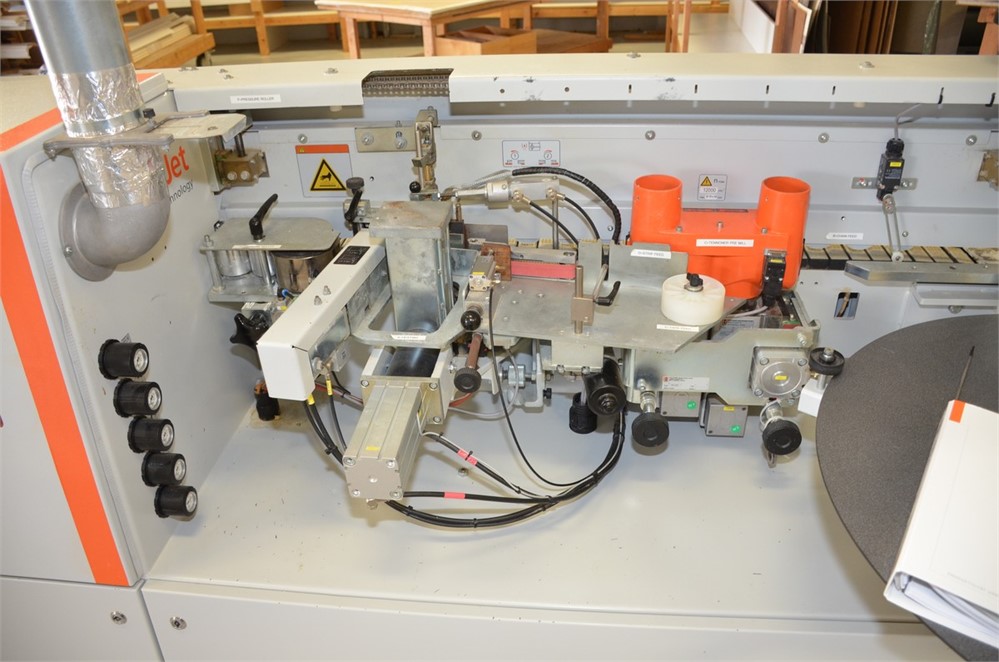

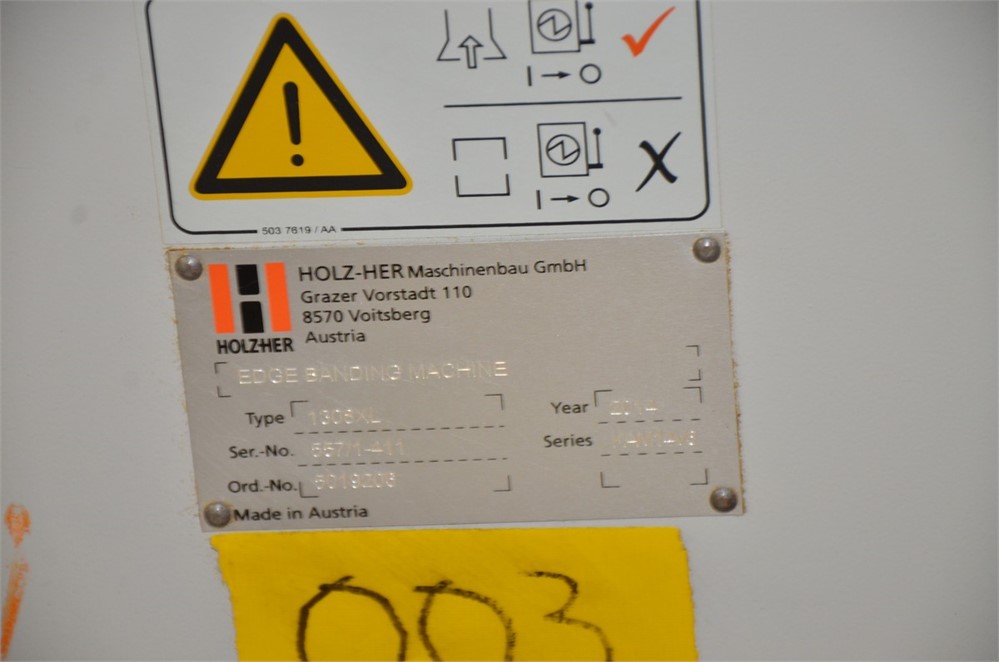

Holz-her "Auriga 1308 XL" Edgebander w/ Pre-Mill (2014)  Ended

Ended

Able Closets in Stuart, FL - Complete Facility being offered!

