Homag "Ambition 1130 FC" Edgebander  Ended

Ended

Complete Closet Manufacturing Facility - Tracy, CA

- Winning Bid : $32,150.00 USD Sold

- 63 Bid(s)

- High Bidder: T****Y

Complete Closet Manufacturing Facility - Tracy, CA ( Closed #21551832 )

Complete closet manufacturing facility has closed its doors. 2018 Homag Ambition 1130 FC edgebander, 2018 Altendorf WA 8X sliding table saw, Belfab dust collector, 2018 Atlas Copco air compressor, Southworth scissor lift, Gannomat, Maggi and Omal boring machines, clamp-together ducting, quick-fit air line and much more! Assets Moved to Tracy, CA for the convenience of the buyer.

-

Pick Up Location

Tracy, CA

-

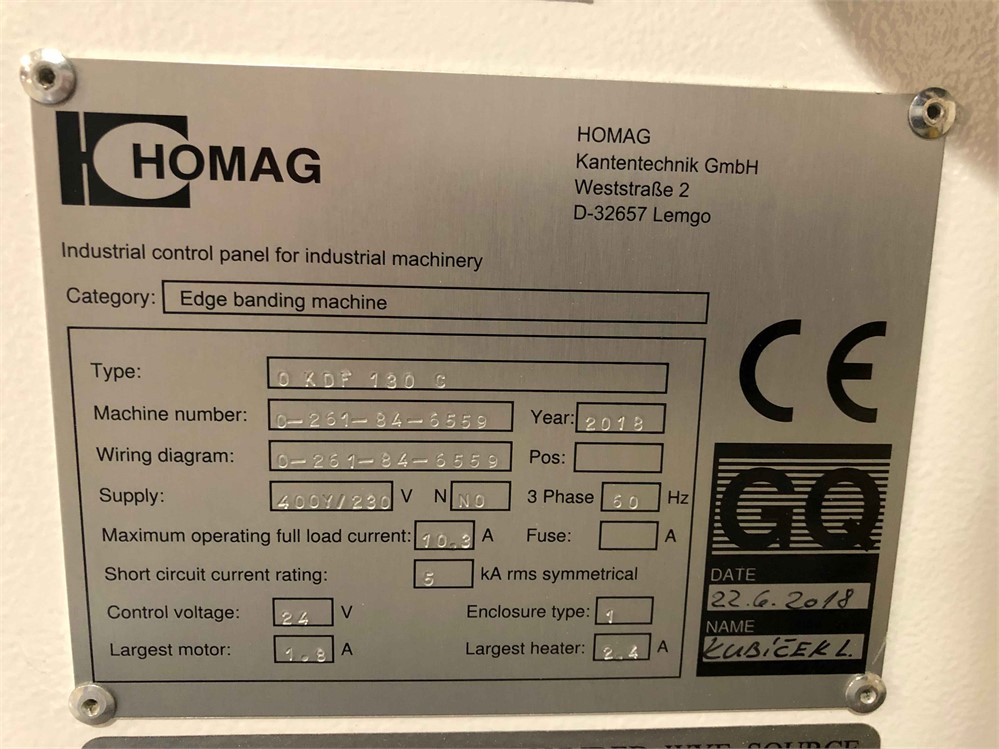

Make

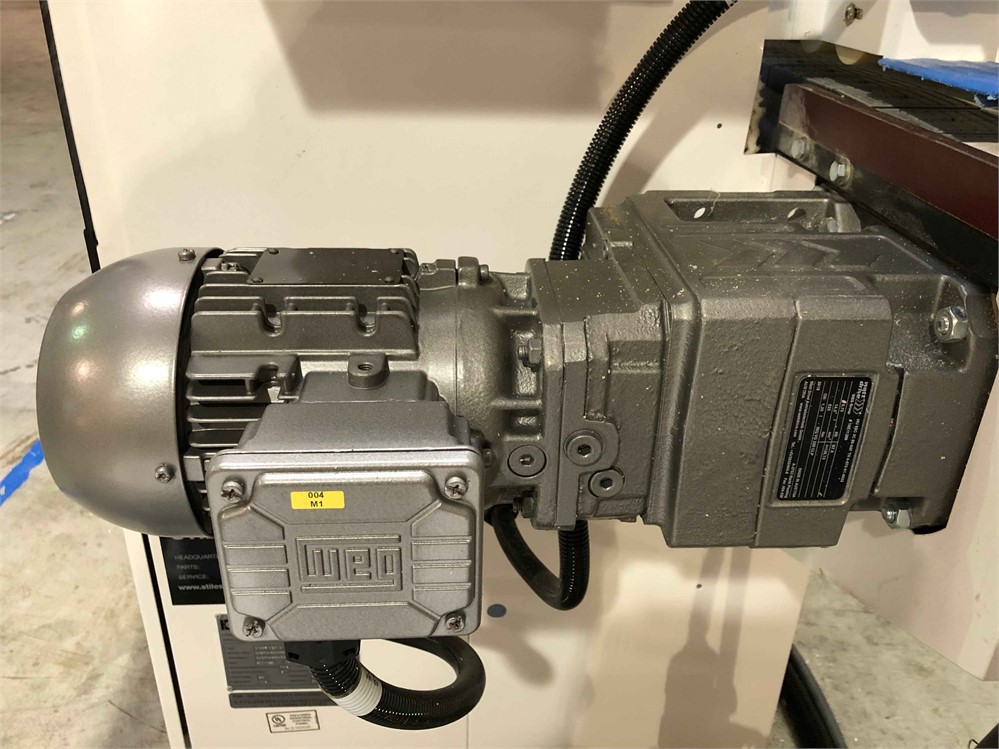

Homag

-

Model

Ambition 1130 FC (KDF-130C)

