Giben "Y 3000 SPT" Rear/Side Load Beam Saw w/ moveable grippers  Ended

Ended

Complete Liquidation of entire shop in San Jose, CA

- Winning Bid : $2,050.00 USD Sold

- 17 Bid(s)

- High Bidder: s****7

COMPLETE PLANT CLOSURE - AMBERWOOD PRODUCTS - SAN JOSE, CA ( Closed #16156824 )

After 45 years in business, Amberwood Products INC is closing its doors. 210 lots of Machinery, Tooling, Vehicles and supplies being auctioned in this complete liquidation. Featuring: Weeke "BHC Venture 2.5" CNC Router w/ C-axis, Giben "Y 3000 SPT" Rear/Side Load Beam Saw w/ moveable grippers, Brandt "Profiline KDF 540" Edgebander, Butfering "SWO 313 RRF" Wide Belt Sander - 3-Head, SCMI "M3" Gang Rip Saw, Voorwood "A111" Shape & Sand, Extrema "XR-12 Timberjack" Straight Line Rip Saw, Ritter "R-950" Oscillating Edge Sander, Powermatic "075-3" Dust Collector, TigerStop "TS-10" Programmable Stop/Pusher, Whirlwind "1000L" Pneumatic Up-Cut Saw, Ritter "R-250" Face Frame Table - ,Castle "TSM-21" Pocket Borer ,Holz-Her "1243" Sliding Panel Saw, Extrema "DC-120" Dust Collector, Sawstop "ICS73230" Industrial Cabinet Saw, SCM "TF110 Nova" Shaper, Automotive Spray Booth, plus much more!

-

Pick Up Location

San Jose, CA

-

Make

Giben

-

Model

"Y 3000 SPT" Rear/Side Load Beam Saw

-

Serial Number

402.04.380

-

Year

2004

-

Phase

3 PHASE

-

Voltage

460 VOLT

-

Load Out Period

June 10- June 18

-

Estimated Dimensions

30' of deck space on flate bed truck required (approx).

-

Estimated Weight

-

Seller Comment

A rigger is required for this lot. CONTACT ALWAYS TRUCKING for shipping quote 541-608-6532

-

page views

2860

149.6" (3,800 mm) Overall cutting length; 4.5" (115 mm) max. saw blade projection.

25 HP (18 kW) main saw motor, 17" (430 mm) dia. (3,960 RPM) main blade; 3.5 HP (2.6 kW) Scoring saw motor, 8.5" (215 mm) dia. (6,095 RPM) scoring blade.

Travel speeds 16 - 558 FPM (5 - 170 MPM), 558 FPM (170 MPM) constant return, powered by Inverter drive.

Phusher fence has variable forward speed 3.3 - 295 FPM (1 - 90 MPM), pusher return speed 295 FPM (90 MPM)

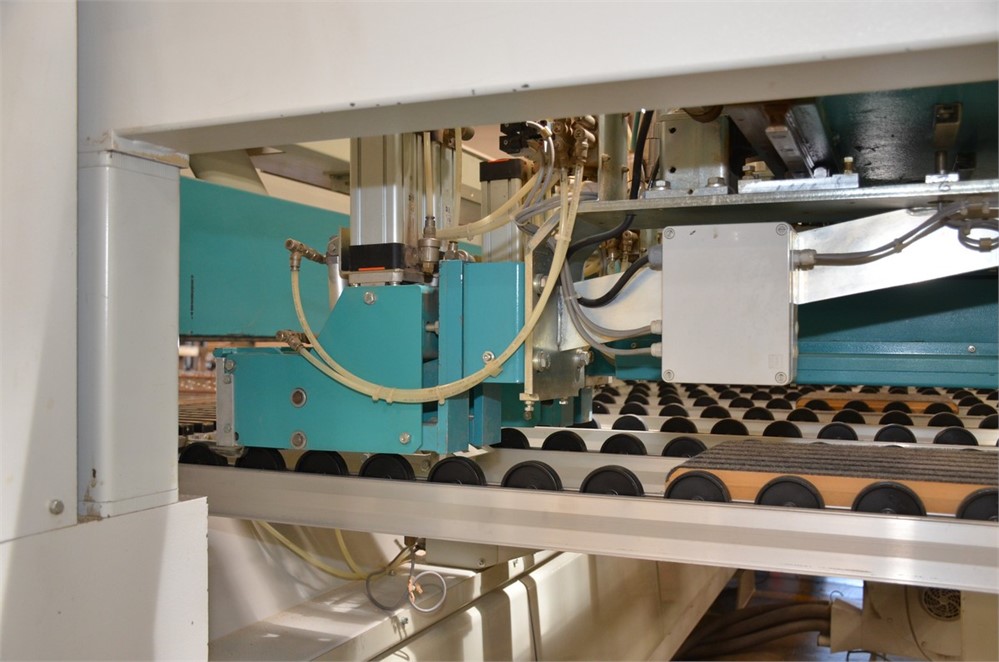

Unique "PM" gripper system: Programmable Grippers move side to side on the "X" axis to always position the grippers in the required position for processing any width of component(s) from the lift table or during the cutting cycle; One (1) "X" programmable gripper with (2) clamps & one (1) "X/Y" programmable gripper with (2) clamps;

Positioning speed on X-axis: 98 FPM (30 MPM) (Simultaneous with pusher movement)

Positioning speed on Y-axis: 66 FPM (20 MPM) (Simultaneous with pusher movement);

Each gripper is double width for clamping either 1 or 2 strips; Max. gripper opening: 4.6" (117 mm)..