- Winning Bid : $24,650.00 USD Sold

- 74 Bid(s)

- High Bidder: k****0

Able Closets - Stuart, FL ( Closed #17134423 )

Complete facility has closed and all assets and inventory being offered. Some of the highlight are: Biesse Rover B CNC, Holzher Auriga 1308XL Edgebander (2014), Nederman NFP-S1000 Dust Collector (2015), Atlas Copco GX11FF Air compressor, dryer & tank combo (2014), GMC Cargo Van (2014)...and much more. Over 75 lots! Rigger Info: Marvin Baltodano Sr. Pedowitz Machinery Movers 1550 NW 24th Avenue Pompano Beach, FL 33069 Ph: (305) 836-9945 Cell: (786) 236-1482 [email protected]

-

Pick Up Location

Stuart, FL

-

Make

Holz-her

-

Model

"Auriga 1308 XL" Edgebander w/ Pre-Mill

-

Serial Number

557/1-411

-

Year

2014

-

Phase

3 PHASE

-

Voltage

220 VOLT

-

Load Out Period

08/09/2019

-

Estimated Dimensions

200" x 48" x 65"

-

Estimated Weight

4,000#

-

Seller Comment

A rigger is required for this lot. CONTACT ALWAYS TRUCKING for shipping quote 541-608-6532

-

page views

5991

See Video!!

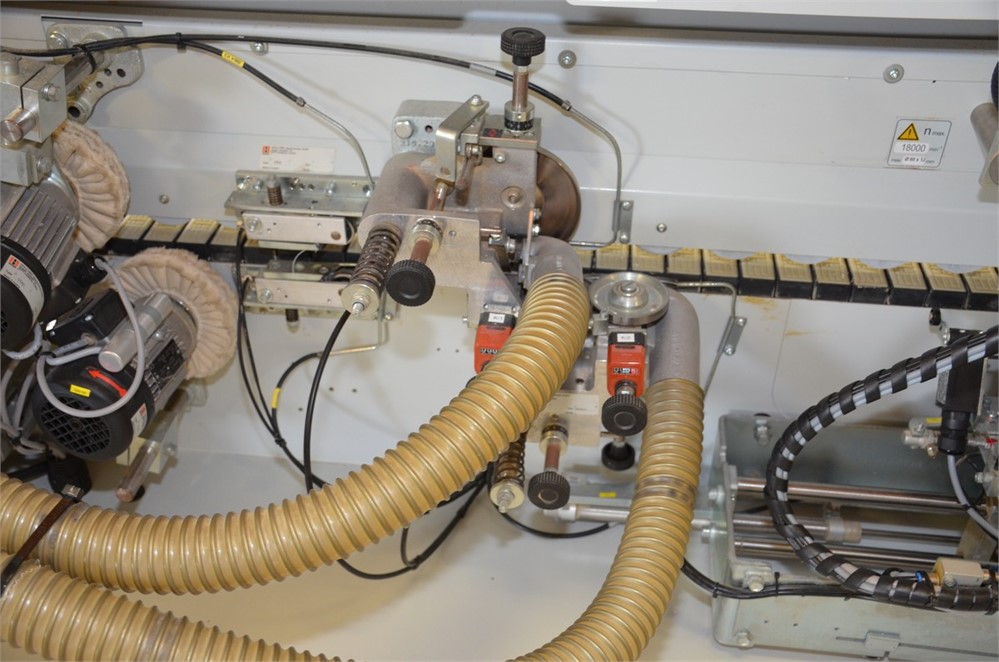

Edge thickness min./max. 0.4 - 3 mm (0.02 - 0.12"), coiled material, optional with flush cutters max. 6 mm (0.24"); Panel thickness 6 - 60 mm (0.236 - 2.362"), workpiece width min. of 65 mm (2.559"); workpiece length min. 160 mm (6.299"); Feed speed 10 MPM (33 FPM).