-

Serial Number

0-261-84-6559

-

Year

2018

-

Phase

3 PHASE

-

Voltage

230 VOLT

-

Load Out Period

May 8, 2020

-

Estimated Dimensions

186" L x 51" W x 61" H

-

Estimated Weight

4,000 Pounds

-

Seller Comment

Seller has forklift available for loading, $250 loading fee, palletizing, crating or packaging at additional cost

-

Load Fee

250

-

page views

5148

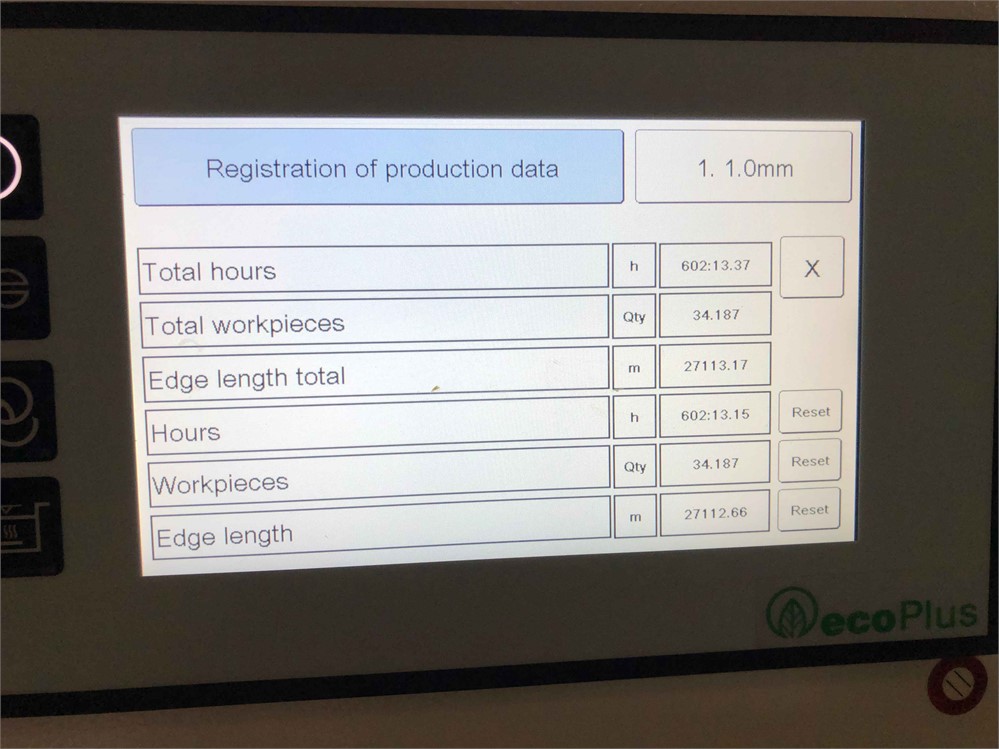

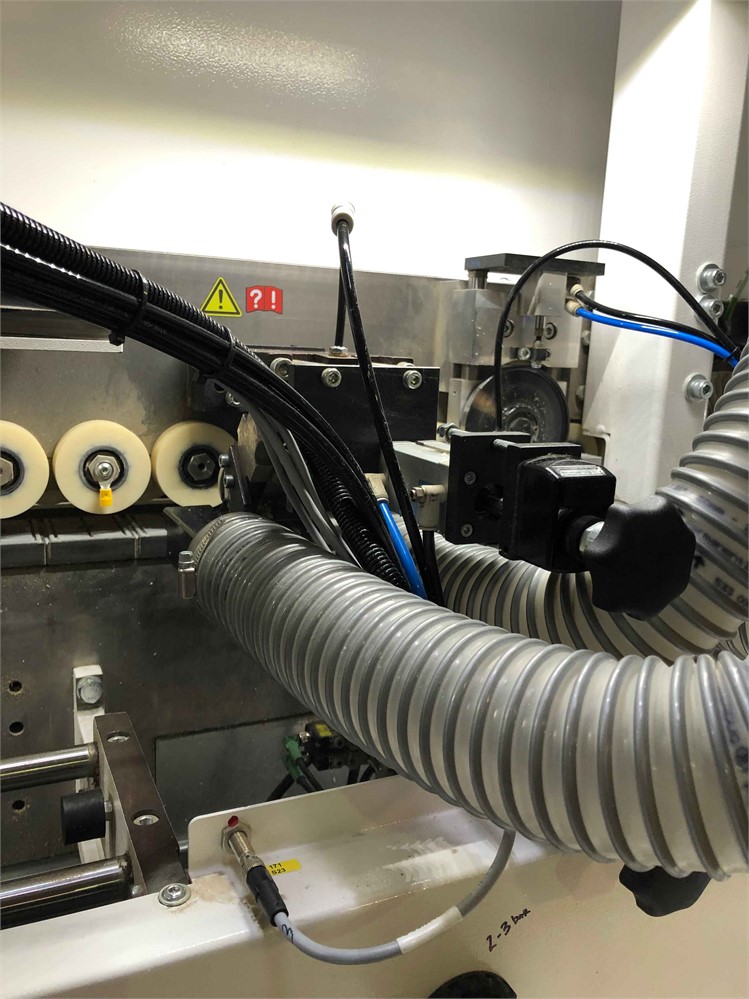

Homag "Ambition 1130 FC" Edgebander

EasyTouch Program Control

Electrical equipment installed according to UL regulations

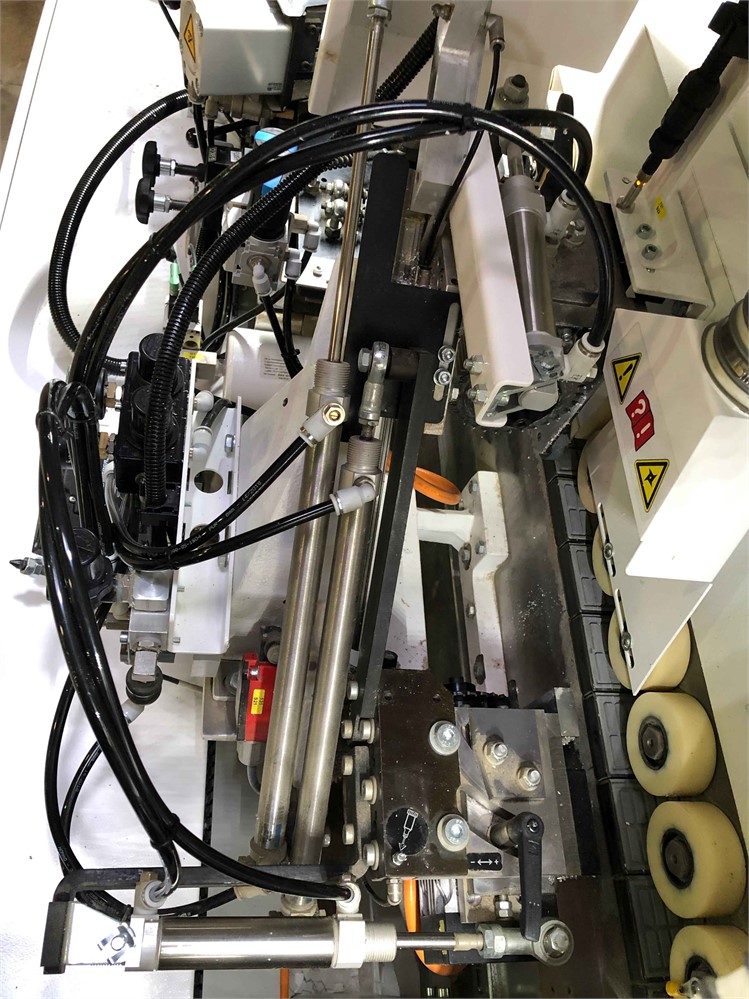

