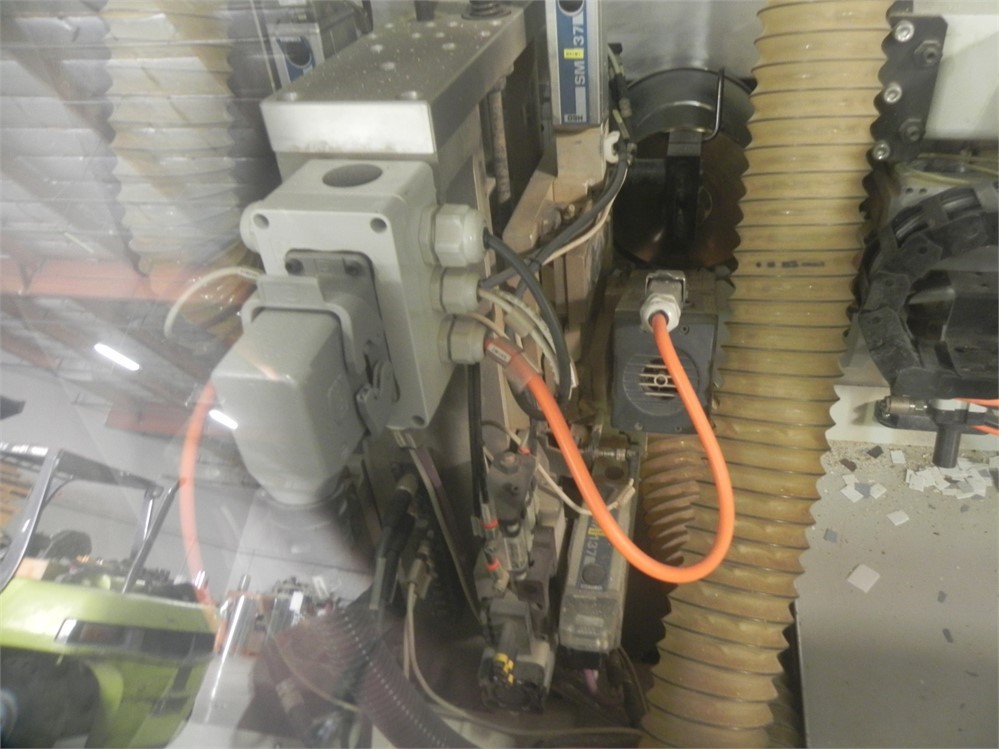

BIESSE "STREAM B1 5.5 SERIES" AUTOMATIC EDGEBANDER, YEAR 2013  Ended

Ended

OVER 20 LOTS UP FOR BID, TRACY CALIFORNIA

- Winning Bid : $11,251.00 USD Sold

- 35 Bid(s)

- High Bidder: B****e

TRACY, CALIFORNIA WAREHOUSE AUCTION 84, OVER 20 LOTS UP FOR AUCTION - Tracy, Ca ( Closed #21206591 )

TRACY CALIFORNIA WAREHOUSE AUCTION 84. ALL ITEMS HAVE BEEN MOVED TO TRACY CALIFORNIA FOR CONVENIENCE OF BUYERS. AUCTION INCLUDES 2015 SAGETECH LIMITED TS75 VERTICAL SAW WITH FESTOOL SAW, KENTWOOD GANG RIP SYSTEM, BIESSE STREAM EDGEBANDER, TIGER STOP SYSTEM, AND MORE. AUCTION CLOSES ONLINE ONLY AT MACHINERYMAX.COM STARTING @ 11:00 AM PACIFIC TME ON WEDNESDAY, APRIL 8TH, 2020. IF YOU HAVE QUESTIONS OR WOULD LIKE TO VIEW MACHINES PRIOR TO AUCTION CLOSE, PLEASE CONTACT 209-832-0100 OR VIA EMAIL AT [email protected]

-

Pick Up Location

1905 N. MACARTHUR DRIVE, SUITE 110, TRACY CALIFORNIA 95376

-

Make

BIESSE

-

Model

BIESSE EDGE STREAM B1

-

Serial Number

61931

-

Year

2013

-

Phase

3 PHASE

-

Voltage

460 VOLT

-

Load Out Period

APRIL 15TH, 2020

-

Estimated Dimensions

EMAIL OR CALL 209-832-0100 OR [email protected]

-

Estimated Weight

APPROXIMATELY 8200 LBS.

