SCMI "Olympic K800 E" Edgebander  Ended

Ended

Assets No Longer Required - La Verne, CA

- Winning Bid : $4,600.00 USD Sold

- 55 Bid(s)

- High Bidder: j****z

Expression in Wood - Assets No Longer Required - La Verne, CA ( Closed #20814837 )

Very-clean SCM K800E edgebander, and SCM Compact XL moulder

-

Pick Up Location

1738 Brackett St. La Verne, CA 91750

-

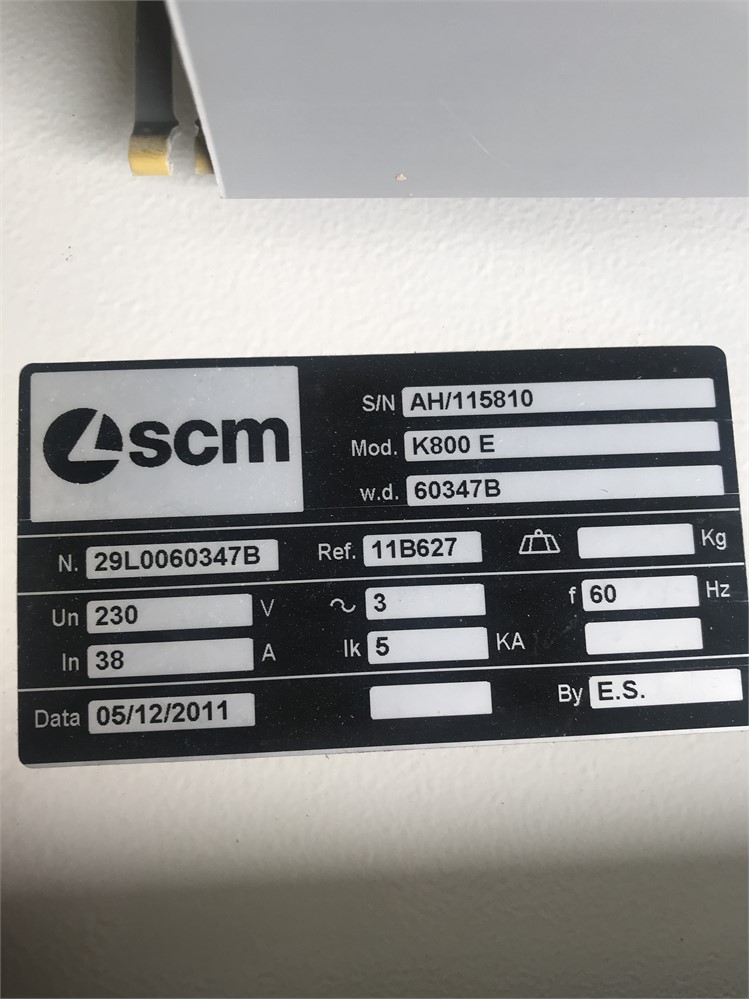

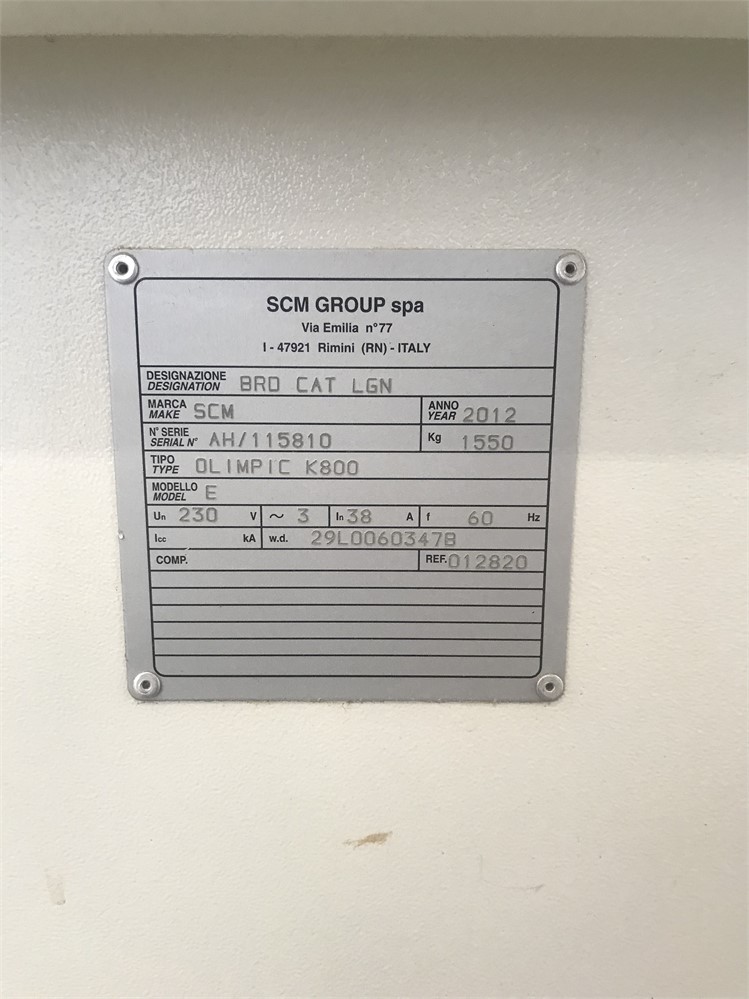

Make

SCMI

-

Model

Olympic K800E

-

Serial Number

AH/115810

-

Year

2012

-

Phase

3 PHASE

-

Voltage

230 VOLT

-

Load Out Period

March 6, 2020

-

Estimated Dimensions

152" L x 36" W x 65" H

-

Estimated Weight

3,410 Pounds

-

Seller Comment