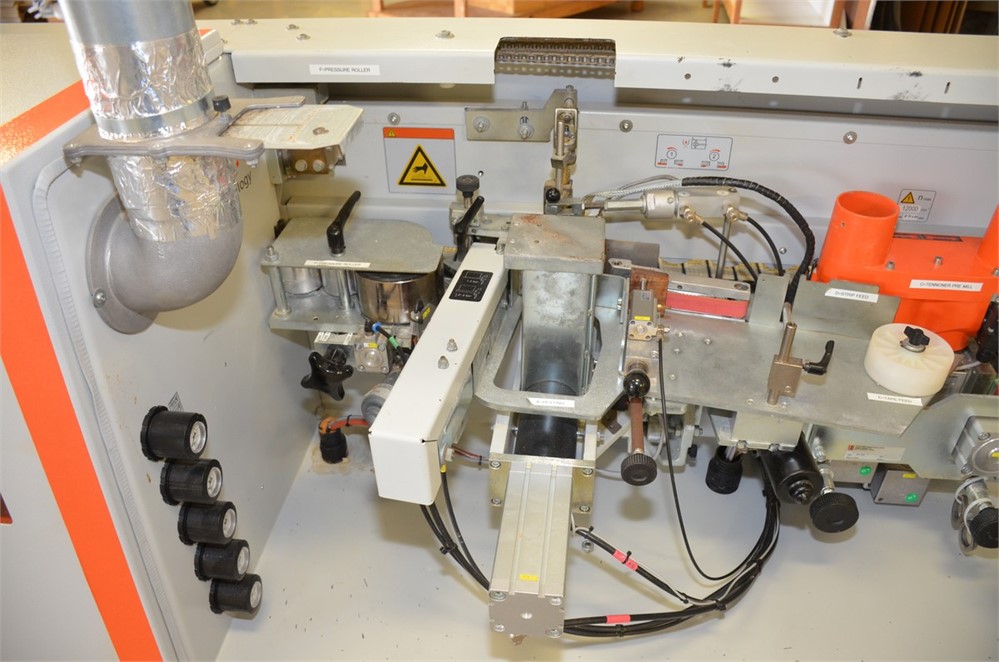

Pre-Milling Station "FG201": 2 x 1.2 KW (1.6 HP) - 12,000 RPM motors; Quick-Lock adjustable in-feed fence with digital indicator.

Edge Magazine "1903": for coil and strip processing, utilizing motion detector to ensure accurate, trouble-free positioning of edge material; exclusive "Tractor-Belt feed System", edge guide equipped with automatic guillotine lock-out for safety, 3° approach angle allows easy feeding of solid wood edges.

Pressure Section "1912": with (1) large driven (synchronized with feed-speed) roller and (2) cantered idle rollers, adjustable by hand wheel and scale.

GLUING SYSTEM "GJ 301" (Glue Jet)... Processes in Cartridge. Upper glue line height positioning is set automatically with hold-down beam setting. Heat-up time to ready stage takes only 2 - 3 minutes!