Heavy machine frame construction with heavy-duty feed track design

Control panel located at machine infeed for operator convenience

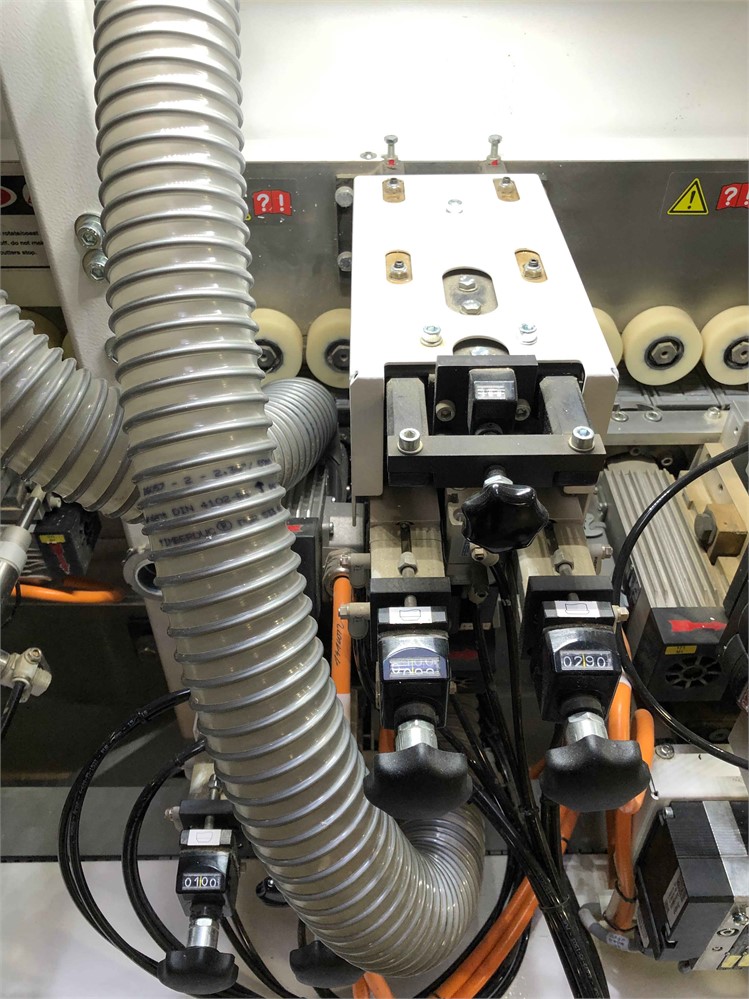

Adjustment on pressure beam and infeed fence via digital height indicator

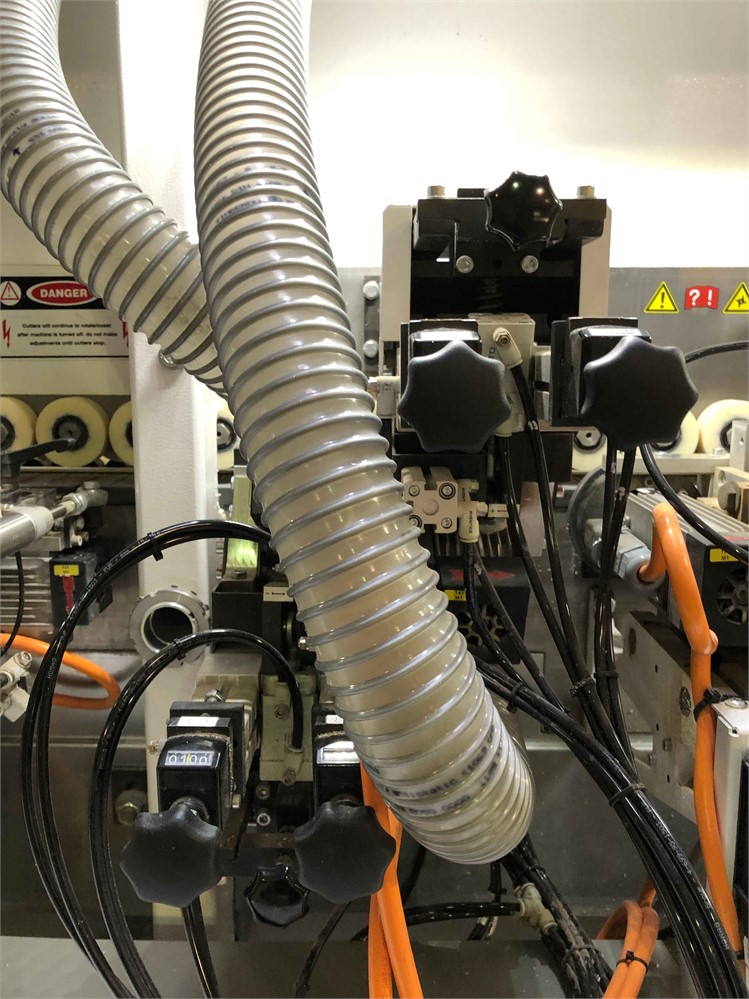

Integrated electronic line control system for increased reliability and diagnostic assistance – no limit switches used for setting operating units

Automatic magazine for strip and coil feeding

Large coil table (800 mm/31.5" diameter) to accommodate large coils of 3 mm PVC

Feed speed: 8 m/min

Workpiece thickness: 40 mm/1.5"

