, ID ( Closed #21610030 )

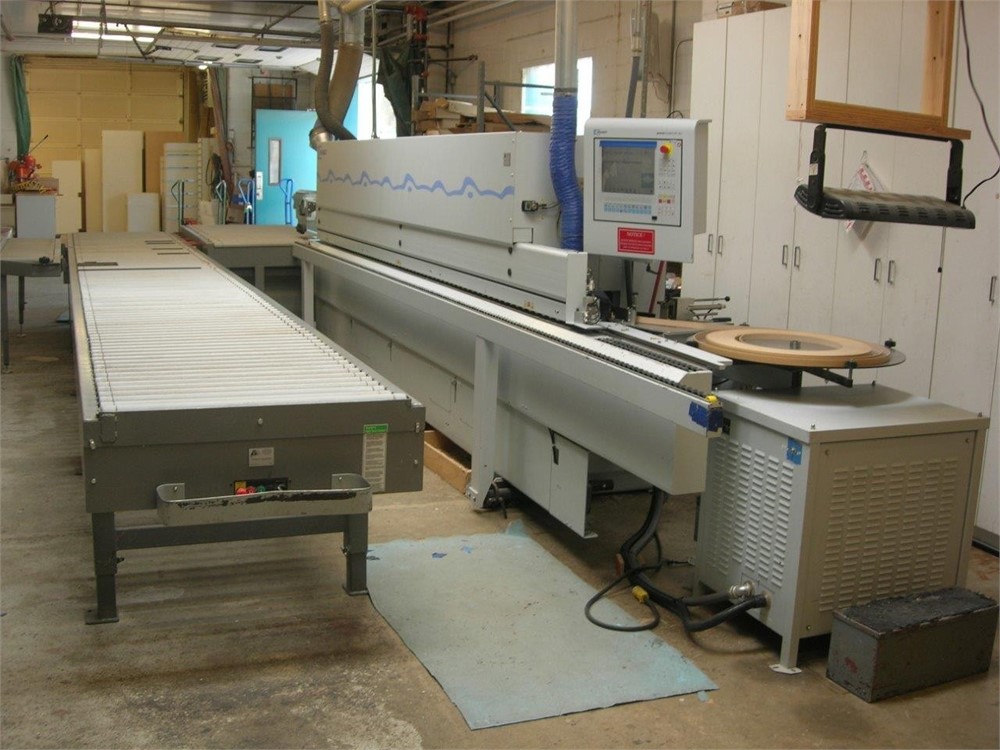

Johnson Brothers Inc in Idaho falls is replacing their edgebander and return conveyor and is offering both machine for auction.

-

Pick Up Location

223 Basalt St, Idaho Falls, ID 83402

-

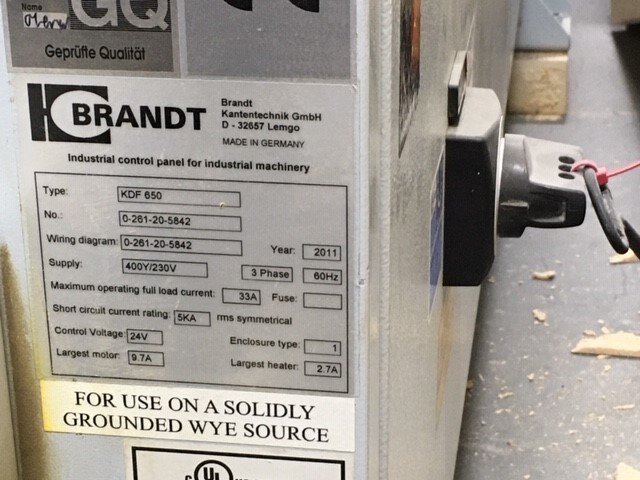

Make

Brandt

-

Model

KDF 650

-

Serial Number

0-261-20-5842

-

Year

2011

-

Phase

3 PHASE

-

Voltage

230 VOLT

-

Load Out Period

May 15th

-

Estimated Dimensions

19' x 5' x 6'

-

Estimated Weight

5800 pounds

-

Seller Comment

A non negotionable loading fee has been established - See below. This includes the rigging and loading onto a flat bed trailer. Requests for additional labor, crating or pallatization will be extra.