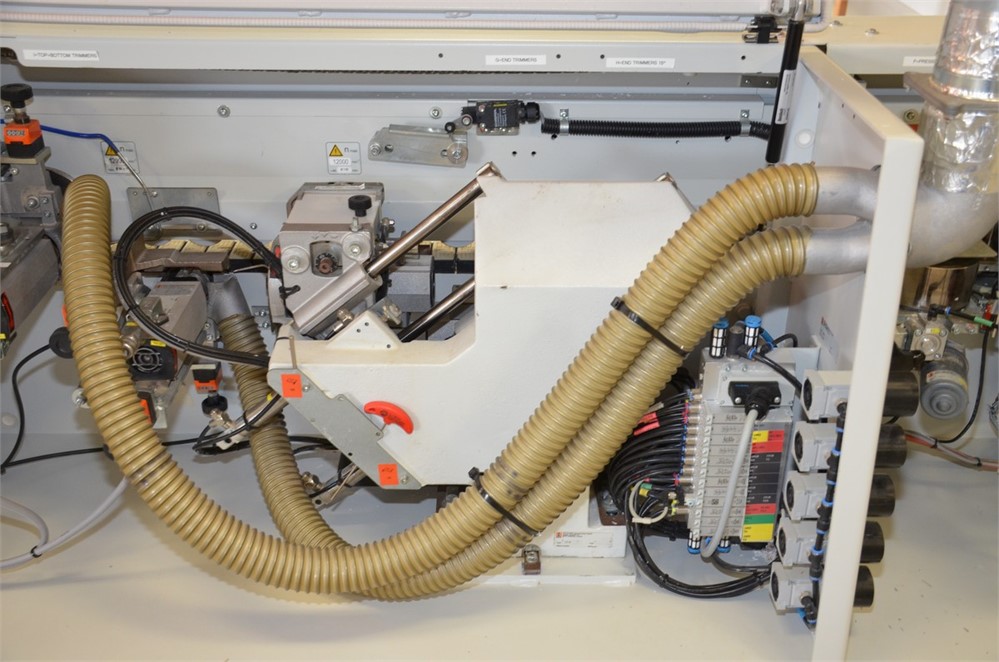

End Trimming Unit "1918": Front & rear 2 x 0.45 KW (0.6 HP) - 9,000 RPM motor each, uni-point swivel-axis for no re-indexing when changing from flush to bevel end trim (0° - 10° bevel),"PCS" programmable pneumatic change-over from flush to bevel.

Flush/Bevel/Radius Combination Trimming Unit: Flush 6 mm, radius 3 mm trimming, servo controlled, 2 @ servo motors (1) for horizontal copy wheel & (1) for tool spindle position) programmable top & bottom unit 2 x 0.65 KW (0.88 HP) - 12,000 RPM each motor.

Corner Rounding Unit "KPL5": (1) Motor 0.22 KW (0.30 HP) - 9000 RPM for up to 3 mm edge thickness and work-piece thickness min./max. 12 - 60 mm (0.473 - 2.362"), max. feed speed 10 MPM (33 FMP).