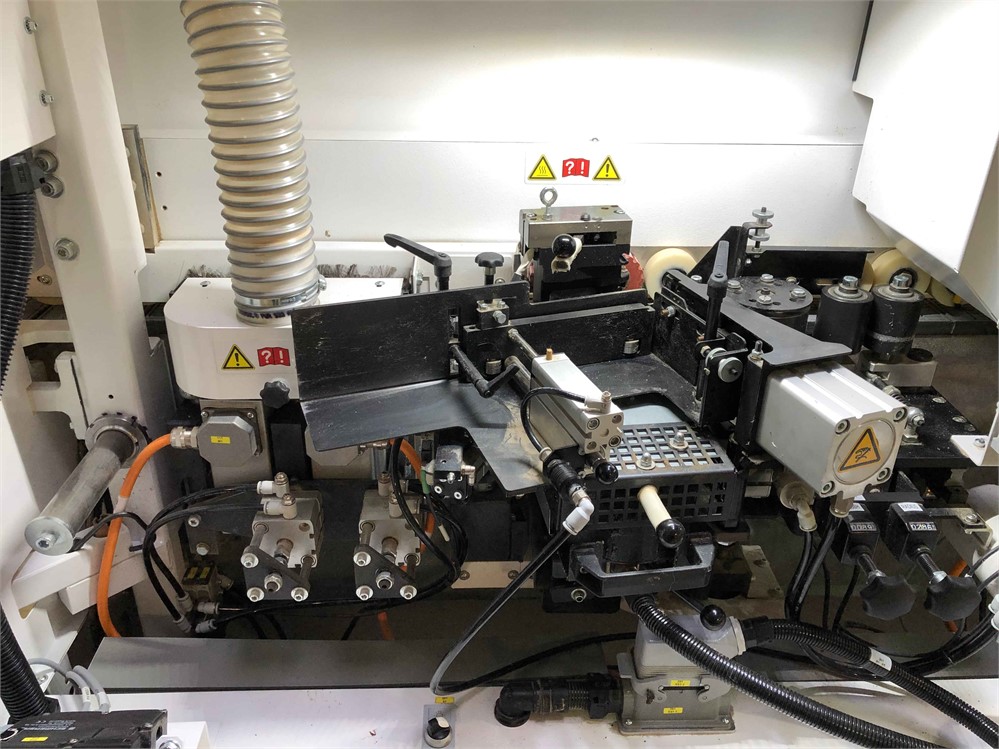

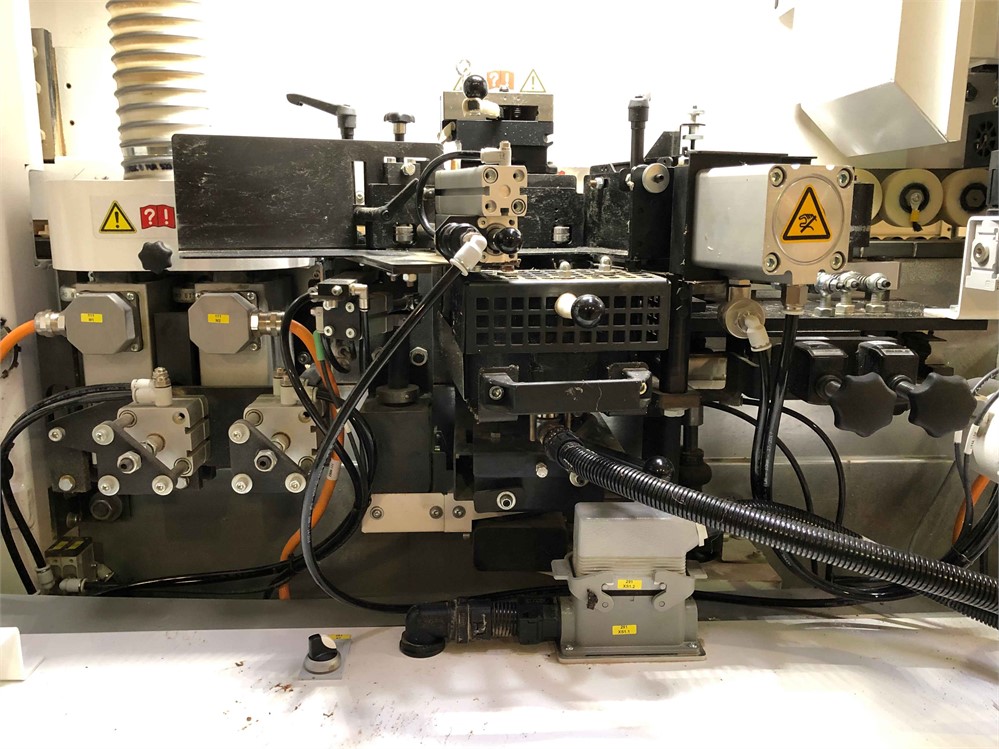

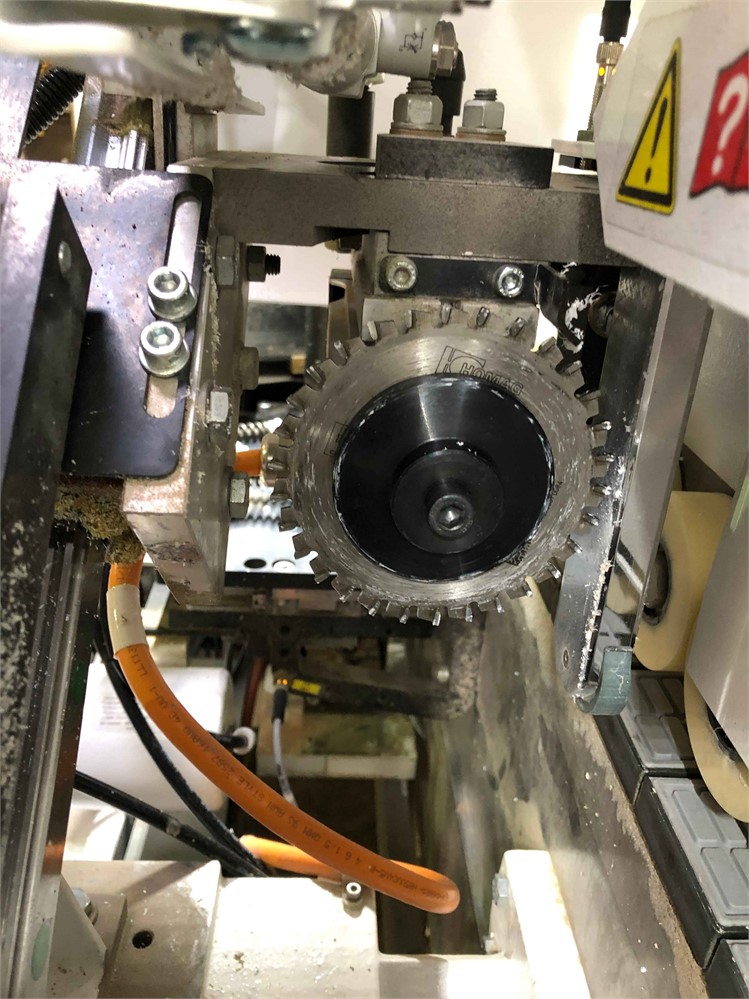

