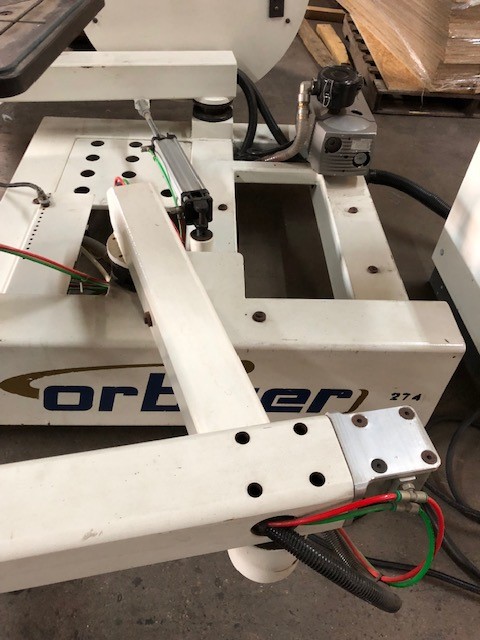

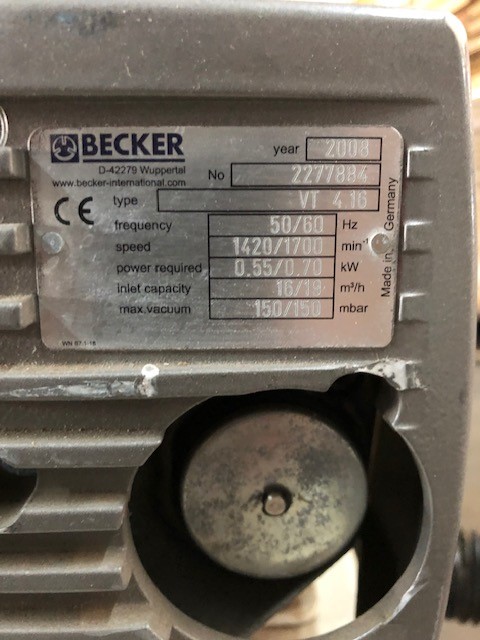

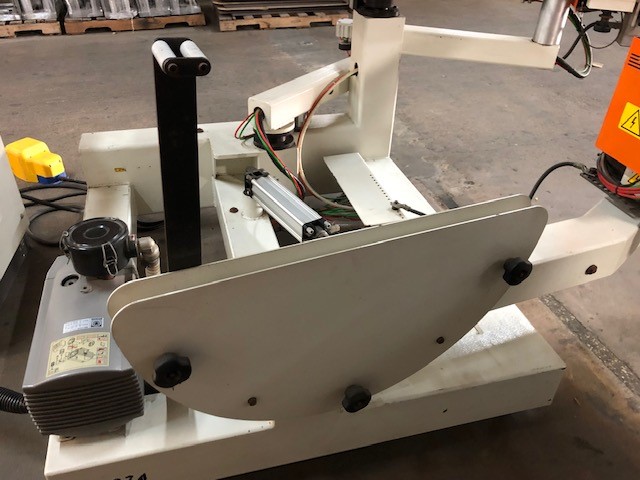

Vitap "Orbitor" Contour Bander (2008)  Ended

Ended

Located in Houston, TX

- Winning Bid : $3,801.00 USD Sold Reserve Price Met

- 26 Bid(s)

- High Bidder: k****y

Vitap "Orbitor" Contour Bander (2008) in Houston, TX ( Closed #14471006 )

Vitap "Orbitor" Contour Bander (2008) in Houston, TX

-

Pick Up Location

Houston, TX

-

Make

Vitap

-

Model

"Orbitor" Contour Bander (2008)

-

Serial Number

801543

-

Year

2008

-

Phase

3 PHASE

-

Voltage

230 VOLT

-

Load Out Period

02/21/19

-

Estimated Dimensions

-

Estimated Weight

-

Seller Comment

A non-negotiable loading fee of $100 that includes pallatization, banding & stretch wrap

-

page views

1436

0.4 - 3 mm Edgebanding thickness and panel thickness from 16 - 50 mm (5/8" - 1.96").

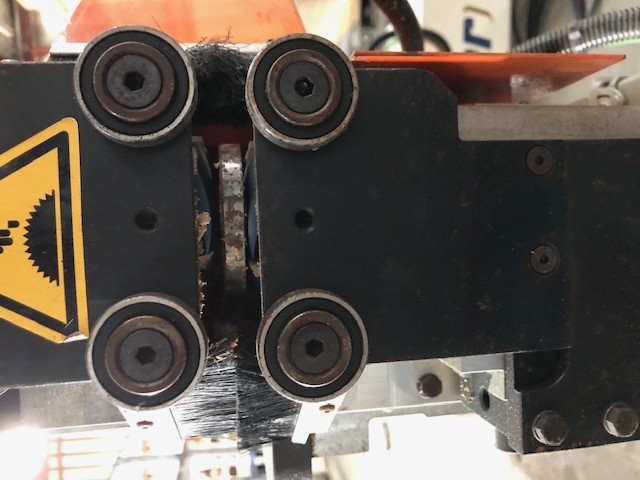

Radius tolerances dependent upon tape thickness and pliability; Edgethickness 1 mm, min. = R 30; edge thickness 2 mm, min. = R 50 mm; Edge thickness 3 mm, min. = R 50 mm.

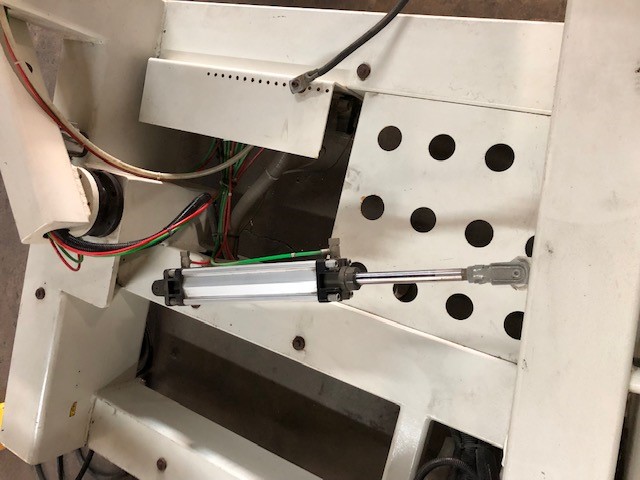

(2) Pressure rollers to copy the shape of the piece, automatic guillotine for coiled material up to 3 mm thickness & 45 mm height.

Motorized turn table for automated edgebanding application to large panels; holding or support arm has large vacuum cup to secure panels for edging and trimming.

The listed specifications & information were taken from the manufacturer’s published information, internet research, or seller’s description.

The specifications & information are assumed to be correct; however, in no way, guaranteed. Bidders are encouraged to inspect the machine, call with questions, or contact the manufacturer for more information.

Please log in to view the bid history

Login

All buyers agree to make full payment to MachineryMax, Inc. within 48 hours of the online closing date for the auction lots purchased. All invoices over $1,500.00 are to be made by bank wire transfer or cashier’s check payable to MachineryMax, Inc. Purchases under $1,500.00 may be made using Visa MasterCard, or American Express (2% credit card processing fee will be added to the invoice). All payments are to be made in USD currency only. Bidder represents and warrants to MachineryMax, Inc. that such bidder has immediately available funds to fully pay for its successful bids within 48 hours of the online closing date. All payment questions should be directed to Sabrina Burns at 209-839-7707 or [email protected] All buyers agree that there will be a 15% Buyers premium that will be added to the final invoice.