-

Load Fee

250

-

page views

4108

Notes from seller

-Machines have been fully maintained on manufacturer’s schedule.

-Edgebander has brand new glue pot.

-Pre-mill heads newly re-tipped.

-Tooling inserts and saw blades only have one month’s use.

Specifications as taken from manufacturer.

Specifications:

• Edge & Workpiece Capacity:

0.4 - 12 mm (0.016 - 1/2") edge; 8 - 60 mm (5/16 - 2-3/8") panel thickness; 160 mm (6-3/8") min. panel length and 70 mm (2-3/4") min. panel width.

Equipped with:

• Motorized Panel thickness adjustment.

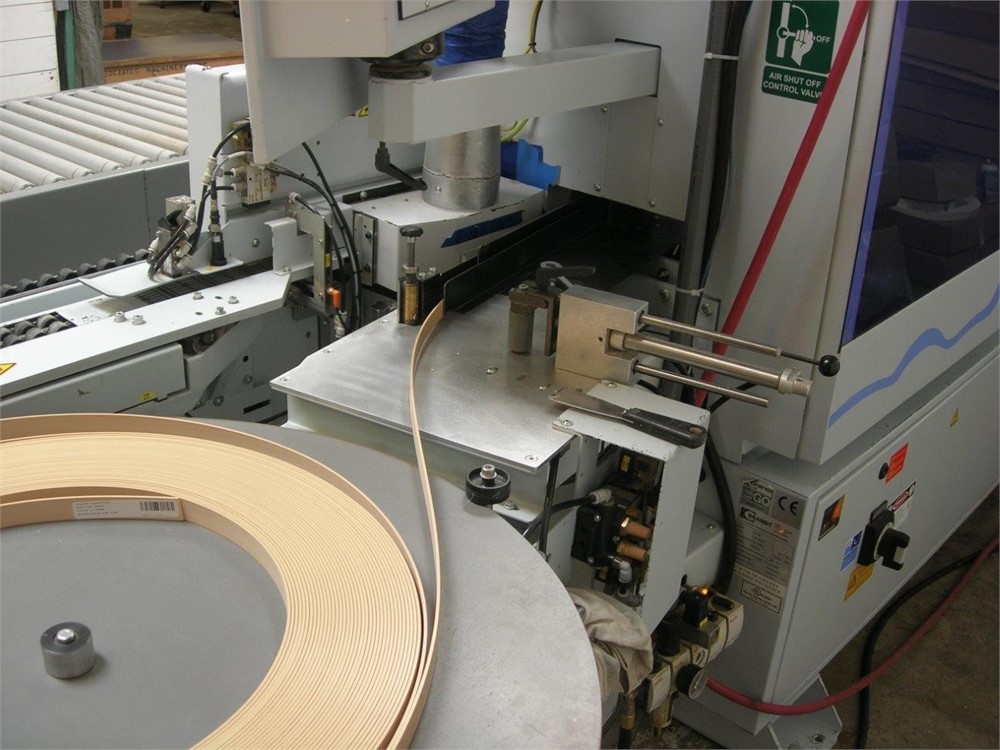

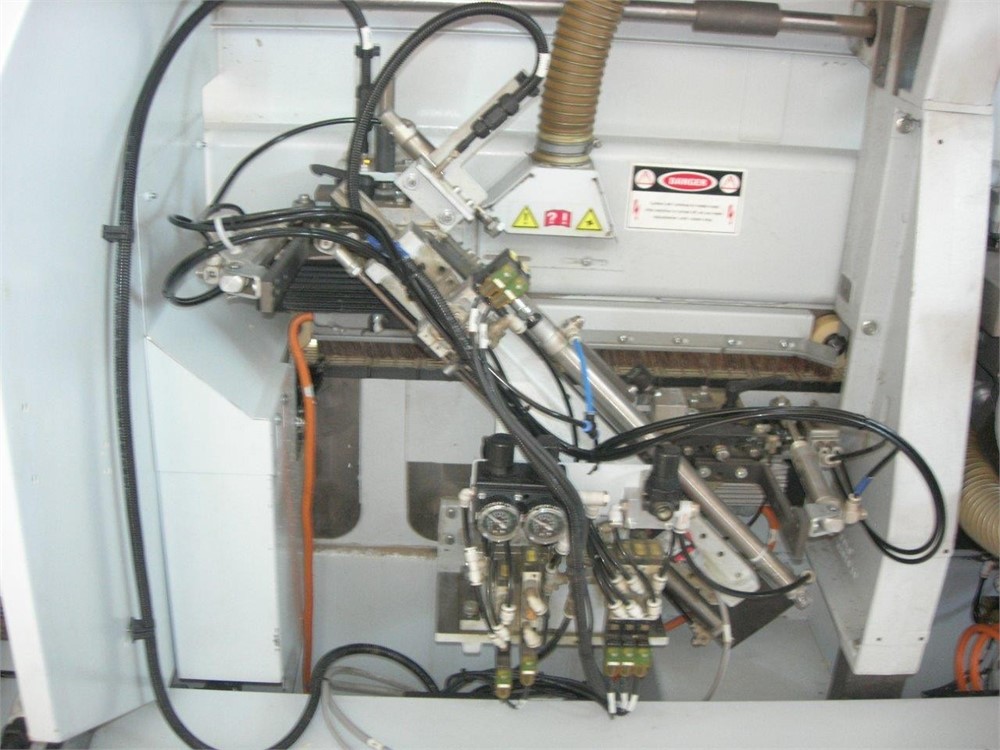

• Pre-Milling Station, (2) motors @ 2.25 kW (3.0 HP), 12.000 RPM, LH & RH rotation w/pneumatic jump control for chip-free and clean panel edges.

• Infrared Radiant Quartz Heating Unit between glue roller and pressure section.

• Automatic Edge Magazine, for strip & coil stock, strips 0.4 mm - 12 mm (0.016 - 0,5"), coils up to 3 mm PVC and "HD" guillotine.

• "Quick Change" Glue Tank for maintenance & glue color change.

• Pressure Section, 1st. roller driven plus (3) idle rollers, timed pneumatic pressure controlled; Servo motor positioning for programmable edge thickness changeover.

• Feed Speed, variable 8 - 18 MPM. (26 - 59 FPM), 14 MPM (46 FPM) when using contour trimming.

Operator & Machine Control:

• BRANDT "PC-20" Program Control (Industrial PC) 600 MHz, Memory: 256 MB Ram, 1 GB Flash Card Drive, Operator control panel w/12" color active TFT display screen, soft keypad & internal modem for remote diagnostic link.

Workstations:

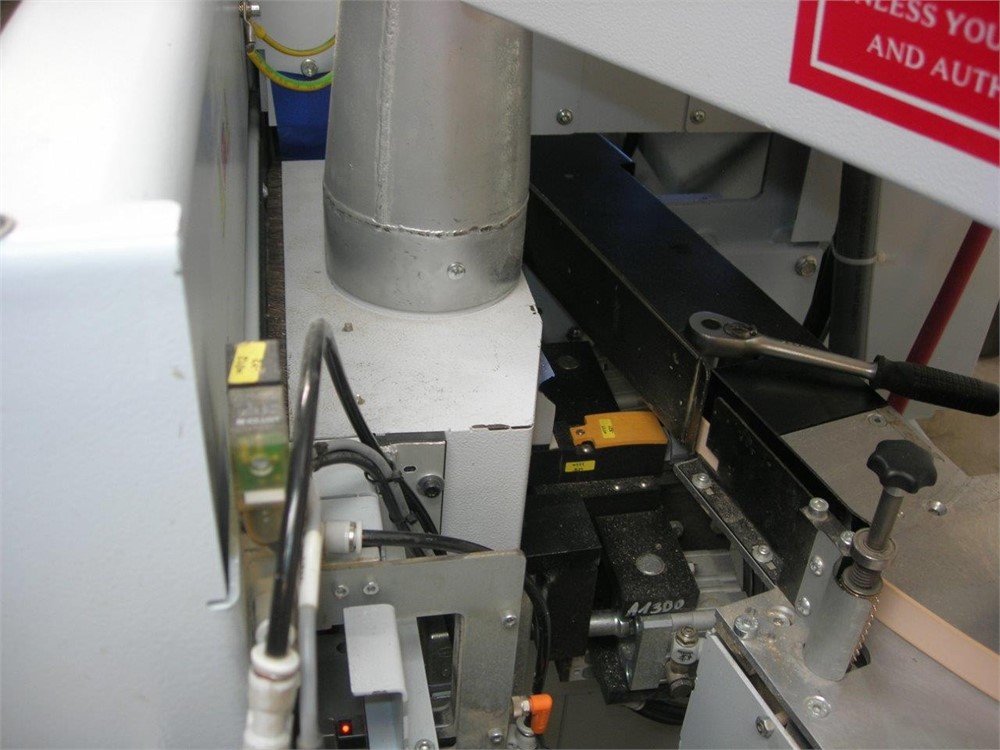

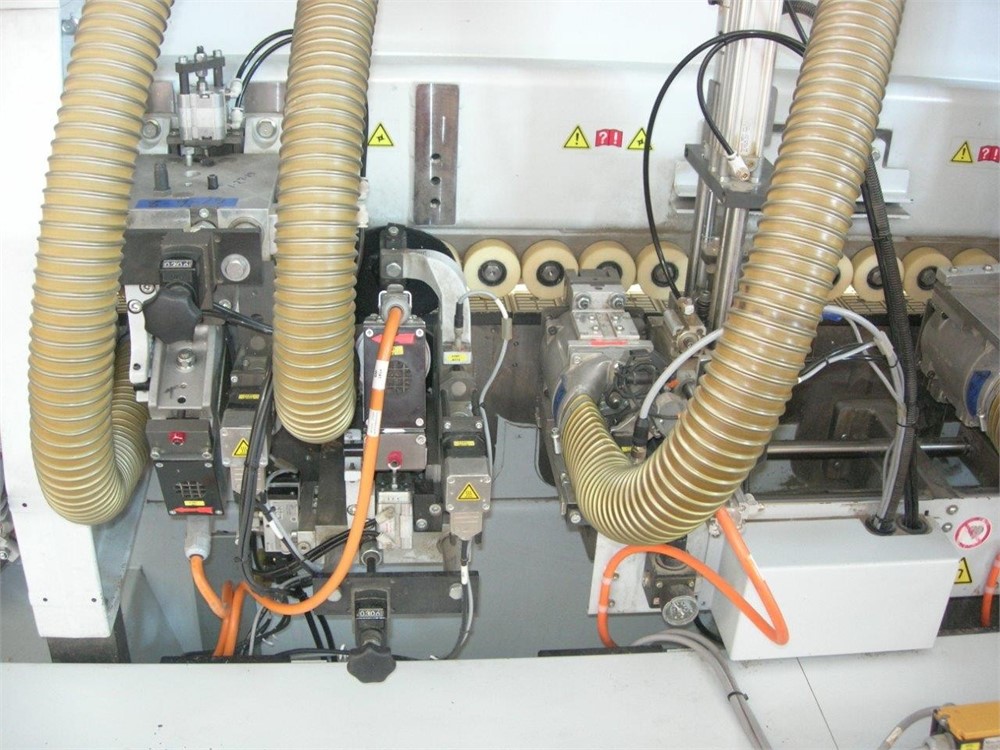

• End Trimming: (2) Motor @ 0.35 kW (1/2 HP) 12,000 RPM, automatic chamfer from control panel 0°- 15°.