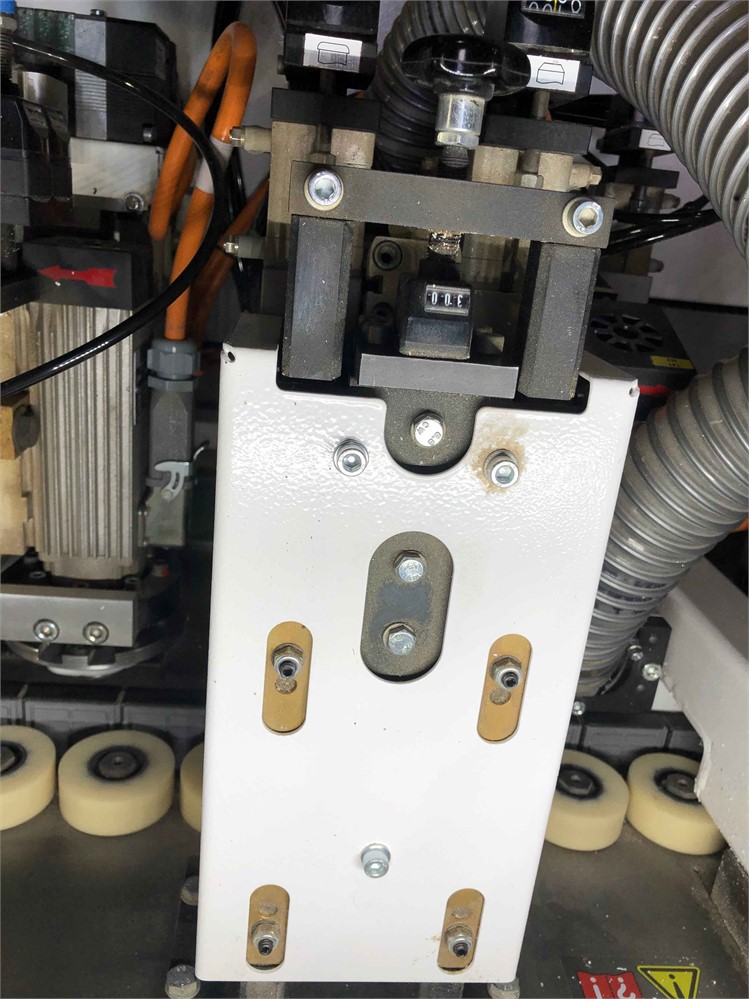

Joint Trimming Unit (premill) for pre-trimming the workpiece edge prior to processing