This item requires a rigger, see shipping section for details. Rigger estimates $500 to load. Palletizing, crating or packaging at additional cost.

-

Load Fee

-

page views

2948

Automatic single sided edgebander designed to be used for edgebanding straight vertical profiles with coiled material (veneer and PVC) and with strips (high-pressure laminate and solid wood) with a maximum thickness of 8mm.

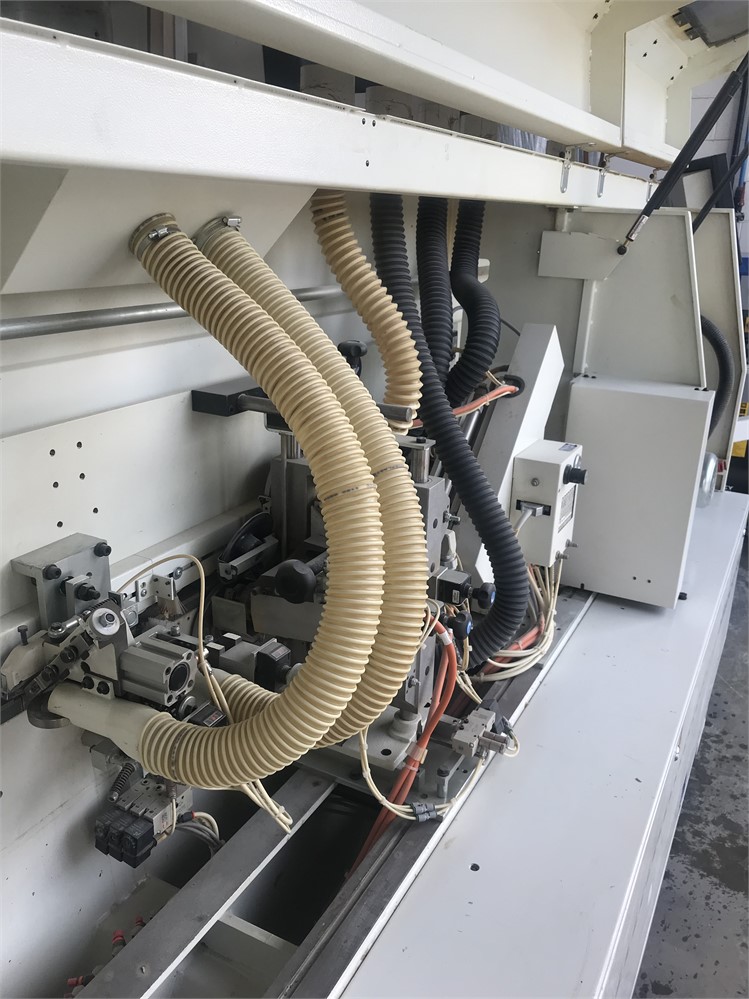

MACHINE BASE

The machine base is a rigid, ribbed steel structure and is designed to provide maximum support for

the working units. The ribs provide stability and, at the same time, provide openings in the base to facilitate removal of the chips/dust.