-

Seller Comment

-

Load Fee

-

page views

2049

BIESSE MODEL #STREAM B1 HEAVY DUTY AUTOMATIC EDGEBANDER

YEAR 2013 BUILT MACHINE

460 VOLT, 3-PHASE

SERIAL #61931

***SPECS TO FOLLOW:

2013 STREAM B1/5.5 Edgebander

N0000001 SINGLE-SIDED EDGE BANDING MACHINE STREAM B1/5.5

TECHNICAL DATA

Description Um Min Max

Panel overhang (fixed) mm 35

Panel thickness mm 10 60

Chain advance speed meters / min 10 – 25 Variable

Work table height mm 950

Panel working width mm 100 - 3200

Panel length mm 150 - 3200

NOTE : Maximum machine capabilities (work speed, edge thickness, adjusting ranges) are

conditioned by the capabilities of the single units installed.

BASE MACHINE STANDARD EQUIPMENT

Top Belt pressure beam with Double “V” profile

Electronic pressure beam height adjustment

Inverter for track speed adjustment

Separate Inverter on every work unit

PC operator interface; Windows XP

Statistic software with export system on Excel file. Infinite Log file

Base frame dust extraction

INPUT/OUTPUT

Feeder guide adjustable according to the machining edge being used, with mechanical digital display.

BASE

Base made of electro-welded elements stabilised to form a single, monolithic, high-rigidity structure.

It rests on the ground on a suitable number of cross-bars, each of which is fitted with adjustable feet and

set up to be anchored to the floor.

Auxiliary suction and dust collection system along the base, with D.160 suction mouth on one side of the machine.