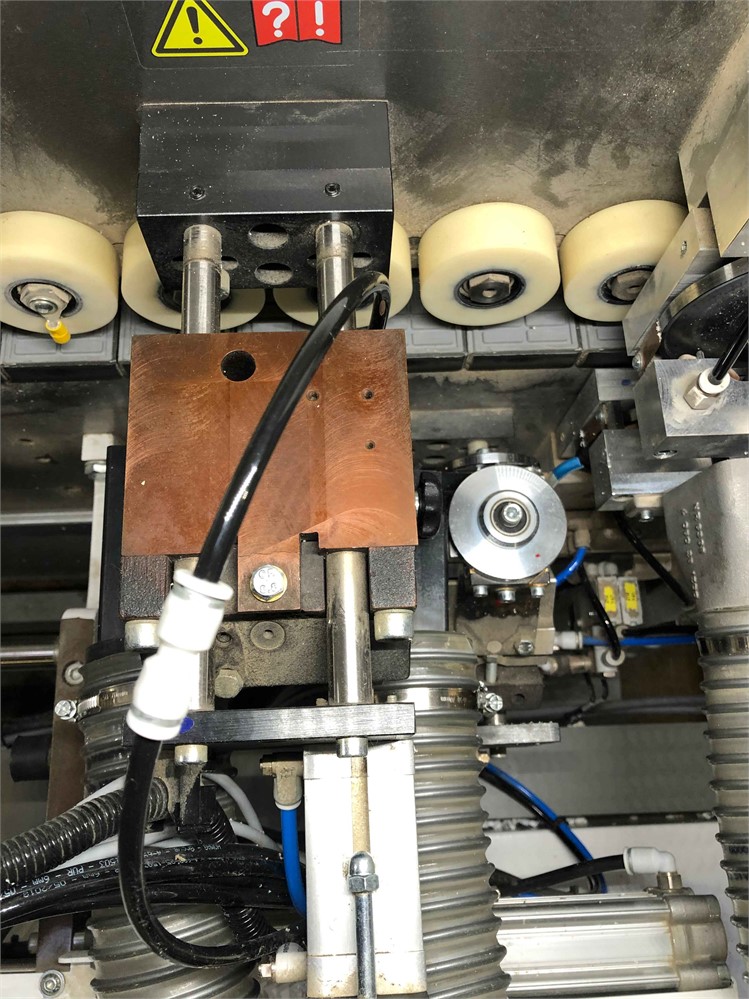

Granulate glue application system

Automatic temperature reduction feature lowers the glue temperature if no workpiece is run over a 15-minute span (reheating accomplished in three minutes)

First pressure roller driven and two (2) idle pressure rollers with 2 position auto setting system with extra-robust pressure zone to accommodate wood strips