CAPACITIES AND SPEED

Edgebanding thickness: .4mm

8mm (.016-5/16”)

Guillotine capacity: 3mm

Feed speed: 36/52ft/min.

Panel height: 3/8” min –

2 3/8” max Minimum panel length: 5 1/2”

Minimum panel width: 2”

Minimum distance between panels: 24”

STARTOUCH CONTROLLER

The K 800 comes equipped with the new "Startouch" controller. This controller features a 12" touch

screen display. Capable of storing 100 programs, 6 at the touch of a single key. Color graphic display of all the working units. Tracks production information, diagnostic information and monitors maintenance schedules. Choose mm's or inches, as well as 5

different languages. Swivels 270 degrees and tilts for easy access.

ACOUSTICAL SOUND ENCLOSURE

Machine comes standard with an acoustical sound enclosure that reduces the noise leveland covers the entire machine.

K 800E TOP PRESSURE BEAM

All operating units raise and lower simultaneously when the pressure beam is adjusted. No adjustment is required for the glue roller when changing panel thickness. The pressure beam has two rows of staggered pressure rollers with steel bearings.

The height of the pressure beam is displayed with a mechanical digital readout.

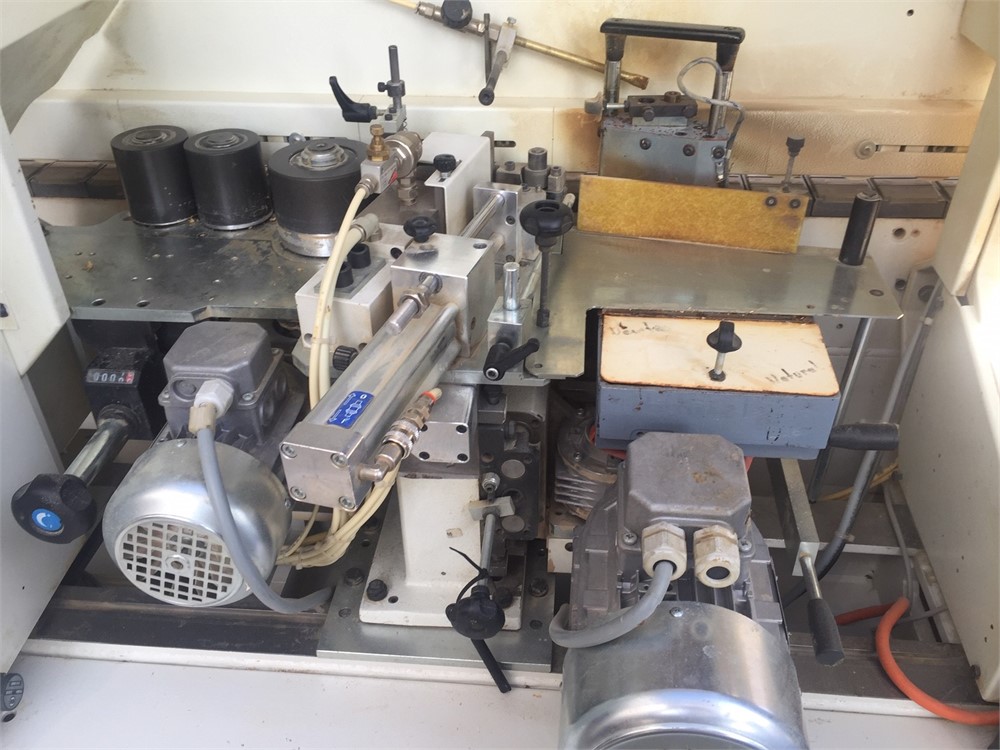

GLUE STATION

Teflon coated glue pot to facilitate glue changeover.

Warm up time is approximately eight to ten minutes.

The unit is also equipped with a quick disconnect

plug for changing from one pot to another, change

out time is less then a minute. An automatic

temperature kickdown feature extends glue life and

reduces glue scorching.

Extra glue pot included, two (2) total.

PRESSURE SECTION

There are a total of three pressure rollers for pressing the banding to the workpiece edge. The first roller is

powered and applies pressure pneumatically. It is also Teflon coated to prevent the banding material from slipping. The last two idle rollers have opposing one-degree tilt to provide extra pressure along the top and bottom edge. The unit comes standard with a mechanical digital readout for the positioning. The pressure section is also equipped with pneumatic jumping so the unit activates exactly on the leading/trailing edges.