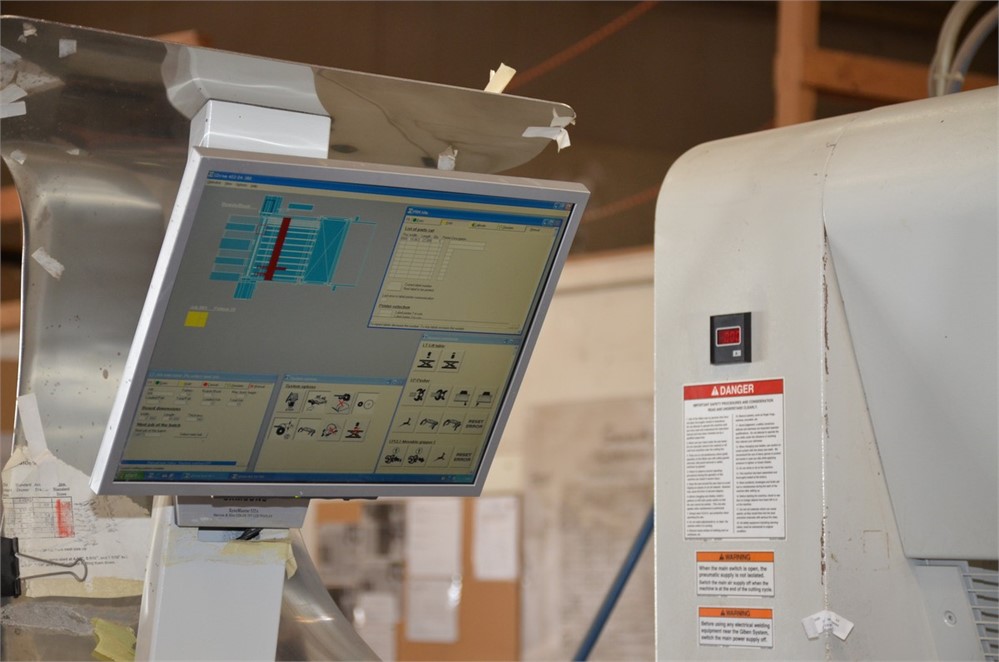

PC Front end with Giben "G-DRIVE "RT" + Windows "NT" operating system; Klockner Moeller PLC

Memory capacity for approximately 3000 jobs with (99) patterns per job repeatable 99 times; 15" VGA color monitor with "Real Time" graphics, standard keyboard & mouse; G-DRIVE function keypad; 1.44MB floppy disk drive.

G-Drive RT operating system offers "Real Time" graphics, machine and cutting patterns displayed to scale, hardware self-testing, improper occurrence alarms, trouble-shooting assistance, incremental and absolute programming, pattern processing individually or as groups, PC Editing feature allows programming during operation, RS-232 data port for downloading from remote PC to the machine controller is possible.

4-Column rear load lift table with loading from the rear of the machine; max. panel size 149.5" x 63" (3,800 x 1,600 mm); max lift table stroke 32.7" (830 mm); max. stack height without pit or risers 27" (680 mm).

(1) Powered side in-feed and out-feed conveyor; Riser blocks to raise the machine 8.6" (220 mm) to allow loading of bunks up to 31.5" (800 mm)

4.8 HP (3.6 kW) motor for Raise & lower; raise & lower speed 2.3 FPM (7.5 MPM); (2) material front aligners located behind the cut line. 0.31" (8 mm) min. thickness for automatic loading from the rear lift table

Safety photocell barrier for direct loading from the rear to avoid the possibility of a collision between lift truck and pusher

(4) Air floatation tables 79" x 20" (2,000 x 510 mm); Front safety flaps on the pressure beam; safety fencing rear & side of machine.

All above information is taken from known literature and visiual inspection. This information is thought to be accurate, but not guaranteed. Buyer is encouraged to inspect for themselves and verify ALL information.

The listed specifications & information were taken from the manufacturer’s published information, internet research, or seller’s description.

The specifications & information are assumed to be correct; however, in no way, guaranteed. Bidders are encouraged to inspect the machine, call with questions, or contact the manufacturer for more information.

Please log in to view the bid history

LoginPick-ups are to be scheduled by appointment only. Please contact Sabrina Burns at 209-839-7707 or [email protected] to schedule an appointment. For freight quotes please contact Buyer bears all costs to remove and load this lot. Buyer must remove entire lot purchased.

A non-negotiable loading fee has been established for each item sold. Buyer agrees to pay this fee and agree to terms of the seller for loading instructions.

All buyers agree to make full payment to MachineryMax, Inc. within 48 hours of the online closing date for the auction lots purchased. All invoices over $1,500.00 are to be made by bank wire transfer or cashier’s check payable to MachineryMax, Inc. Purchases under $1,500.00 may be made using Visa MasterCard, or American Express (2% credit card processing fee will be added to the invoice). All payments are to be made in USD currency only. Bidder represents and warrants to MachineryMax, Inc. that such bidder has immediately available funds to fully pay for its successful bids within 48 hours of the online closing date. All payment questions should be directed to Sabrina Burns at 209-839-7707 or [email protected] All buyers agree that there will be a 15% Buyers premium that will be added to the final invoice.