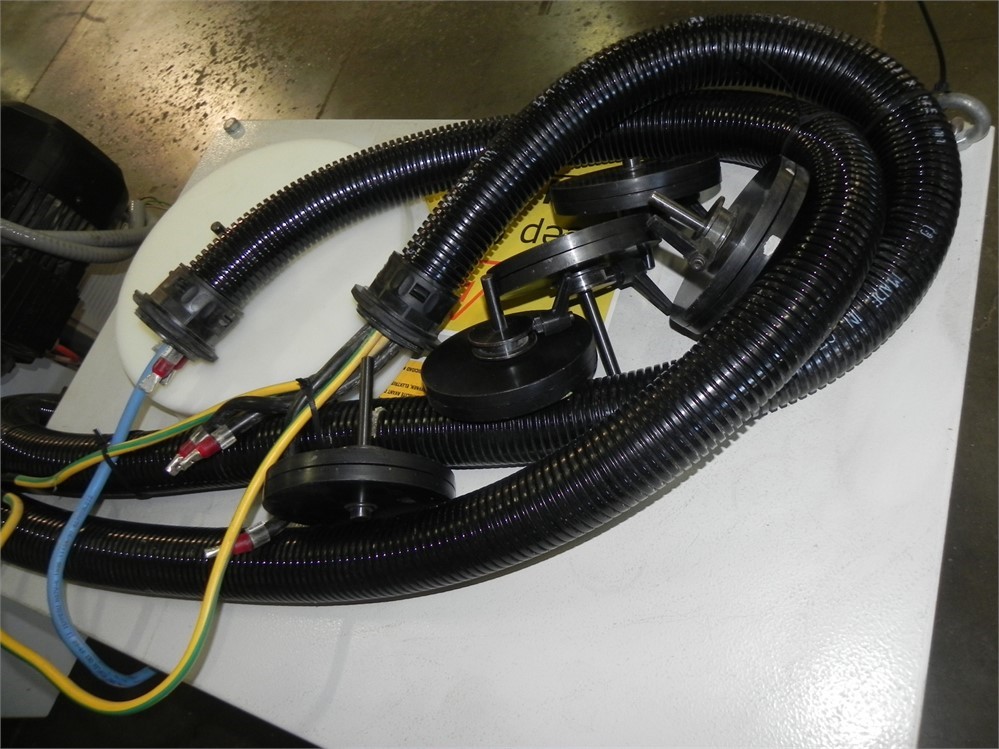

DRIVE CHAIN

The drive chain comprises a high precision, minimum distortion chain (50.8 mm links). Free, straight advance is guaranteed by the presence of guides, which are round on one side and flat on the other, both tempered and

rectified, housing slide blocks made of techno-polymer and self-lubricating material .

The panel rests on high grip, rectified, stain-proof rubber tables.

The speed of the drive chain is continuously adjustable from 10 to 25 m/min. by INVERTER controlled directly from the NC, with rapid braking function.

The drive pinions are made of heat tempered, high-strength steel.

TOP BELT PRESSURE

The top presser comprises a rubber belt with a stain-proof coating. The thrust exercised on the panel is provided by springs housed on technopolymer connecting rods. The whole assembly is fitted on a extruded aluminium structure, whose section guarantees high rigidity .

SOUND-PROOF CABIN FOR EDGEBANDING SECTION

All the units fitted with rotating tools are located inside cabins coated with sound-proofing material.

During machining, the units can be viewed through wide, transparent polycarbonate windows.

If the doors are opened at unauthorised times this will trigger an emergency and shut down the machine.

Internal lighting provided by anti-glare neon lights.

Suction hoods of each unit are connected through pipes to individual exits placed in the upper part of the cabin.

MECHANICAL PANEL SPACER FOR B1

Device allowing manual introduction of panels only when the distance between panels is enough for working.

Distance between panels is set up on NC.

AUTOMATIC TRACK LUBRICATION B1

PANEL PIECE SUPPORT

Side piece support supporting the panels as they pass through the machine.

Fixed supports, nr. 1 manually adjustable roller bar.

PC FLAT SCREEN NUMERICAL CONTROL COLOR GRAPHICS

Multiple axis numerical control with PC interface for management of single edgebanding machines or complete

edgebanding lines.

Main SOFTWARE characteristics:

Windows XP Professional Operating System

SINTRA machine control software, based on Windows XP like interface

Electronic axes positioning (machine set-up)

Electronic feed chain speed adjustment

Electronic pressure height adjustment according to panel thickness

Automatic management of edge banding coils exchange device.

Management of machining list

Automatic management of coil magazine by codes

Cascade type motor start-up

Management of diagnostics

Video capable

CE SAFETY FEATURES

The machine is manufactured to comply with EC safety regulations.

N0000015 NC Y AXIS FOR FEEDER GUIDE

The kit includes motorised movement of the machine feeder guide and relevant NC management

N0000136 SPRAYING LIQUID APPLICATION UNIT

Device for the application of liquid using nozzles located above and below the panel.

It can be used with the following liquid types:

- ïAnti-adhesive liquid

- ïAnti-static liquid

- ïCleaning liquid

Manual adjustment of nozzle direction.

N0001294 ANTIADHESIVE LIQUID

Avoids the adherence of any glue waste on the panel surfaces.

N0000669 PRE-MILLING UNIT RT20

Milling unit comprising two vertical axis motors with timed pneumatic drive. The unit can be adjusted manually according to the panel overhang, by digital position indicator.

Maximum workpiece thickness with standard tool : 40 mm. For panels with thickness up to 60 mm, it is necessary to use diamond tool with height

63 mm, code N0000336.

TECHNICAL DATA

Description Um Min Max

Tool rotation speed RPM 9000

Motor size kW 3,5 + 3,5

Shaft (diameter x length) mm 30 x 50

Tool dimensions (diameter x height x bore) mm 125 x 43 x 30

Pneumatic drive stroke mm 10

2 dust hoods mm 80

Inverter Included

Tools provided DIA included

N0000336 SUPPLEMENT PAIR DIAMOND MILLING CUTTERS FOR H=60 ON RT UNIT

Pair of diamond milling cutters 125x63x30 to replace the standard ones 125x43x30.