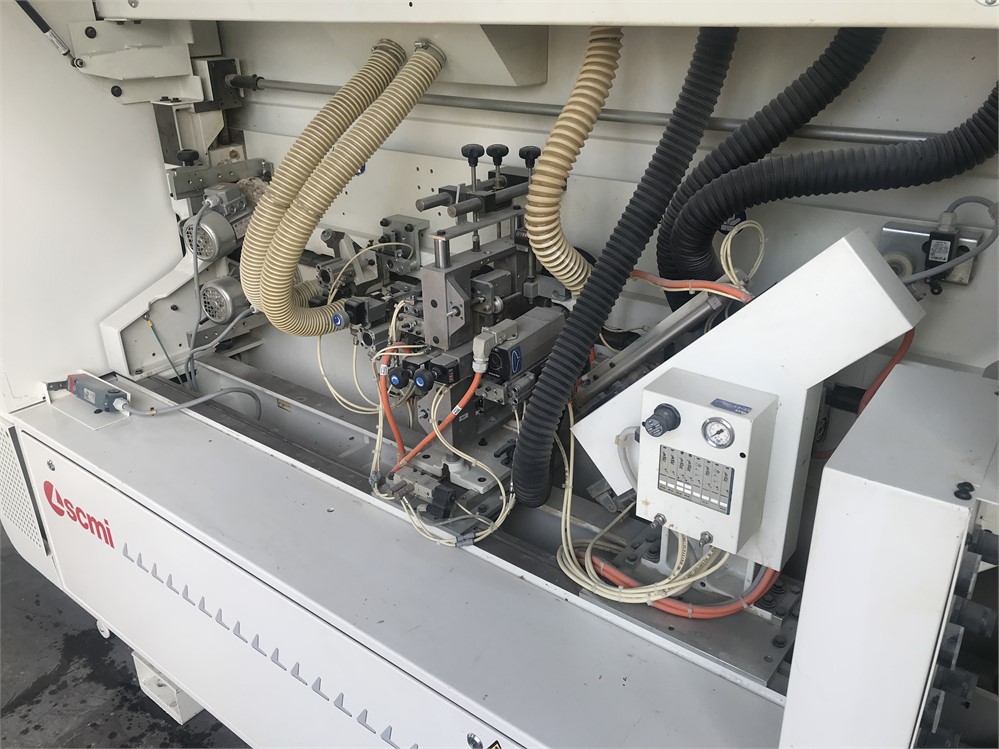

“K-SEL” END TRIMMING STATION

This unit is composed of two independent .50 hp motors mounted on THK guides. End trim utilizes a draw cut system for reduced blade projection on thick panels. The unit comes standard with automatic tilting of the unit from the control panel with two preset positions, and dust extraction.

K 800E EDGE TRIMMING STATION:

The trimmers have1.0 hp operating at 12,000 rpm.,

large diameter vertical and horizontal copying devices with precise digital indicators. The unit

mechanical digital readouts for all the

adjustments. Two position pneumatics is standard, it allows the operator to go from thick pvc to thin pvc through the controller.

RAS/1000” PROFILE SCRAPING STATION

The profile scraping station designed to remove knife marks from thick PVC. The unit is equipped with pneumatic in/out positioning through the controller. It

has a large diameter horizontal copy wheel and side copy wheel device with digital indicators. The unit comes standard with 3mm knives.