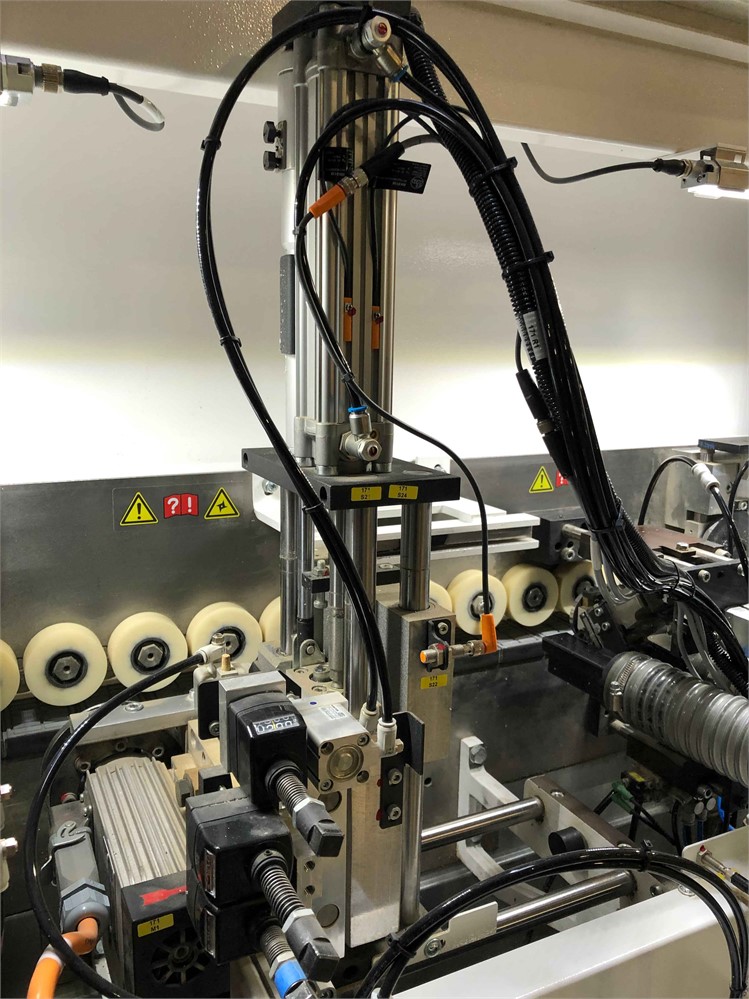

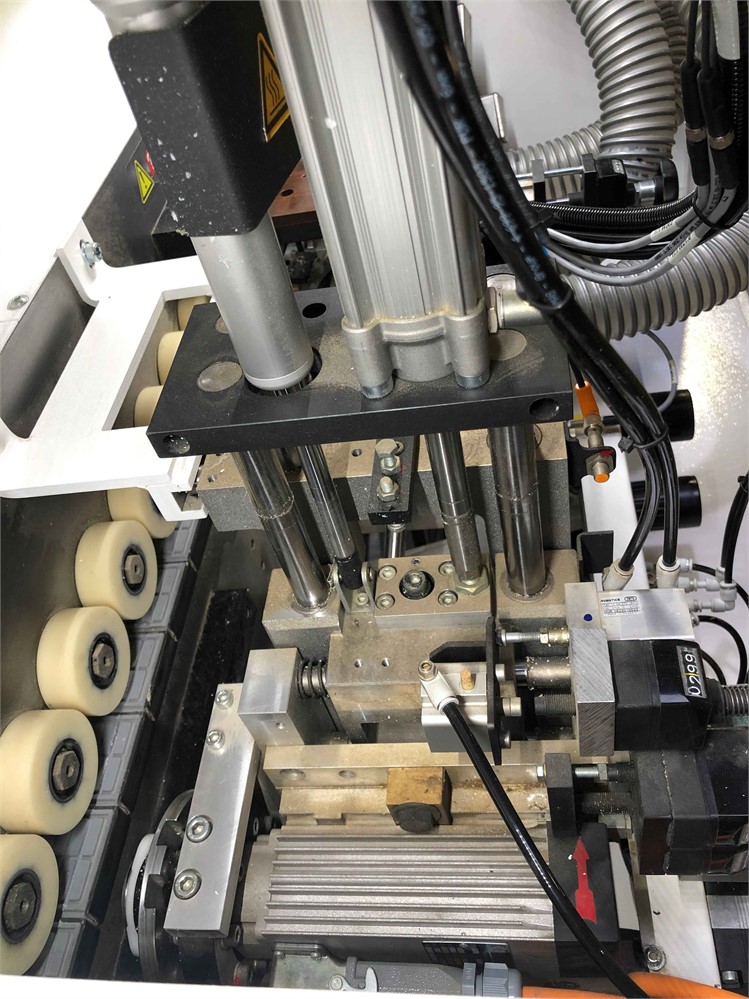

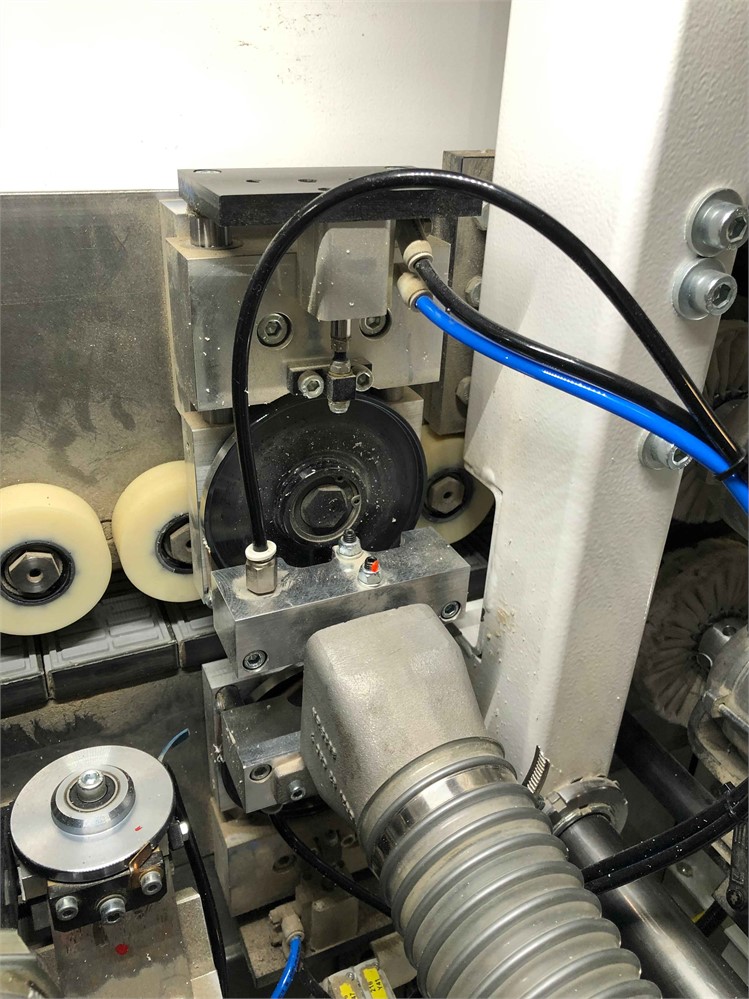

Double-Motor End Trimming Unit with straight and chamfer capability. Chamfer up to 15 degrees. Program-controlled indexing from straight to bevel end trimming