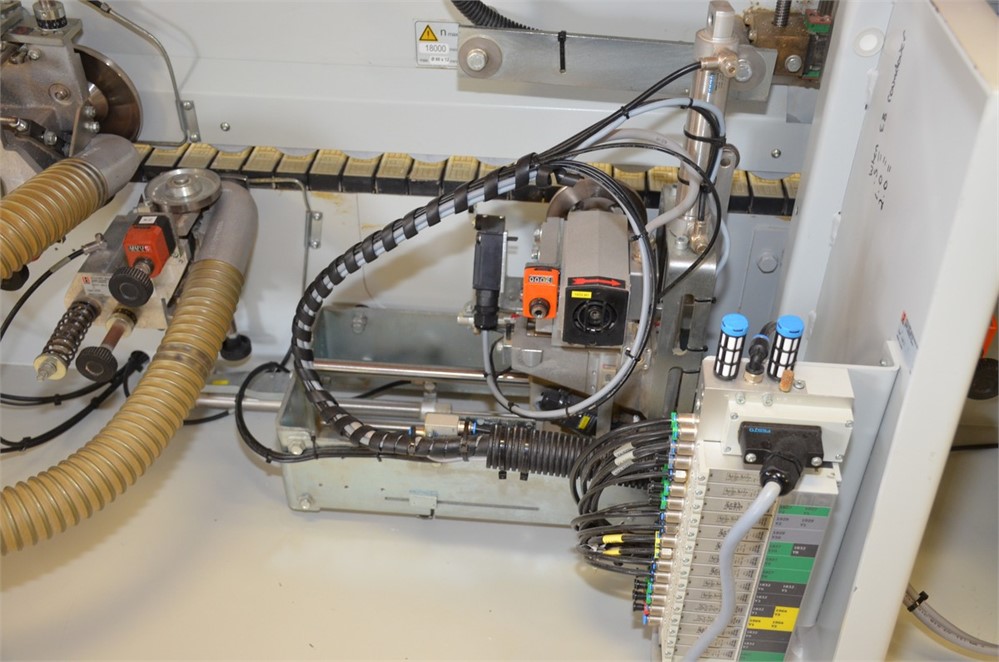

Profile Scraping Unit "RSV1 4912": Top/Bottom, servo motor controlled/programmable knife position, vertical copy wheel adjustment with quick setting spindle - for PVC edges, reversible insert carbide knives, equipped with air-jet blowers and chip collector box.

Glue Scraping Unit "1964": Flat surface, top/bottom, ball bearing guided and pneumatic controlled. Reversible - replaceable knife inserts and blow-off nozzles.

Buffing Station "1940": Top & bottom, 2 x 0.09 KW (0.25 HP) buffing motors with 150 mm ( 6.0") cloth buffing wheel diameter, adjusts in any direction (vertical tilt is 0° - 5°, horizontal swivel is 0° - 20°); 1,440 RPM wheel rotation.

EdgeControl, Windows like interphase with large program storage capacity. Up to (10) individual users with password protection. USB connection and Ethernet network connections.

Flat Screen 8.4" VGA Color, dust-proof soft key input panel surface, programs can be easily created and recalled at will; Graphic interface makes programming easy, icon of each unit may be brought up on the screen to show the operator the status of the unit and the parameters which can be programmed; Edgebander can be operated manually when required, without the necessity to write a program.

Fixed outboard panel support, sound enclosure over all workstations of the machine, used tooling on the stations and original factory machine documentation.

PLEASE NOTE: All specifications for this item were taken from literature & visiual inspection. They are considered accurate, but not guaranteed. Please take advantage of the inspection to verify for yourself.

The listed specifications & information were taken from the manufacturer’s published information, internet research, or seller’s description.

The specifications & information are assumed to be correct; however, in no way, guaranteed. Bidders are encouraged to inspect the machine, call with questions, or contact the manufacturer for more information.

Please log in to view the bid history

LoginPick-ups are to be scheduled by appointment only. Please contact Sabrina Burns at 209-839-7707 or [email protected] to schedule an appointment. For freight quotes please contact Aaron at All-Ways Trucking at 541-608-6532. Buyer bears all costs to remove and load this lot. Buyer must remove entire lot purchased. Anyone removing non-hand carriable lots must provide MachineryMax, Inc. with a certificate of insurance (COI) before purchased items can be removed.

Rigger Info:

Marvin Baltodano Sr.

Pedowitz Machinery Movers

1550 NW 24th Avenue

Pompano Beach, FL 33069

Ph: (305) 836-9945

Cell: (786) 236-1482

All buyers agree to make full payment to MachineryMax, Inc. within 48 hours of the online closing date for the auction lots purchased. All invoices over $1,500.00 are to be made by bank wire transfer or cashier’s check payable to MachineryMax, Inc. Purchases under $1,500.00 may be made using Visa MasterCard, or American Express (2% credit card processing fee will be added to the invoice). All payments are to be made in USD currency only. Bidder represents and warrants to MachineryMax, Inc. that such bidder has immediately available funds to fully pay for its successful bids within 48 hours of the online closing date. All payment questions should be directed to Sabrina Burns at 209-839-7707 or [email protected] All buyers agree that there will be a 15% Buyers premium that will be added to the final invoice.