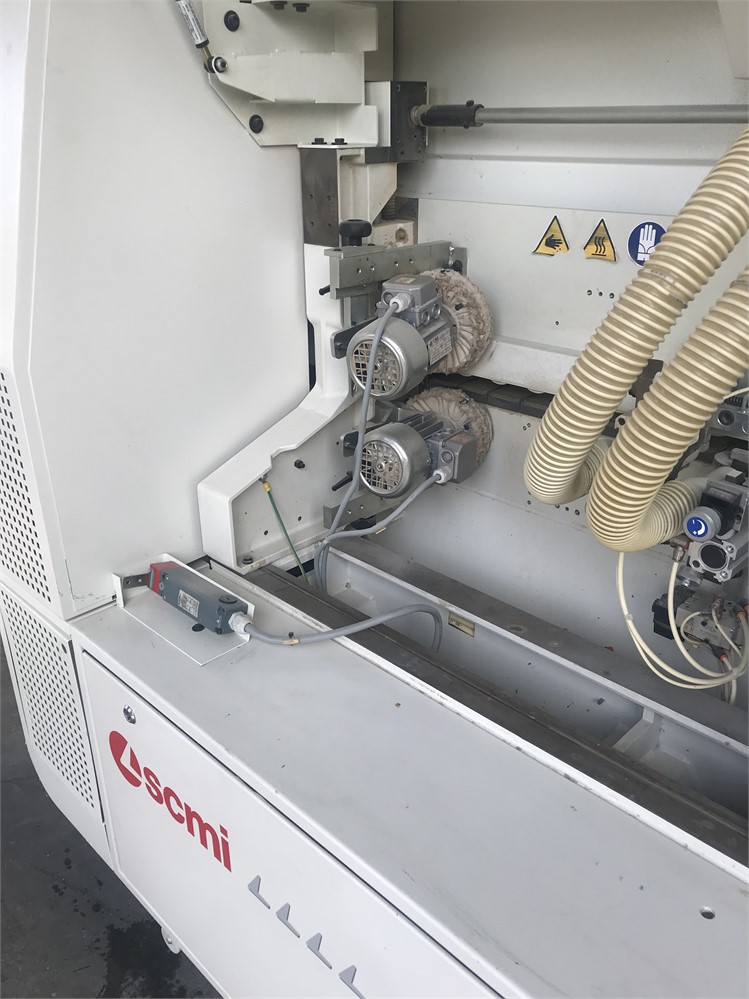

SPN BUFFING UNIT

The buffing unit has two .25 hp motors. The unit cleans and polishes the panel edge. The unit

is equipped with extra wide cotton cloth buffing wheels that break the edge and prevent rounding of the panel’s leading edge.

TECHNICAL SPECIFICATIONS

Glue Pot Unit: Heating TimeApprox. 8-10 min.

Glue Capacity3.3 lbs.

End Cutting Trimming Station:Horsepower.50 HP ea. RPM 12,000 RPM Tilting 0-15 degrees

Blade Diameter/Bore 100mm/32mm

Tiltable Edge Trimming Unit:

Horsepower1.0 HP ea. RPM 12,000 RPM Tilting 0-15 degrees

Cutting Tools 70x20x16mm

3mm radius knives

Scraping Unit: Knife Radius 3mm inserts

Buffing Unit:: Horsepower .25 HP RPM 3,000 RPM

Diameter/Bore

152mm/17mm

Feed Motor Horsepower 2.5 HP

Feed Speed 36/ 52 FPM

Frequency Converter

200 Hz

Pneumatic Operating Pressure

90 PSI

The listed specifications & information were taken from the manufacturer’s published information, internet research, or seller’s description.

The specifications & information are assumed to be correct; however, in no way, guaranteed. Bidders are encouraged to inspect the machine, call with questions, or contact the manufacturer for more information.

Please log in to view the bid history

LoginPick-ups are to be scheduled by appointment only. Please contact Sabrina Burns at 209-839-7707 or [email protected] to schedule an appointment. For freight quotes please contact Aaron at All-Ways Trucking at 541-608-6532. Buyer bears all costs to remove and load this lot. Buyer must remove entire lot purchased. Anyone removing non-hand carriable lots must provide MachineryMax, Inc. with a certificate of insurance (COI) before purchased items can be removed. For machinery moving/rigging, please contact Marco Salinas at West Coast Machinery Movers, 323-588-3533, [email protected].

All buyers agree to make full payment to MachineryMax, Inc. within 48 hours of the online closing date for the auction lots purchased. All invoices over $1,500.00 are to be made by bank wire transfer or cashier’s check payable to MachineryMax, Inc. Purchases under $1,500.00 may be made using Visa MasterCard, or American Express (2% credit card processing fee will be added to the invoice). All payments are to be made in USD currency only. Bidder represents and warrants to MachineryMax, Inc. that such bidder has immediately available funds to fully pay for its successful bids within 48 hours of the online closing date. All payment questions should be directed to Sabrina Burns at 209-839-7707 or [email protected] All buyers agree that there will be a 15% Buyers premium that will be added to the final invoice.