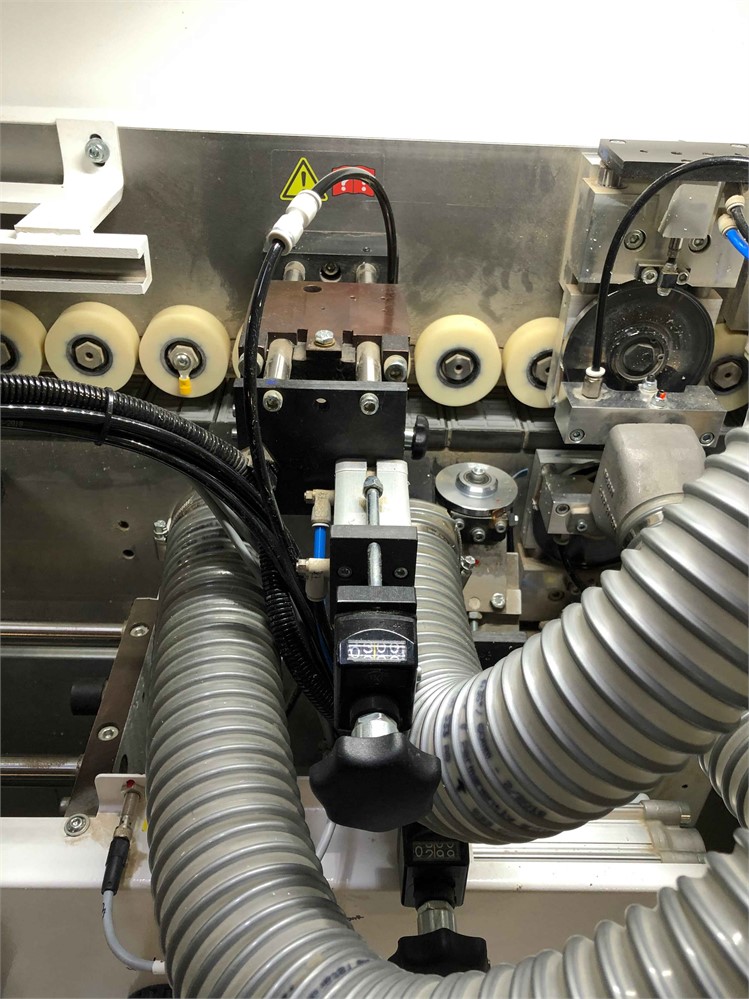

Fine Trimming Unit with program-controlled pneumatic indexing, “quick tilt” feature, and combination radius / straight carbide inserts. Nested top copy system. (R = 3 mm)

Single-Motor Contour Trimming Unit with automatic indexing for thick or thin tape. (R = 3 mm)

Quick-Change Profile Scraping Unit with pneumatic indexing and equipped with two (2) reversible profile knives to remove knife marks from thick PVC, (R = 3 mm) one (1) set of tooling with nested top and bottom copy system (R = 1.3mm)

Finish Scraping Unit

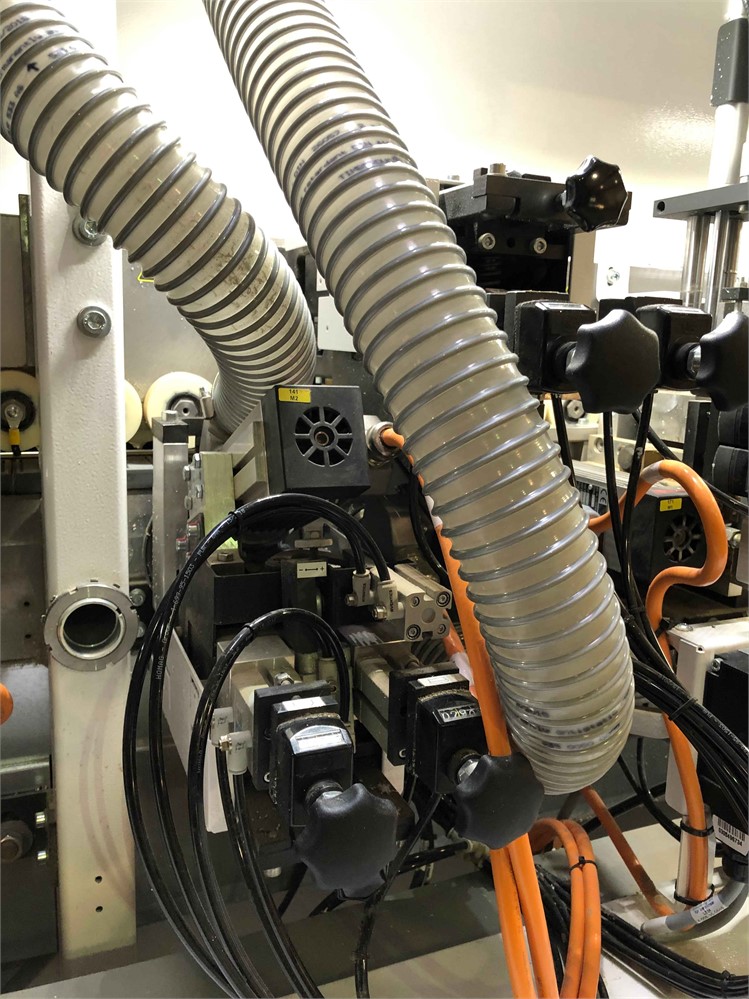

Buffing Unit with two (2) motors, two (2) cloth buffing discs (150 x 20 mm/6" x 0.75" diameter)

Lighted sound enclosure with window

Extendable workpiece support track

Electronic frequency changer for all trimming motors – including electronic motor braking

Isolation transformer with variable infeed voltage for balancing all three (3) phases of incoming power and increasing the lifetime of the machine’s electrical components

Extra set of scrapers

Manuals, tool kit

Dust pipe, flex hose and airline NOT included

The listed specifications & information were taken from the manufacturer’s published information, internet research, or seller’s description.

The specifications & information are assumed to be correct; however, in no way, guaranteed. Bidders are encouraged to inspect the machine, call with questions, or contact the manufacturer for more information.

Please log in to view the bid history

LoginPick-ups are to be scheduled by appointment only. Please contact Sabrina Burns at 209-839-7707 or [email protected] to schedule an appointment. For freight quotes please contact Aaron at All-Ways Trucking at 541-608-6532. Buyer bears all costs to remove and load this lot. Buyer must remove entire lot purchased. Anyone removing non-hand carriable lots must provide MachineryMax, Inc. with a certificate of insurance (COI) before purchased items can be removed.

All buyers agree to make full payment to MachineryMax, Inc. within 48 hours of the online closing date for the auction lots purchased. All invoices over $1,500.00 are to be made by bank wire transfer or cashier’s check payable to MachineryMax, Inc. Purchases under $1,500.00 may be made using Visa MasterCard, or American Express (2% credit card processing fee will be added to the invoice). All payments are to be made in USD currency only. Bidder represents and warrants to MachineryMax, Inc. that such bidder has immediately available funds to fully pay for its successful bids within 48 hours of the online closing date. All payment questions should be directed to Sabrina Burns at 209-839-7707 or [email protected] All buyers agree that there will be a 15% Buyers premium that will be added to the final invoice.