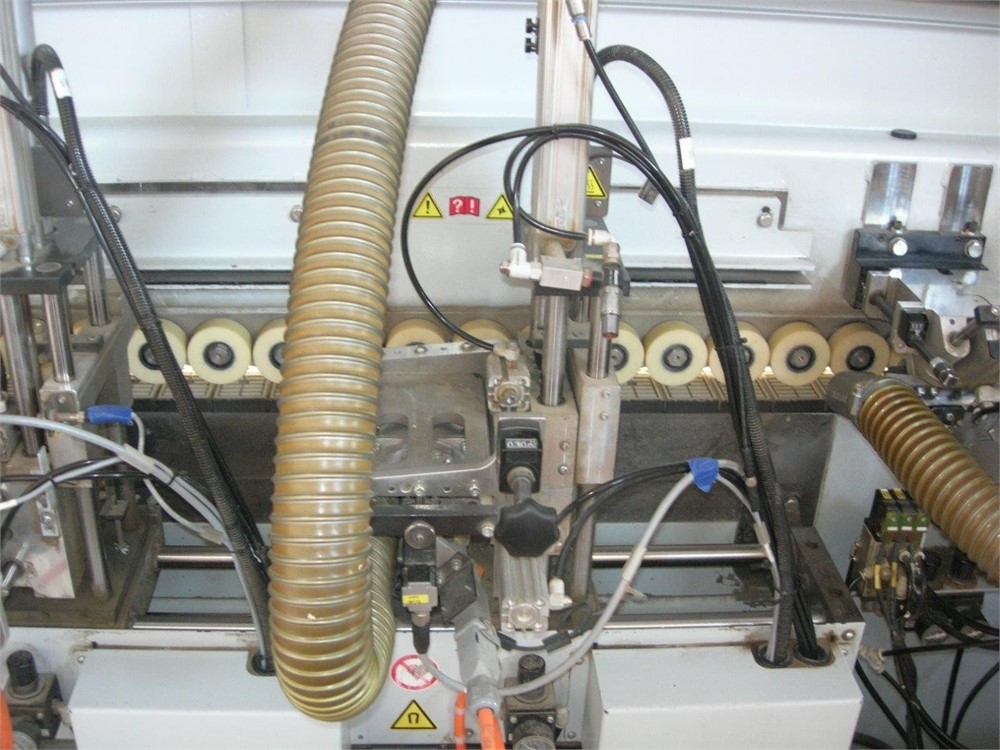

• Flush/Bevel-Fine/Radius Trimming Unit: NC Controlled Top/bottom (2) motors, 0.55 kW (3/4 HP) 12,000 RPM, auto tilt postioning 0° - 25°, with combination flush/radius/chamfer cutterheads.

Horizontal and vertical tracing wheels, equipped with brushless multi-axis Servo motors for positioning of work-unit & horizontal copy wheels for quick changeover.

• Multi Functioning Trimming (Corner Rounding) Unit: (2) Motor 0.4 kW (1/2 HP) 12,000 RPM for top/bottom linear edges and leading & trailing edges of panels; either radius or chamfer cutters can be mounted; 3 mm max. edge thickness. Pneumatic (2) positioning indexing, quick change motors for different radius profiles change-over.

• Radius Scraping (PVC): Top/bottom with pneumatic indexing control, PVC scrape collection box.

• Glue Scraping Unit: Flush top/bottom on panel surface with floating insert knives.

• Buffing Unit: Top/bottom (2) motors, 0.10 kW (0.125 HP) 2,800 RPM.

• Complete with:

Motorized, programmable hold-down pressure beam; padded sound enclosure, used tooling.

The listed specifications & information were taken from the manufacturer’s published information, internet research, or seller’s description.

The specifications & information are assumed to be correct; however, in no way, guaranteed. Bidders are encouraged to inspect the machine, call with questions, or contact the manufacturer for more information.

Please log in to view the bid history

LoginPick-ups are to be scheduled by appointment only. Please contact Sabrina Burns at 209-839-7707 or [email protected] to schedule an appointment. For freight quotes please contact Aaron at All-Ways Trucking at 541-608-6532. Buyer bears all costs to remove and load this lot. Buyer must remove entire lot purchased. Anyone removing non-hand carriable lots must provide MachineryMax, Inc. with a certificate of insurance (COI) before purchased items can be removed.

All buyers agree to make full payment to MachineryMax, Inc. within 48 hours of the online closing date for the auction lots purchased. All invoices over $1,500.00 are to be made by bank wire transfer or cashier’s check payable to MachineryMax, Inc. Purchases under $1,500.00 may be made using Visa MasterCard, or American Express (2% credit card processing fee will be added to the invoice). All payments are to be made in USD currency only. Bidder represents and warrants to MachineryMax, Inc. that such bidder has immediately available funds to fully pay for its successful bids within 48 hours of the online closing date. All payment questions should be directed to Sabrina Burns at 209-839-7707 or [email protected] All buyers agree that there will be a 15% Buyers premium that will be added to the final invoice.