N0000469 GLUING UNIT SP20

Gluing unit used to glue:

- ïstraight edges in coils: in melamine resin, ABS, PVC, PP, veneer

- ïedges in strips: solid wood, HPL

Use of EVA-based thermoplastic adhesives.

The glue is spread on the edge of the panel using a knurled roller.

Main characteristics:

- ïHighMelt patented system with separated glue and pot applications.

- ïPatented system for quick frontal extraction of glue pot, by rotating device.

- ïPatented High-Melt pre-melting device

- ïShafts ans reducers for the top handling

- ïPair of infra-red lamps, top and bottom, used to heat the panel

- ïGlue pot and head teflon coated.

- ïGuillotine type batching device for glue roller, accessible from the operator side

- ïCopier to optimize the glue quantity spread on the panel

- ïSensor to detect the glue level inside the bowl

- ïAutomatic start-up of the glue spreader roller on reaching optimum working temperature

- ïAutomatic disabling of the glue spreader roller on stoppage of the machine.

- ïGlue spreader roller rotation speed electronically synchronised with the feed chain speed

- ïGranule tank with vertical magazine fitted directly on the pre-melting device

- ïEdge presence detection device (using photocell)

- ïIndependent edge insertion/clamping device for each position (only with codes N0000682, N0000683, N0000804).

- ïPin rollers driving the wooden strips (up to 20 mm)

- ïStrip magazine (thickness up to 20 mm) with pre-loading side pusher device.

- ïSuction cup strip loading device.

- ïHorizontal edge magazine for one coil

- ïAbility to change edge automatically (NC managed) (only with codes N0000682, N0000683, N0000804).

- ïEnd of roll indicator light, with stoppage of movement if a panel is signalled and there is no edge (only with codes N0000682, N0000683, N0000804).

- ïHorizontal cutter to cut material in rolls: this is suitable for edge materials in: melamine resin, PVC, ABS, PP, veneer up to 3 mm thickness

- ïNC Y axis for presser section: The kit includes motorised edge banding strip presser section drive and relative NC management

The pressing area includes:

- ïNo. 1 presser roller D.150 driven by inverter

- ïNo. 6 idle presser rollers D.65

- ïNr.1 additional panel presser device

TECHNICAL DATA

Description Um Min Max

Edge thickness in malamine and plastic mm 0,3 3

Maximum cutting section cutter mm 135 (3 x 45)*

Wooden edge thickness mm 20

Panel thickness mm 10 60

Edge height mm 15 65

Edge in coils length mm 150

Edge in strips length mm 200

Solid wood length for B1 MDS mm 1950

Glue pot capacity kg 1,3

Tank capacity kg 7

Spreading capacity Kg/h 7

Coil diameter mm 800

*Maximum cutting section is guaranteed on PVC edges, for different edge materials, this value could be lower.

N0000683 6 POSITIONS EDGE MAGAZINE FOR SP10, SP20, SP30, SP40

Six position container for rolls of edge banding strip.

The rolls are supported by a cradle of rollers, so that they do not require any other

locking devices: this makes them extremely quick to replace.

Automatic edge changement, NC managed

Edge banding strip presence detection device (using photocell), also when the one

working is finishing and the other is the same edge type.

Positioning of photocells for edge detecting device and for edge magazine can control a maximum panel length of 2700 mm.

To obtain the control of the edge roll ending on a panel longer than 2700 mm it is necessary to place the edge magazine at a right

distance. The distance (if different from the standard 2700) must be comunicated when ordering the machine.

N0000367 END-TRIMMING UNIT IT90-S

Edge trimming unit complete with 2 motors, for edge banding strips with a thickness of up to 3 mm.

Motors can be inclined on the vertical axis by between 0° and 25° with automatic rotation.

Device to move the trimmer away rapidly during operation.

Micrometer adjustment of side copiers.

Automatic disabling of the unit when motors are stopped.

Central lubrication of slide guides.

Pneumatic drive of two end-trimming units.

TECHNICAL DATA

Description Um Min Max

Speed Rpm 12,000

Motor size kW 0.3 + 0.3

Feed chain speed m/min 28

Edge thickness mm 0.3 3

Panel thickness mm 10 60

Interval between 2 successive panels mm 350

Inverter Included

Minimum panel overhang mm 30

Tools provided Widia included

N0001150 FINE MILLING UNIT RF40

Unit comprising 2 independent motors, which are complete with horizontal and vertical copiers and swings

on slides.

Vertical movement of the top unit associated with the belt presser.

Continuous automatic adjustment of tool position with respect to the material using a DC motor applied

to the group drive.

The position is controlled directly by the machine control system.

In this way it is possible to use tools with a MULTIPROFILE on the unit, allowing the profile/shape to be

changed without having to change the tool.

Automatic pneumatic disabling of the unit from the control panel.

TECHNICAL DATA

Description Um Min Max

Speed Rpm 12.000

Motor size kW 0,65 + 0,65

Panel thickness mm 10 60

Shaft (diameter x length) mm 16 x 20

Inverter Included

Tools provided Yes, multi-profile widia cutter Bevel 25°,

N0001156 FINE MILLING UNIT MOTORS 2 KW RF10

N0001178 PAIR OF WIDIA CUTTERS FOR RF30/RF40 BEVEL 25° - R=1/2/3

N0001004 GLUE SCRAPER RC20

It allows to remove any glue excess from the flat surfaces of the panel close to the edges.

The unit is equipped with 3+3 vertical copiers with bearings .

Equipped with suction hoods.

Complete with spraying device for tool cleaning.

Automatic unit disabling.

N0000171 SUPERIMPOSED OSCILLATING BUFFERS UNIT SZ30

The unit includes 2 motors.

The buffer's position is adjusted by an exclusive 3D recording device by means of a ball joint.

The motors are fitted on a single column and are axially offset from one another to allow pneumatic insertion

and removal of the brushes and the pneumatic swing motion that optimises wear on the brushes themselves.

Vertical movement of the top motor is coupled to the presser to provide automatic adjustment according to the

thickness of the panel.

The unit is supplied complete with fabric brushes.

Automatic disabling of the unit when motors are stopped.

TECHNICAL DATA

Description Um Min Max

Brush rotation speed Rpm 1,400

Motor size Kw 0,37 + 0,37

Shaft (diameter x length) mm 20 x 40

Brush dimensions (diameter x width) mm 150 x 40

N0000300 AIR CONDITIONING SYSTEM FOR B1

N0000225 VOLTAGE OTHER THAN 380V B1

The listed specifications & information were taken from the manufacturer’s published information, internet research, or seller’s description.

The specifications & information are assumed to be correct; however, in no way, guaranteed. Bidders are encouraged to inspect the machine, call with questions, or contact the manufacturer for more information.

Please log in to view the bid history

LoginLOADING FEES WILL BE ADDED TO EACH LINE ITEM SO PLEASE CHECK LOAD FEES ASSOCIATED WITH ITEMS THAT YOU ARE BIDDING ON. LOAD FEES ARE FOR LOADING ONTO FLAT BED TRUCK OR TRAILER ONLY.

PAYMENT IS DUE WITHIN 24 HOURS OF AUCTION CLOSE TIME. CREDIT CARD WILL BE ACCEPTED FOR PAYMENT FOR INVOICES UNDER $2000.00 HOWEVER A 2% PROCESSING FEE WILL BE ADDED TO THOSE INVOICES PAID VIA CREDIT CARD. ALL INVOICES OVER $2000 REQUIRE WIRE TRANSFER, CASHIERS CHECK, CASH, OR APPROVED COMPANY CHECK.

PLEASE CONTACT SABRINA @ 209-832-0100 WITH ADDITIONAL PAYMENT QUESTIONS.